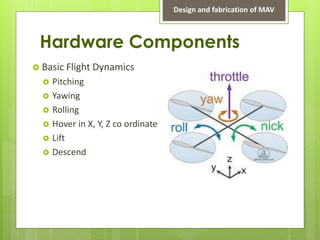

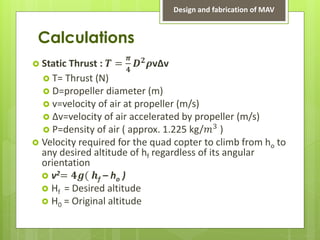

The document describes a project to design and fabricate a micro air vehicle (MAV) under the guidance of Prof. Syed Basith Muzammil. A group of 4 students - Shazaan Sayeed, Suman Mandal, Sushil Kumar, and Md Idris - are working on the project at HKBK College of Engineering. The MAV will have the ability to hover and be equipped with a camera and sensors to detect leaked gas and explosives. It will use basic materials like a frame, motors, propellers, microcontroller, battery, and transmitter/receiver. The working principle involves the microcontroller receiving signals from the transmitter to control the electronic speed controllers and motor speeds to adjust the altitude