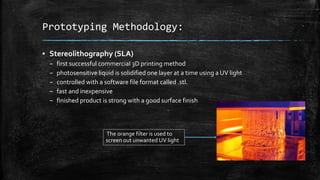

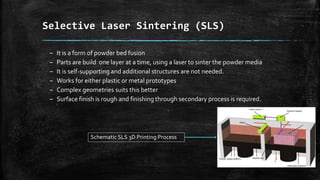

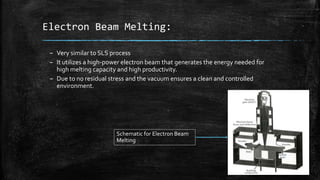

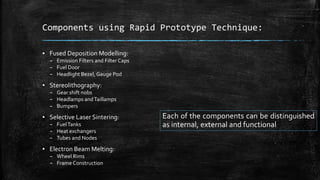

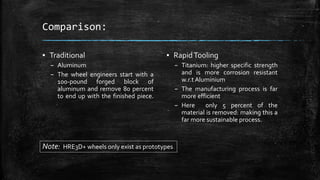

This document discusses rapid prototyping techniques used in automotive product development. It outlines various prototyping methods like stereolithography, fused deposition modeling, selective laser sintering, and electron beam melting. These allow automakers to create early concept models, test designs, gather user feedback, and ensure safety. The document also provides examples of automakers using 3D printing for scale models, wheels, air intake systems, and other vehicle components. Rapid prototyping reduces costs and time to market while improving designs.