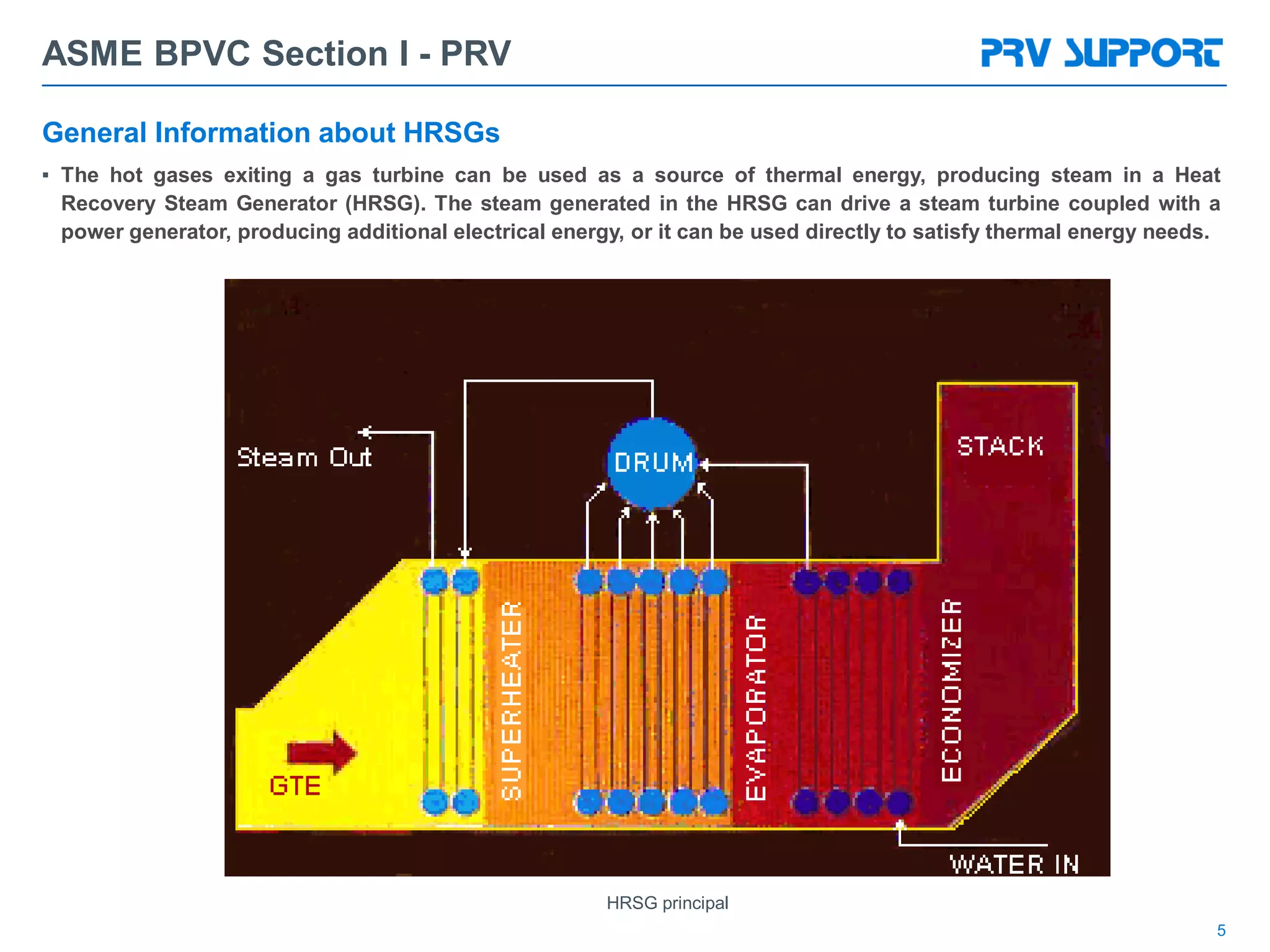

The document provides an overview of ASME B&PV Code Section I requirements for pressure relief valves (PRVs). It discusses the history and development of the code, typical boiler configurations that utilize PRVs, PRV performance requirements including set pressure, blowdown and flow coefficients, material selection standards, and applications for PRVs on boilers, heat recovery steam generators, and other vessels. It also summarizes key operating requirements for PRVs regarding overpressure, blowdown, and accumulation limits.