Embed presentation

Downloaded 215 times

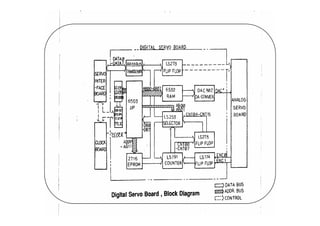

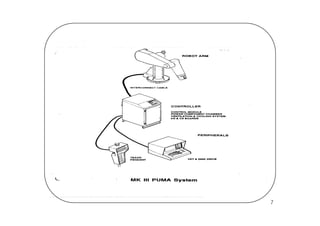

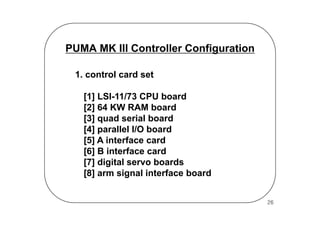

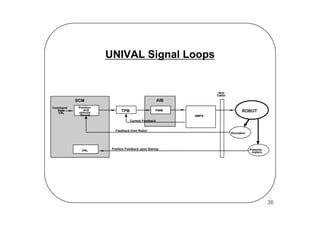

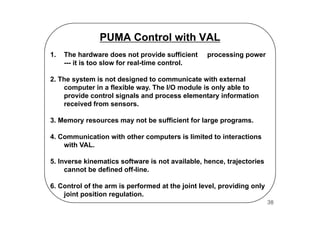

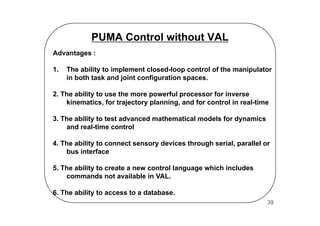

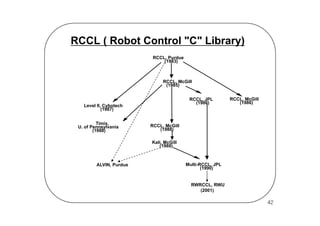

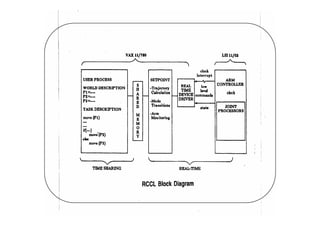

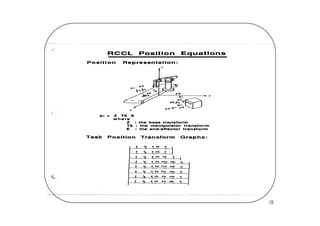

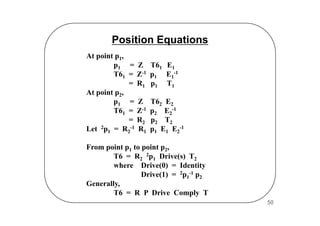

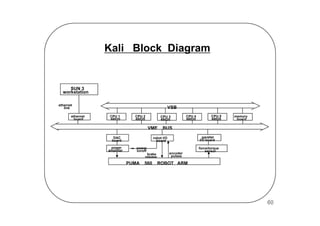

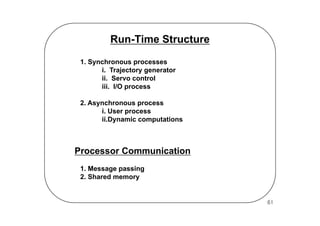

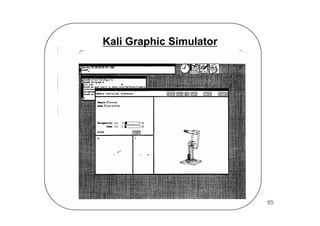

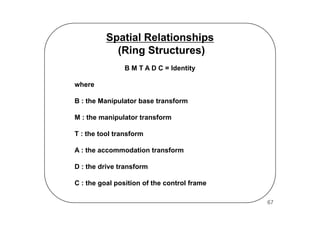

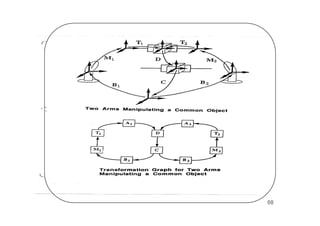

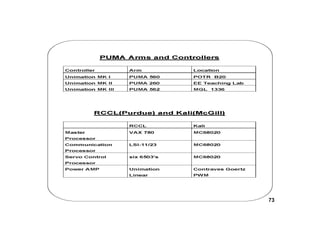

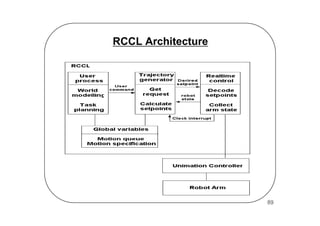

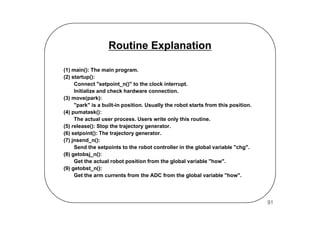

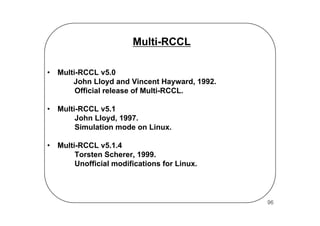

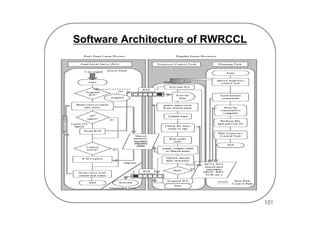

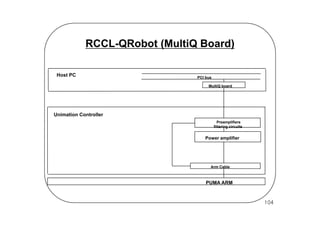

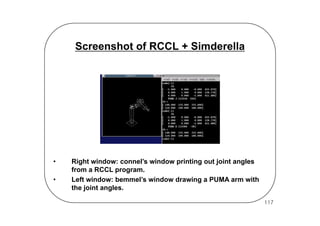

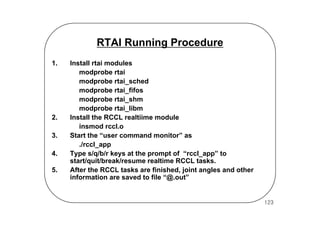

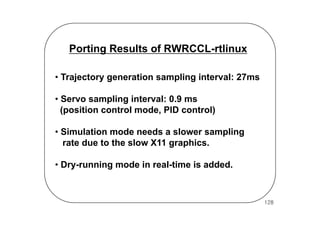

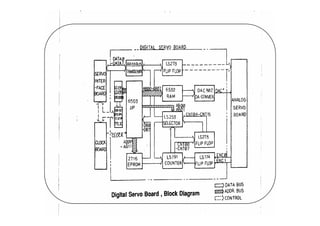

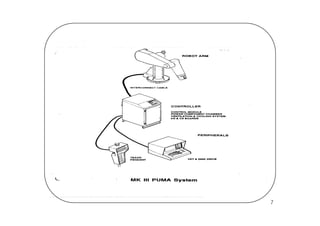

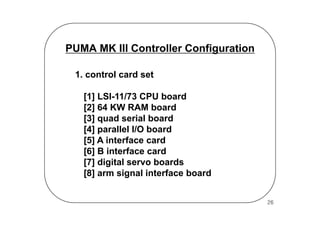

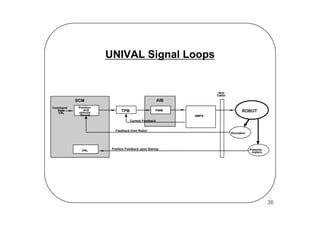

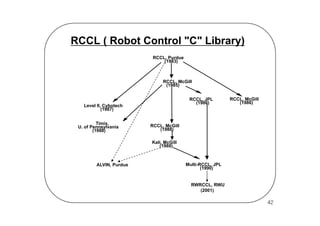

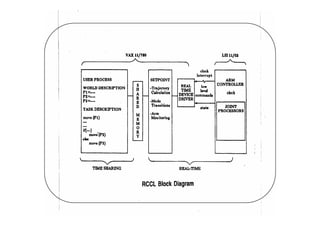

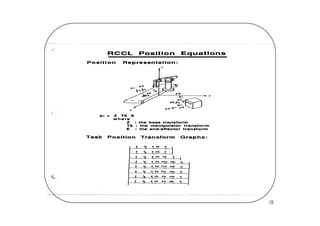

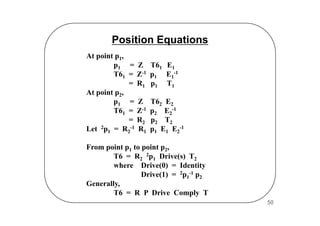

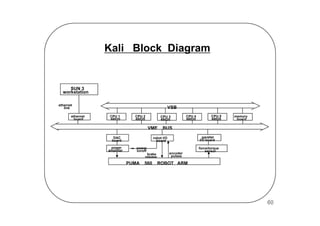

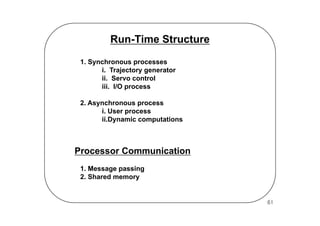

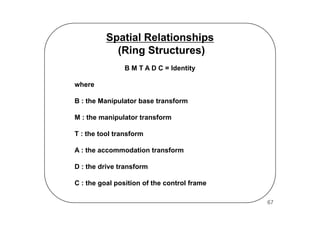

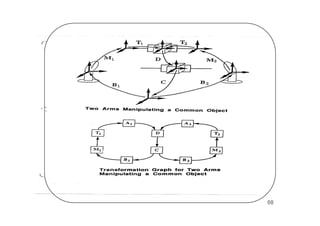

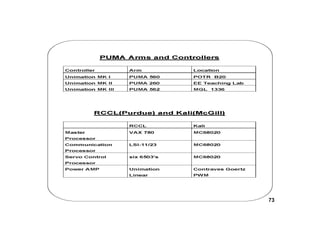

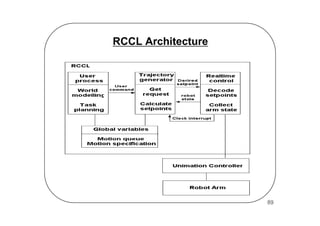

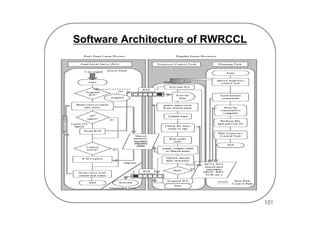

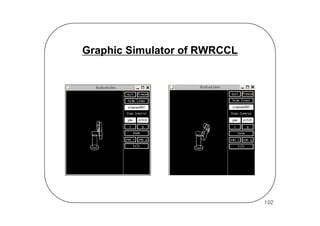

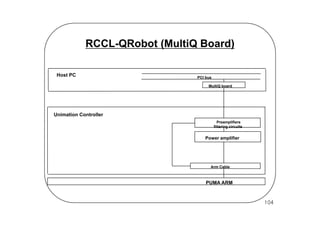

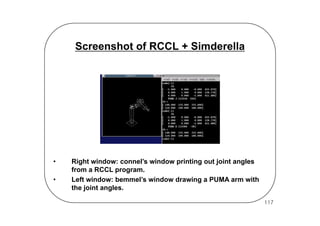

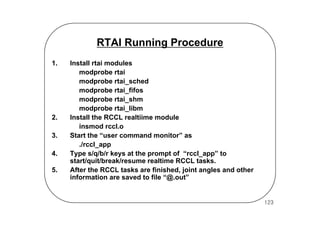

This document discusses programming and controlling PUMA robot arms using various software libraries and controllers. It provides an overview of PUMA robot arms, their controllers including the Mark I, Mark II, Mark III, and UNIVAL controllers. It then discusses various software libraries for controlling PUMA arms including VAL, RCCL, Level II, Kali, and ALVIN. It provides block diagrams and descriptions of how these different software libraries interface with and control PUMA robot arms.