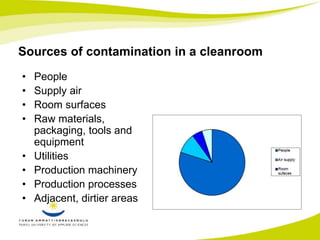

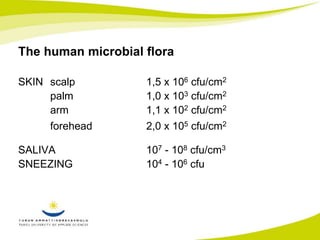

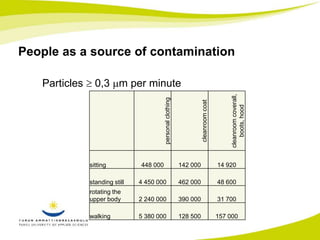

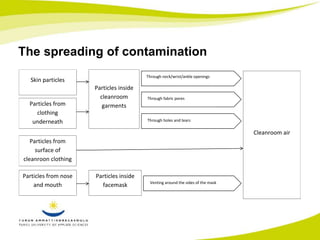

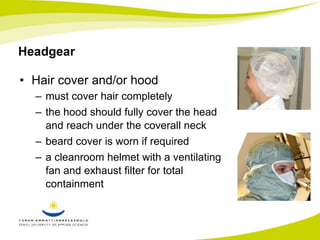

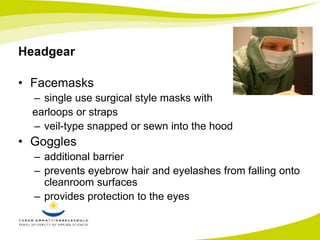

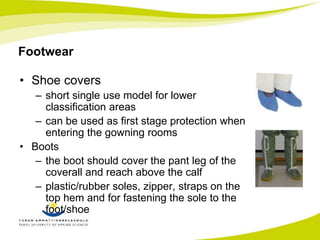

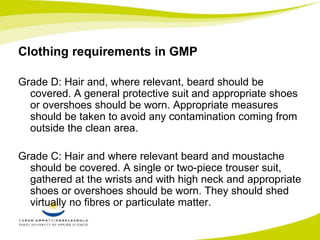

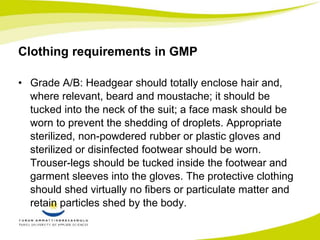

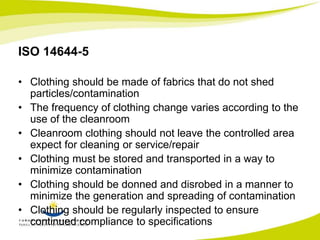

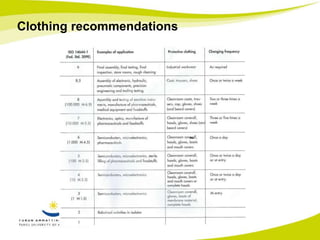

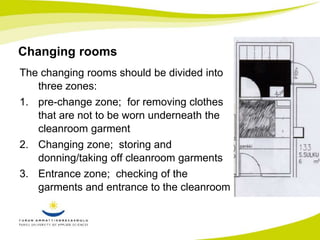

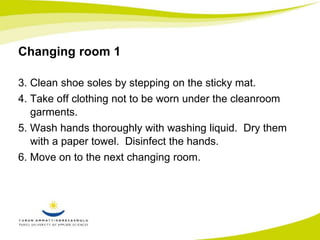

Cleanroom clothing is worn to protect cleanroom environments and products from human contamination. People are the largest source of particles in cleanrooms, shedding skin cells and microbes. Cleanroom clothing must filter these contaminants and include head covers, body suits, gloves, boots, and face masks appropriate for the cleanroom class. The clothing is donned in a changing room process to minimize contamination entering the cleanroom.