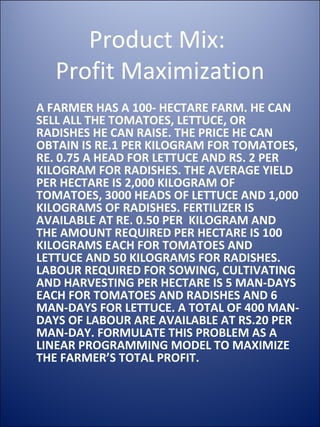

A fertilizer manufacturer uses four ingredients to make two fertilizers. It has limited supplies of the ingredients and wants to determine the optimal mix to maximize profits based on the contribution amounts of each fertilizer.

A toothpick manufacturer makes two types of toothpicks with different production capacities in cutting and packing. It wants to determine the optimal production level to maximize profits.

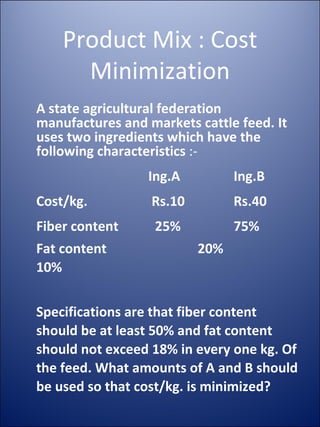

A feed company markets two cattle feed mixes with different ingredient requirements. It wants to determine the optimal mix of ingredients to use to maximize profits based on available supplies and selling prices of the mixes.