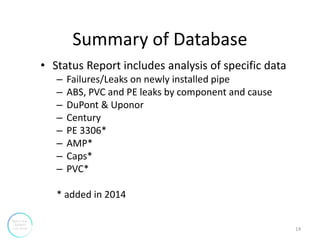

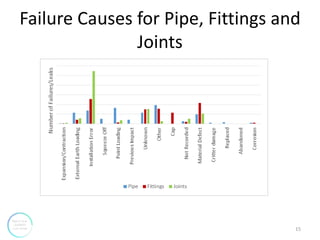

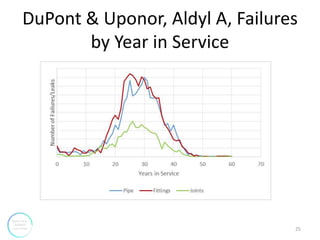

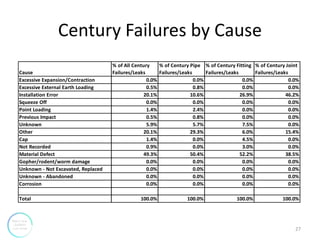

The document summarizes data from the Plastic Piping Database Committee (PPDC) database regarding failures and leaks in plastic gas piping systems in the United States. The PPDC database contains over 45,000 reports of failures and leaks collected over 14+ years from 114 contributing companies representing 76% of plastic mains and 84% of plastic services installed in the US. The database is analyzed by the PPDC biannually to identify failure trends in ABS, PVC, PE, and other plastic piping materials to help operators improve integrity management programs. Installation errors and material defects are among the most common causes of failures identified for different piping materials.