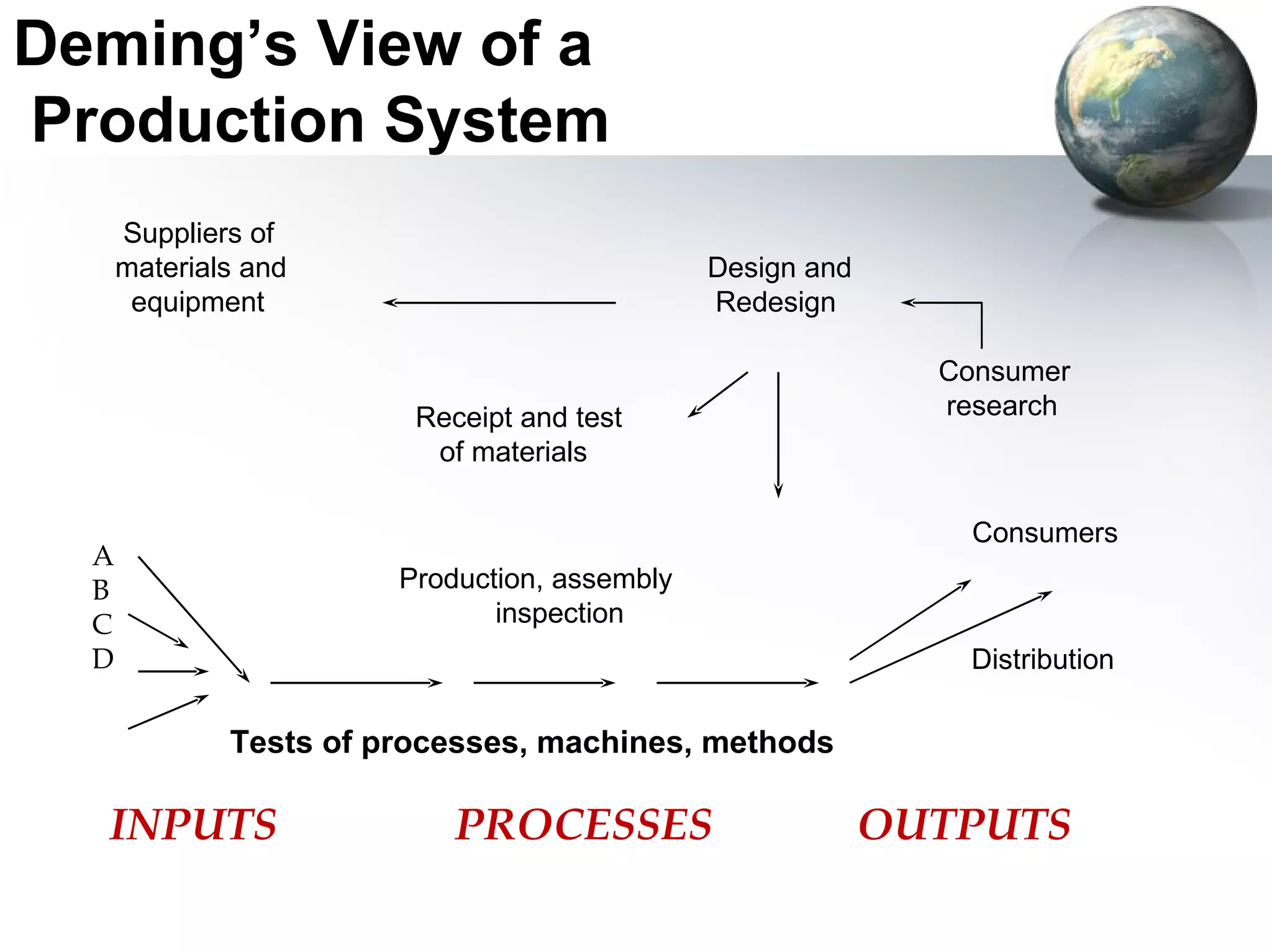

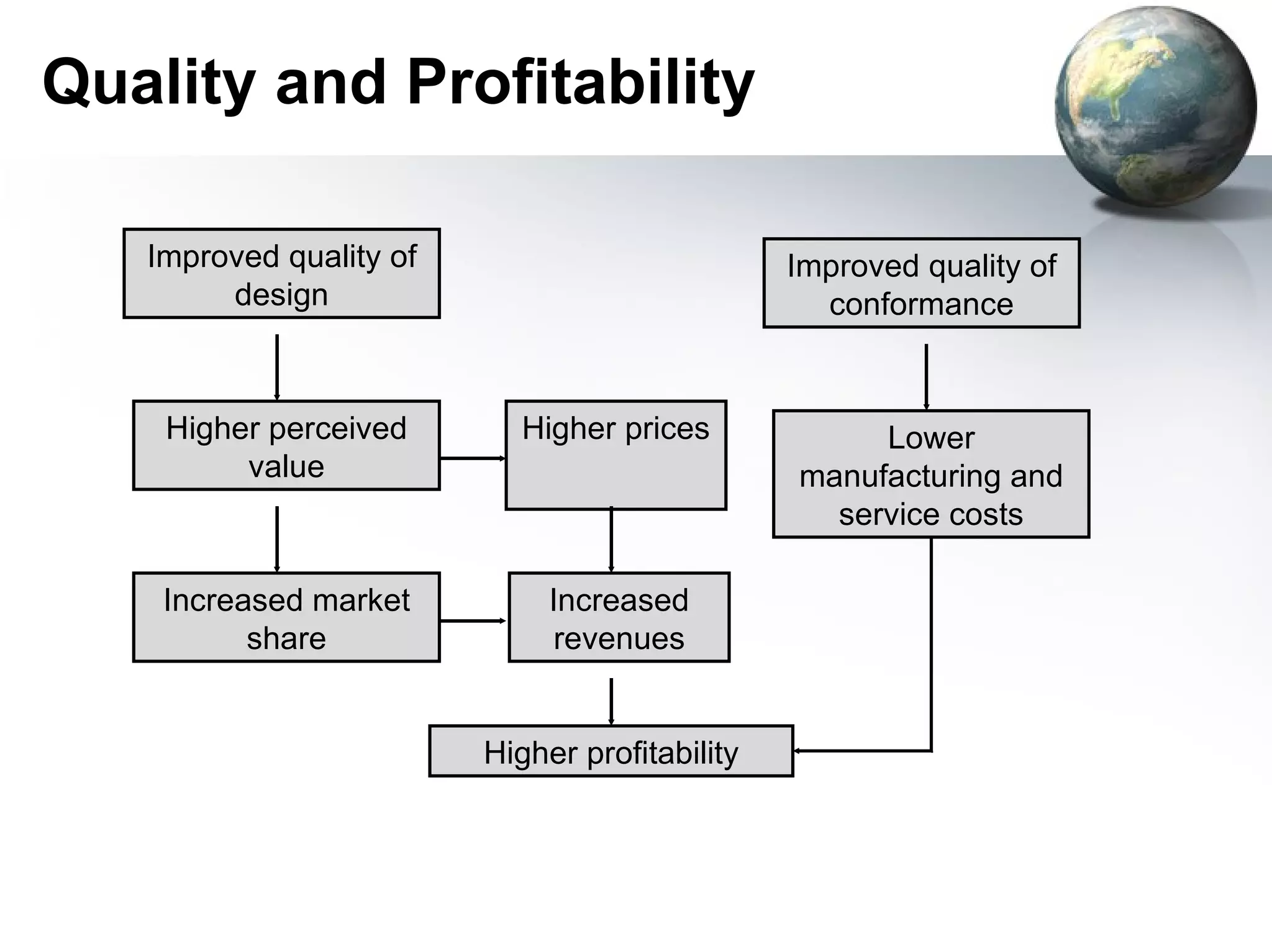

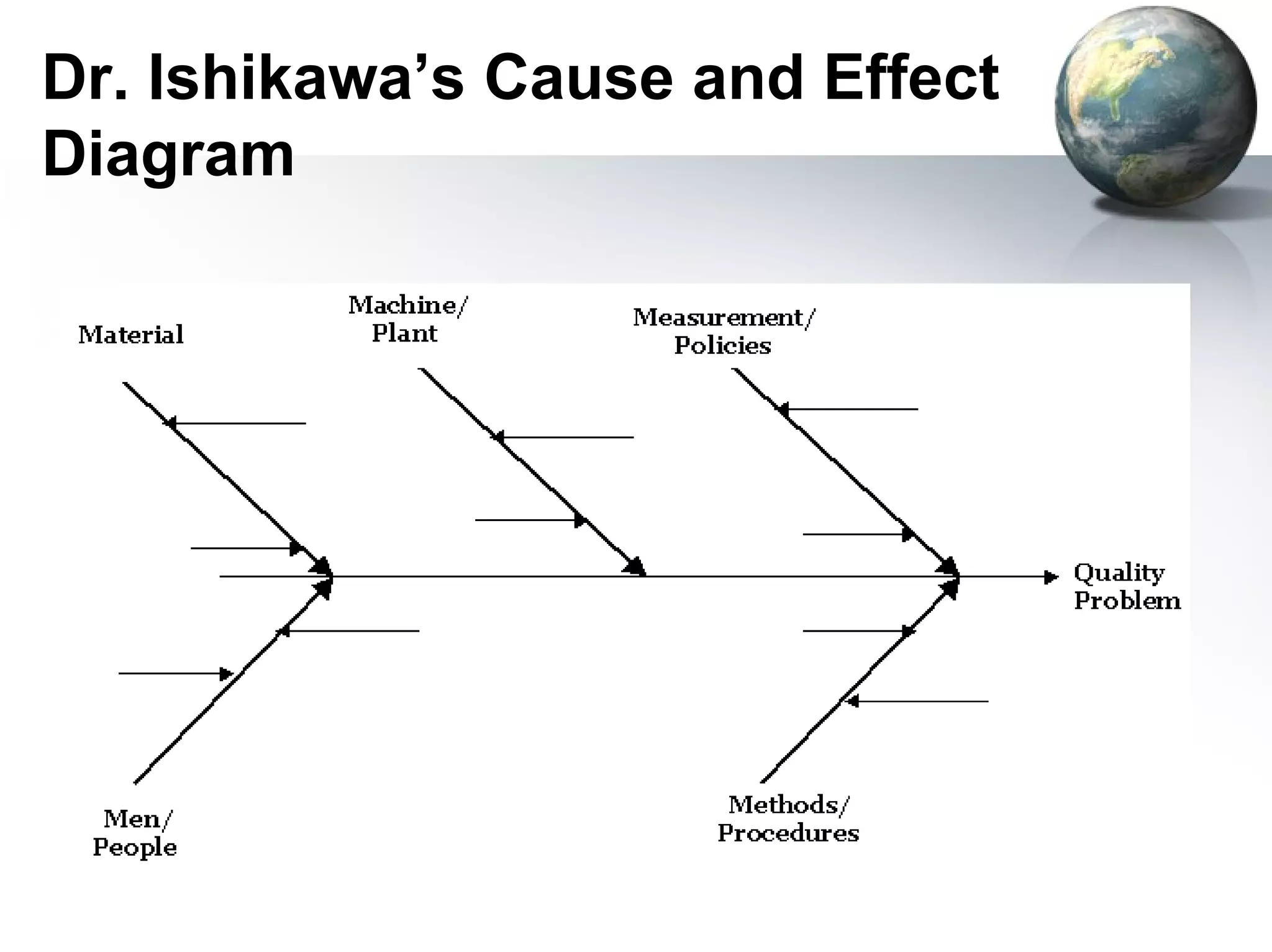

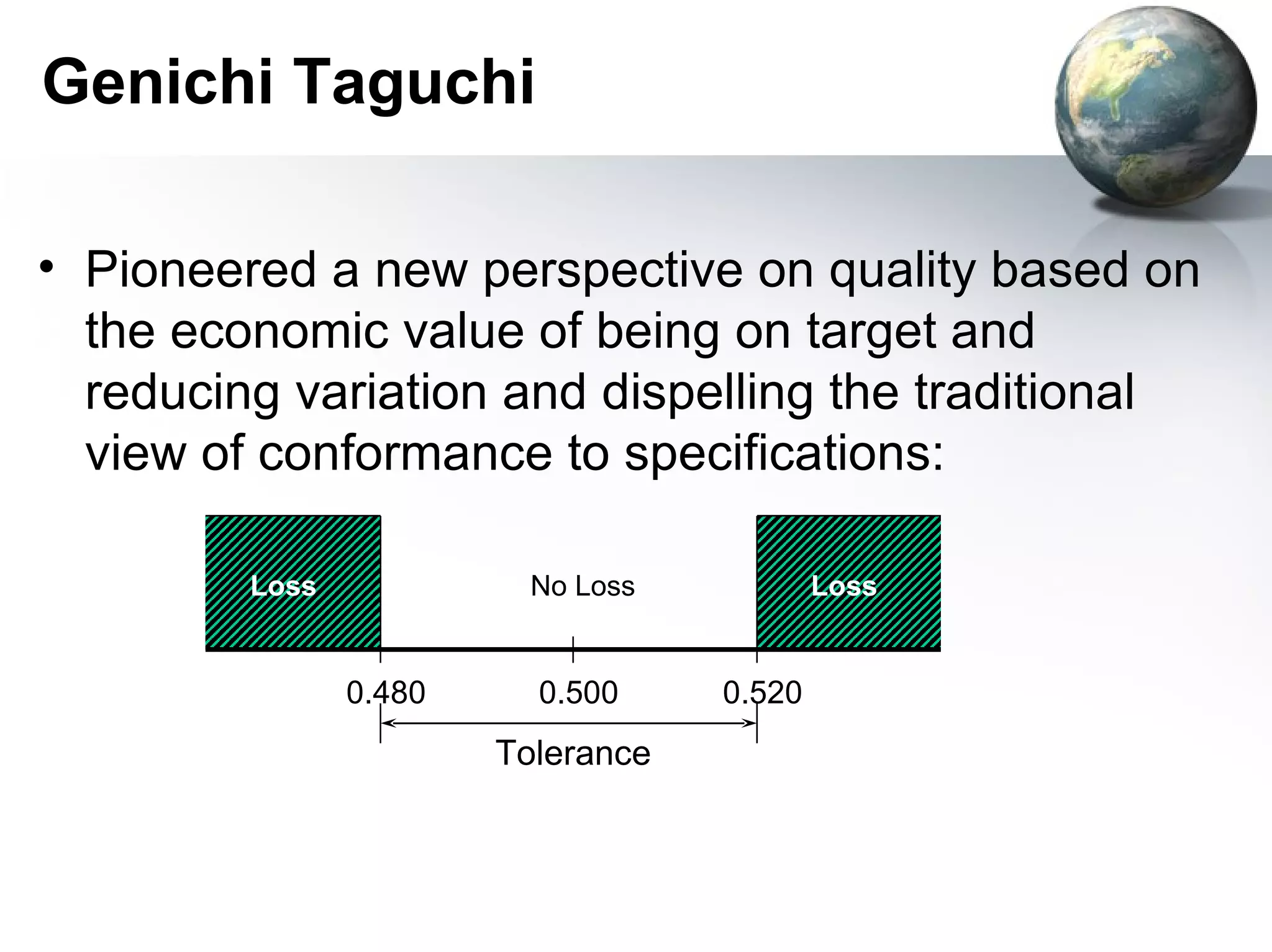

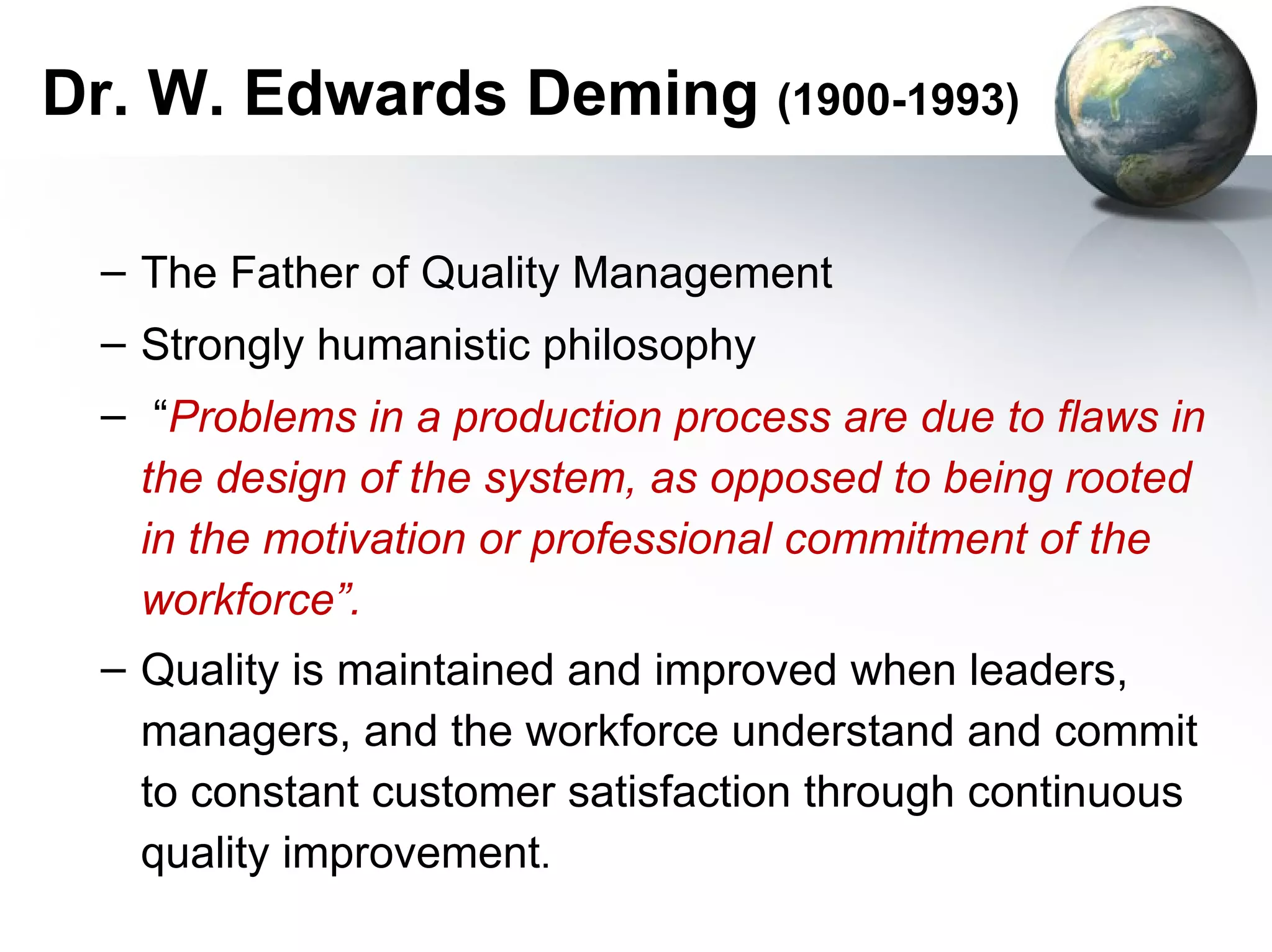

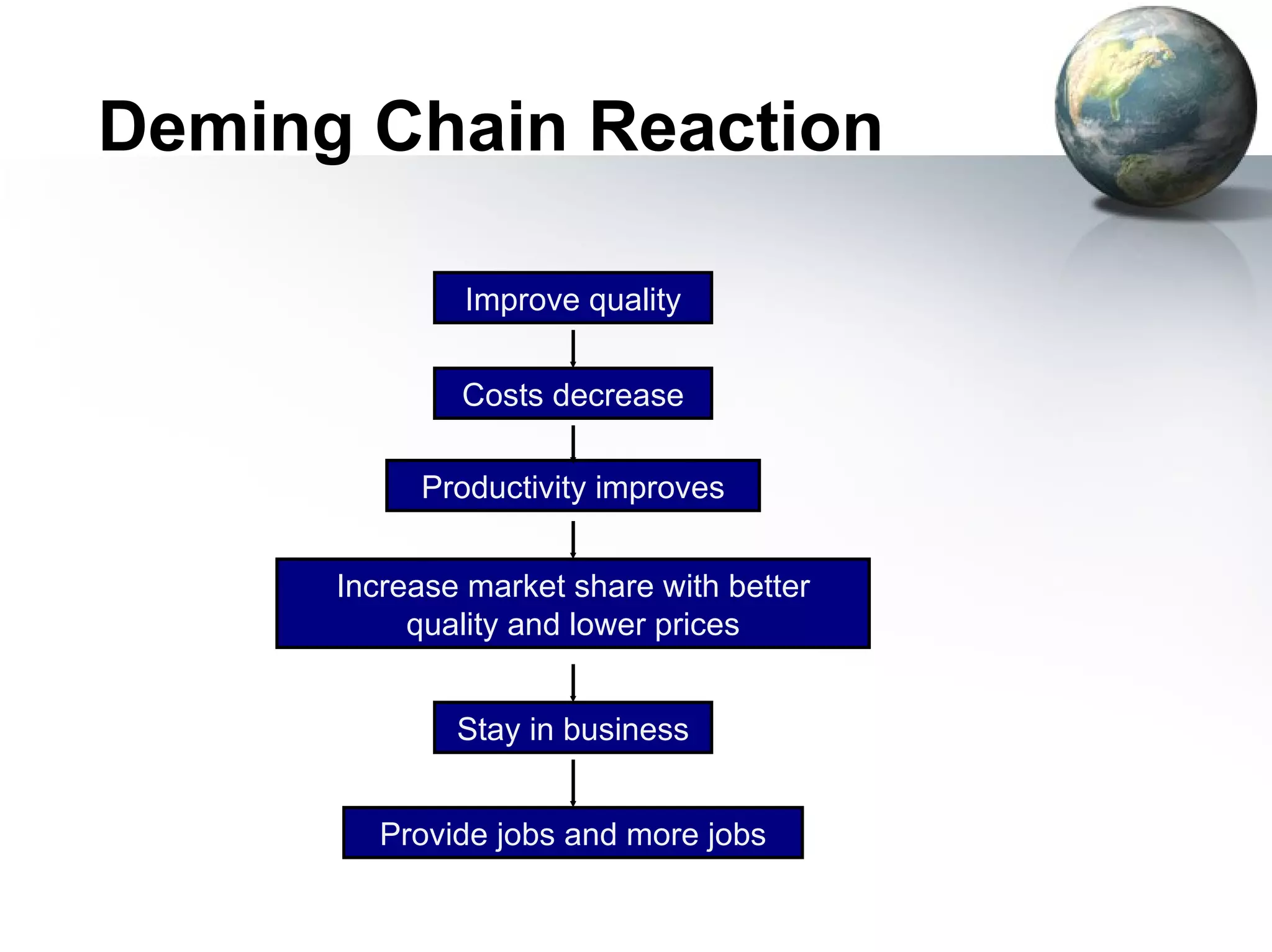

The document provides an overview of total quality management (TQM), including its history and key figures like Deming. It discusses principles of TQM like customer focus, continuous improvement, and defines quality from different perspectives such as products, users, and manufacturing. The document also covers quality tools and approaches including control charts, quality circles, cause and effect diagrams, and Deming's system of profound knowledge.