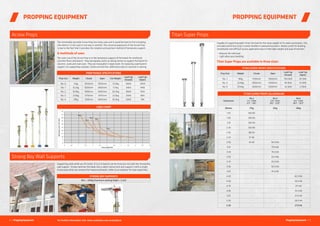

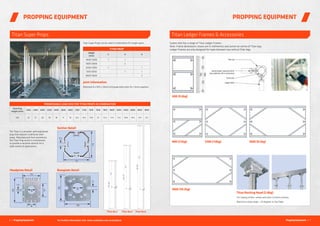

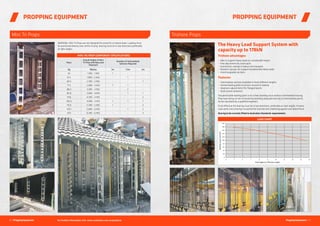

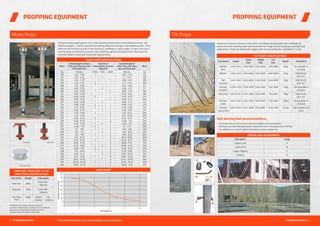

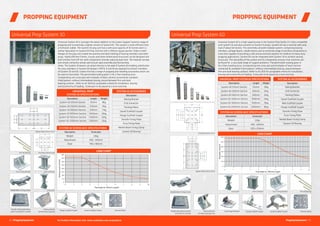

The document provides information on propping equipment available from Coates Hire, including Acrow props, Strong Boy wall supports, Titan super props, Titan ledger frames and accessories, Mini Tri props, and Trishore props. It details the specifications, load capacities, and applications of each type of propping equipment. Coates Hire offers expertise in propping solutions and can assist with engineering design and technical support for projects.