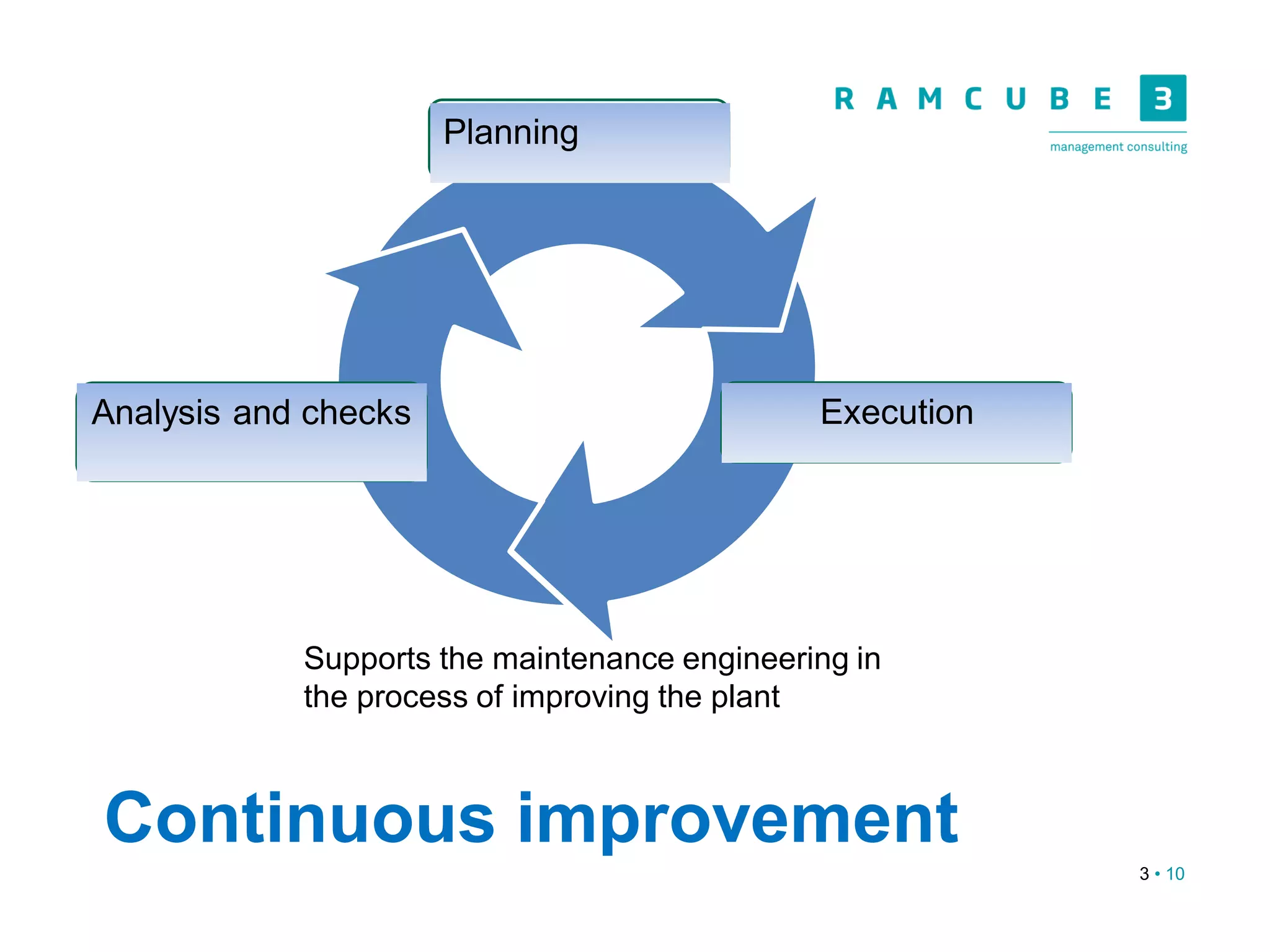

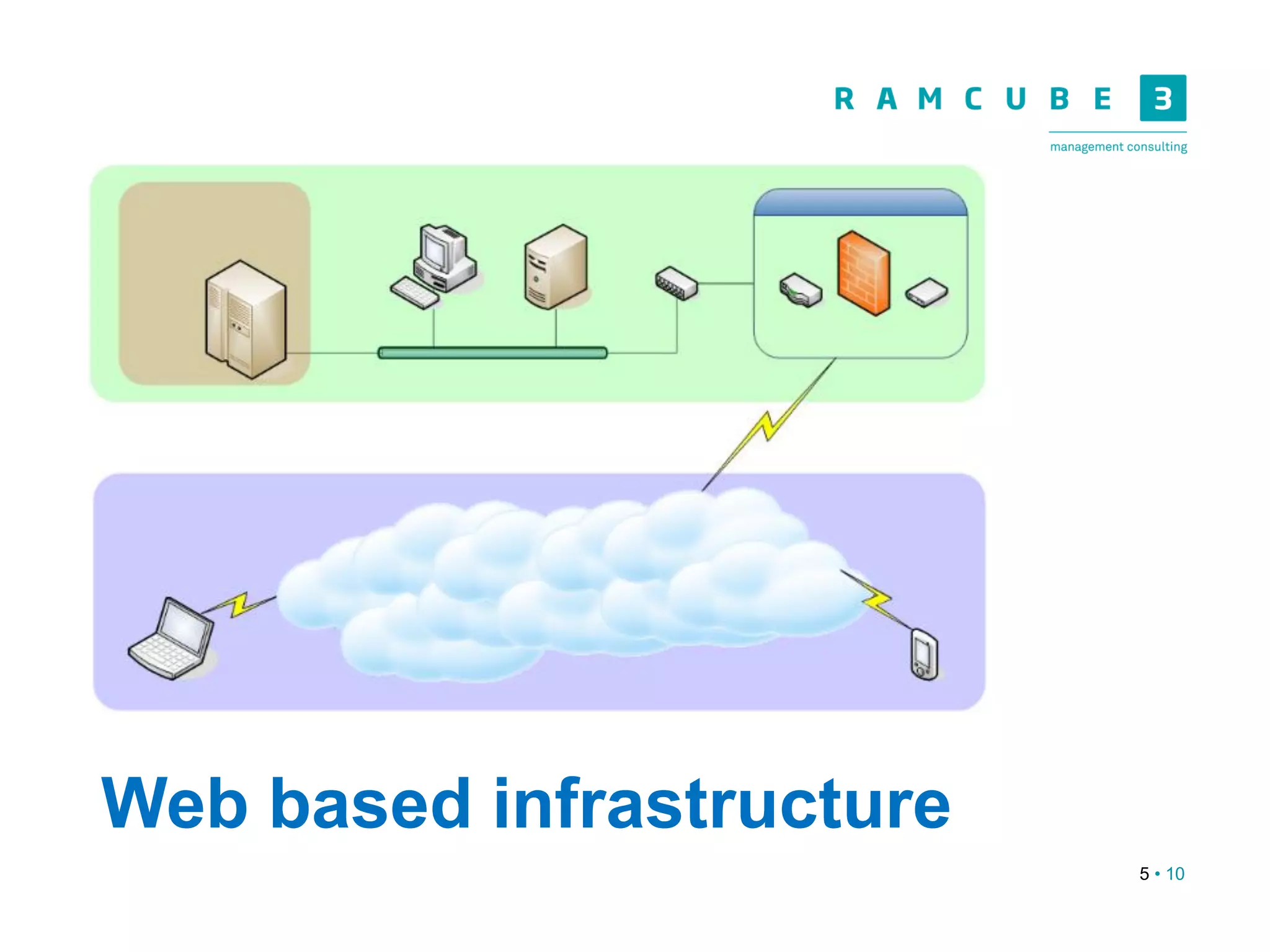

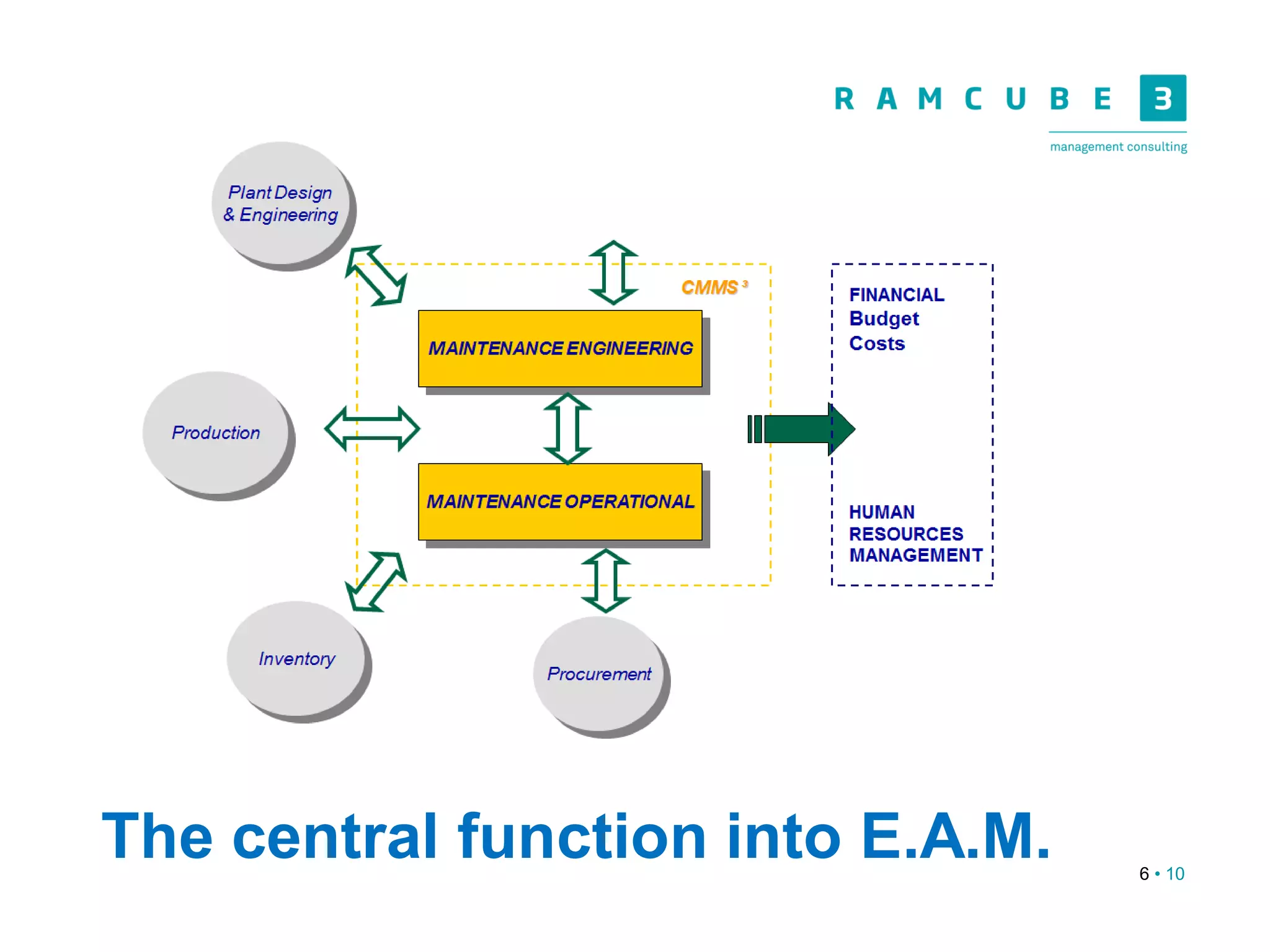

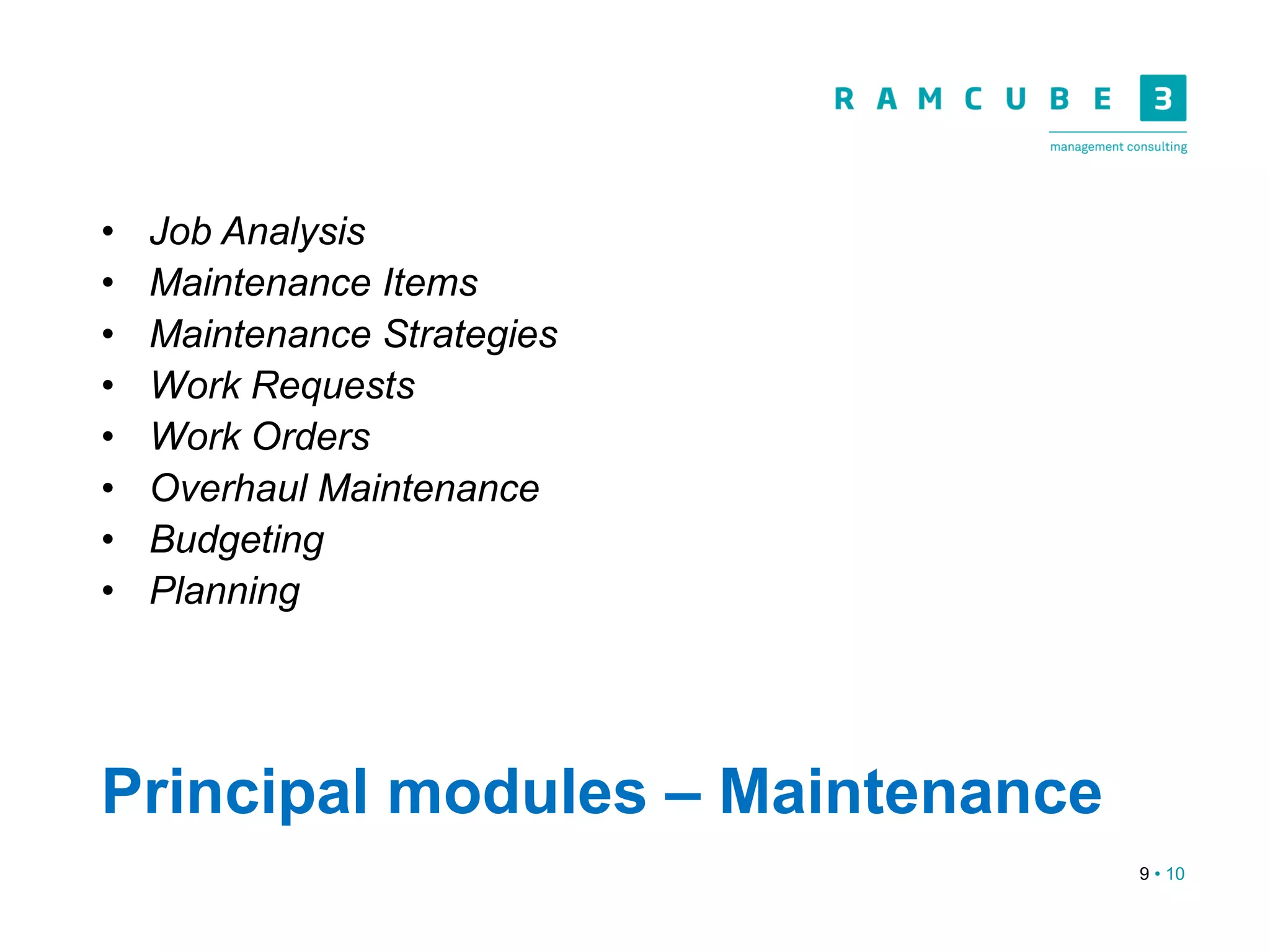

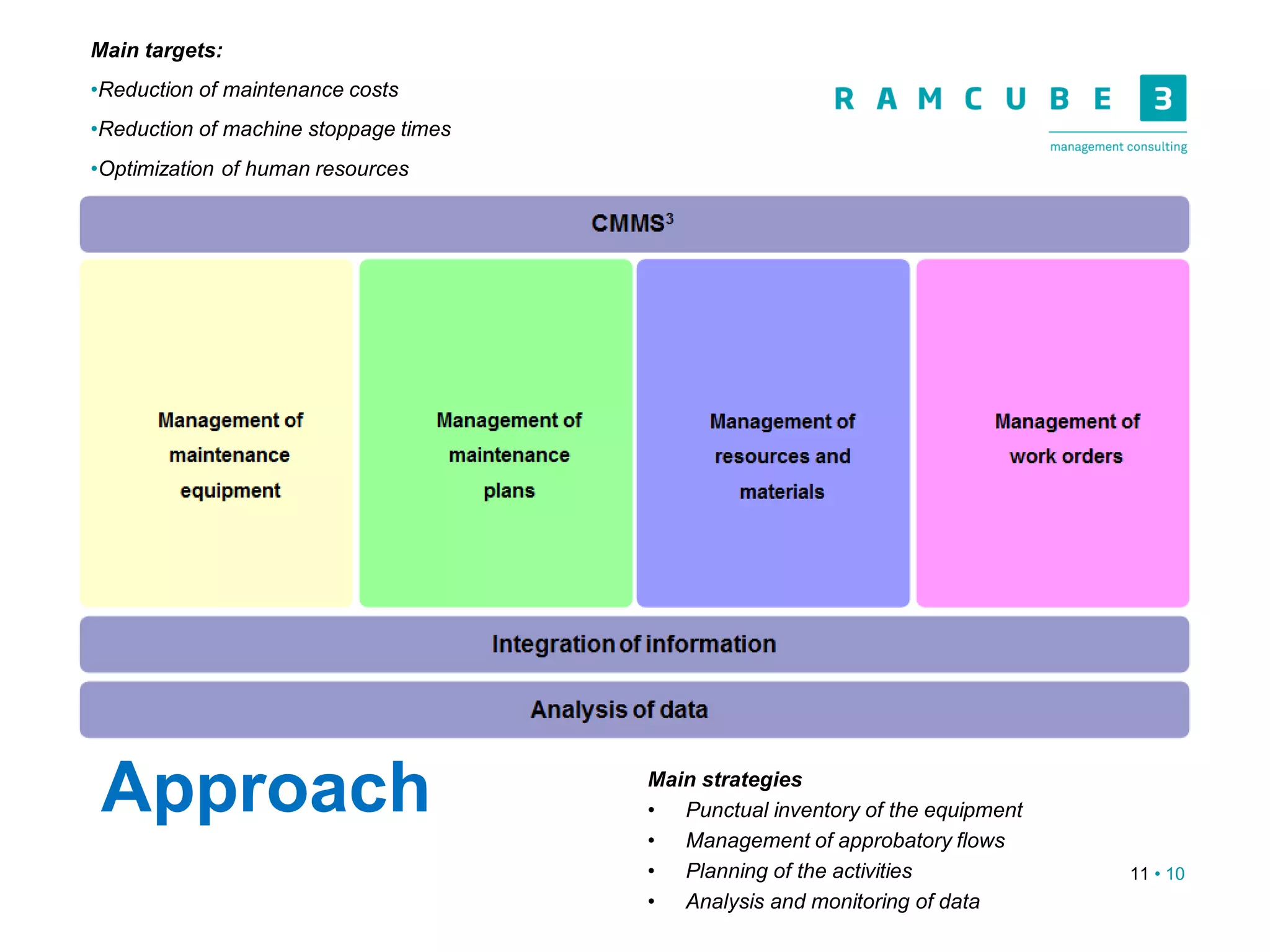

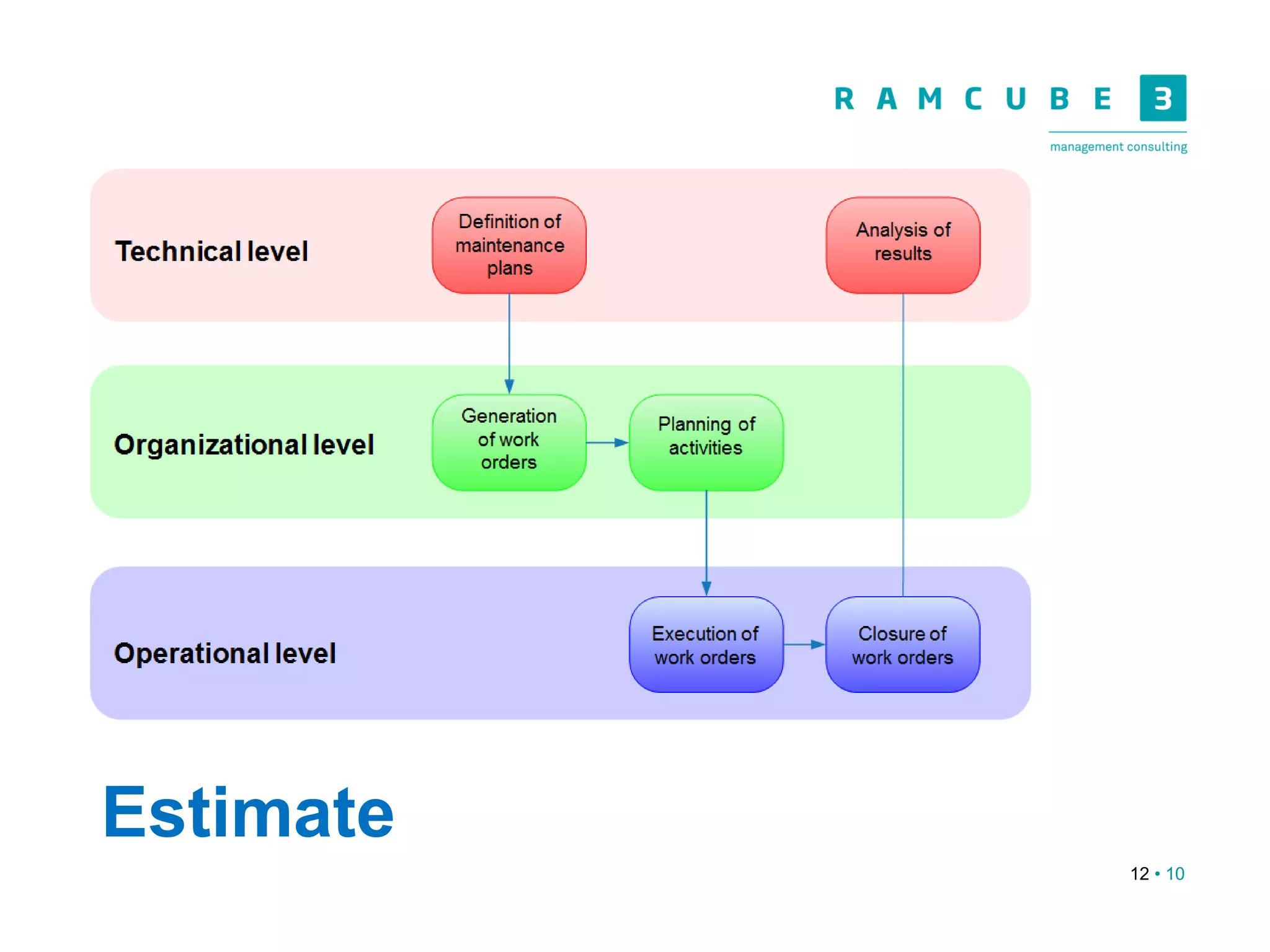

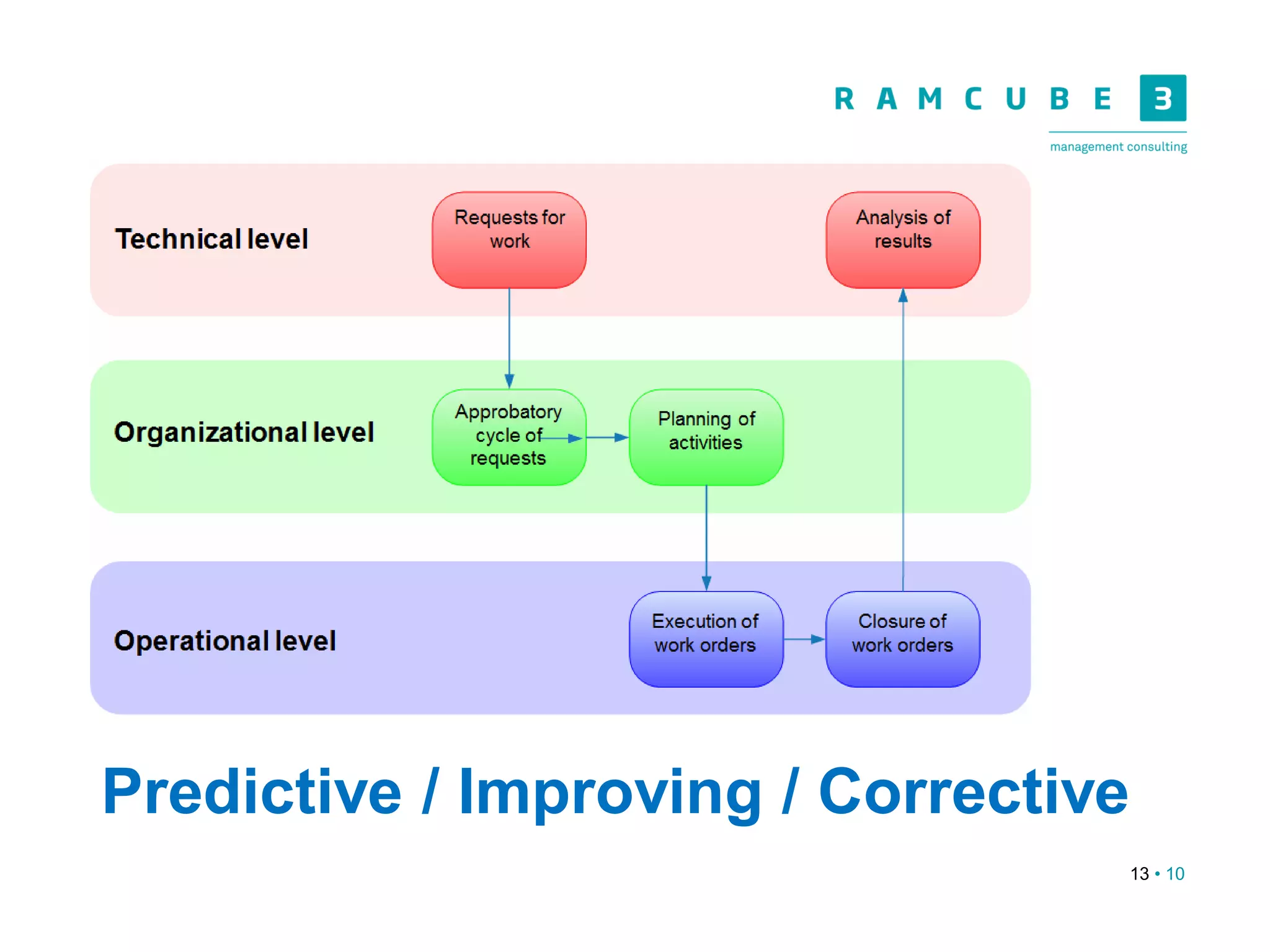

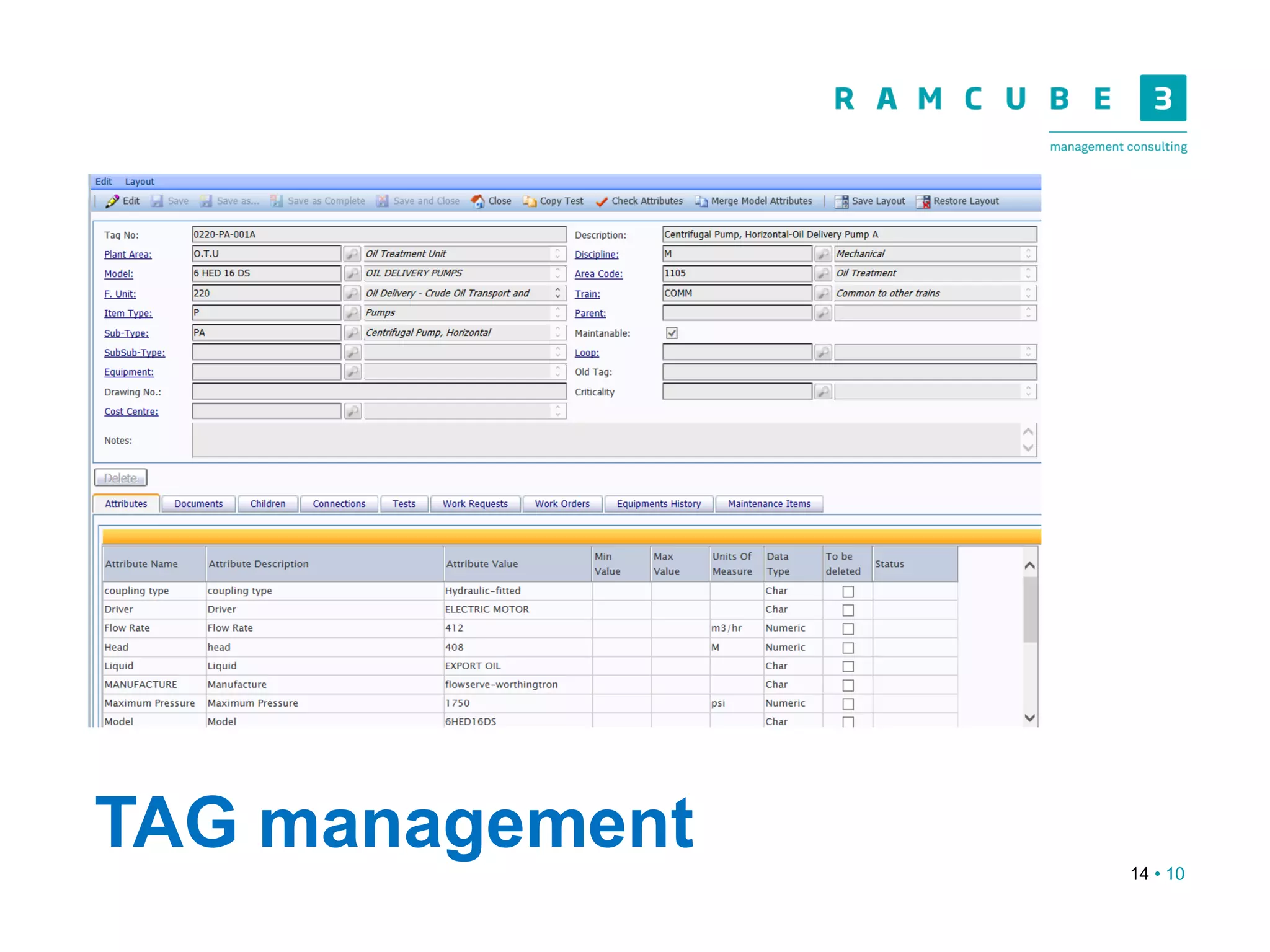

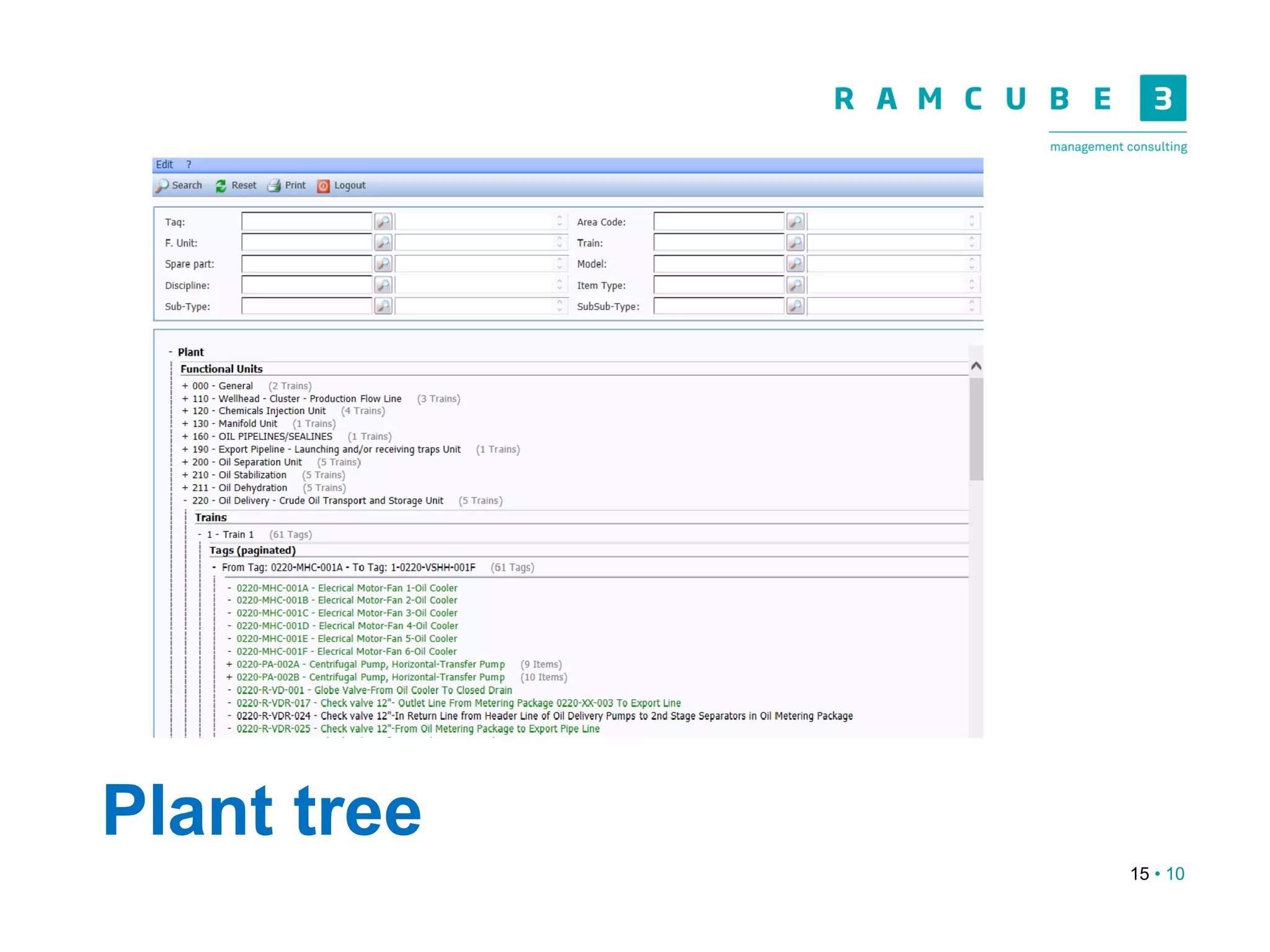

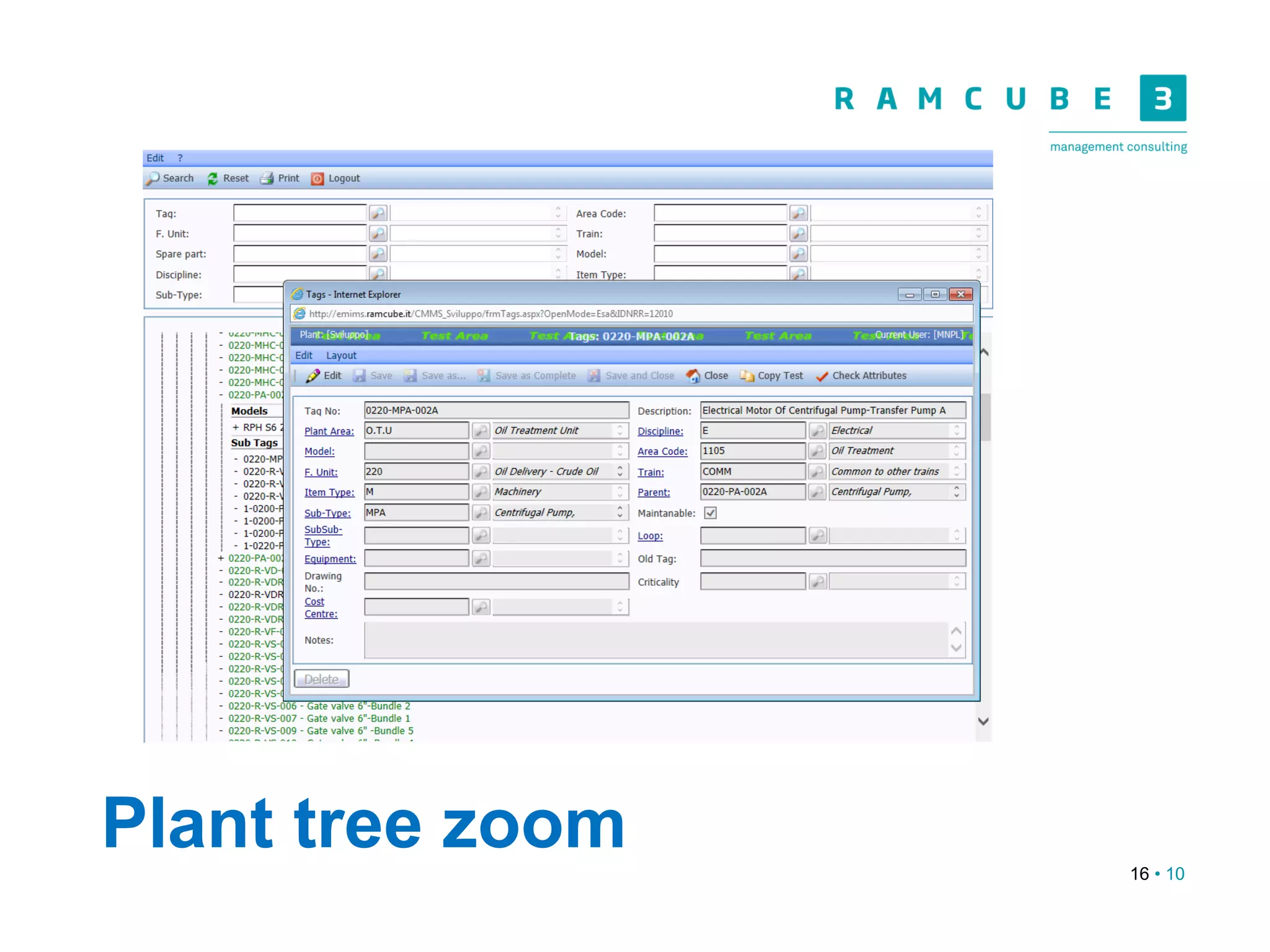

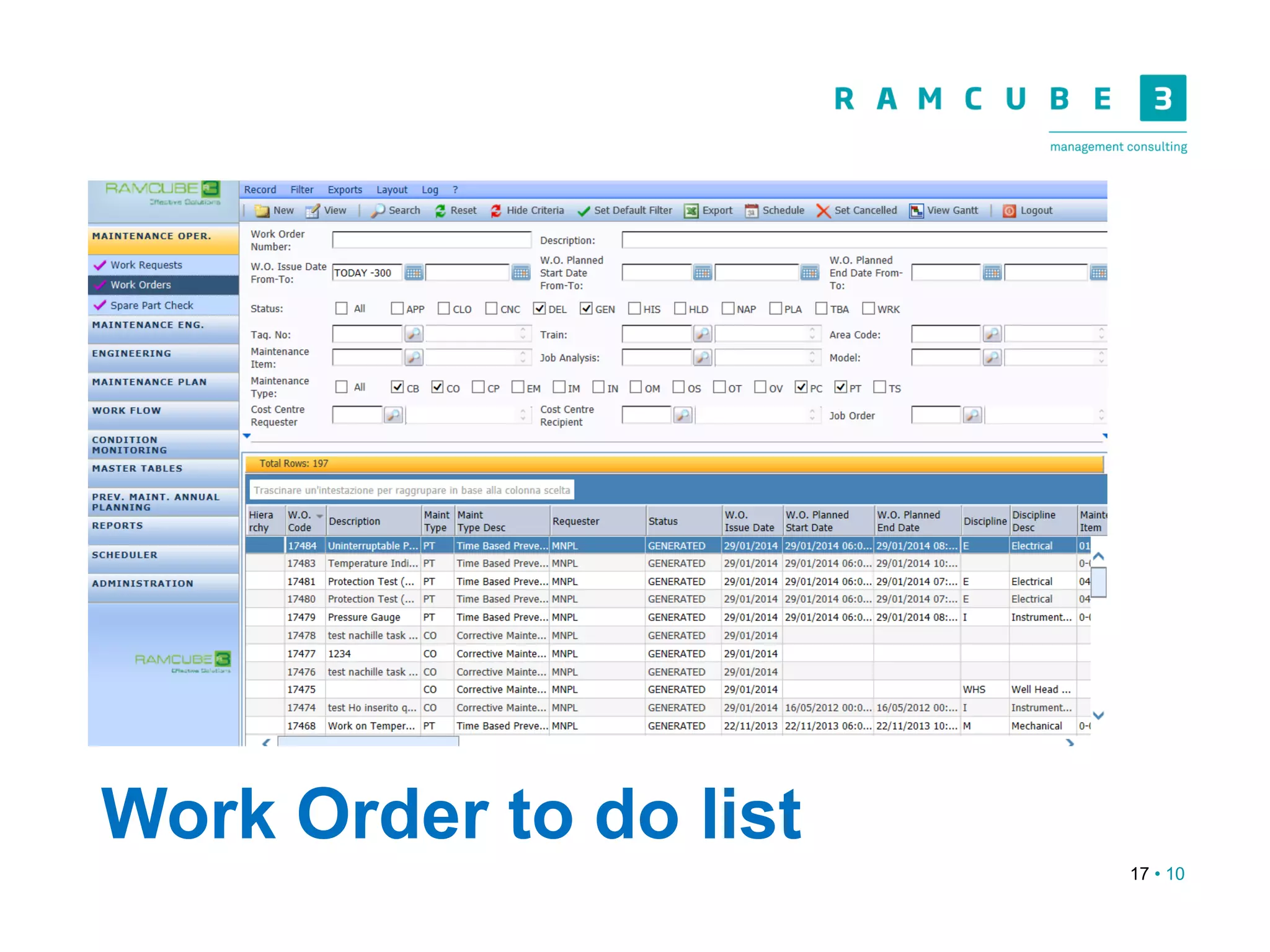

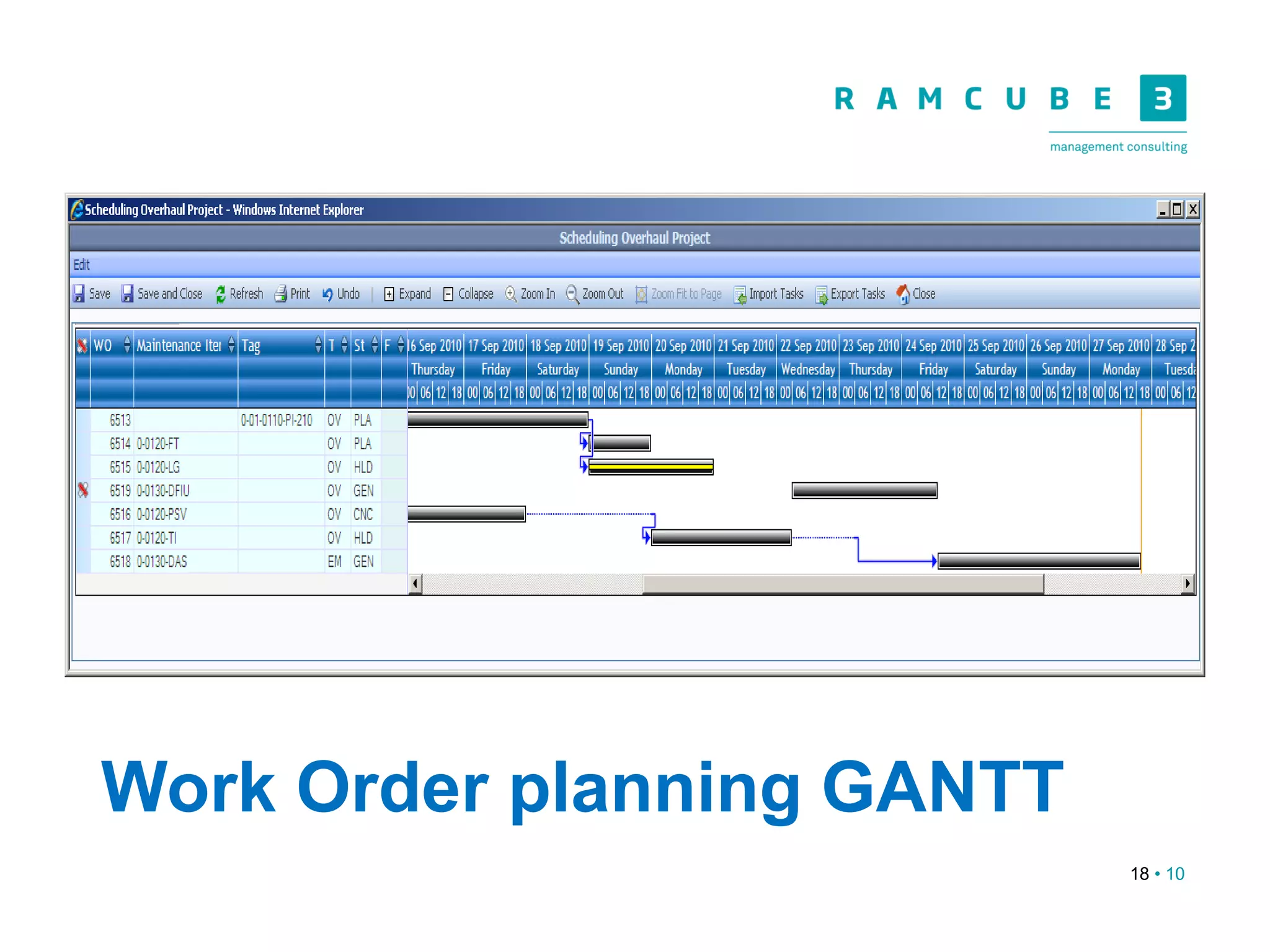

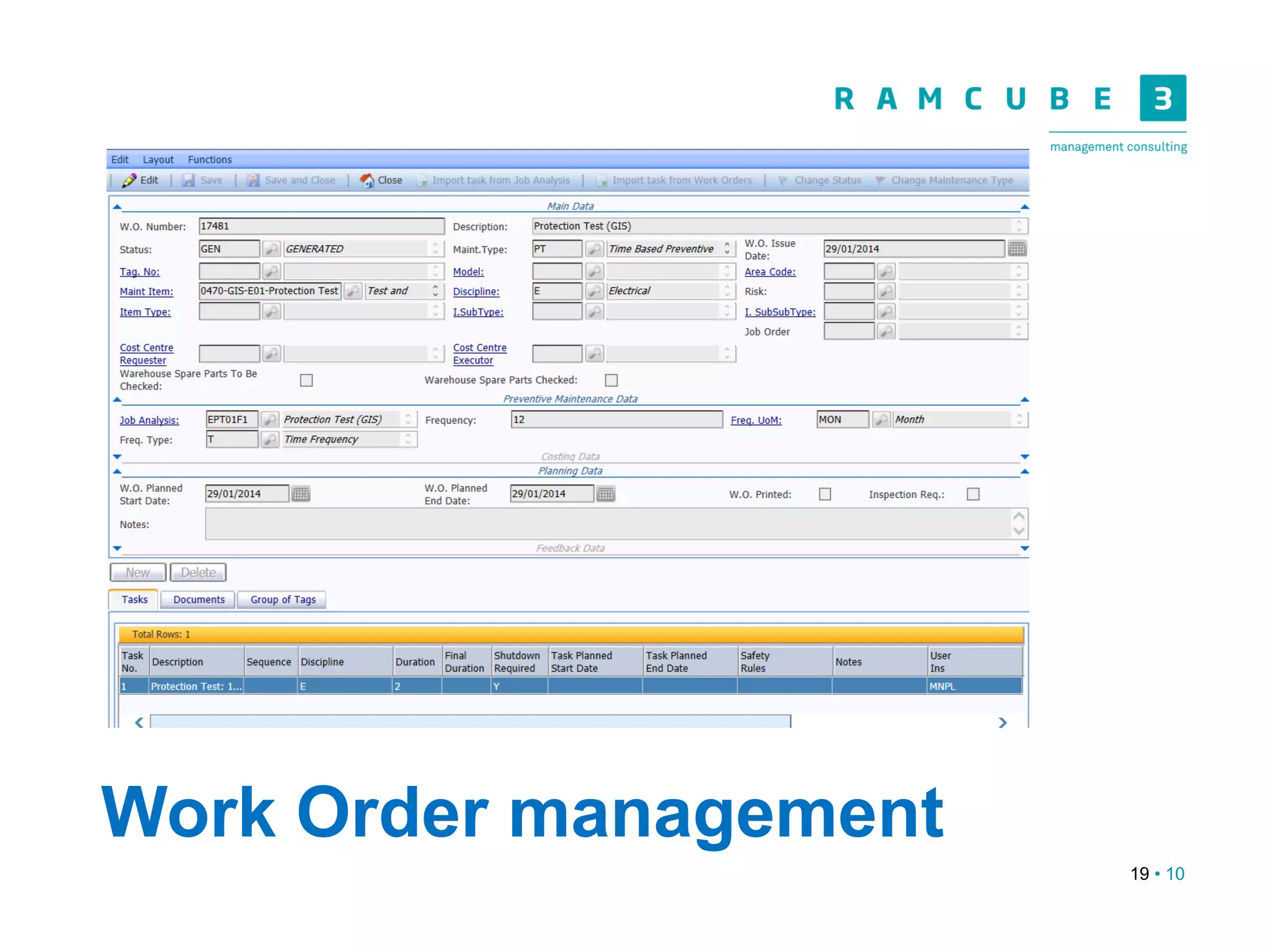

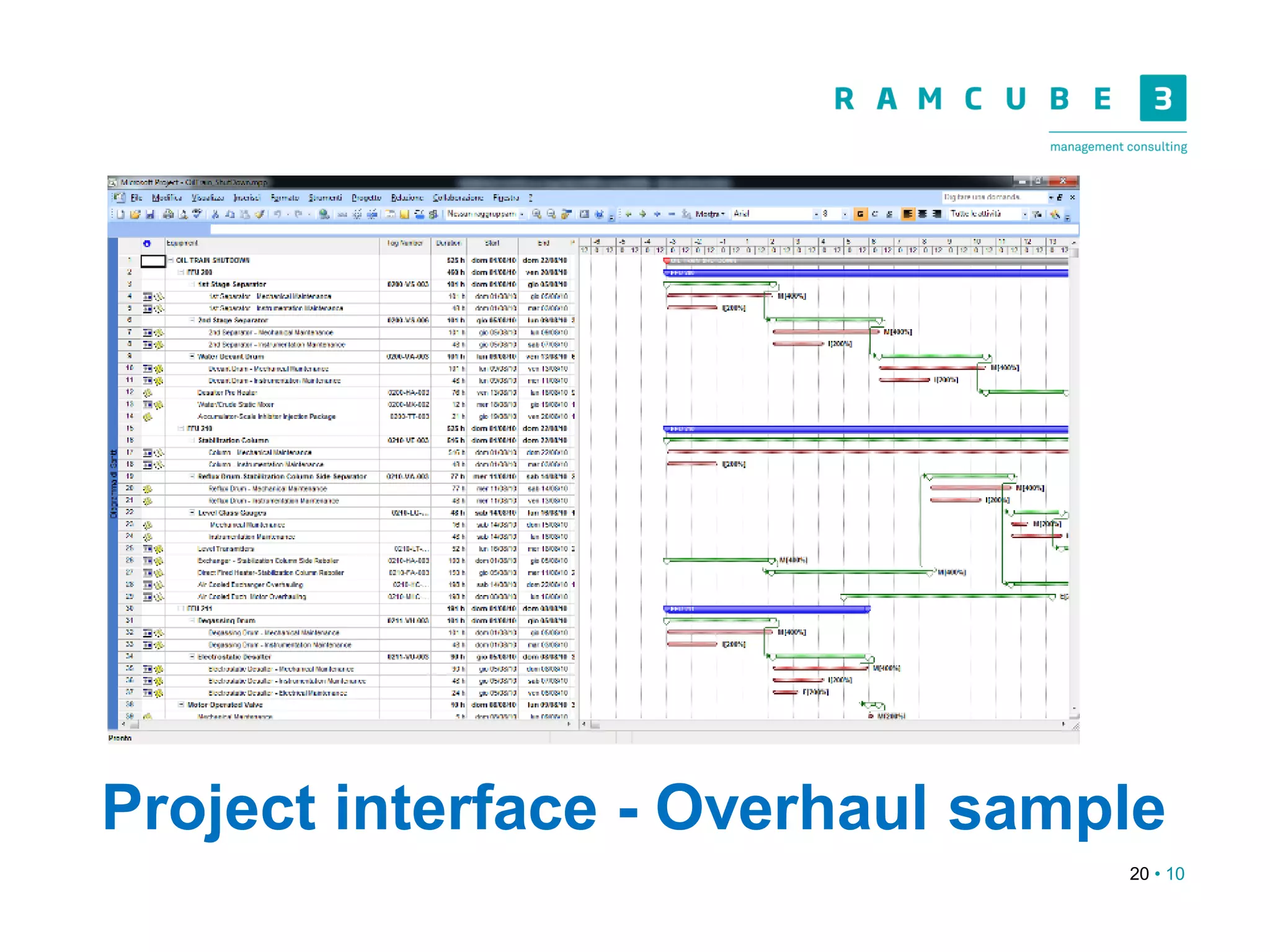

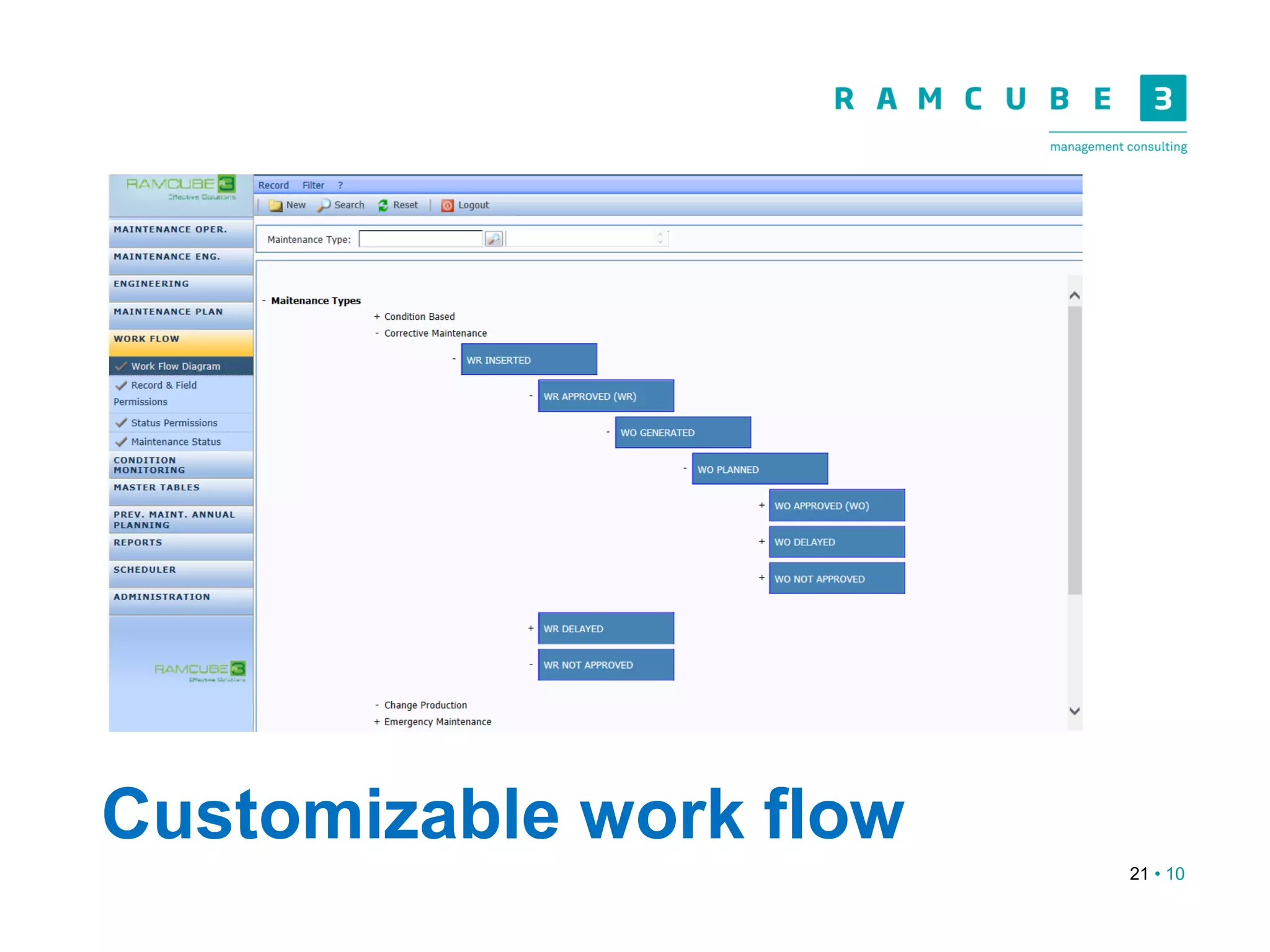

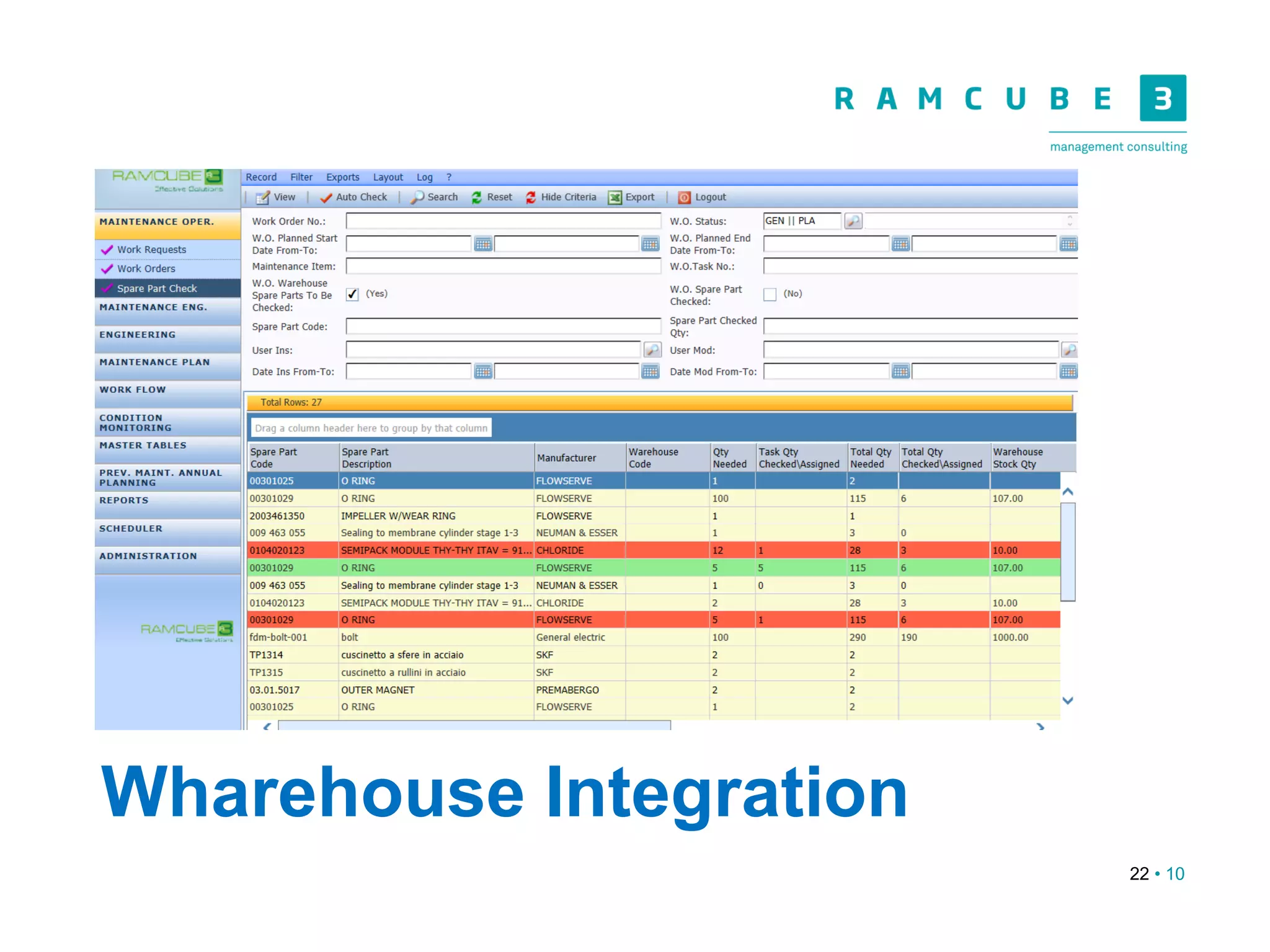

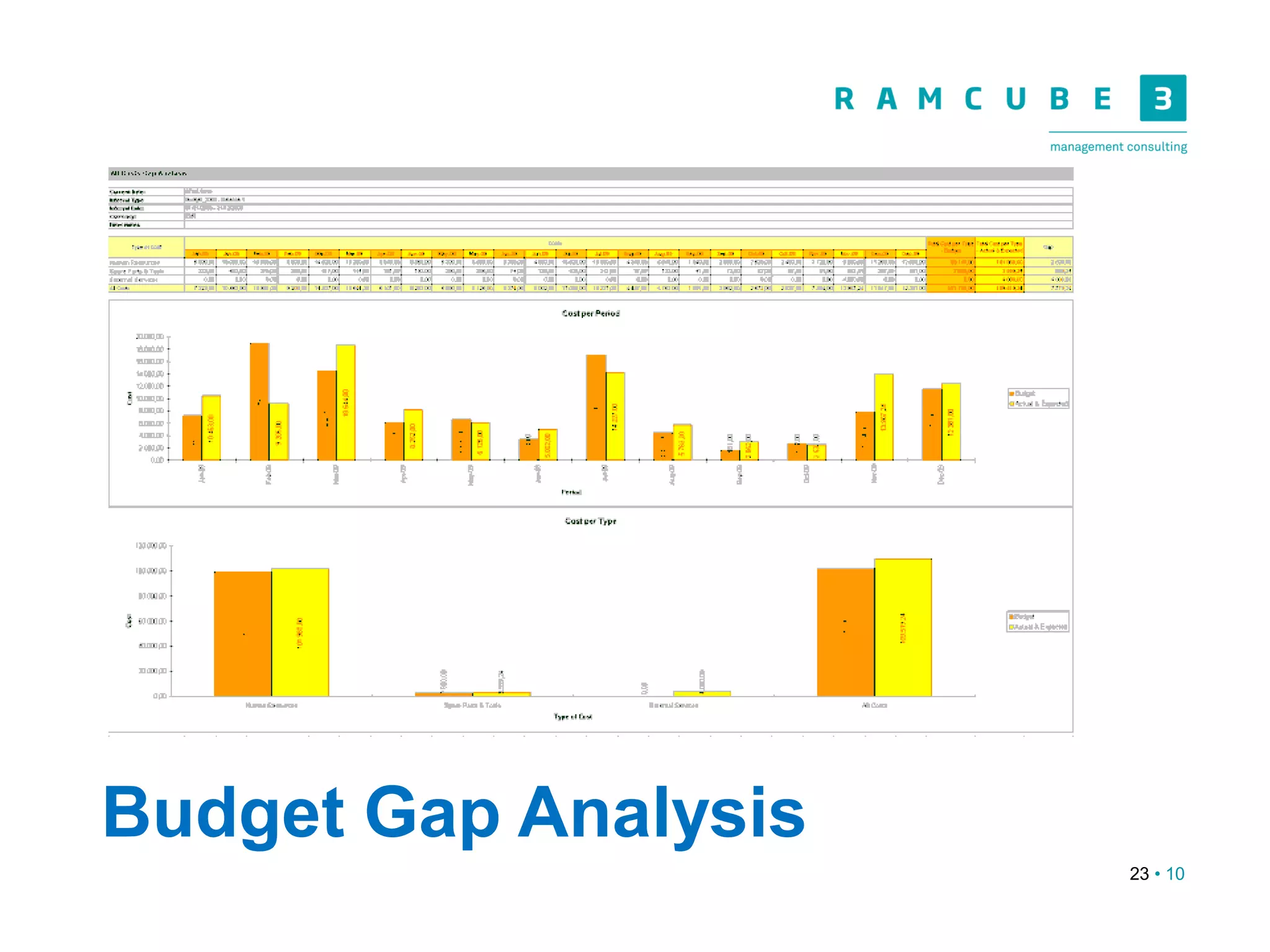

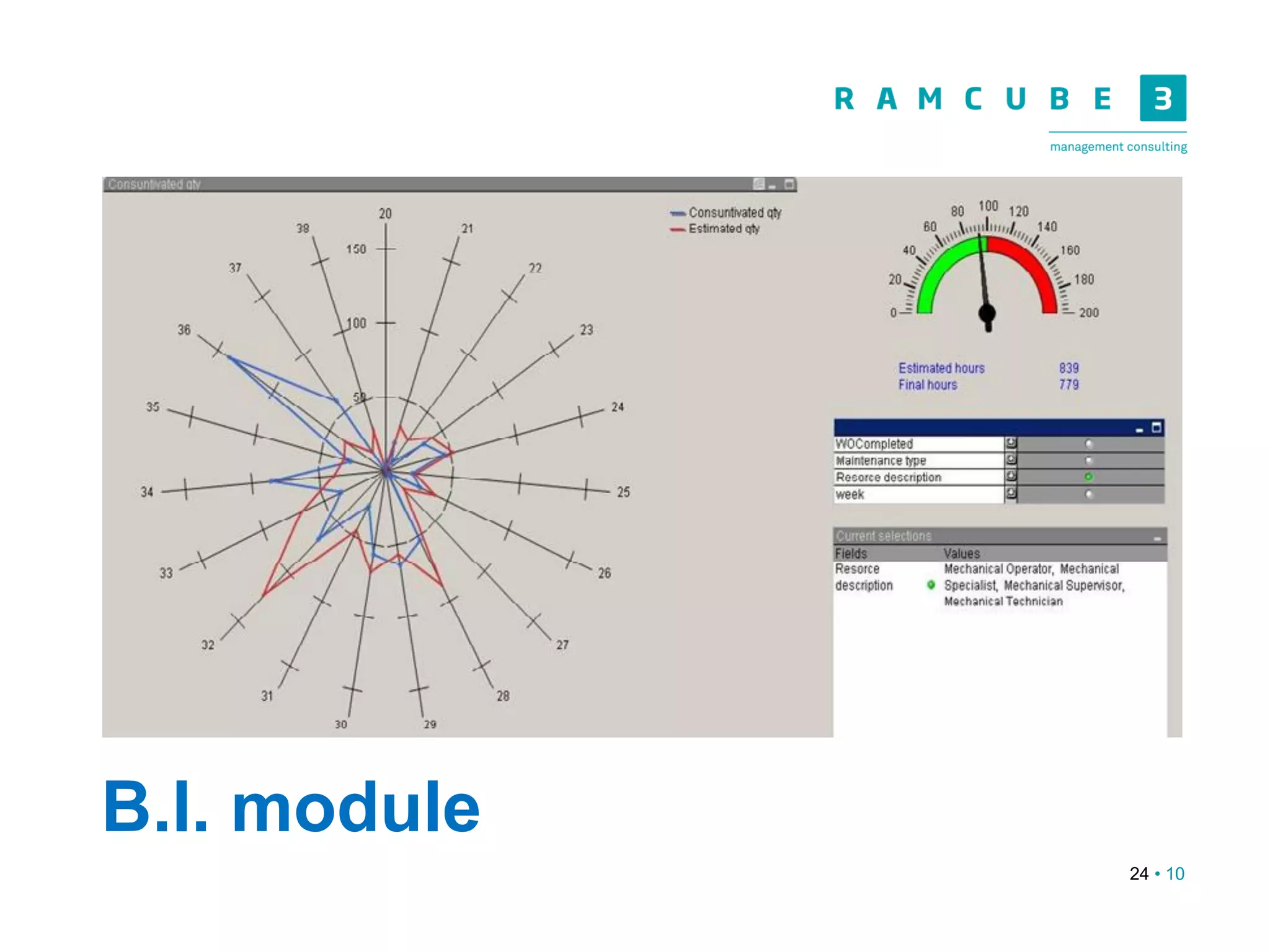

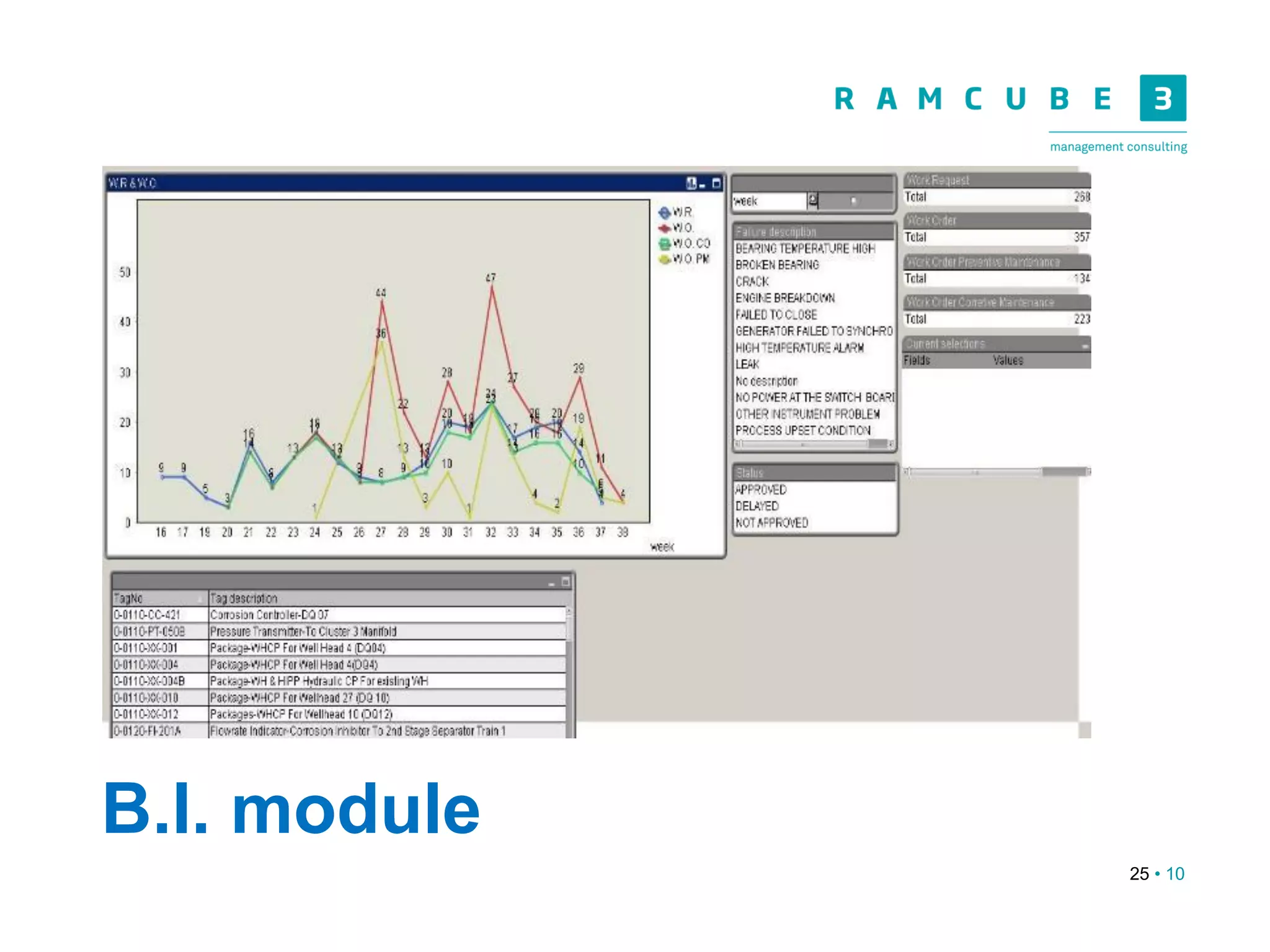

CMMS3 is a leading computerized maintenance management system designed to enhance maintenance services through the development of an informational maintenance system. It features a web-based architecture and integrates various modules for engineering, maintenance, and human resources management while aiming for reduced costs and optimized resource use. Key advantages include system scalability, integrated business intelligence, and rapid implementation and training.