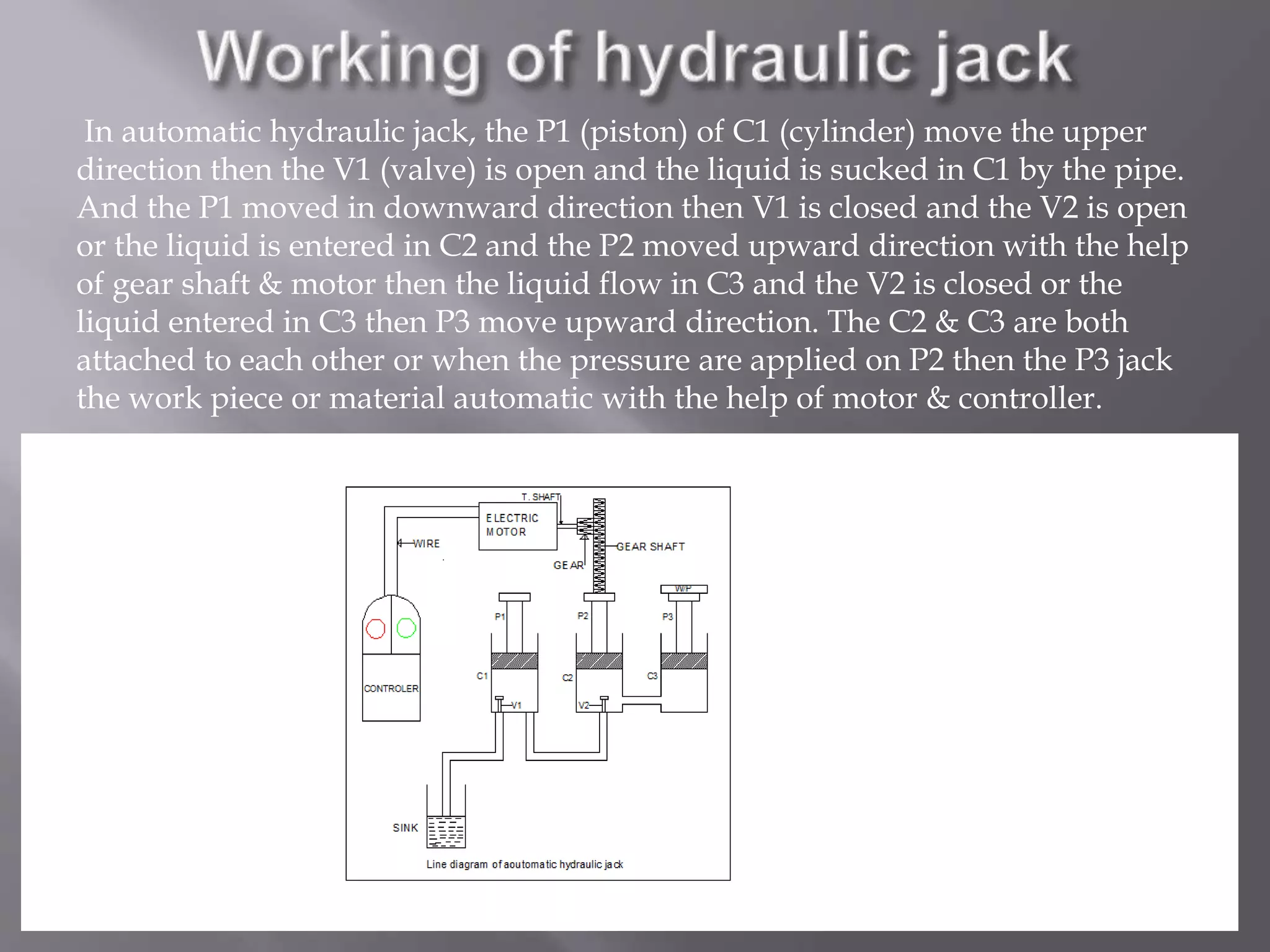

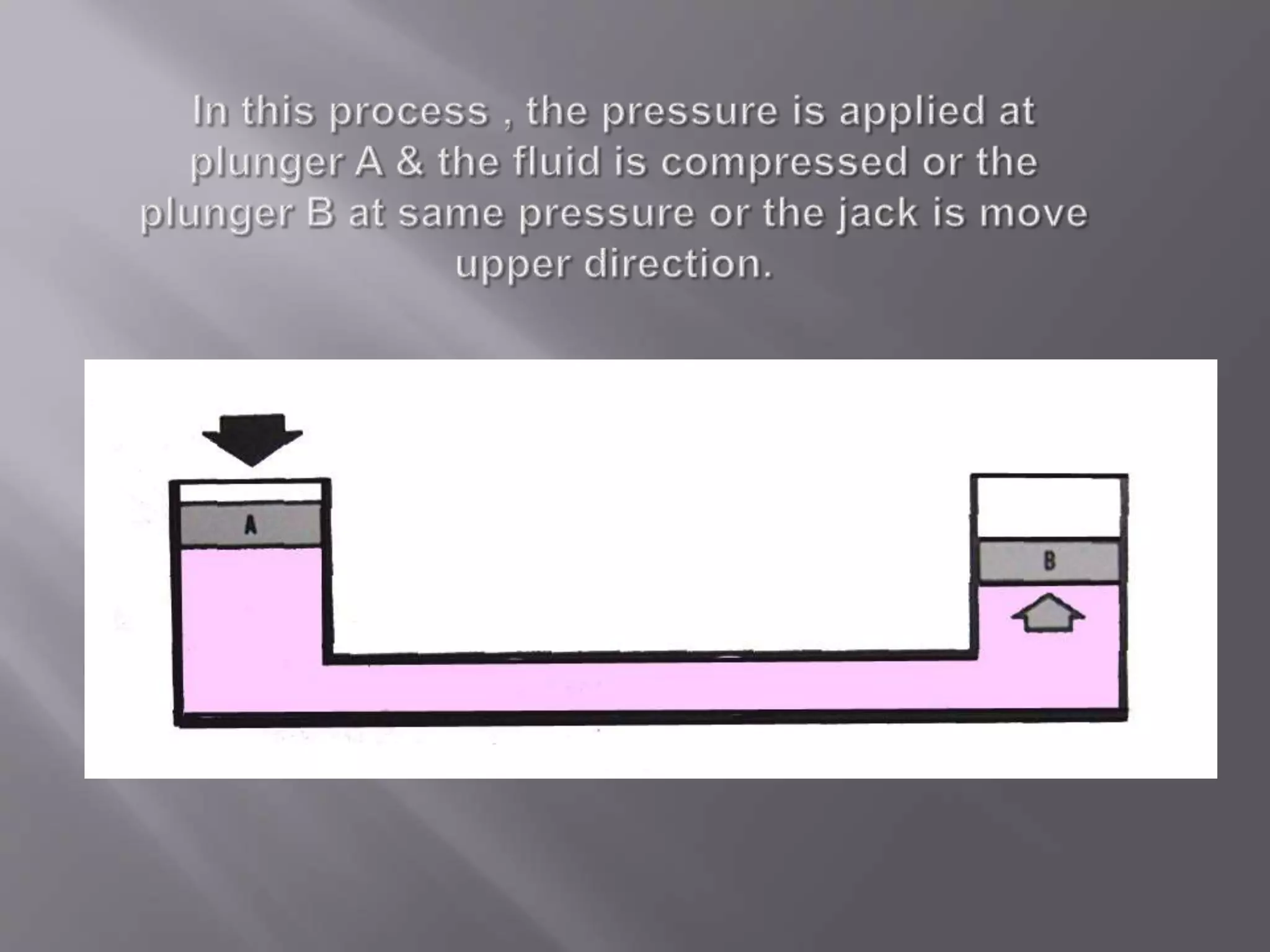

The document describes an automatic hydraulic jack project. It provides background on hydraulics, including Pascal's law and the relationship between pressure, force and area. It then discusses the basic components of a hydraulic system, including a pump, motor, valves, conduits and controller. The project uses syringes to act as actuators and directional control valves. Water is used as the transmission medium, with the syringes working together to lift a load automatically via gears, a motor and controller. Advantages include easy operation and control while disadvantages include potential rupturing losing needed pressure.