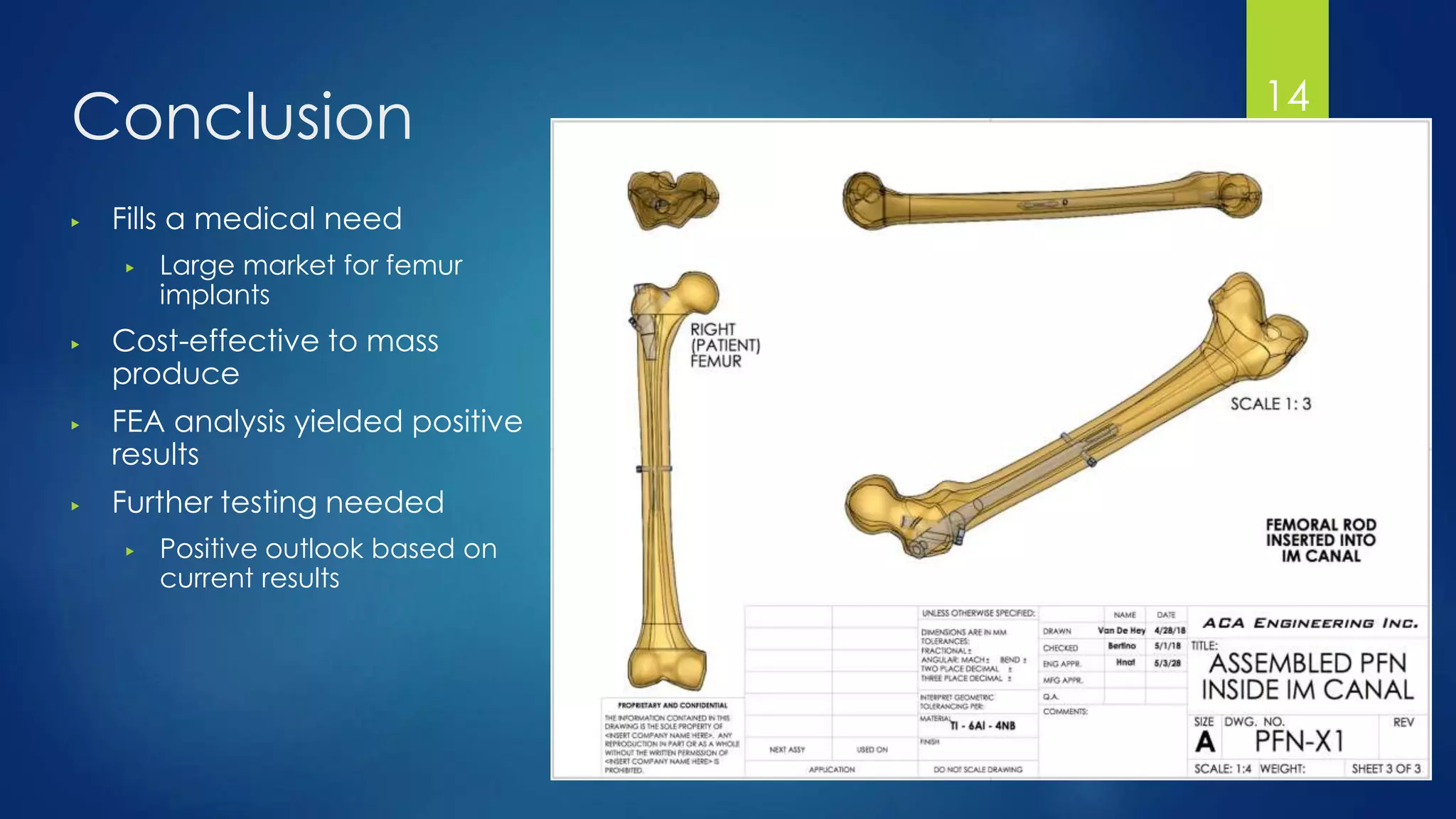

The document discusses the proximal femoral nail, a device designed for femur injuries, highlighting its medical need and effectiveness over traditional casts. It includes details on its components, manufacturing processes, and results from finite element analyses, which indicate its resilience under various forces. The conclusion emphasizes the device's cost-effectiveness and potential for mass production, noting the need for further testing despite positive initial outcomes.