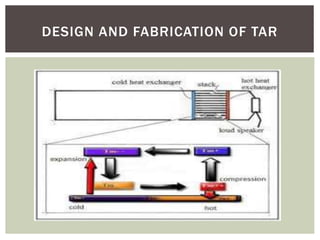

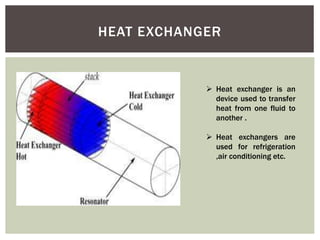

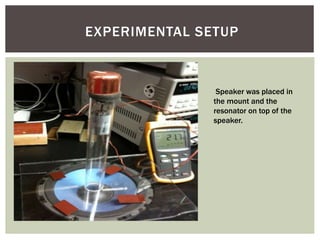

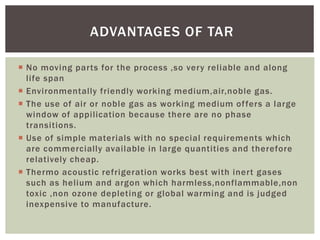

This document describes a mini project on thermo-acoustic refrigeration. It discusses the design and fabrication of a thermo-acoustic refrigerator prototype using a standing wave resonator with air as the working fluid. The prototype was unable to demonstrate a distinguishable thermo-acoustic refrigeration effect due to issues with the heat exchange process, where heat from the hot region did not exit the system properly. The document also provides background on thermo-acoustic refrigeration and outlines its potential advantages over conventional refrigeration techniques.