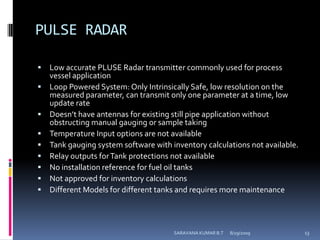

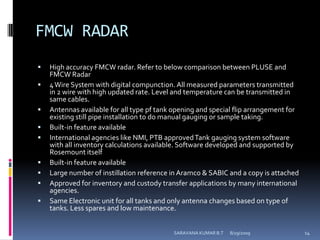

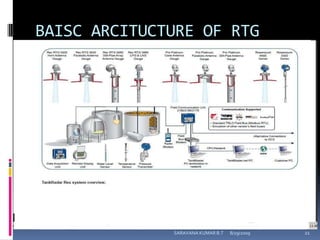

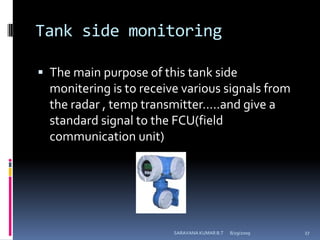

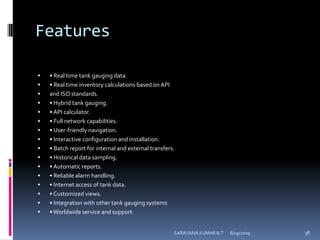

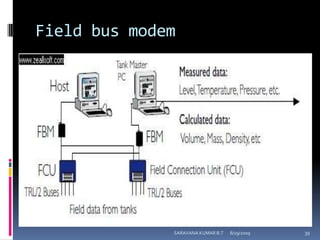

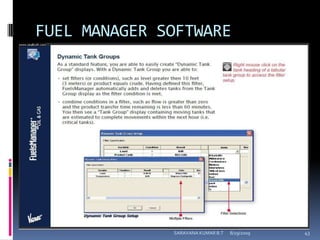

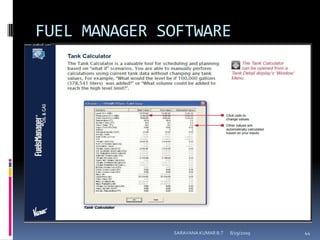

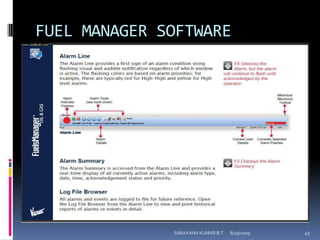

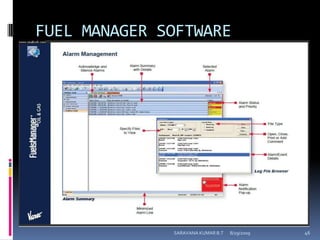

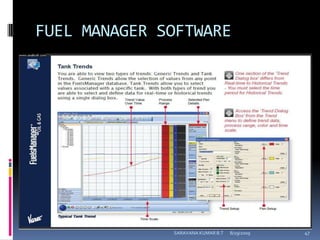

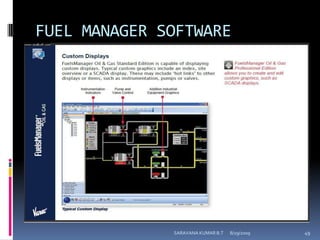

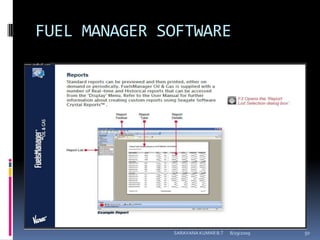

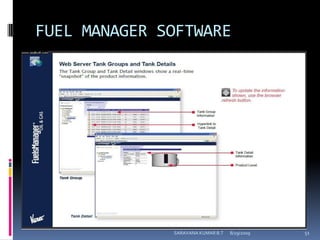

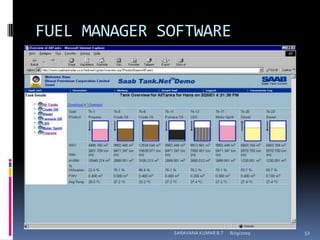

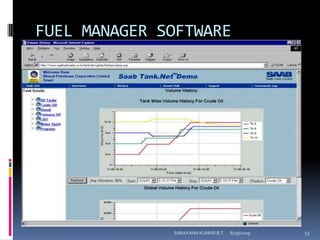

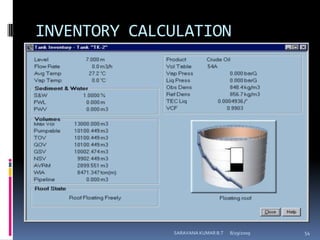

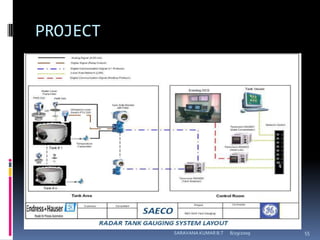

A digital tank gauging system uses radar technology to monitor and control fuel storage tanks. It provides real-time tank level monitoring, inventory calculations, alarm handling and automated reports. The key components include radar level transmitters, temperature transmitters, a field communication unit, and tank inventory management software. The software provides inventory data, calculations, and custody transfer functions to manage fuel storage.