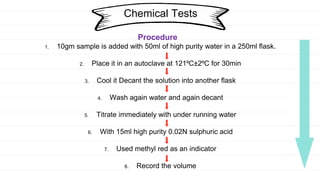

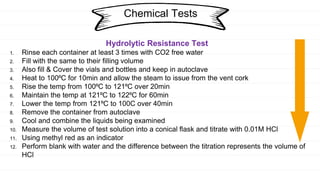

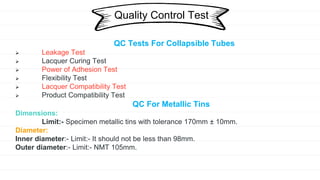

The document outlines the quality control procedures for packaging materials in pharmaceutical product development, emphasizing the importance of packaging characteristics from the design stage. It details various testing methods, including chemical, mechanical, and environmental tests, for primary and secondary packaging components like ampoules, vials, and cartons, alongside acceptable quality limits for defects. Additionally, specific tests such as hydrolytic resistance, arsenic content, and light transmission are described to ensure product safety and compliance.