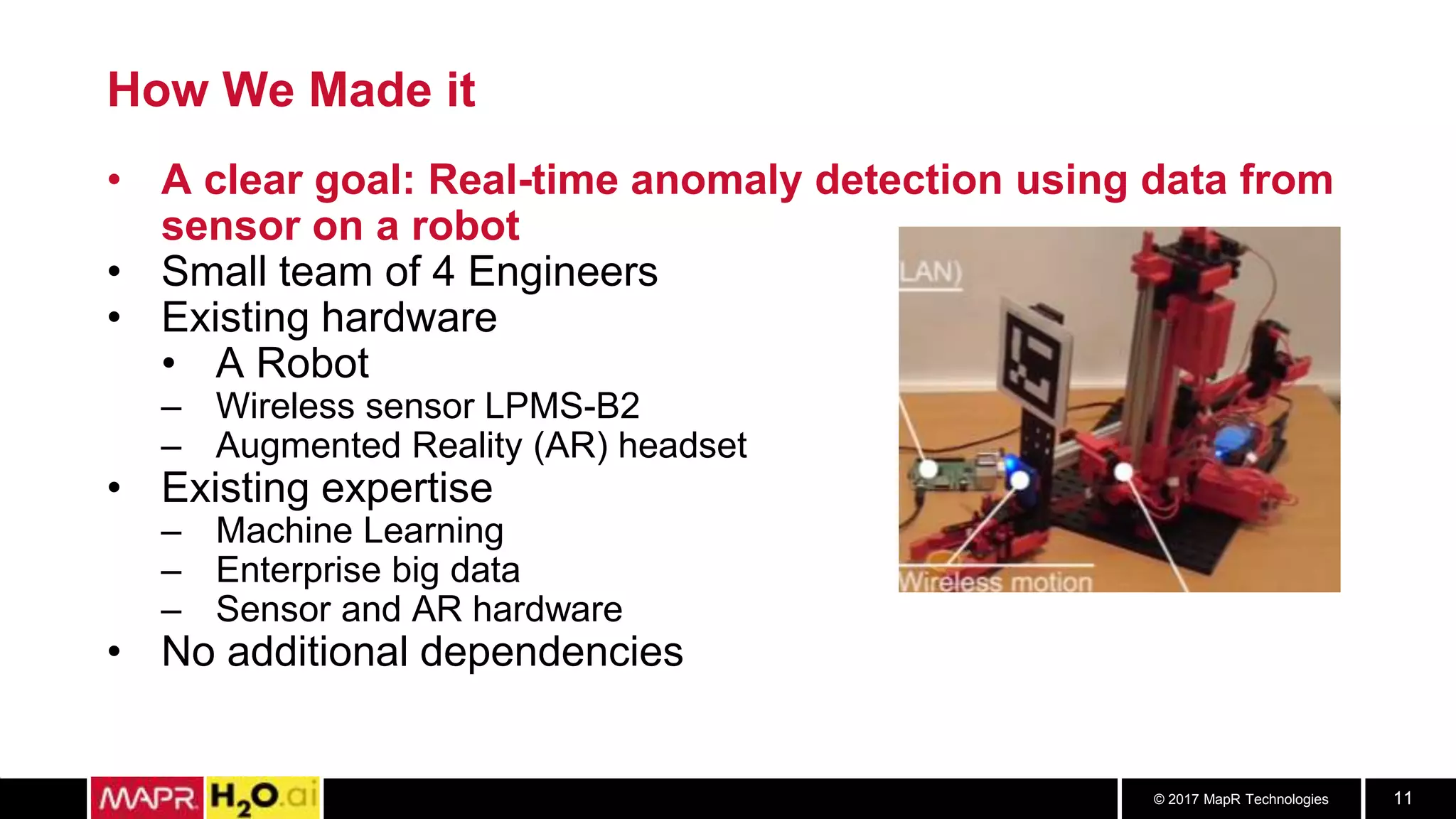

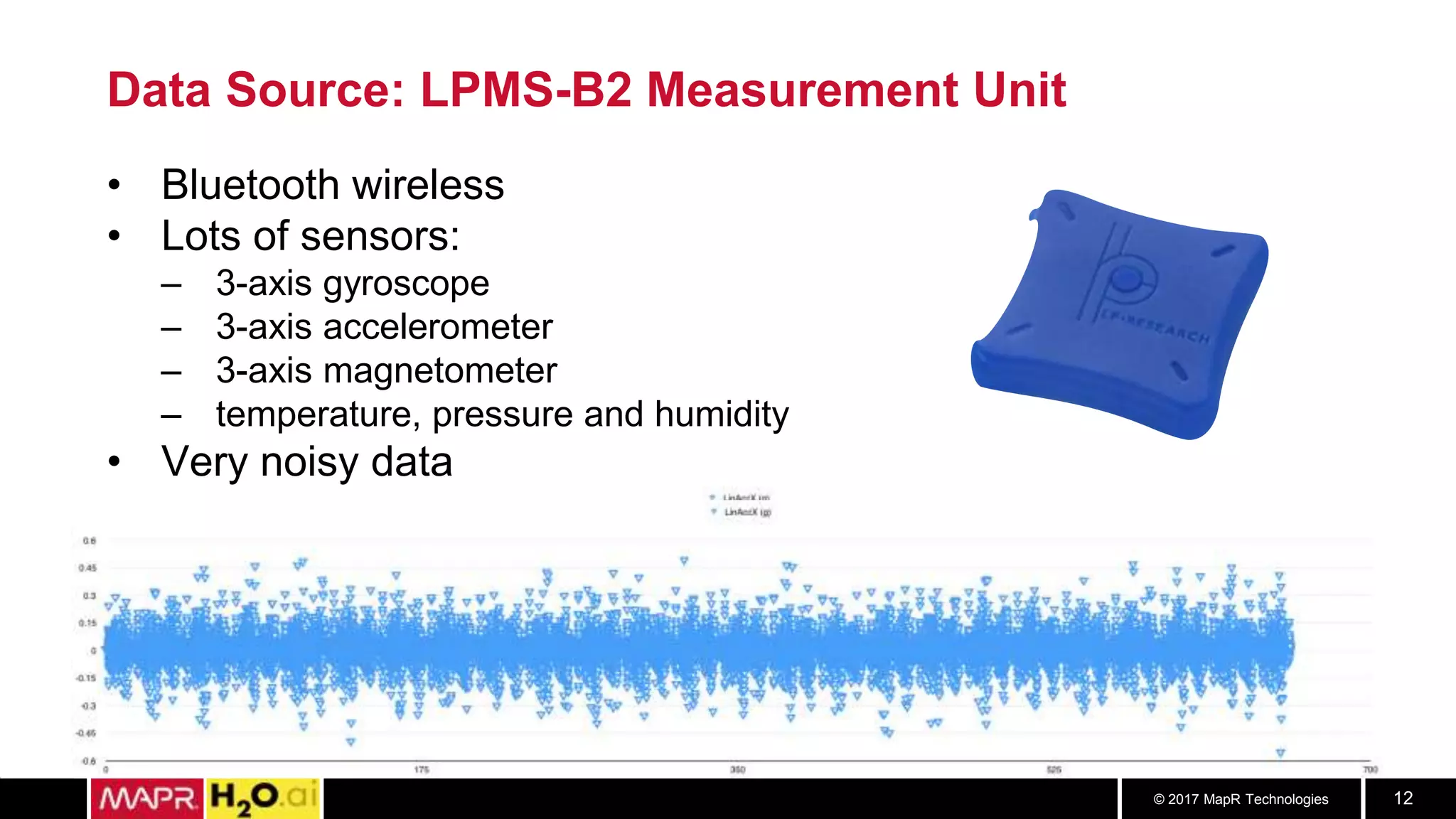

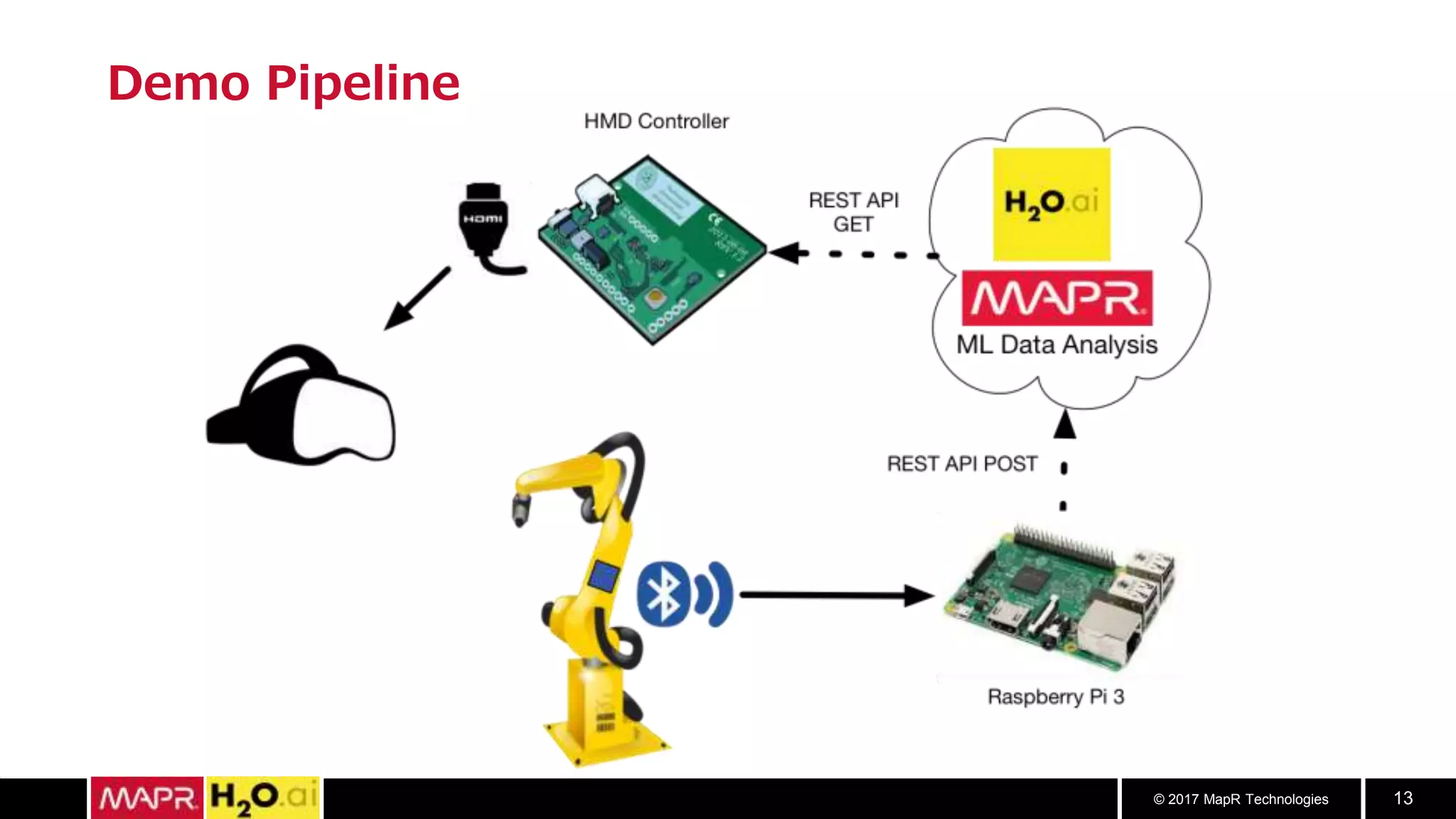

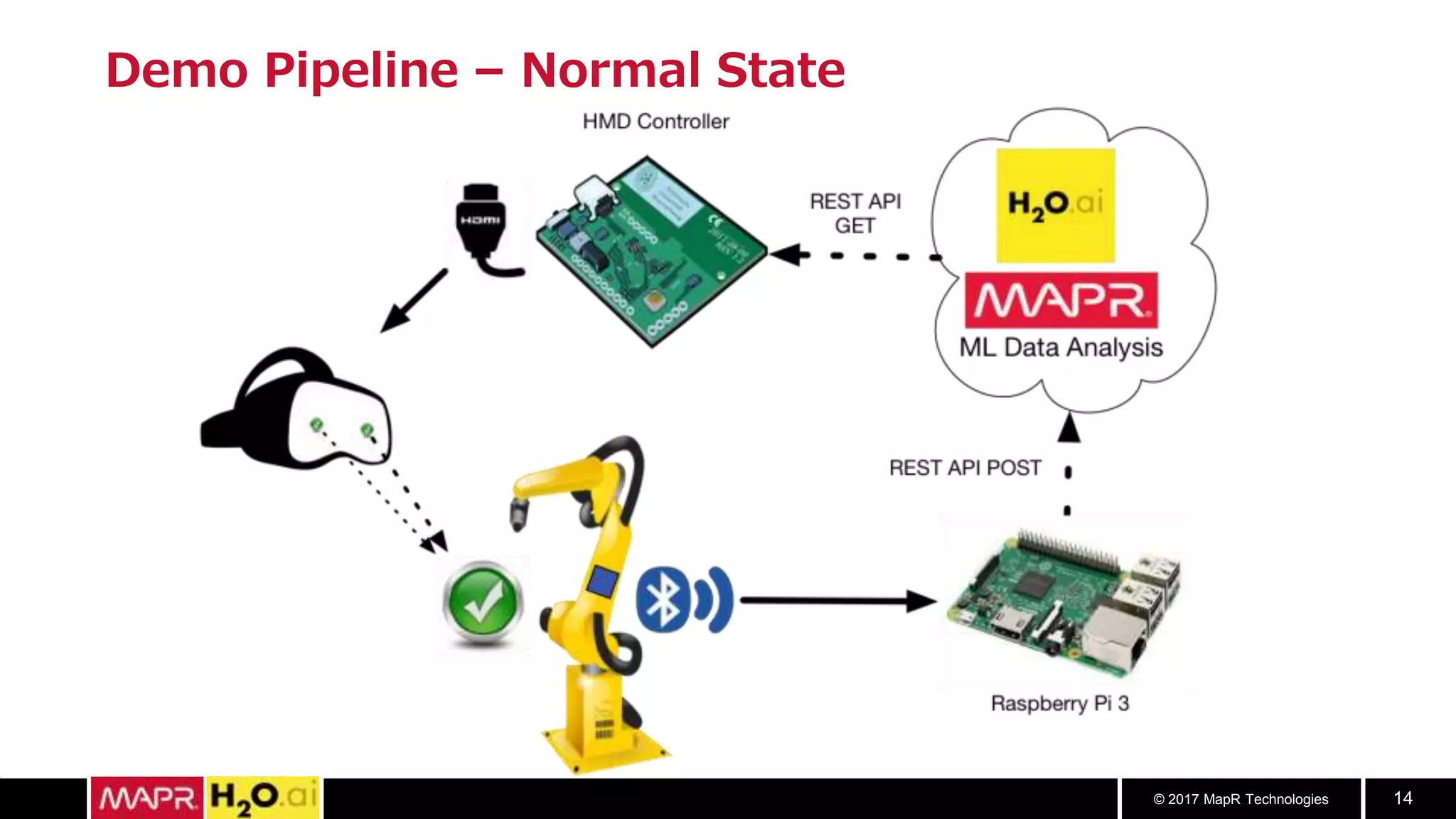

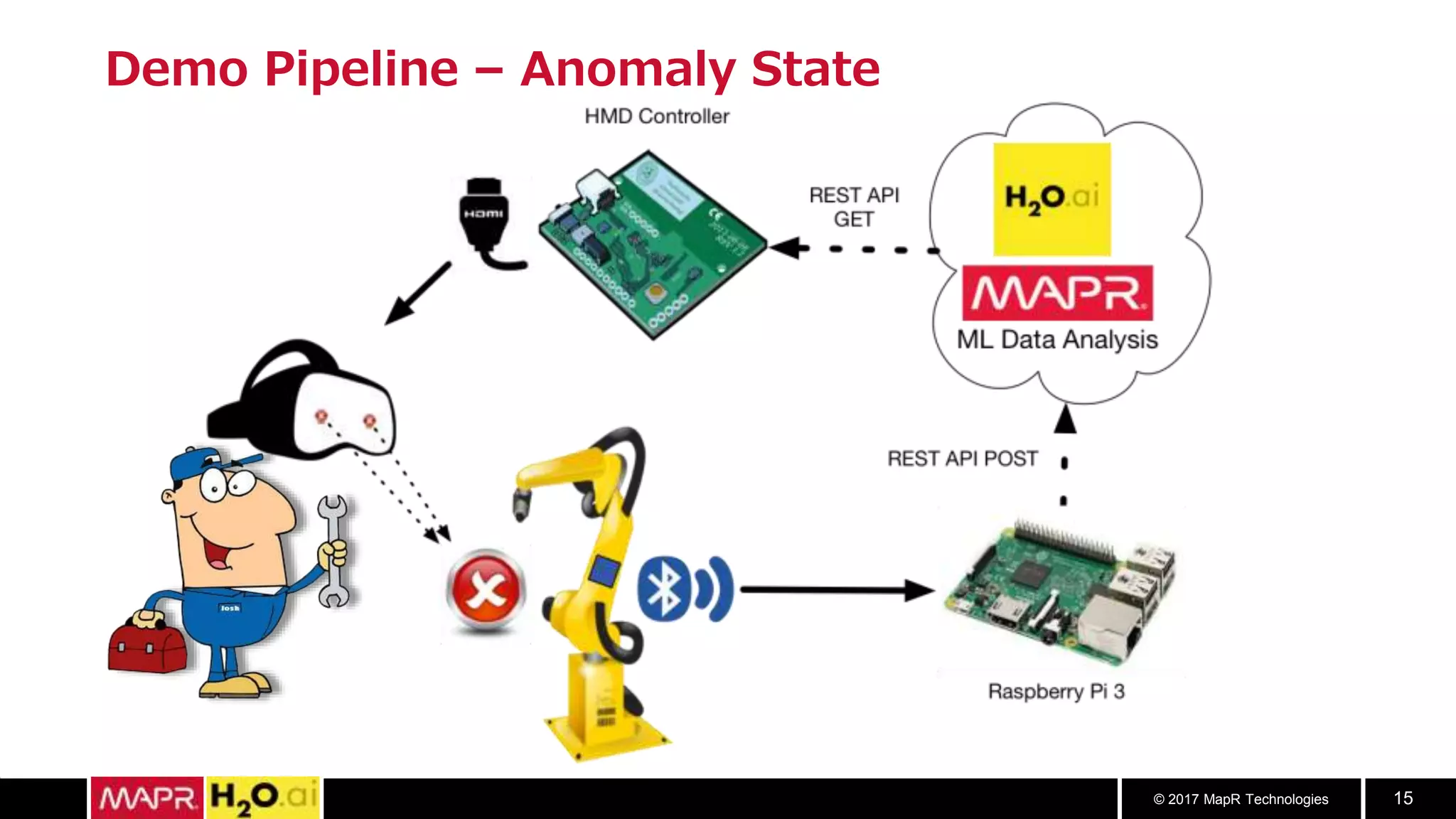

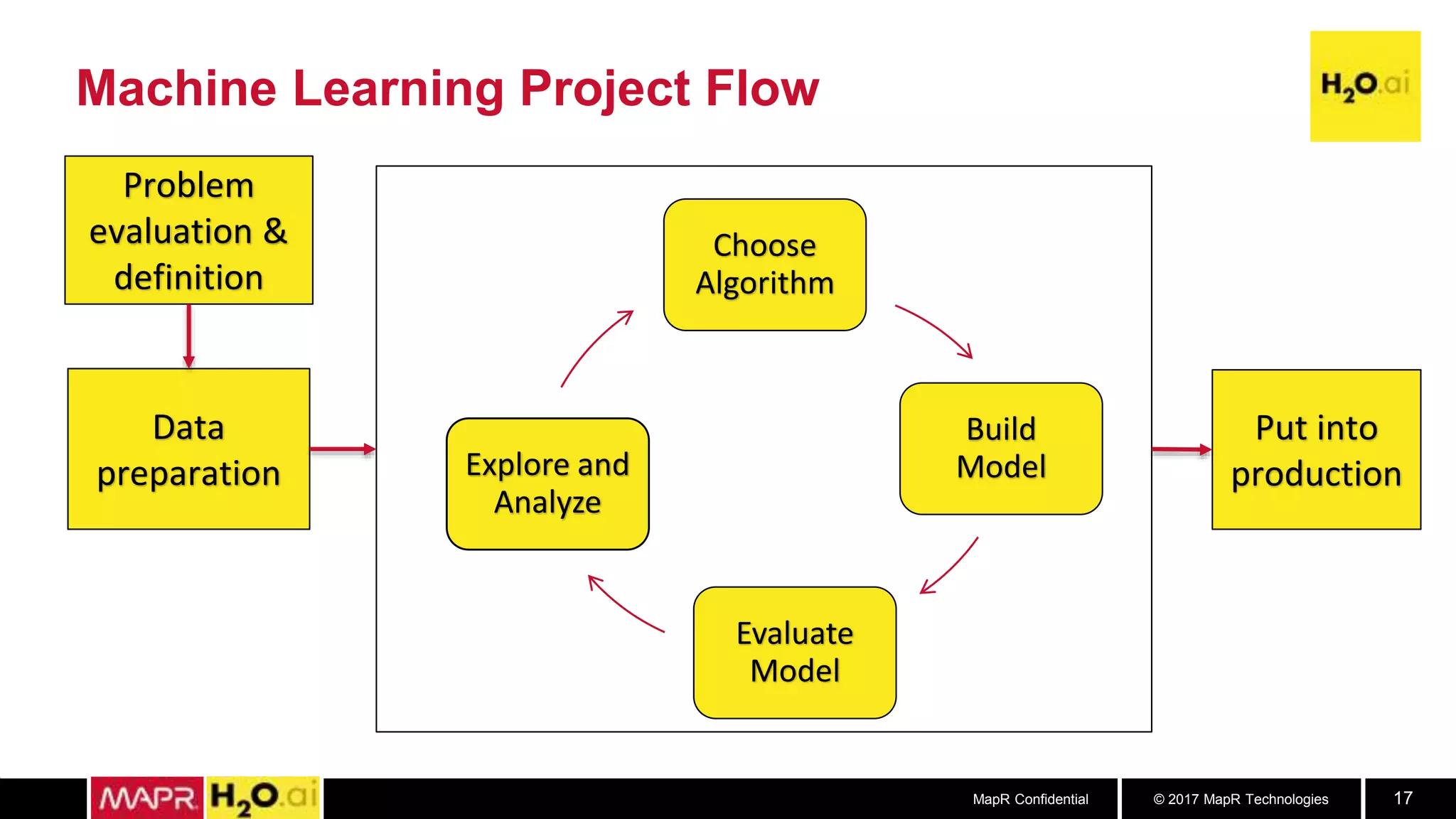

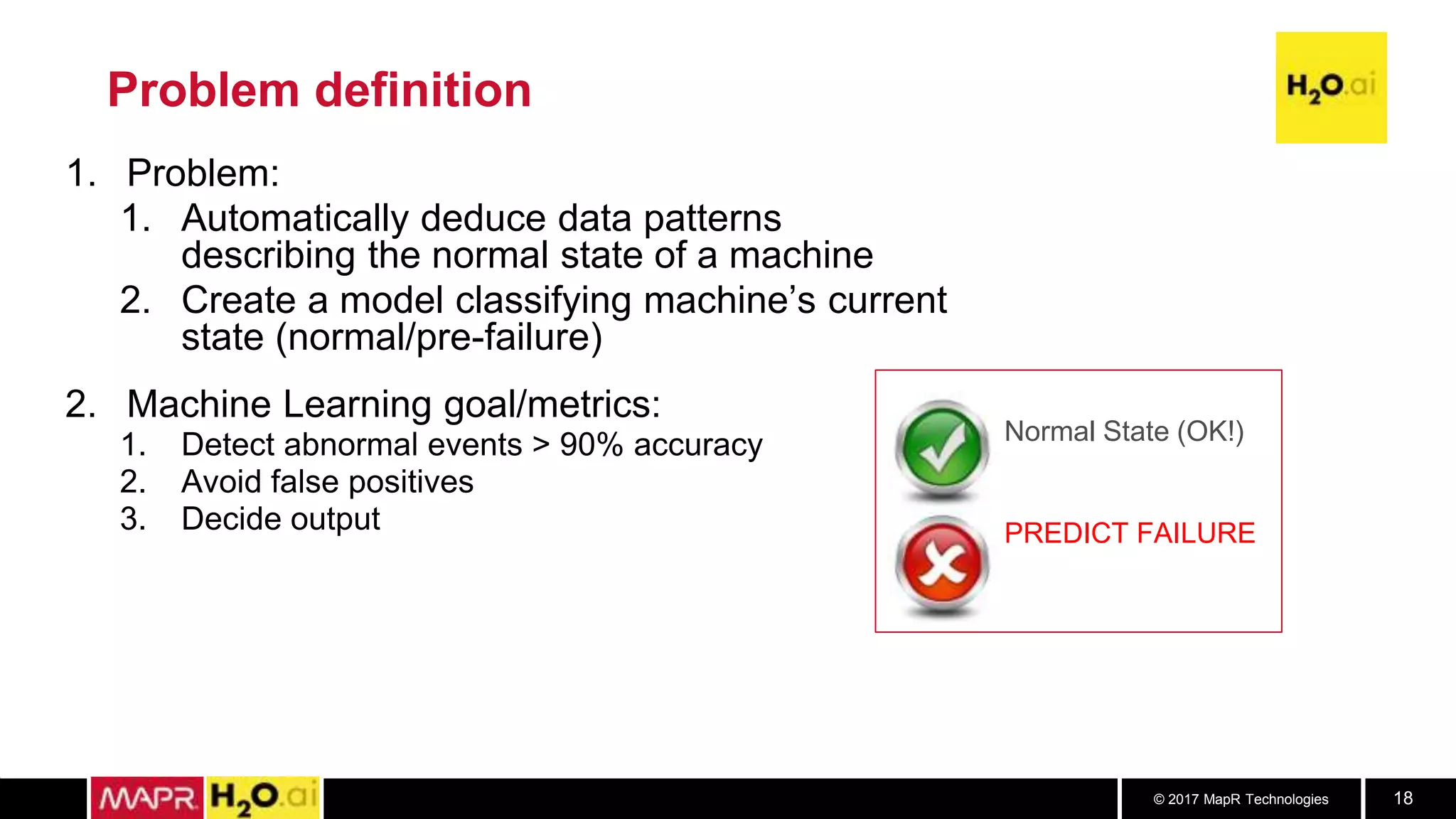

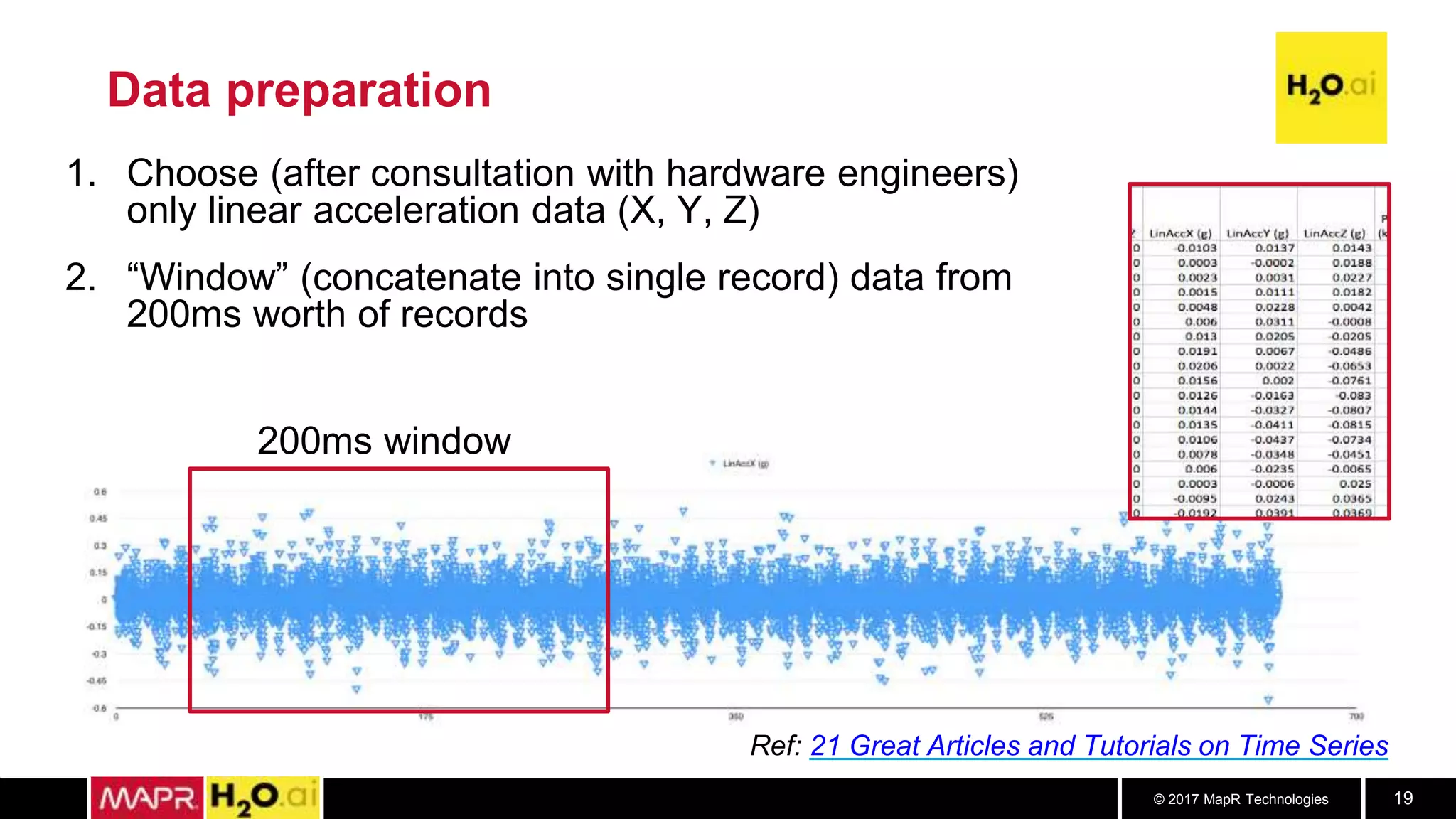

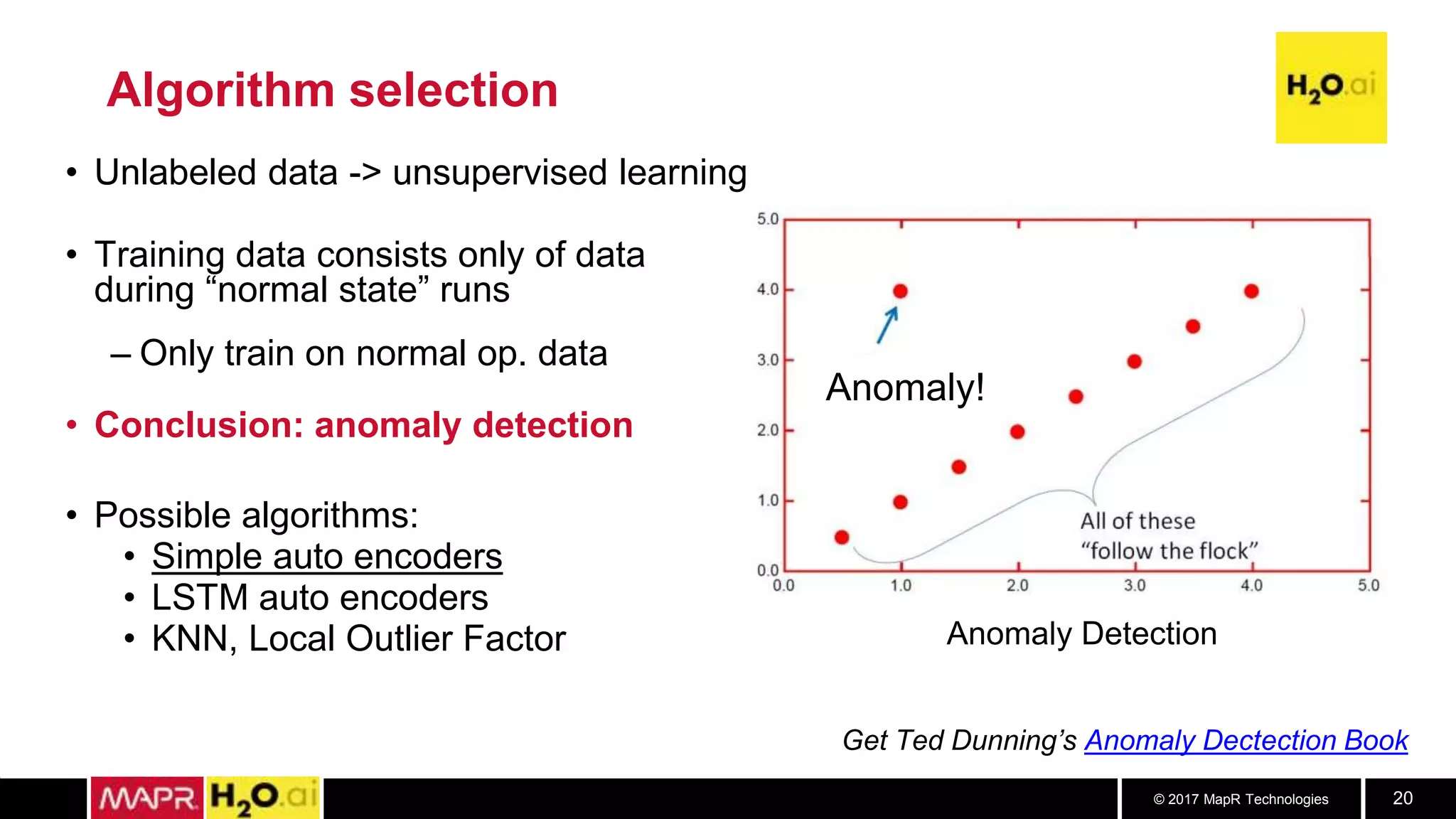

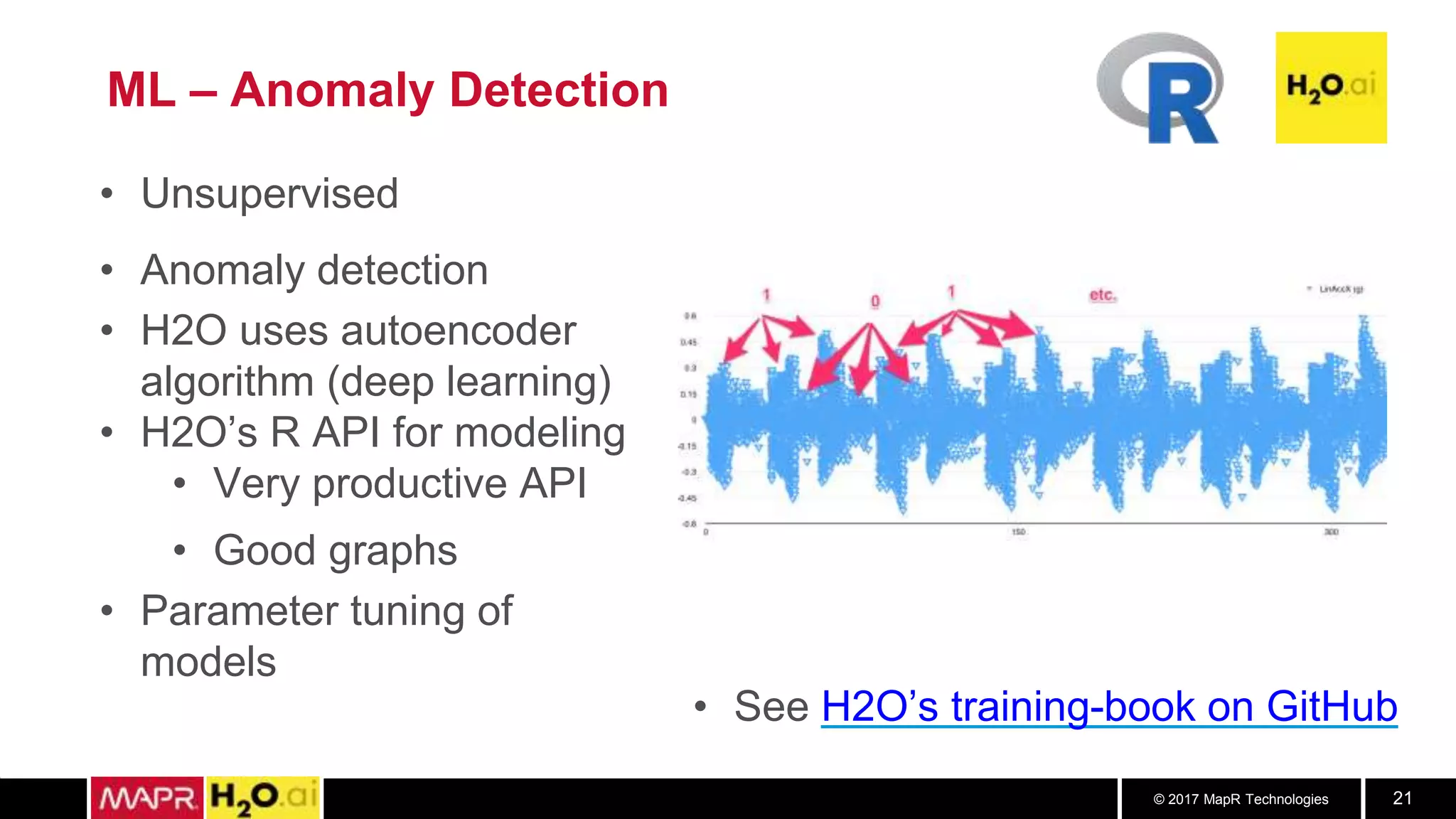

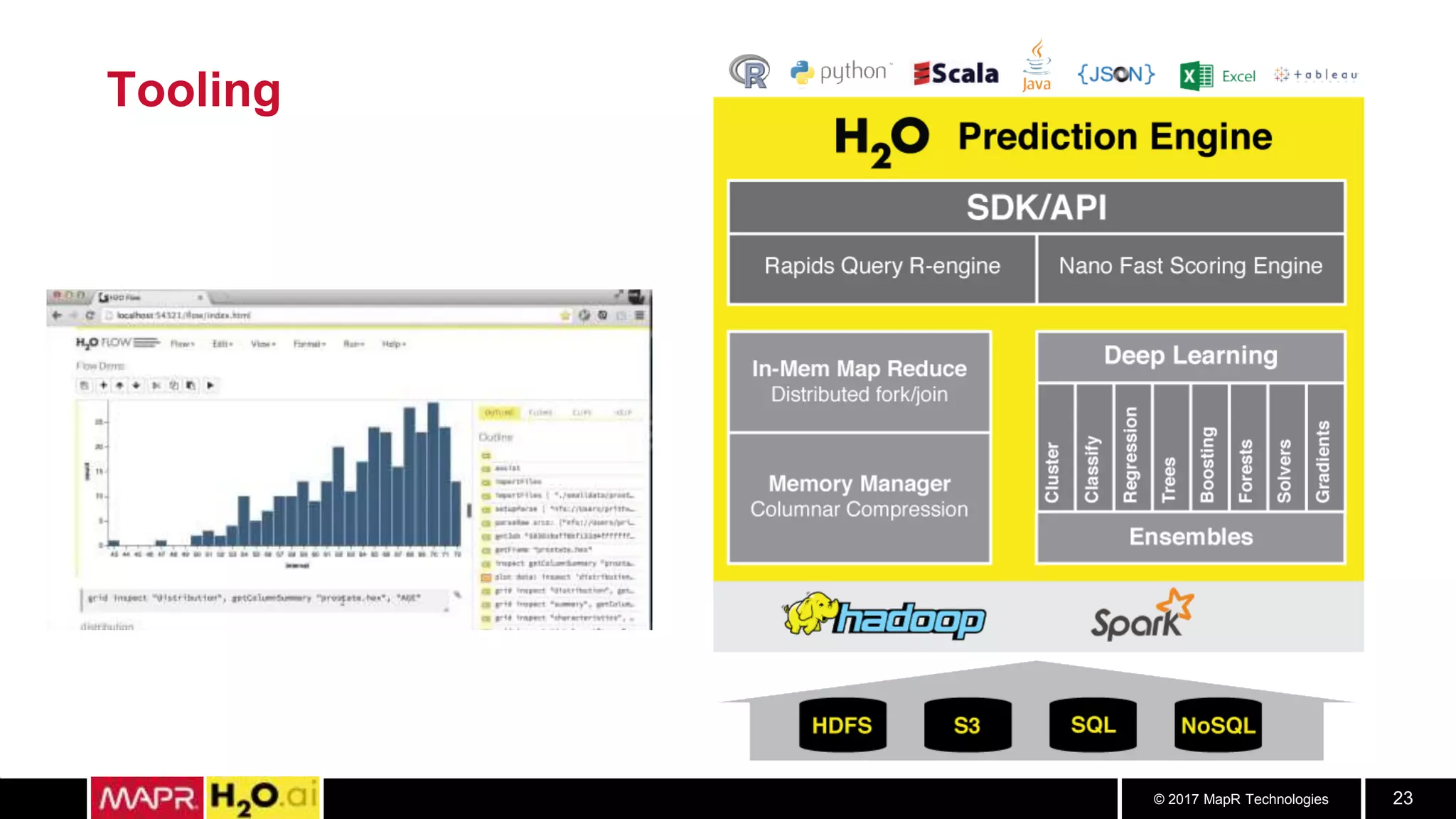

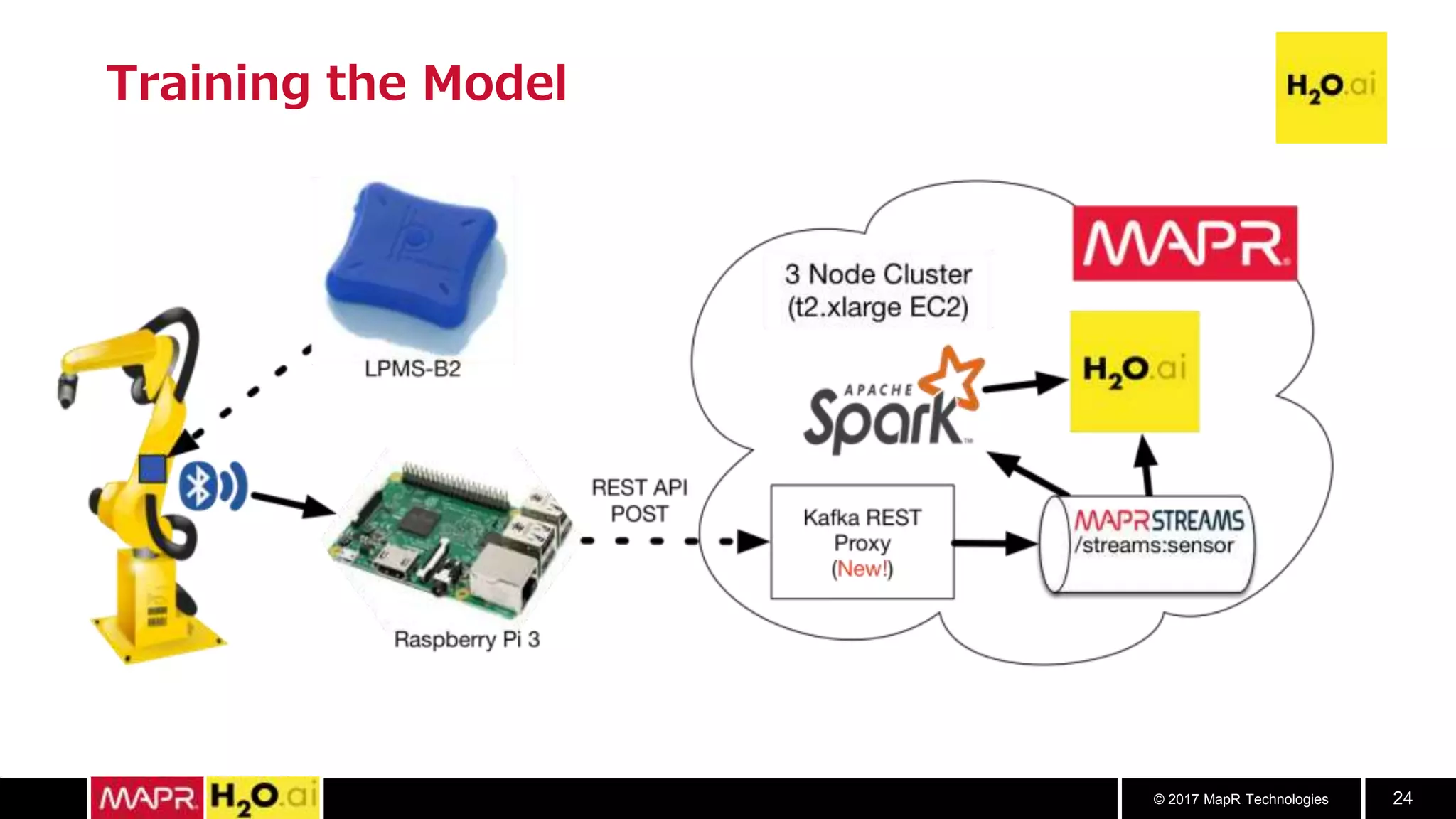

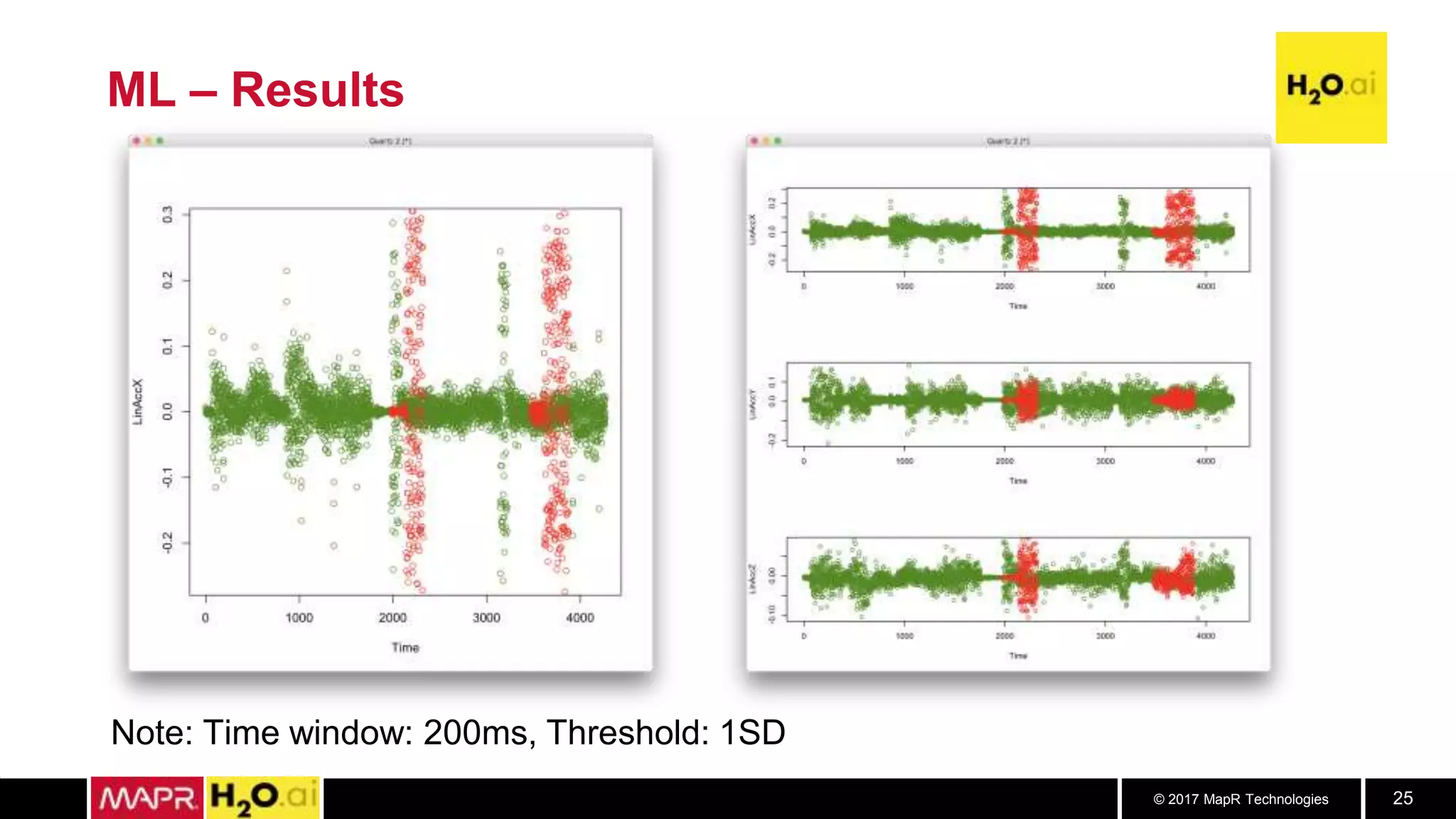

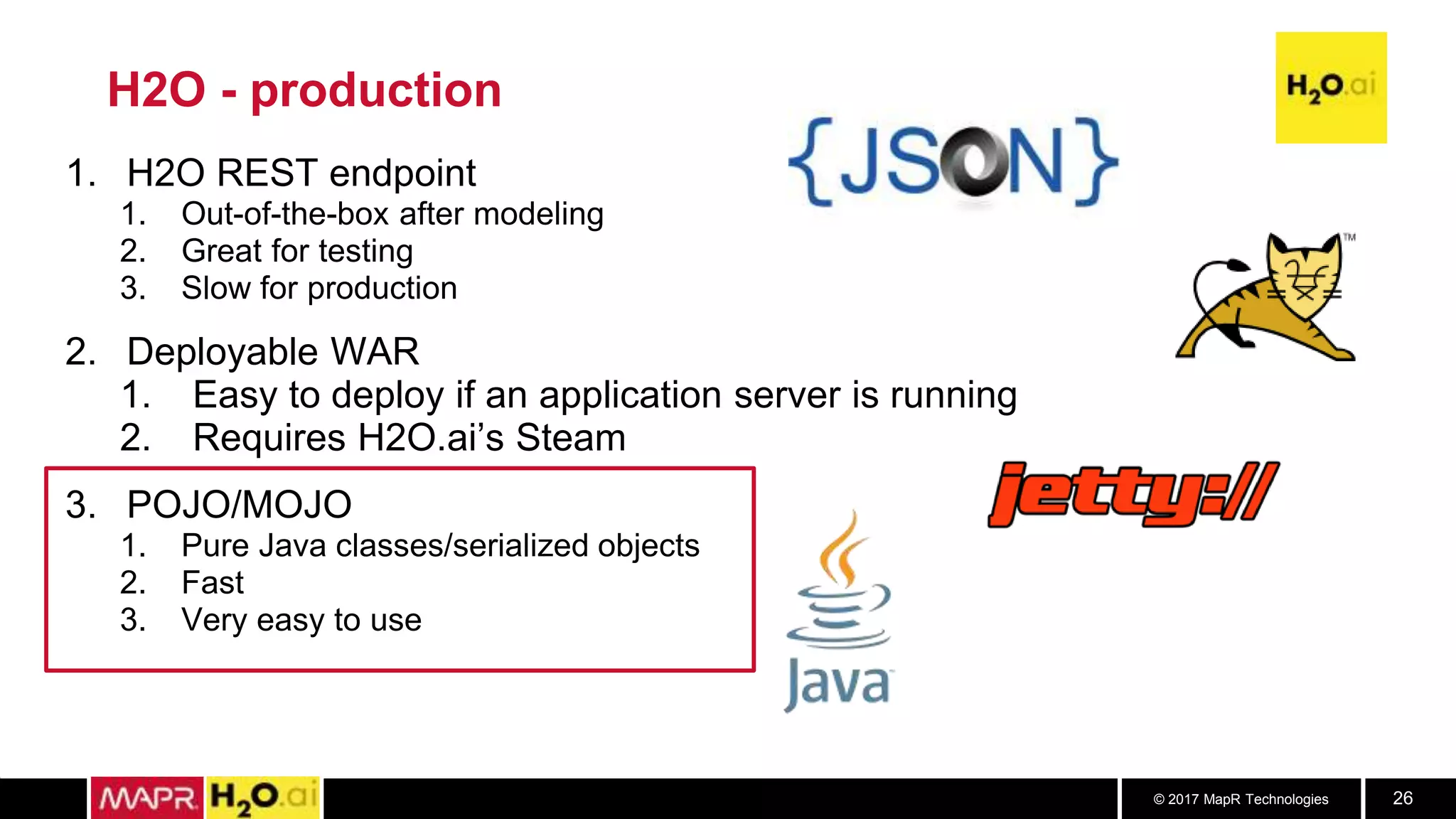

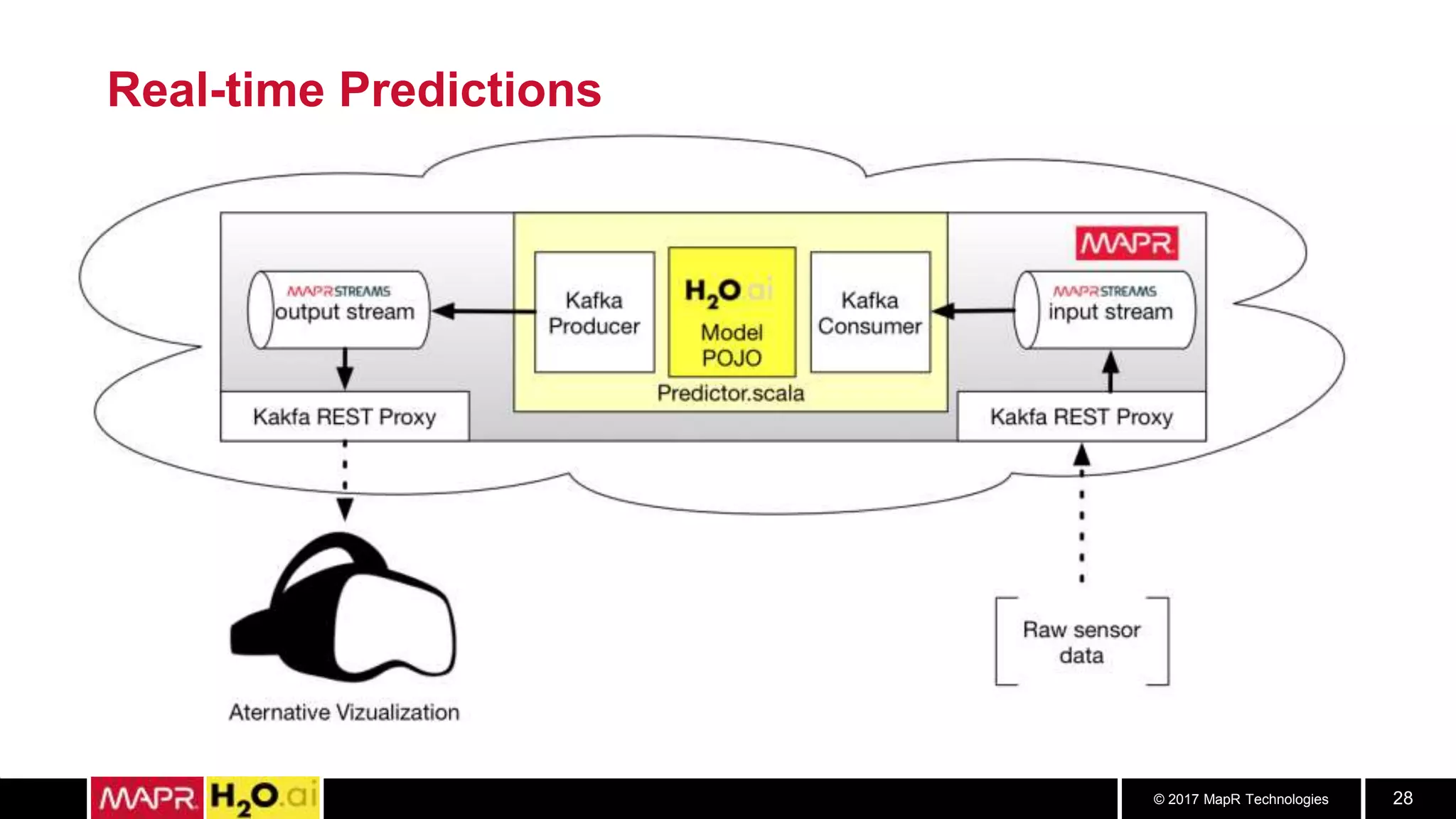

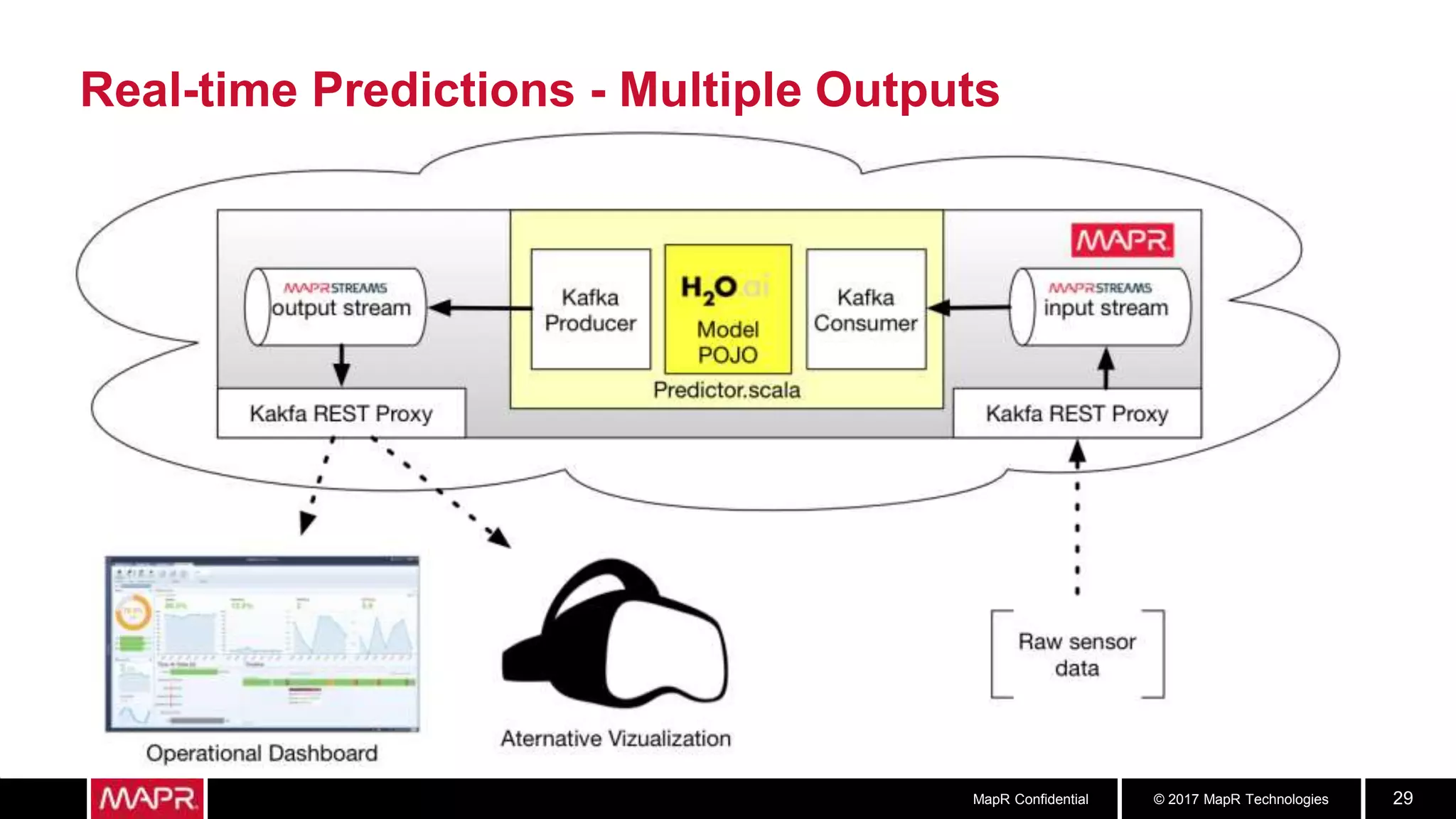

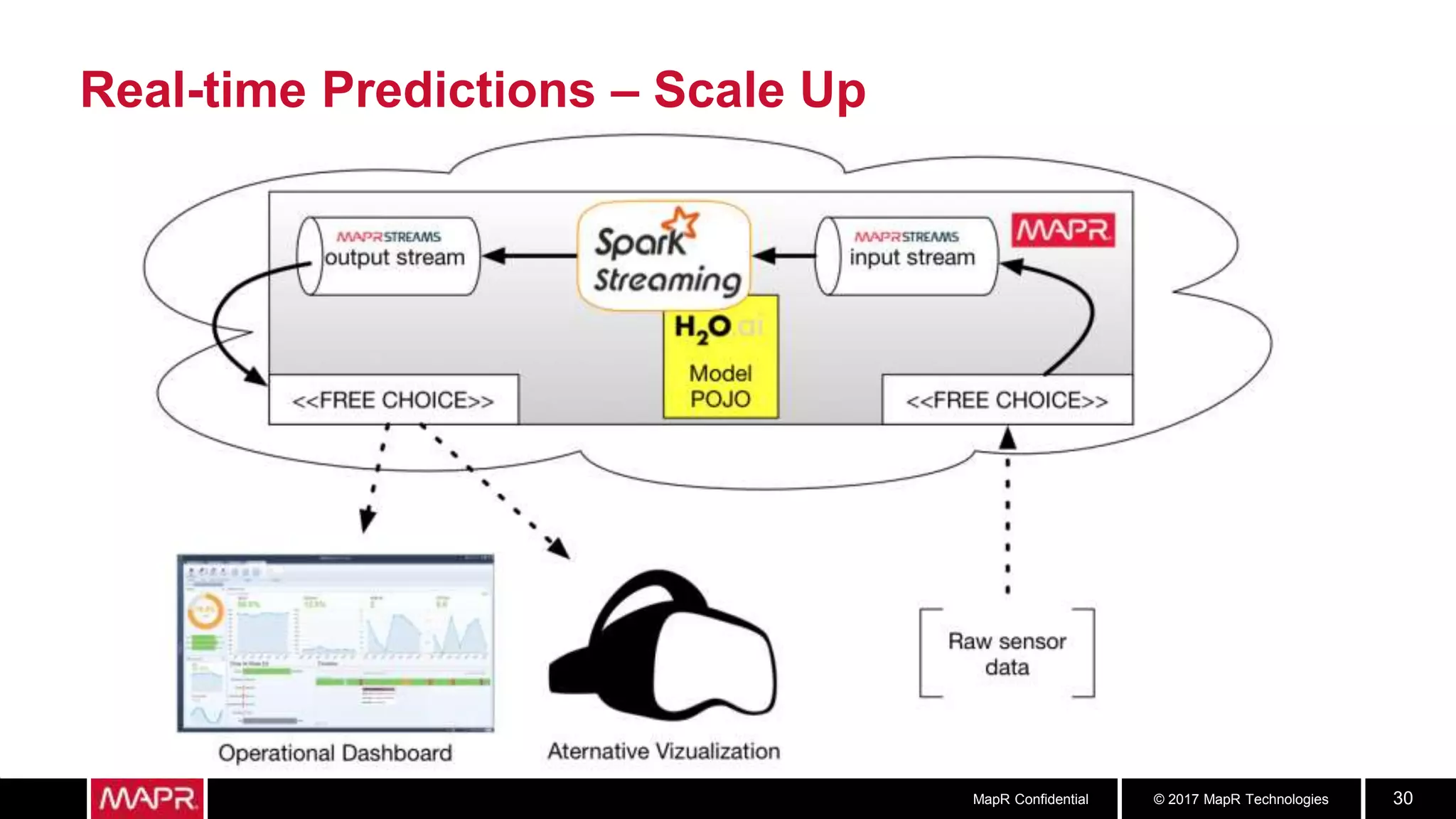

This document describes a predictive maintenance system for robots using real-time sensor data. A team of 4 engineers built a solution in 2 months using standard open source software like H2O and MapR. Sensors on a robot collected accelerometer, gyroscope and other data. This raw data was analyzed using anomaly detection algorithms in H2O to build a machine learning model that identified normal vs abnormal robot states. The model was deployed as a microservice to make real-time predictions on new sensor data and detect potential failures. The solution was able to analyze data from hundreds of robots and identify anomalies within 3 seconds, demonstrating an effective low-cost predictive maintenance system.