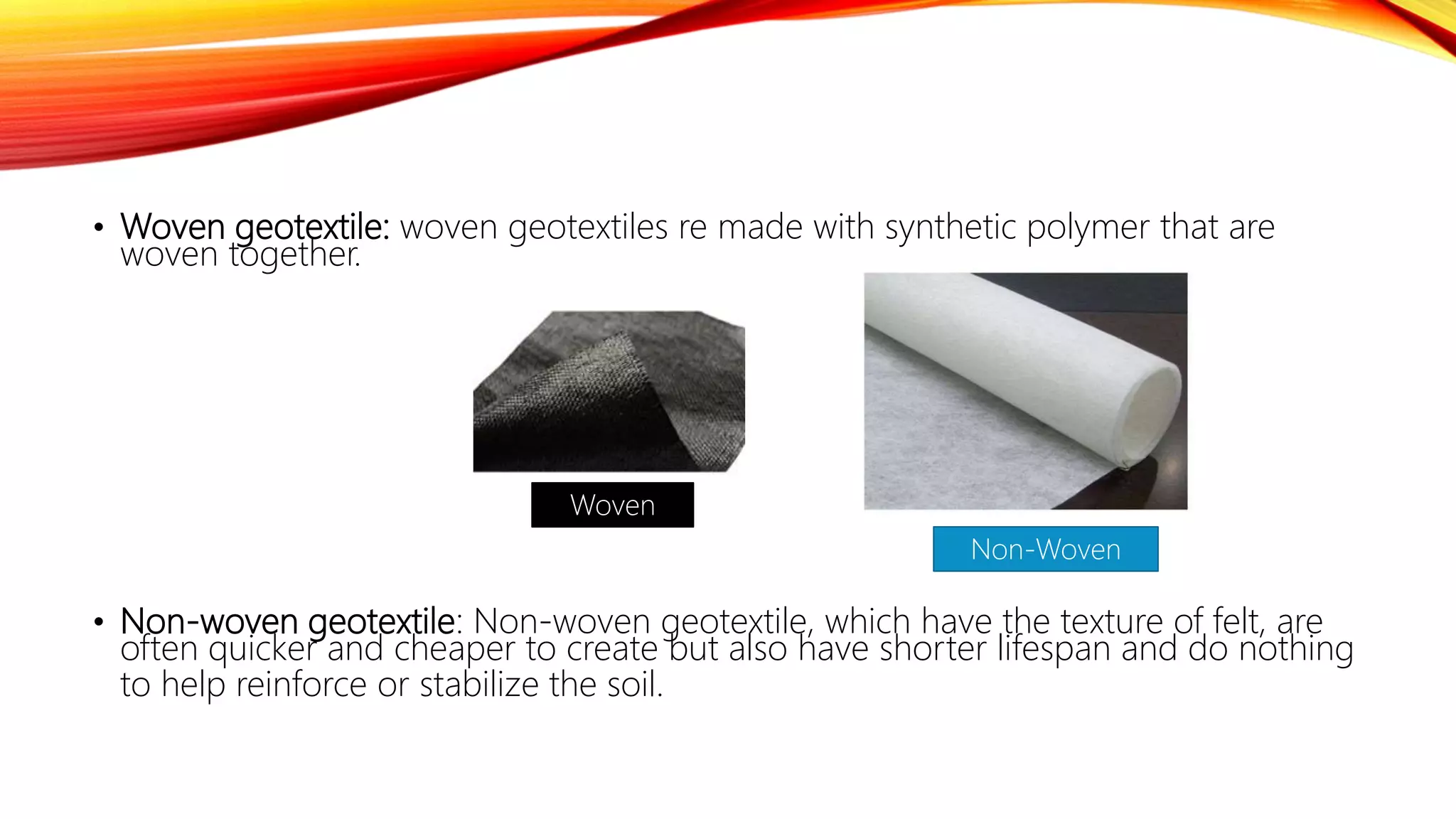

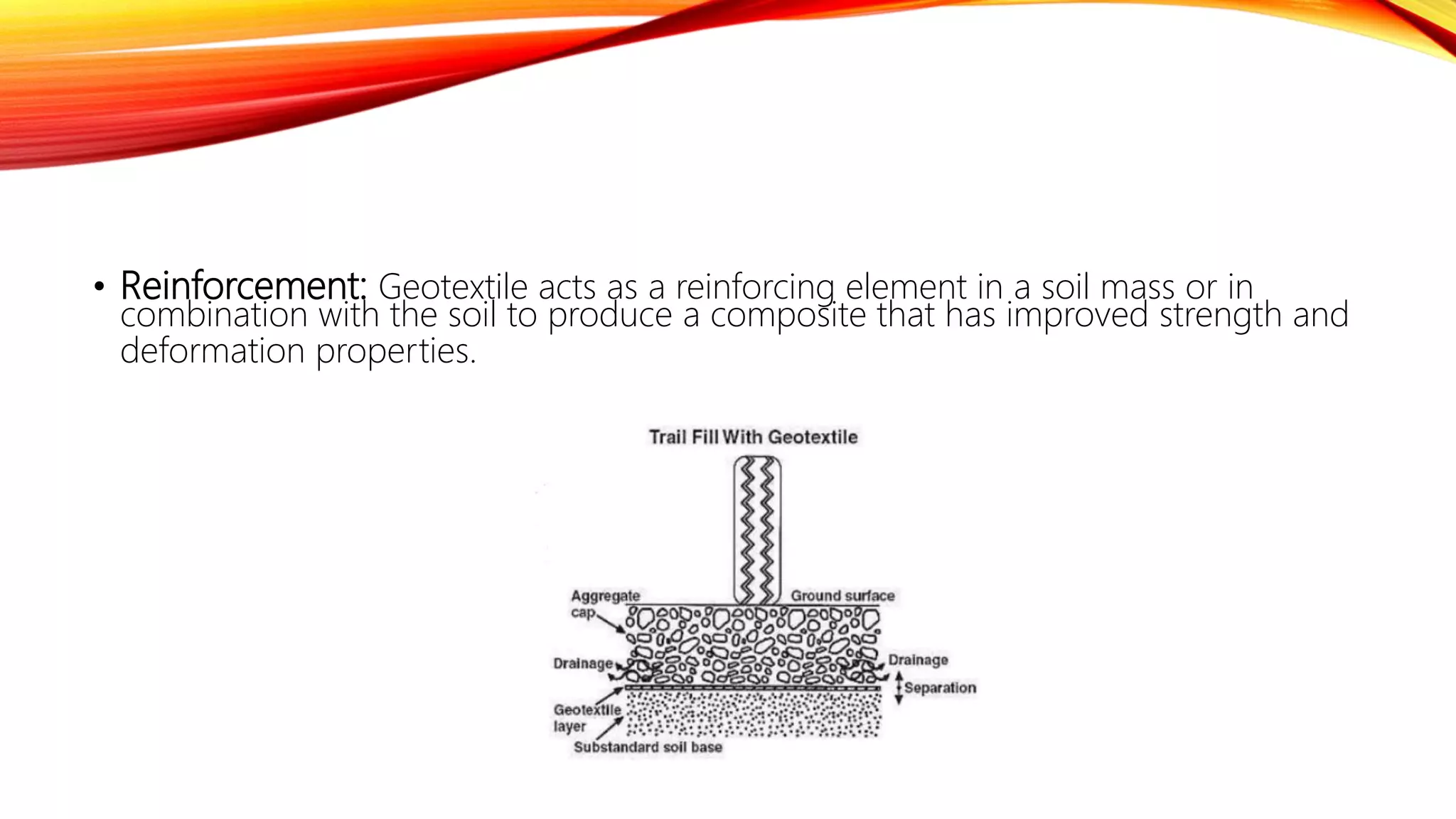

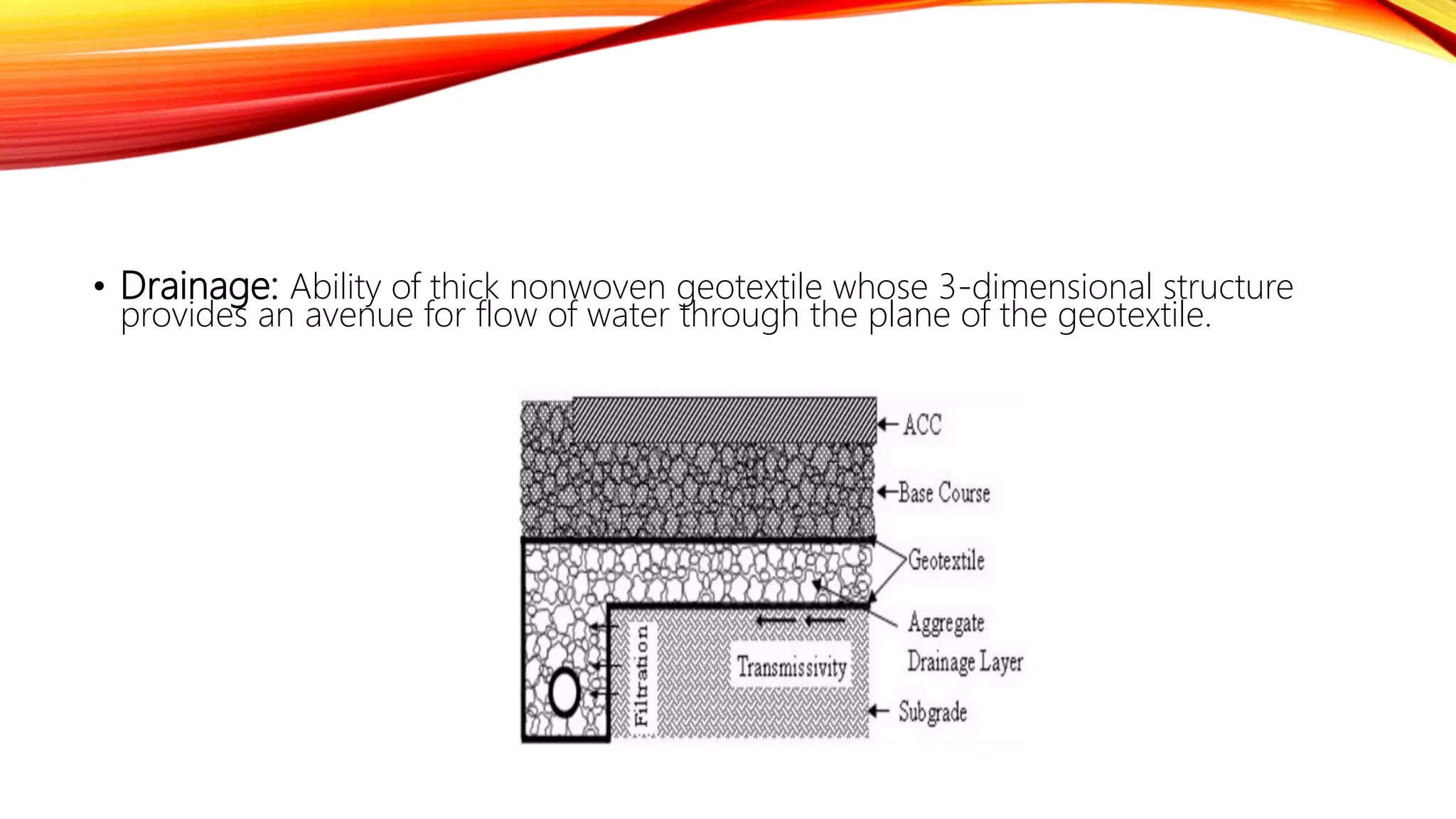

Geotextiles are permeable synthetic materials used in soil stabilization, erosion control, and drainage, with applications dating back to the 1950s. They are categorized into woven, non-woven, and jute geotextiles, with jute emerging as a biodegradable alternative that is eco-friendly and cost-effective. The primary functions of geotextiles include filtration, separation, reinforcement, and drainage, with varied applications in civil engineering and construction.