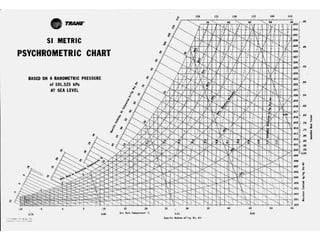

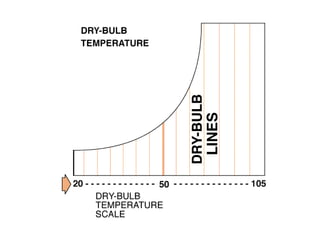

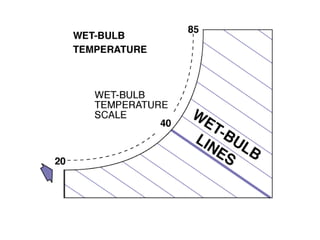

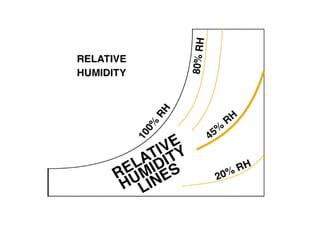

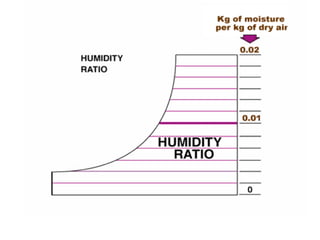

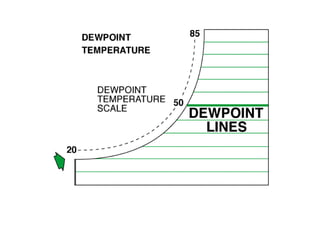

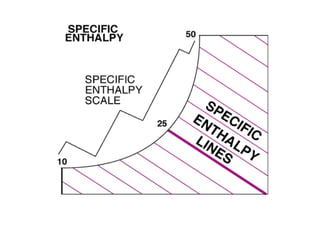

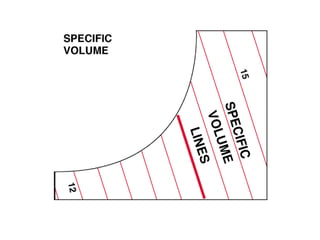

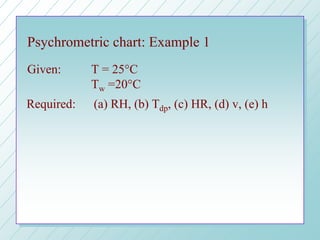

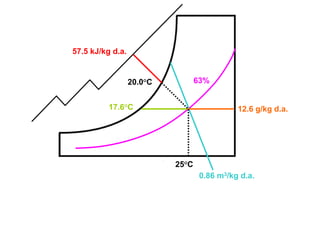

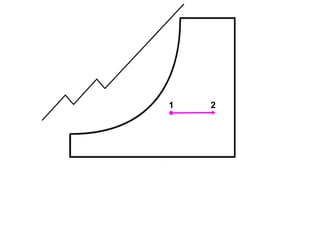

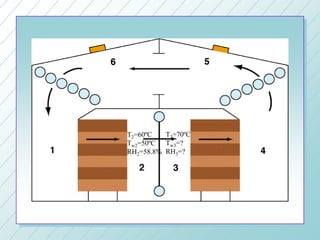

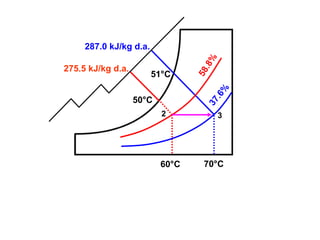

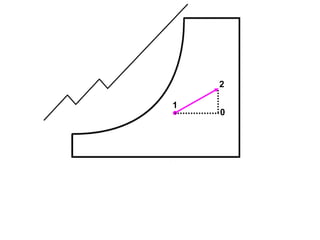

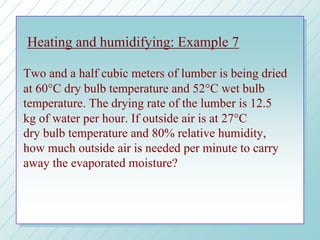

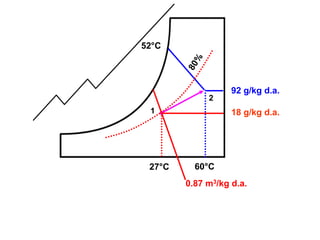

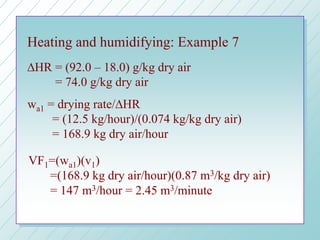

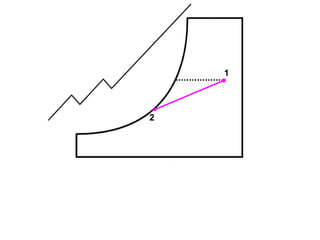

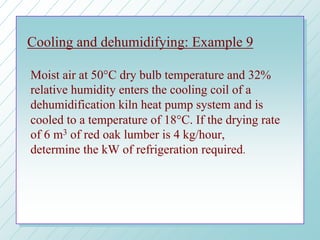

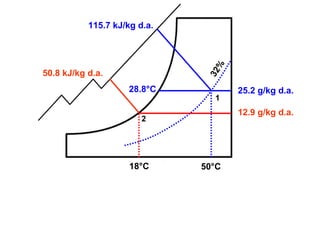

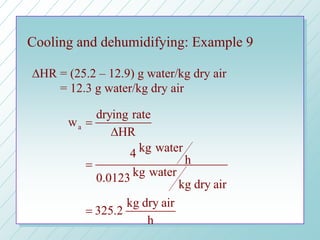

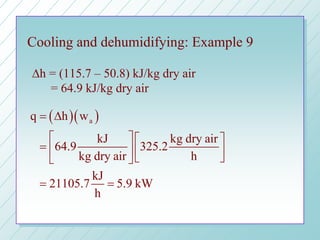

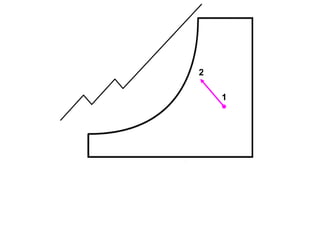

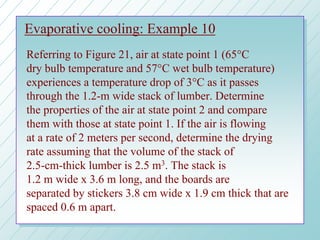

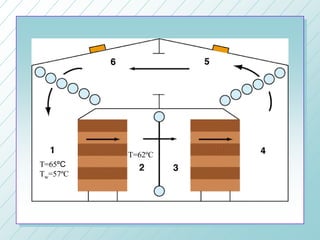

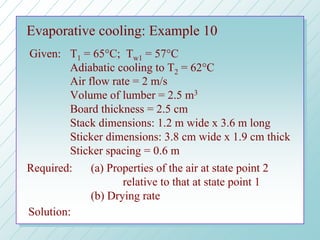

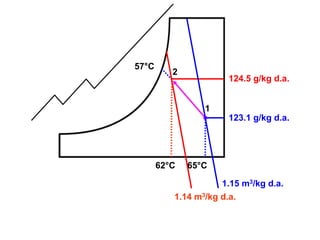

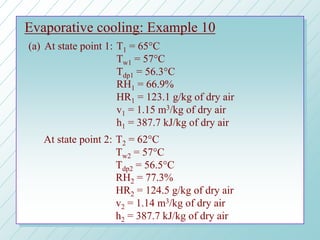

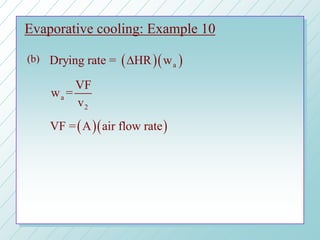

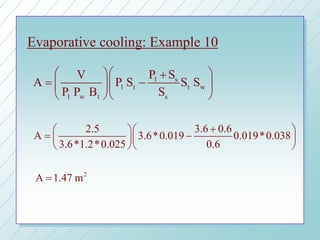

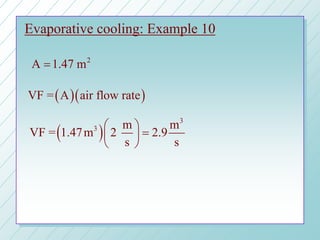

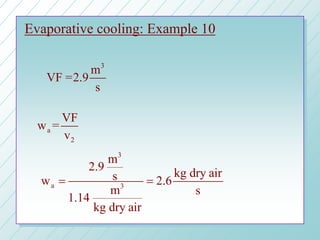

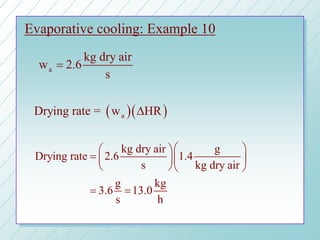

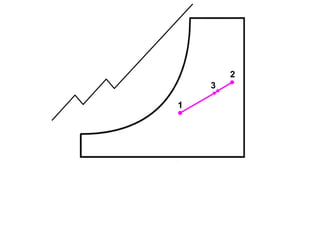

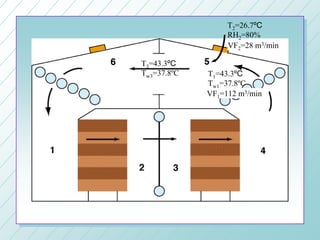

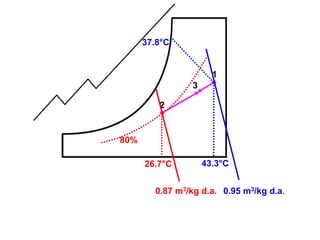

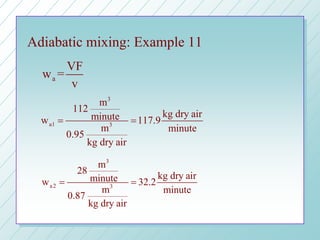

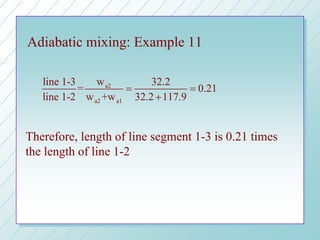

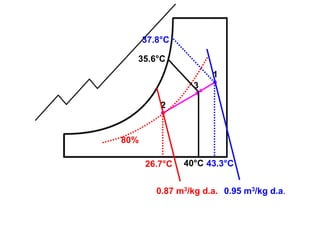

The document discusses the psychrometric chart and various psychrometric processes involving moist air. It begins by identifying parts of the psychrometric chart and explaining how it can be used to determine moist air properties and analyze processes involving moist air. Several examples are then provided to illustrate key psychrometric processes including sensible heating/cooling, heating and humidifying, cooling and dehumidifying, adiabatic or evaporative cooling, and adiabatic mixing of moist air streams. Step-by-step workings are shown for each example to determine various moist air properties and mass transfer rates.