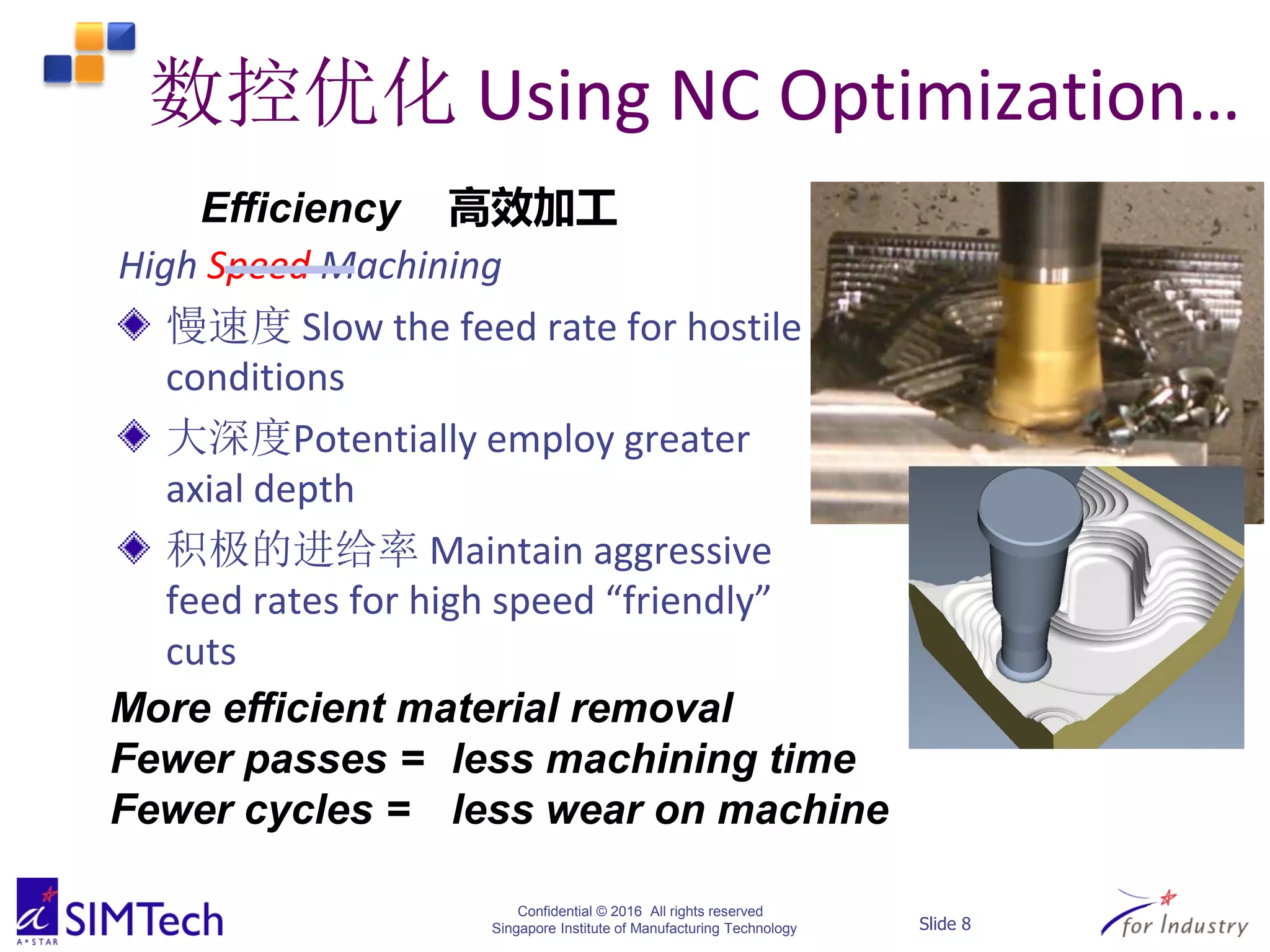

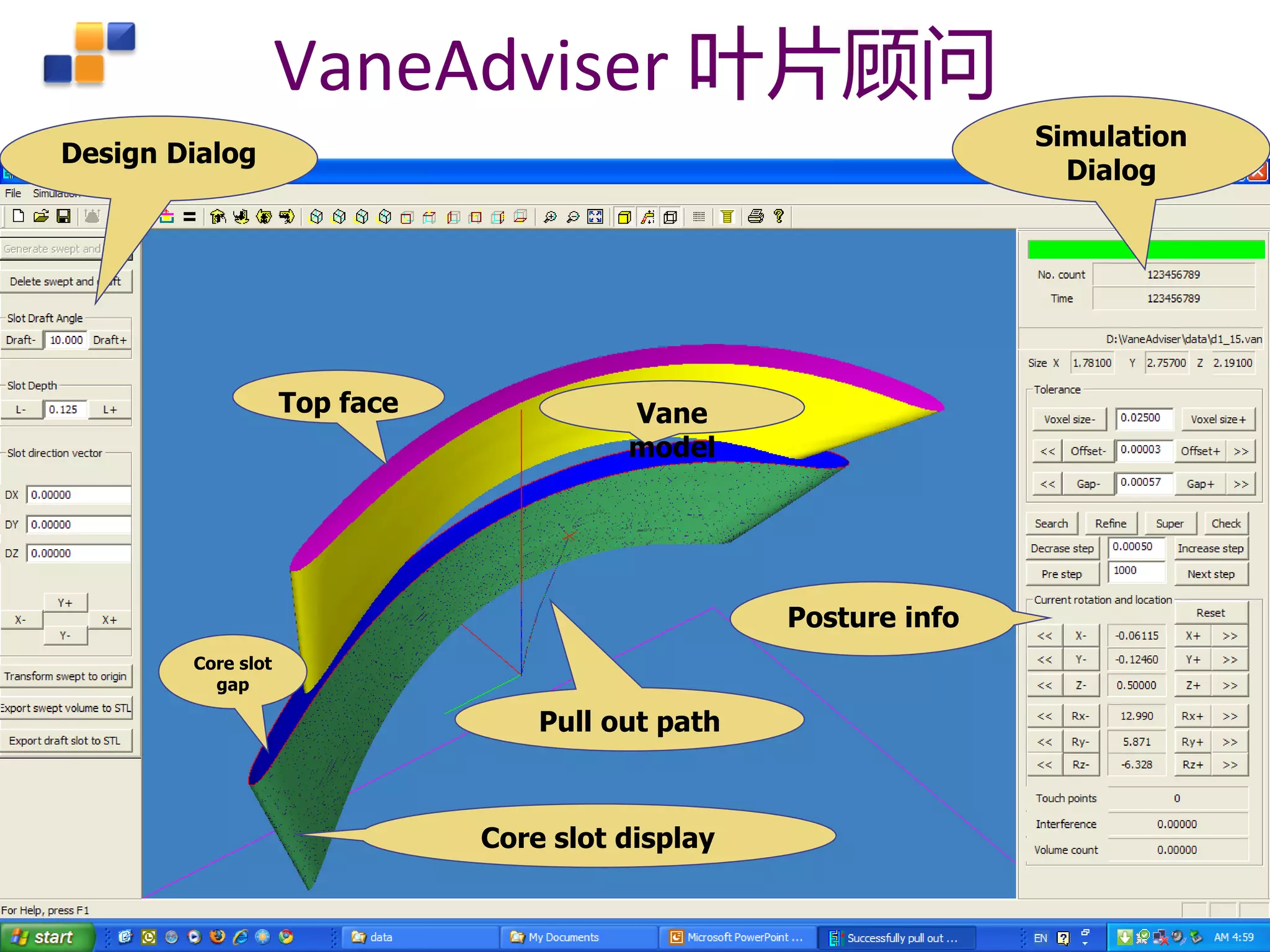

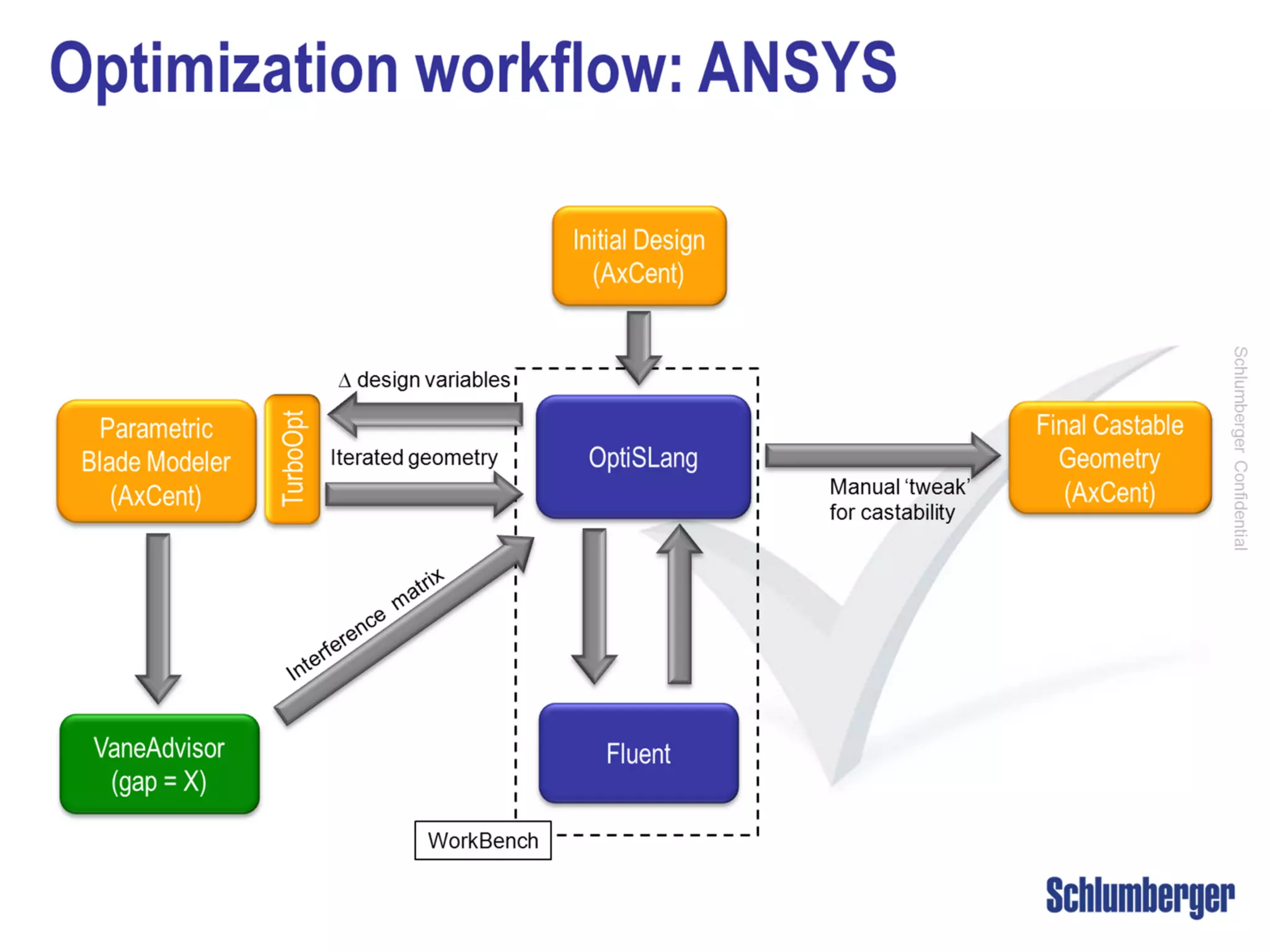

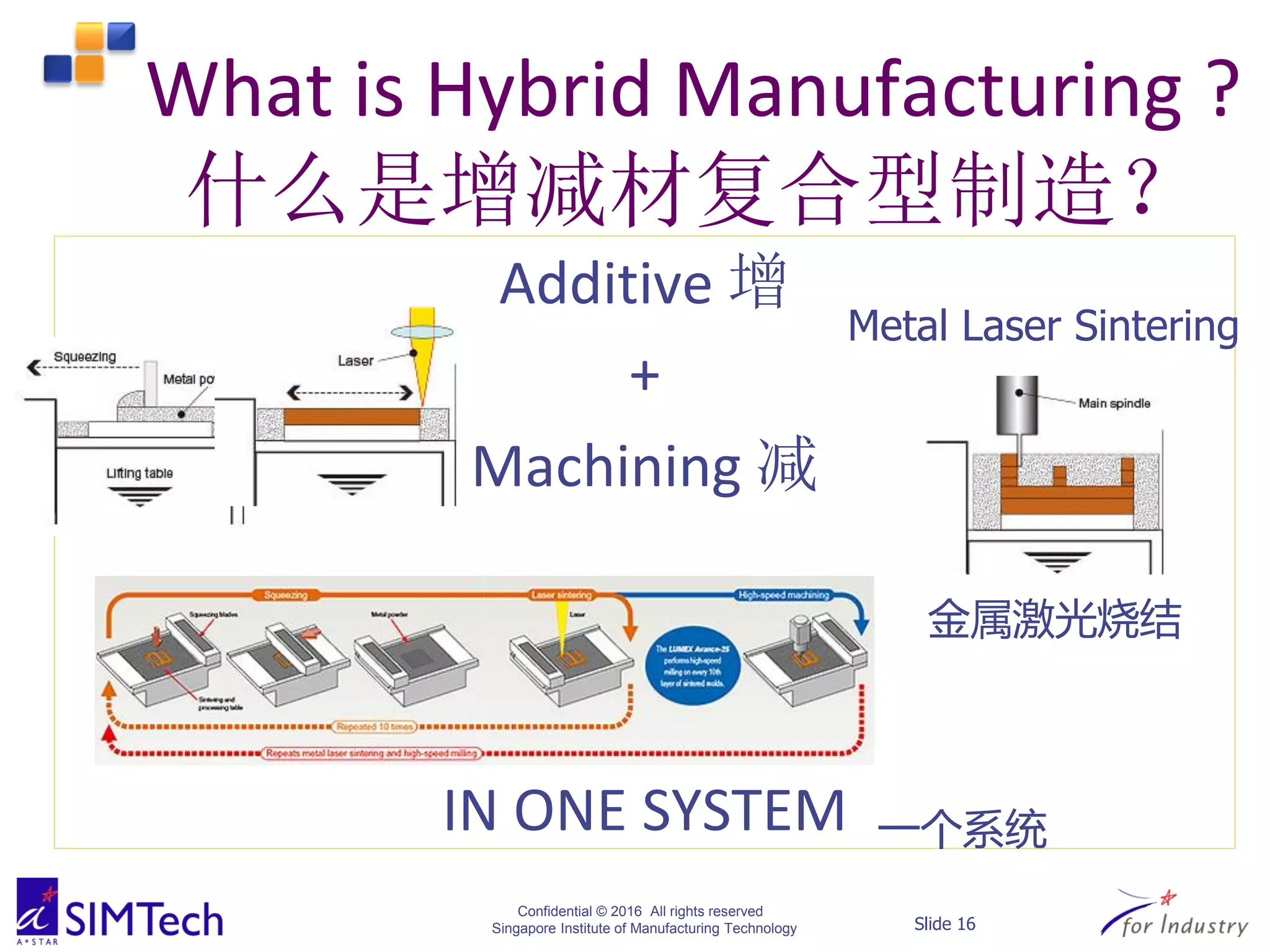

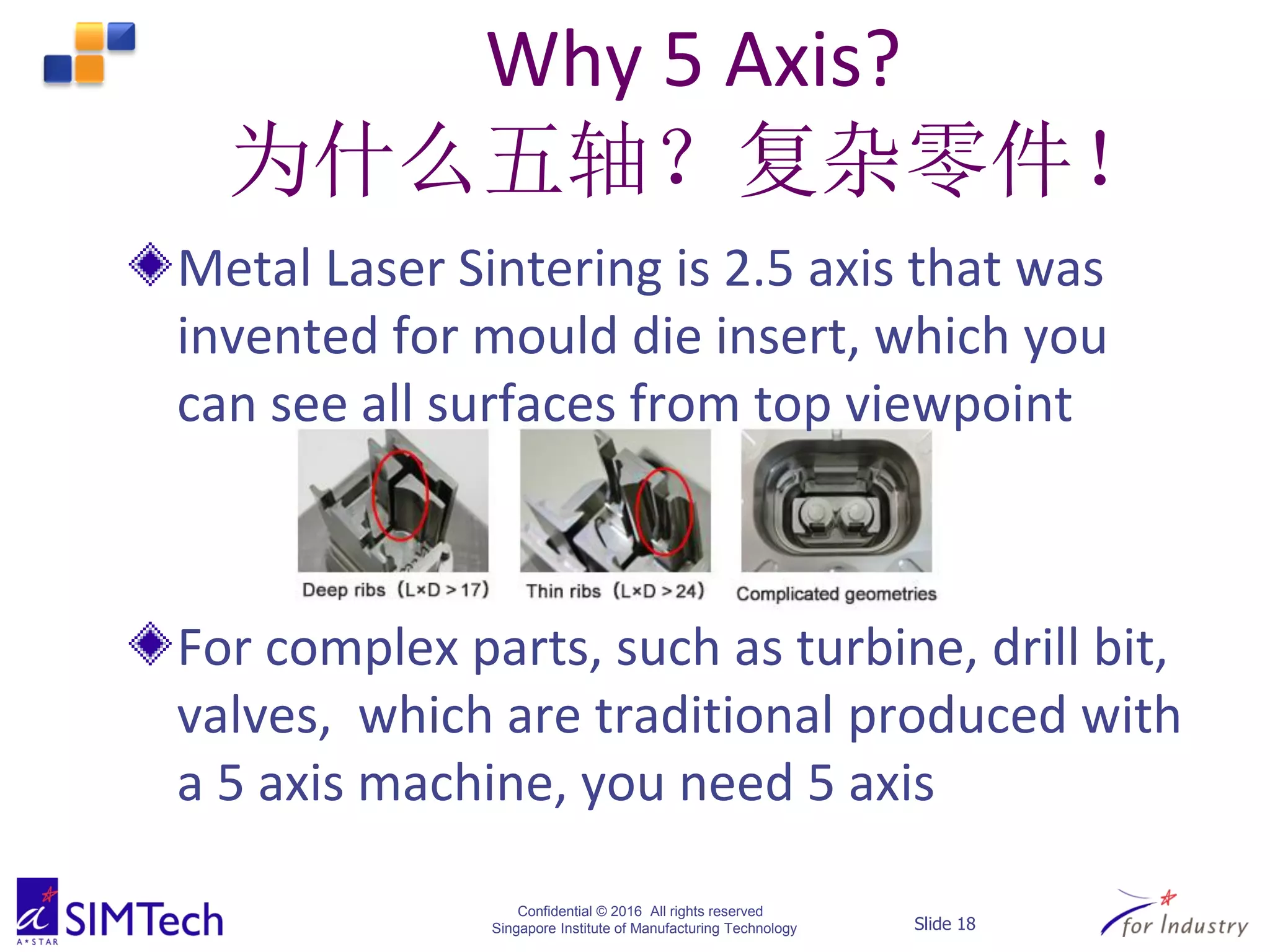

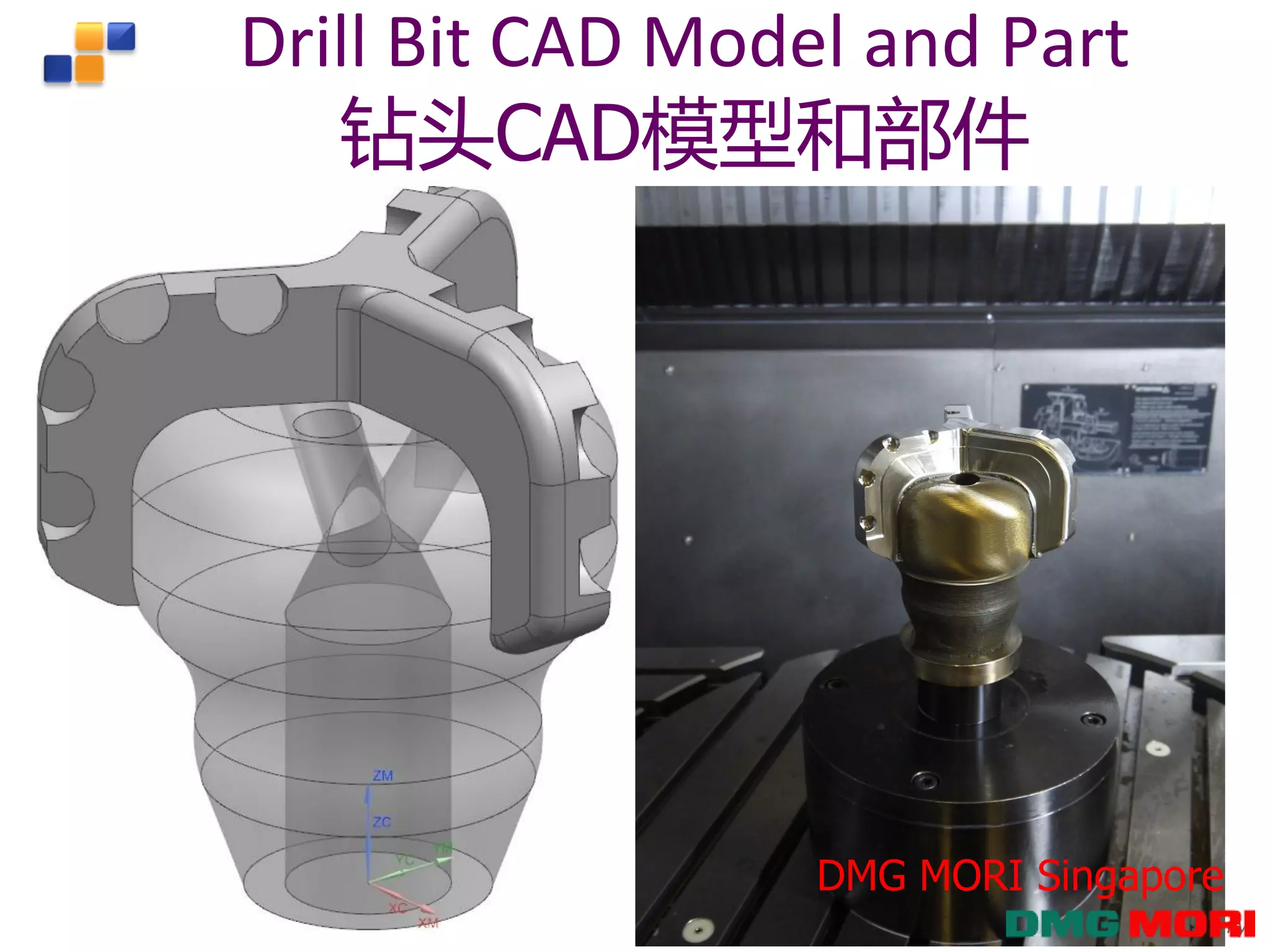

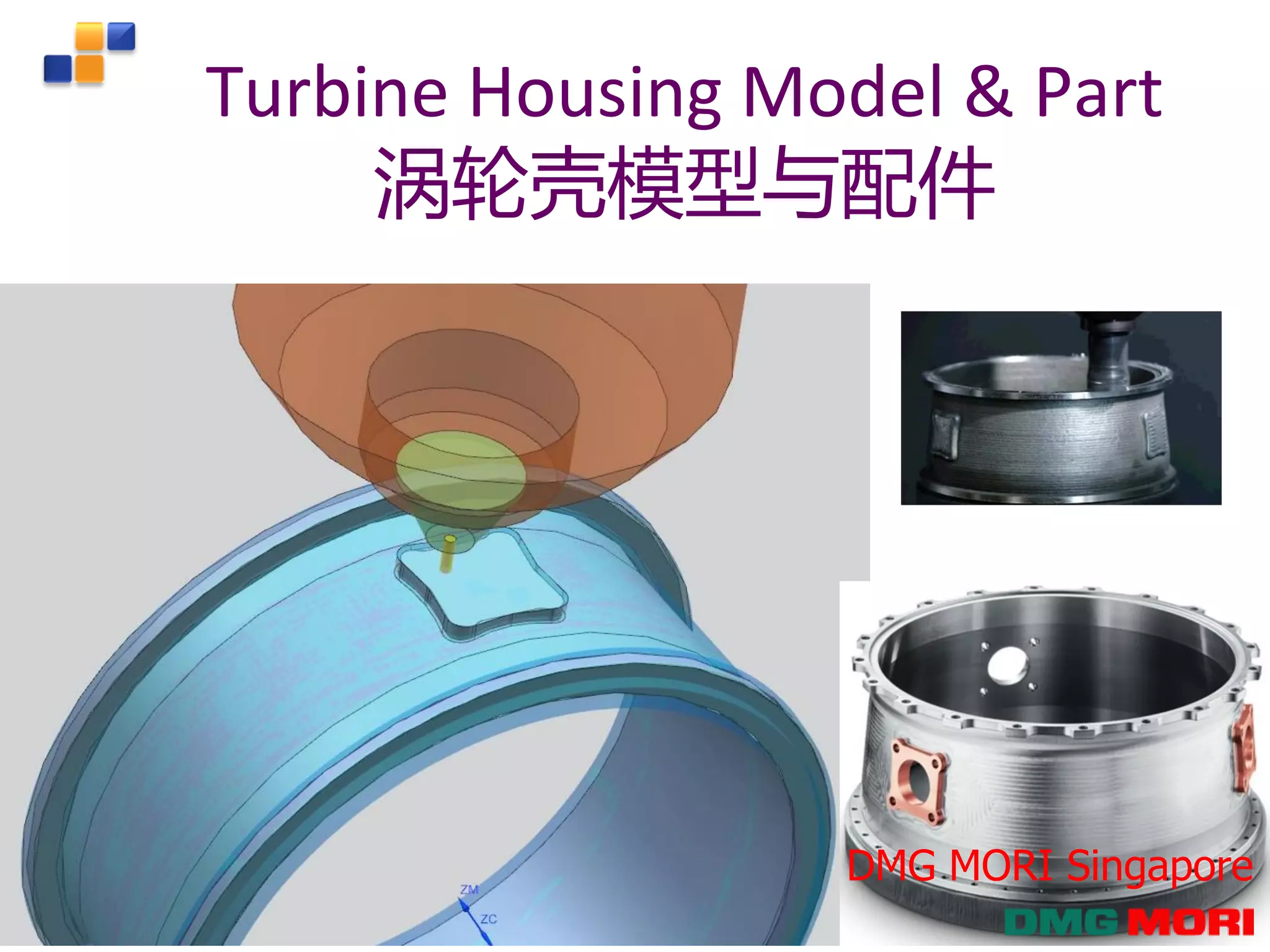

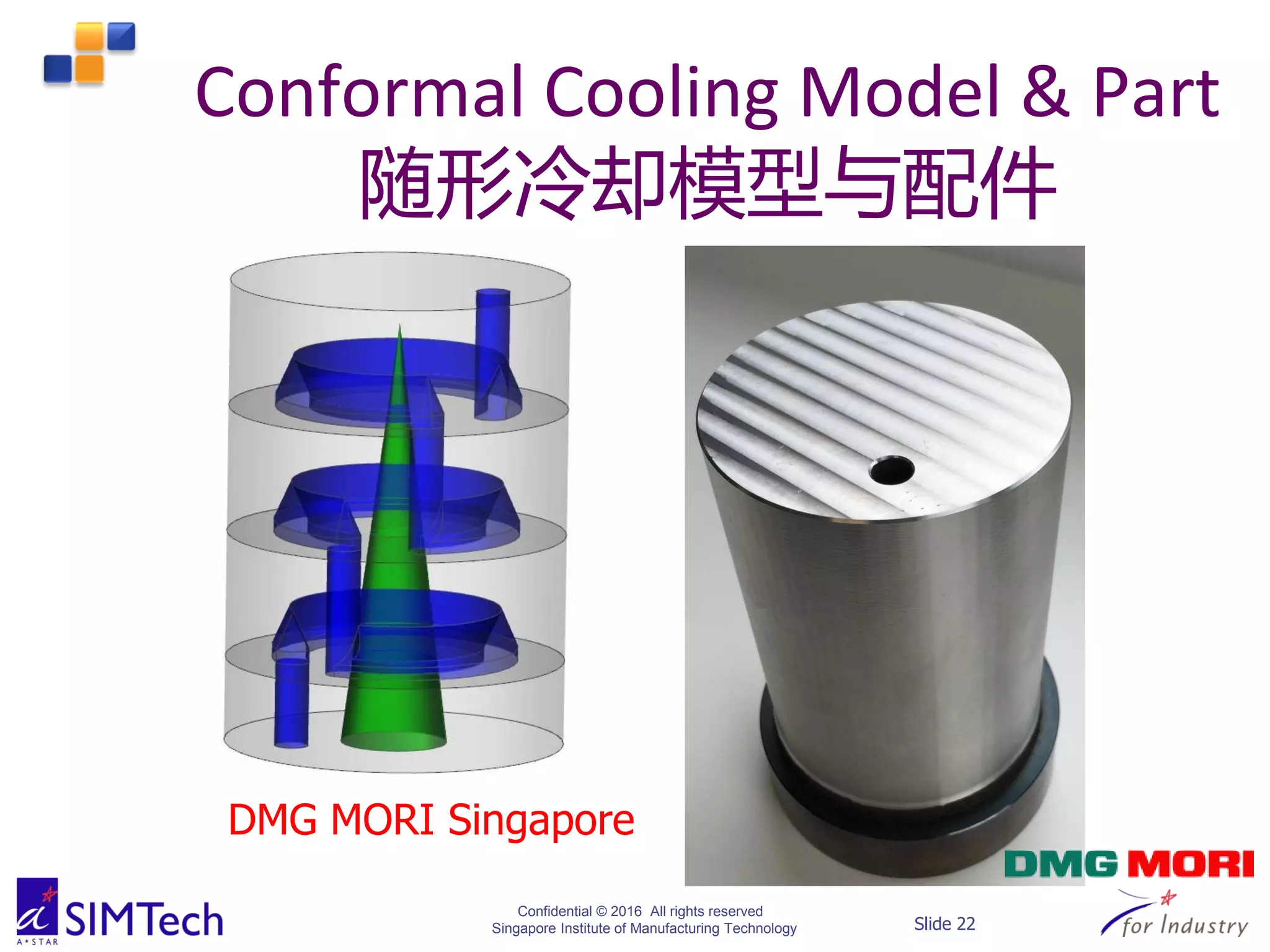

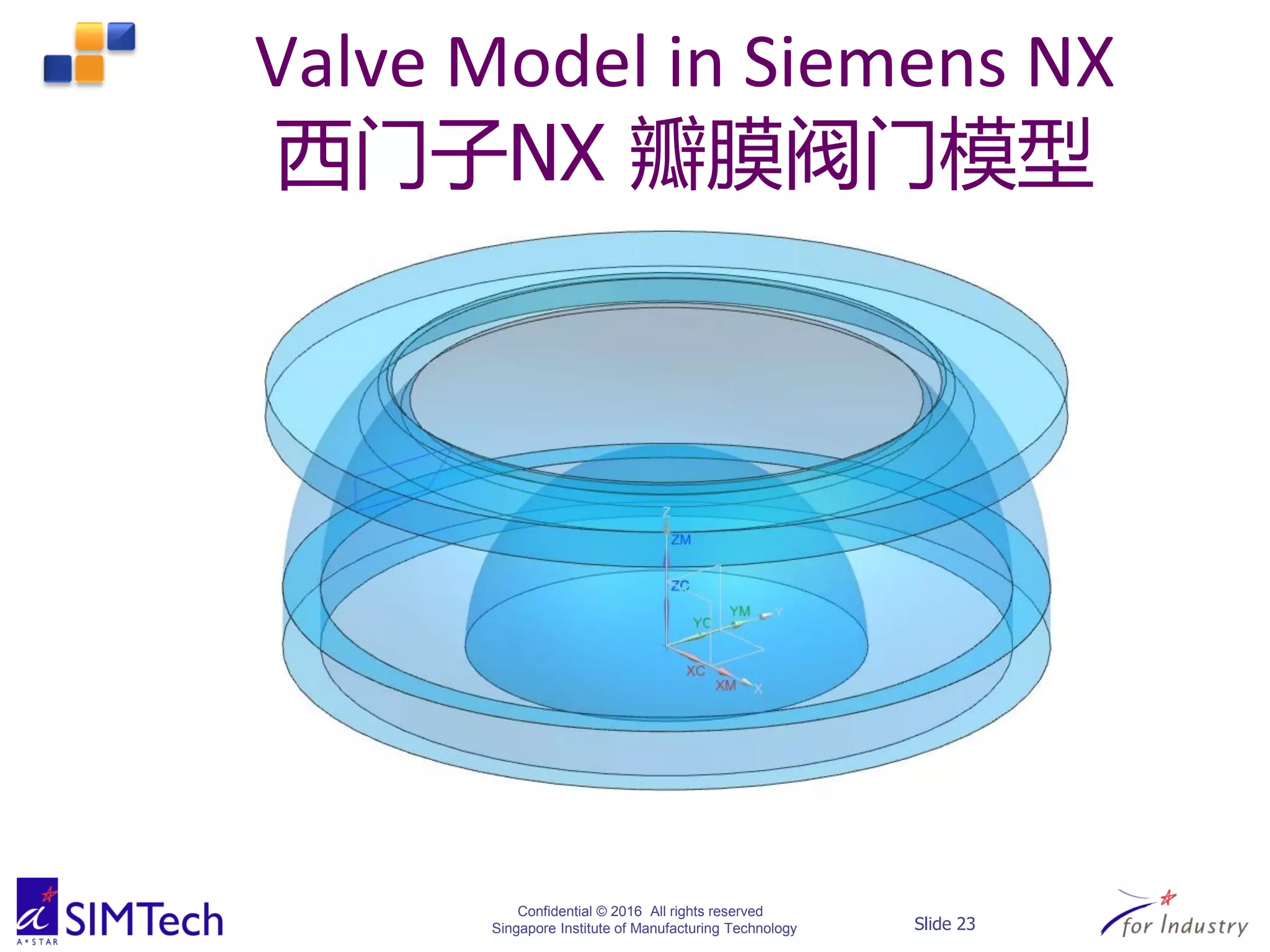

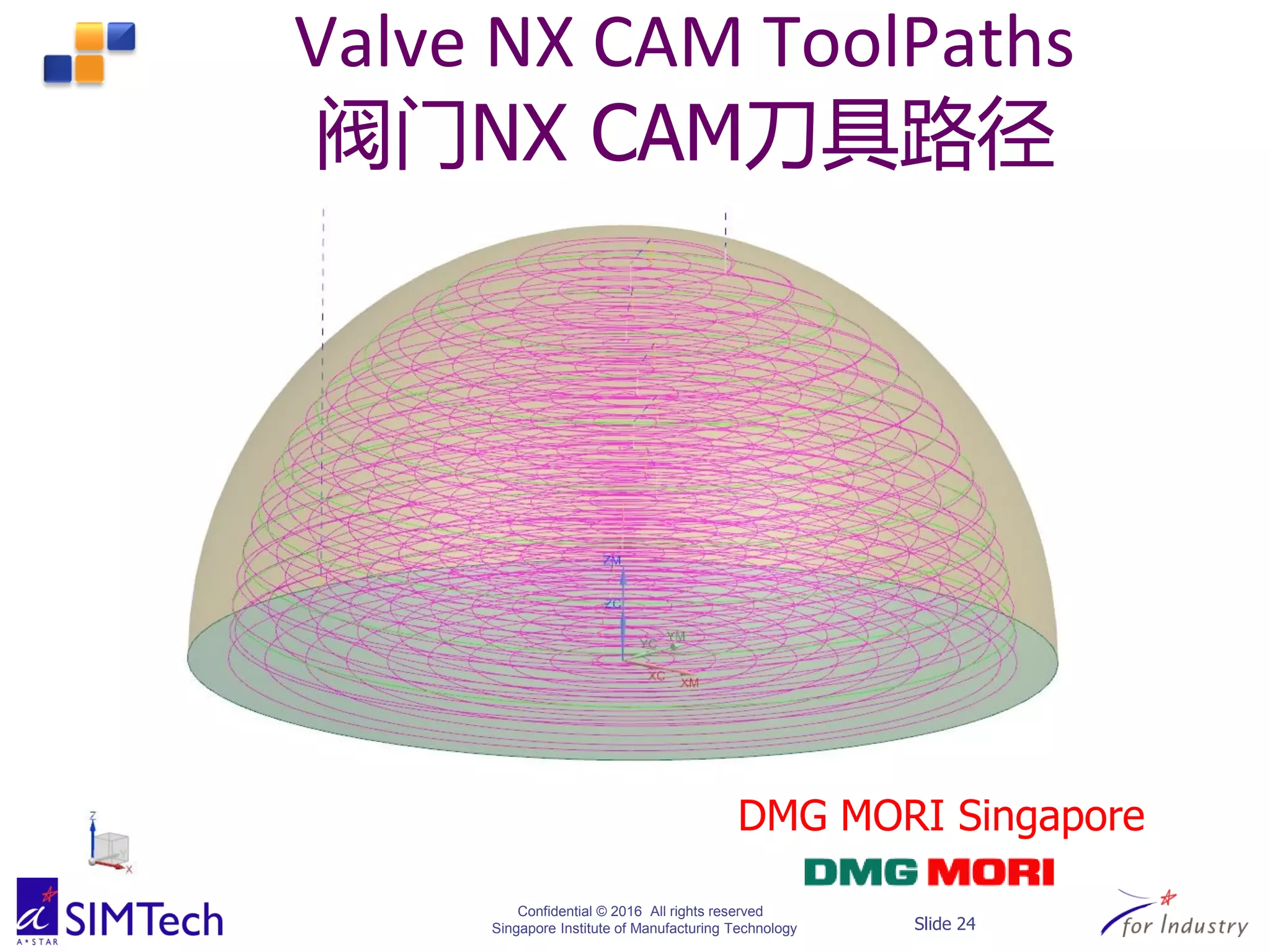

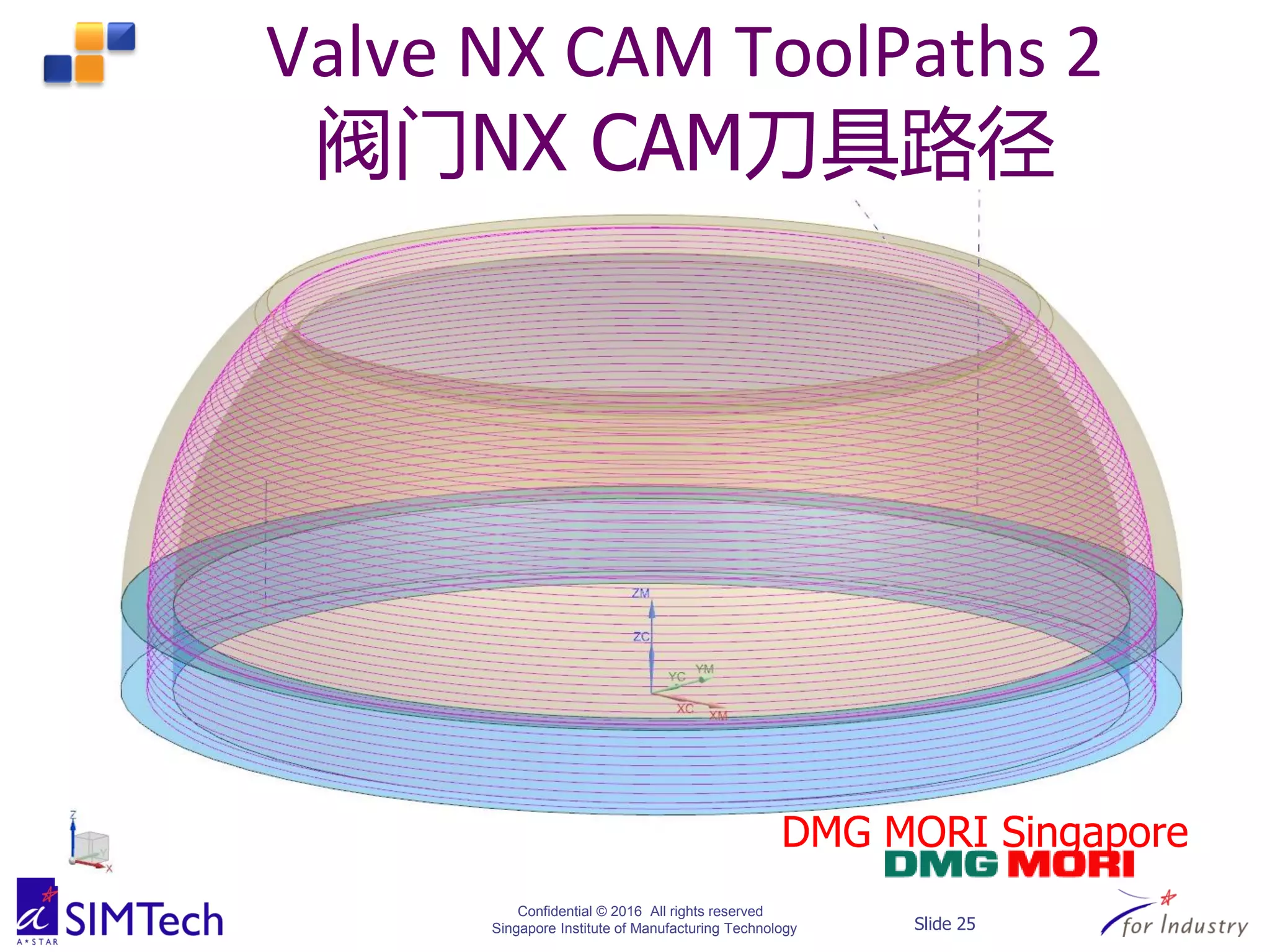

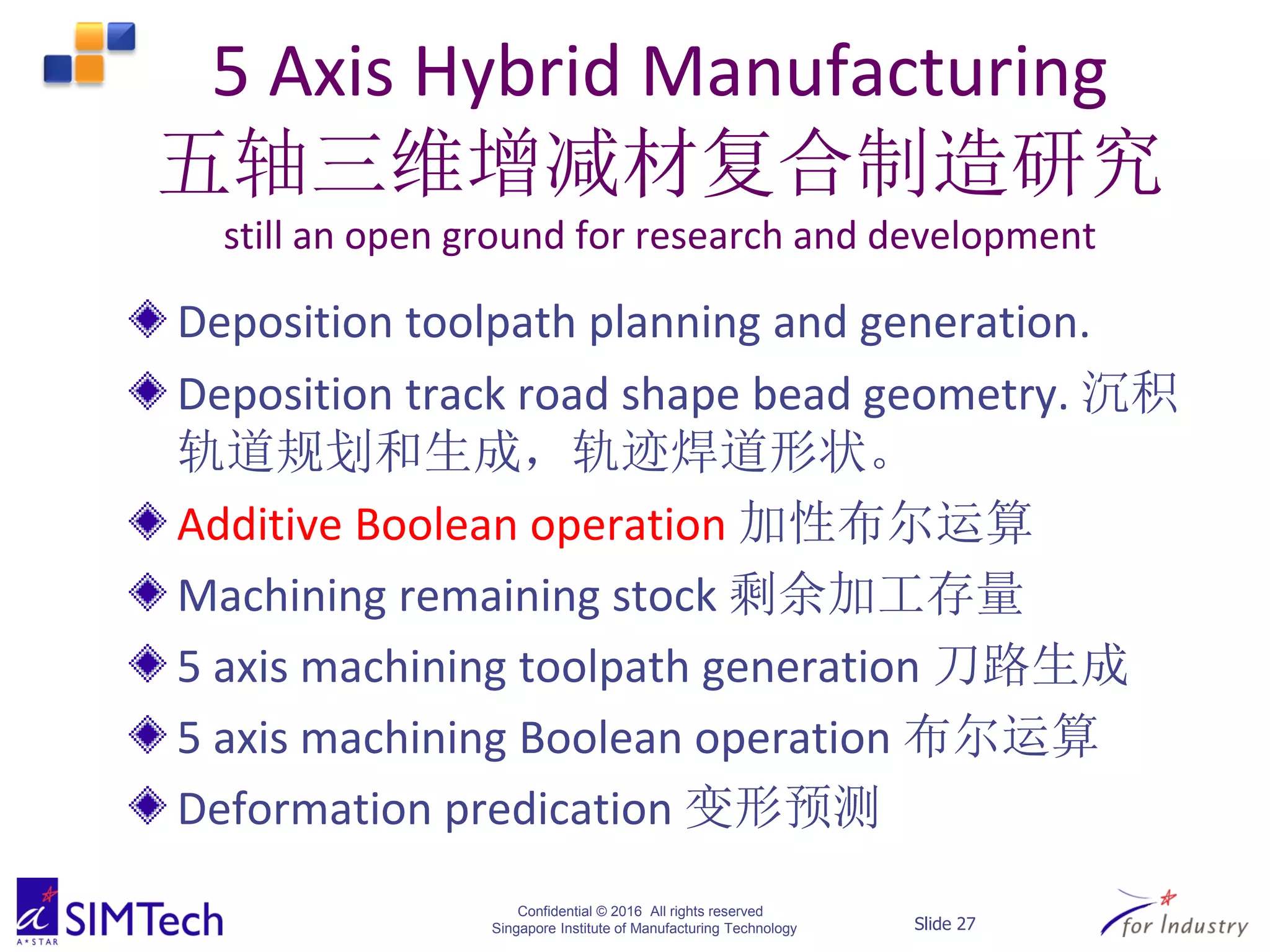

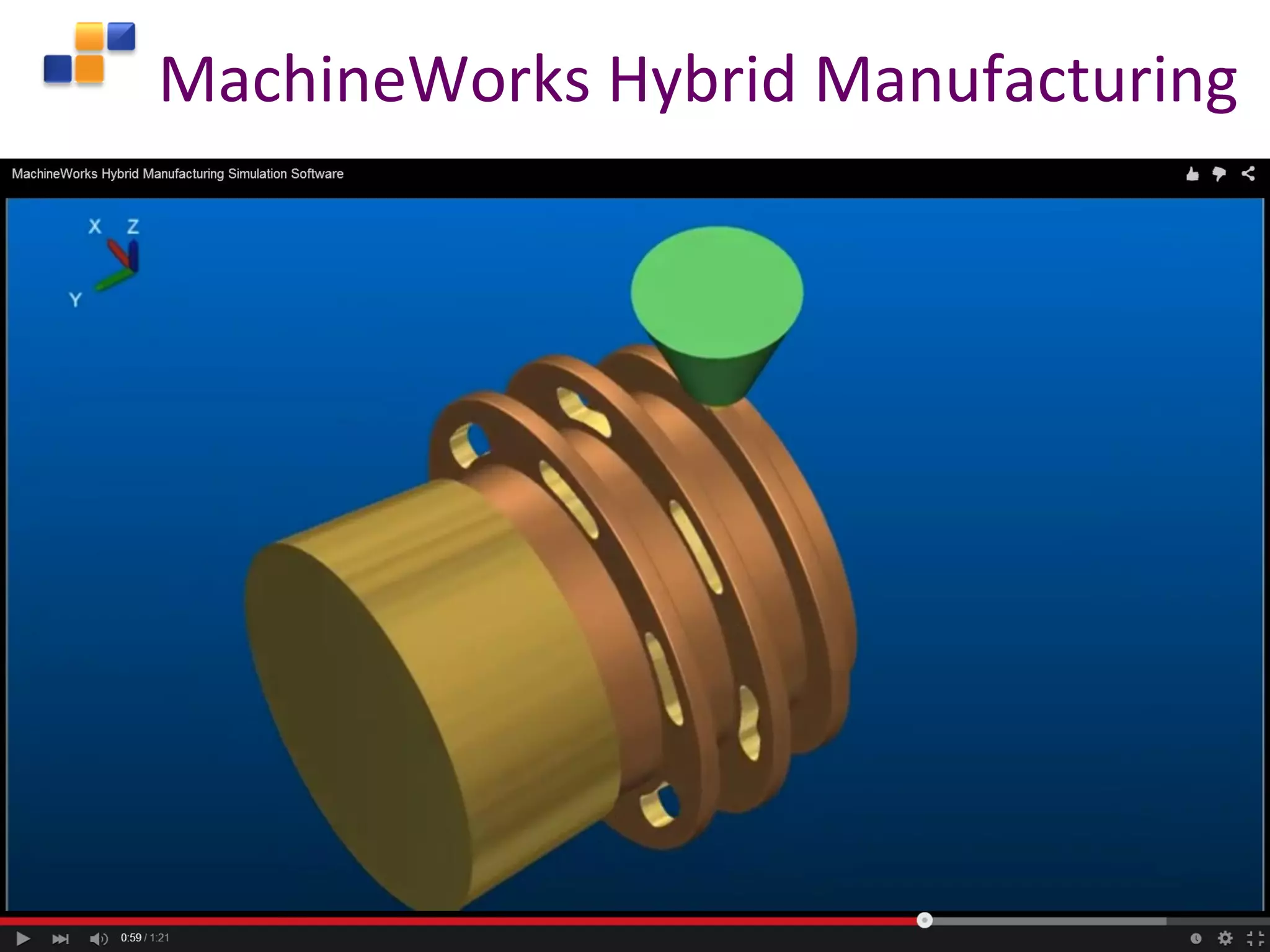

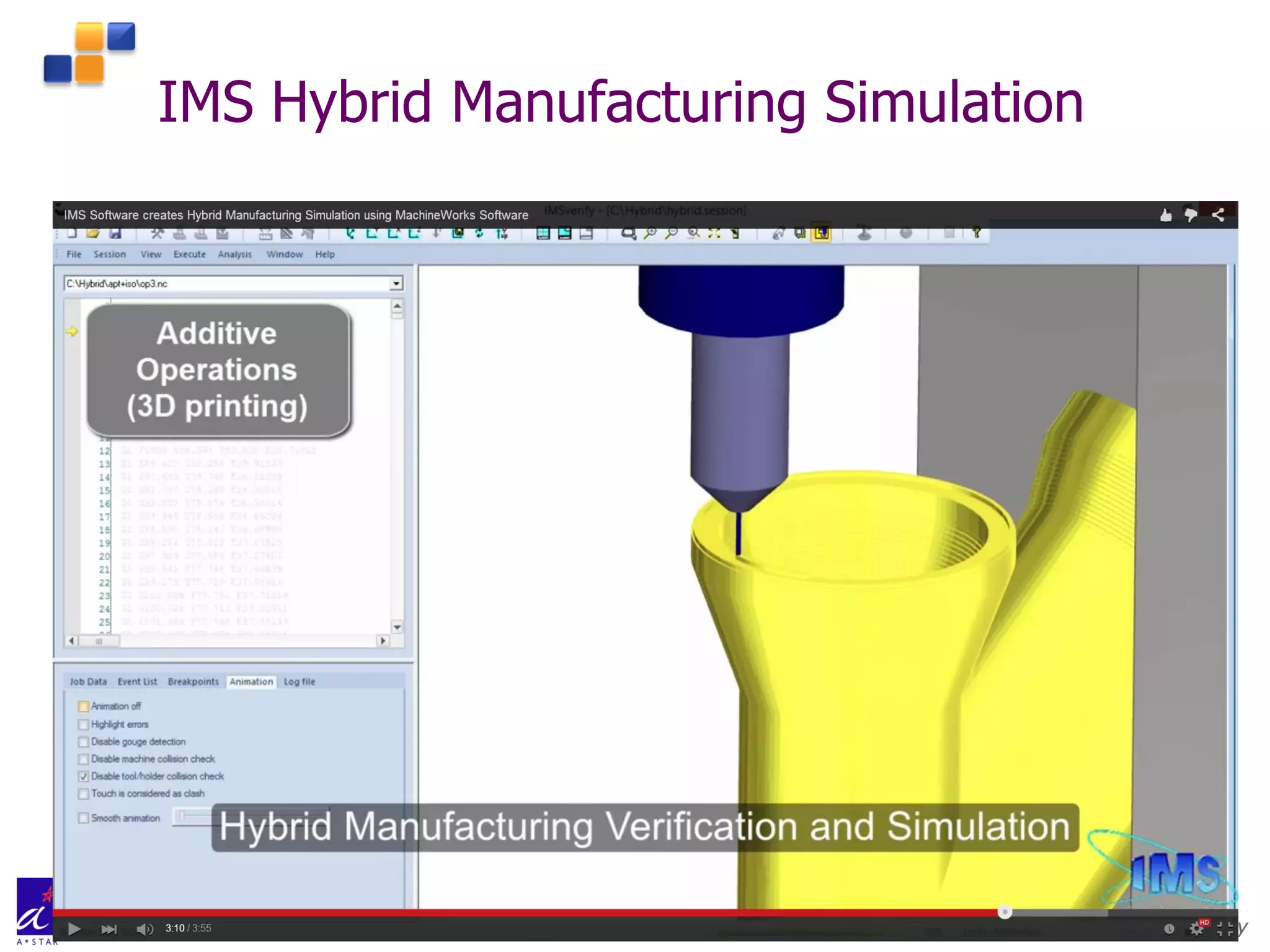

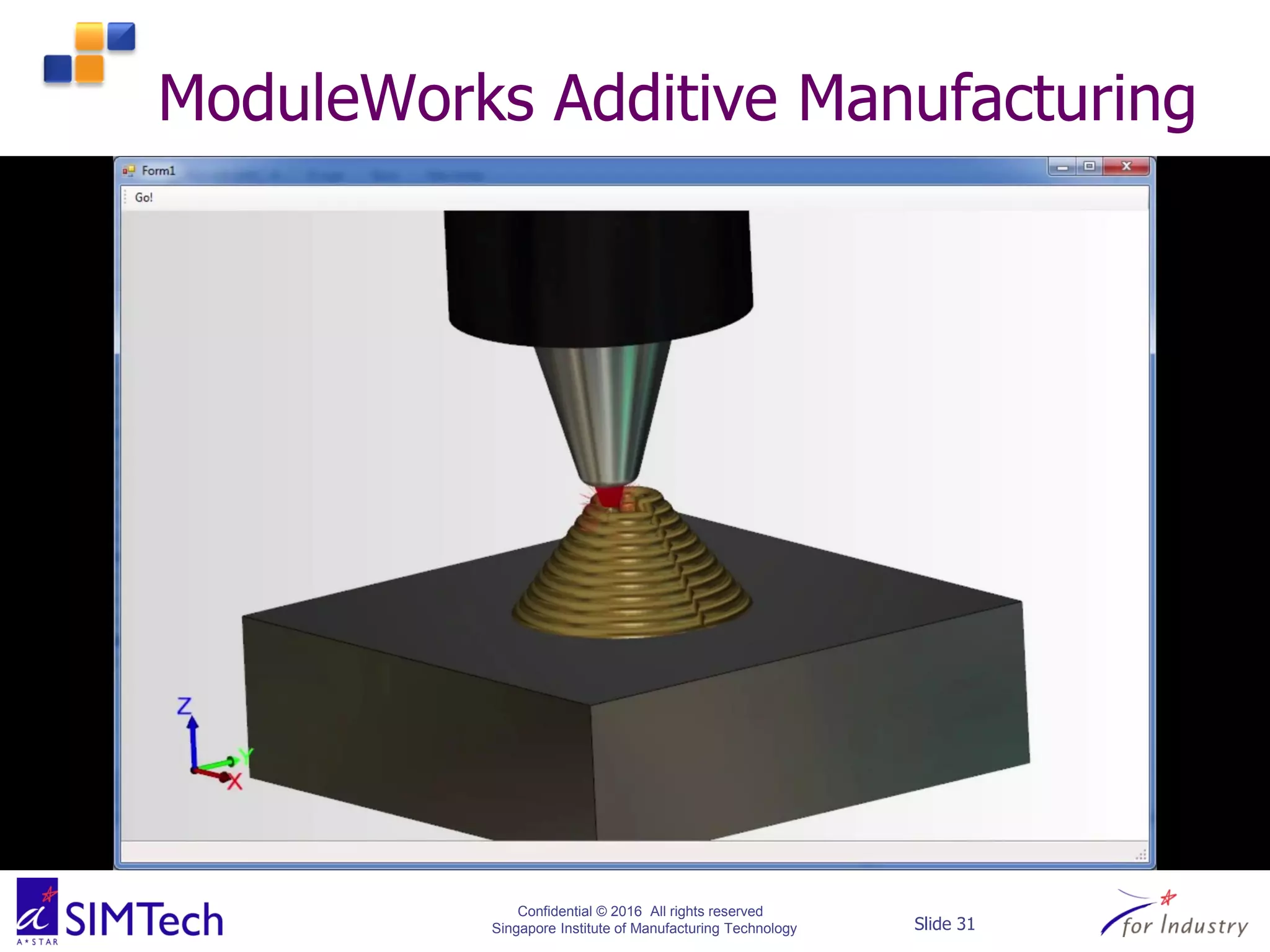

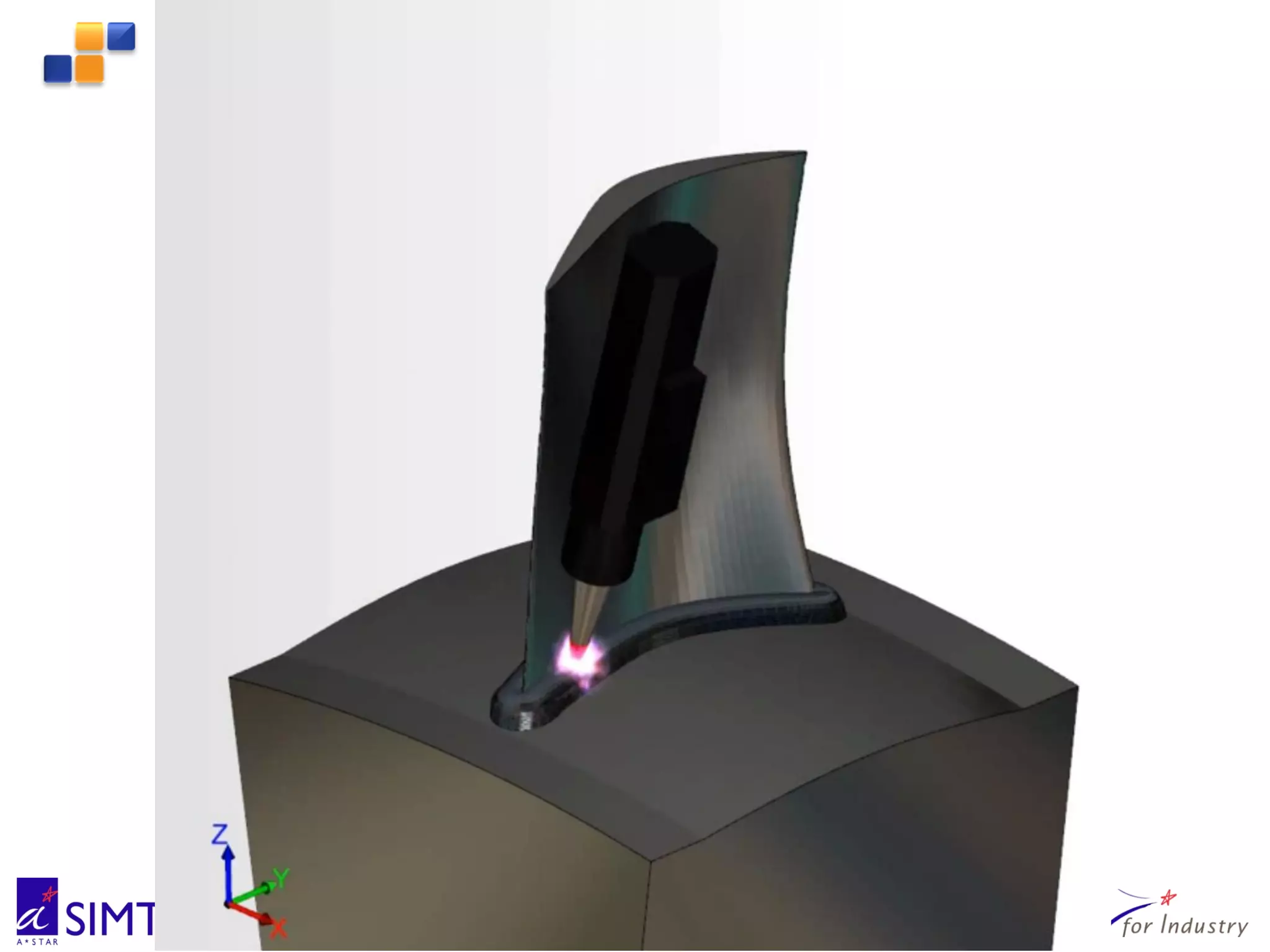

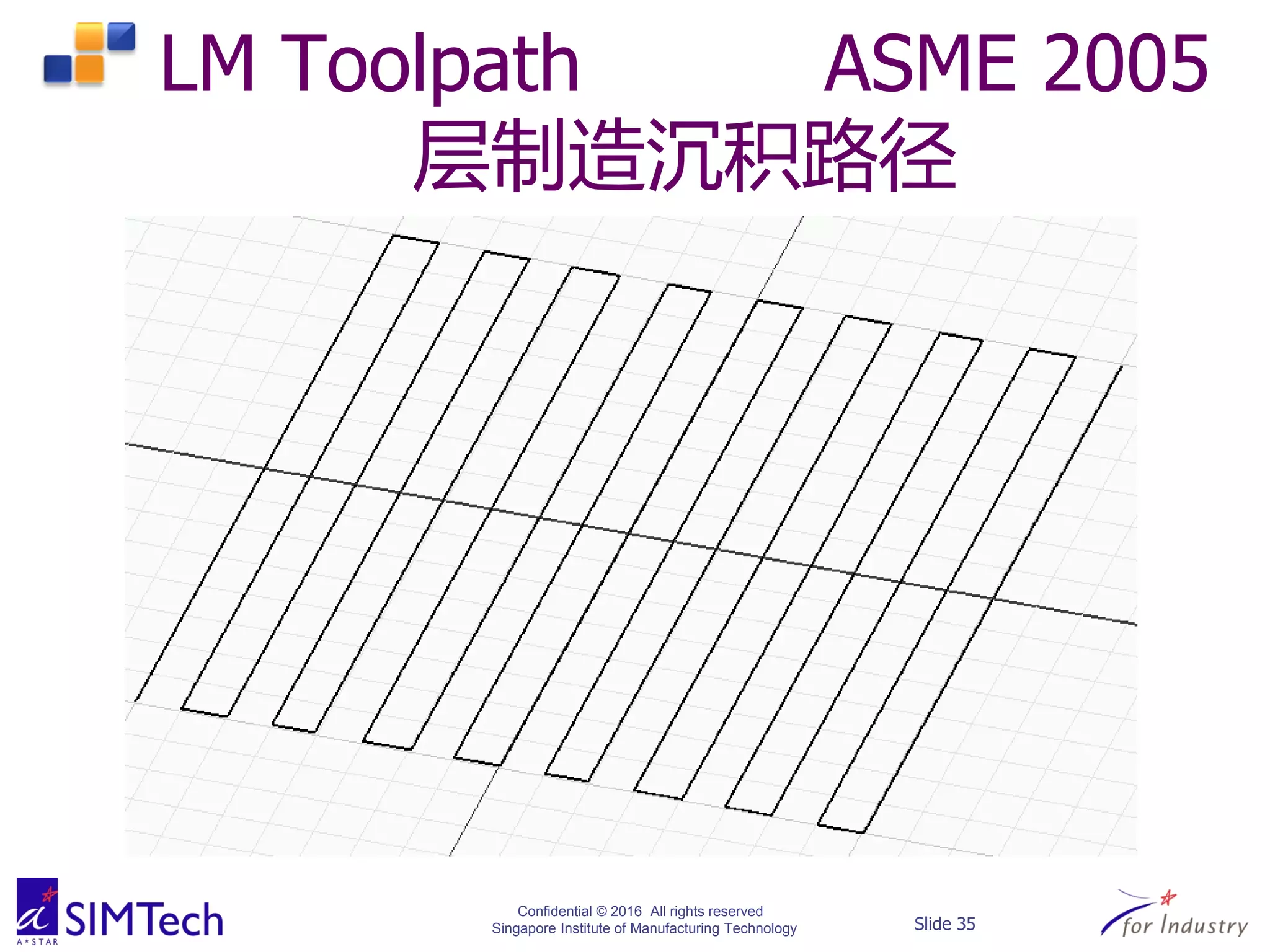

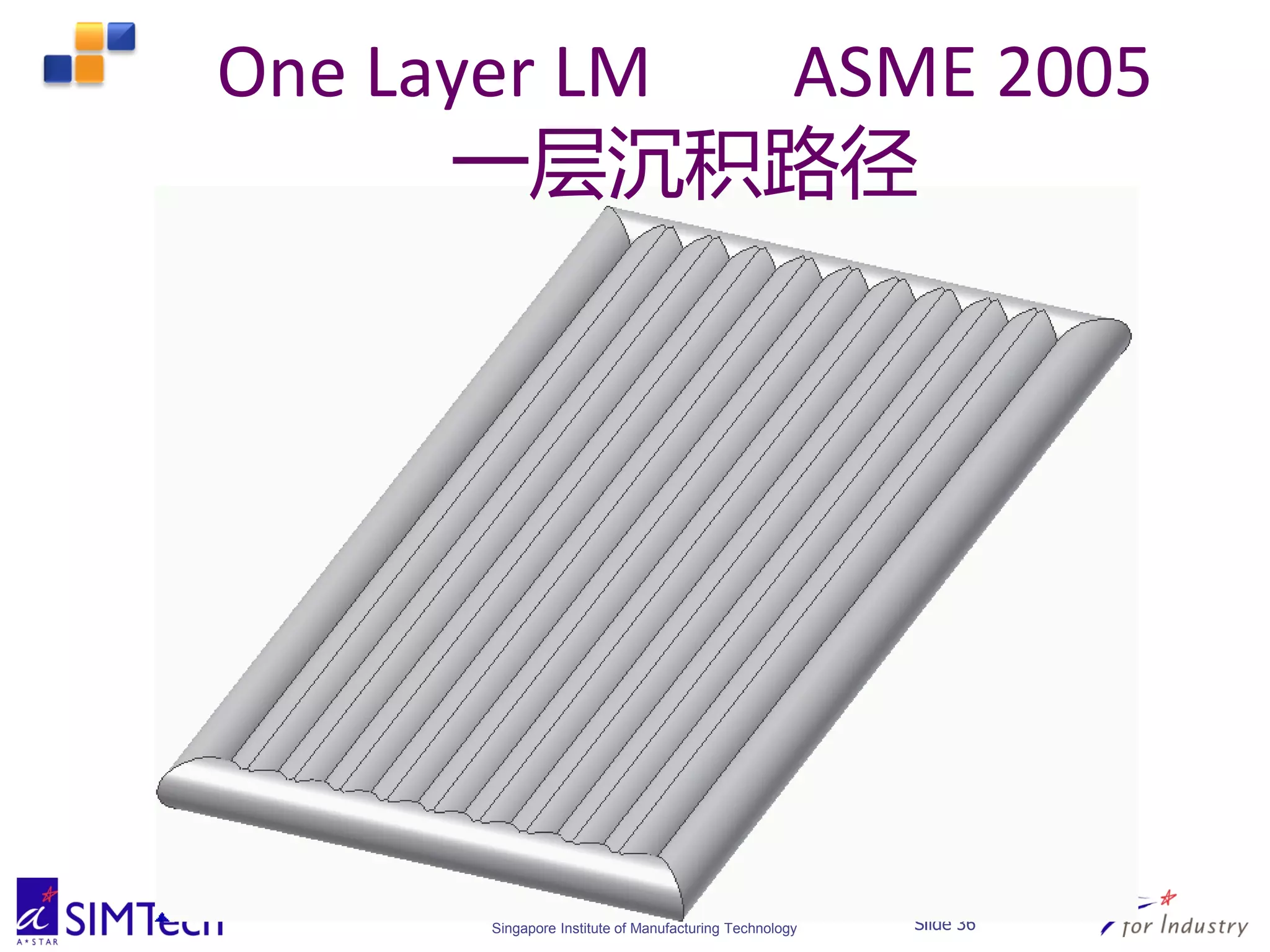

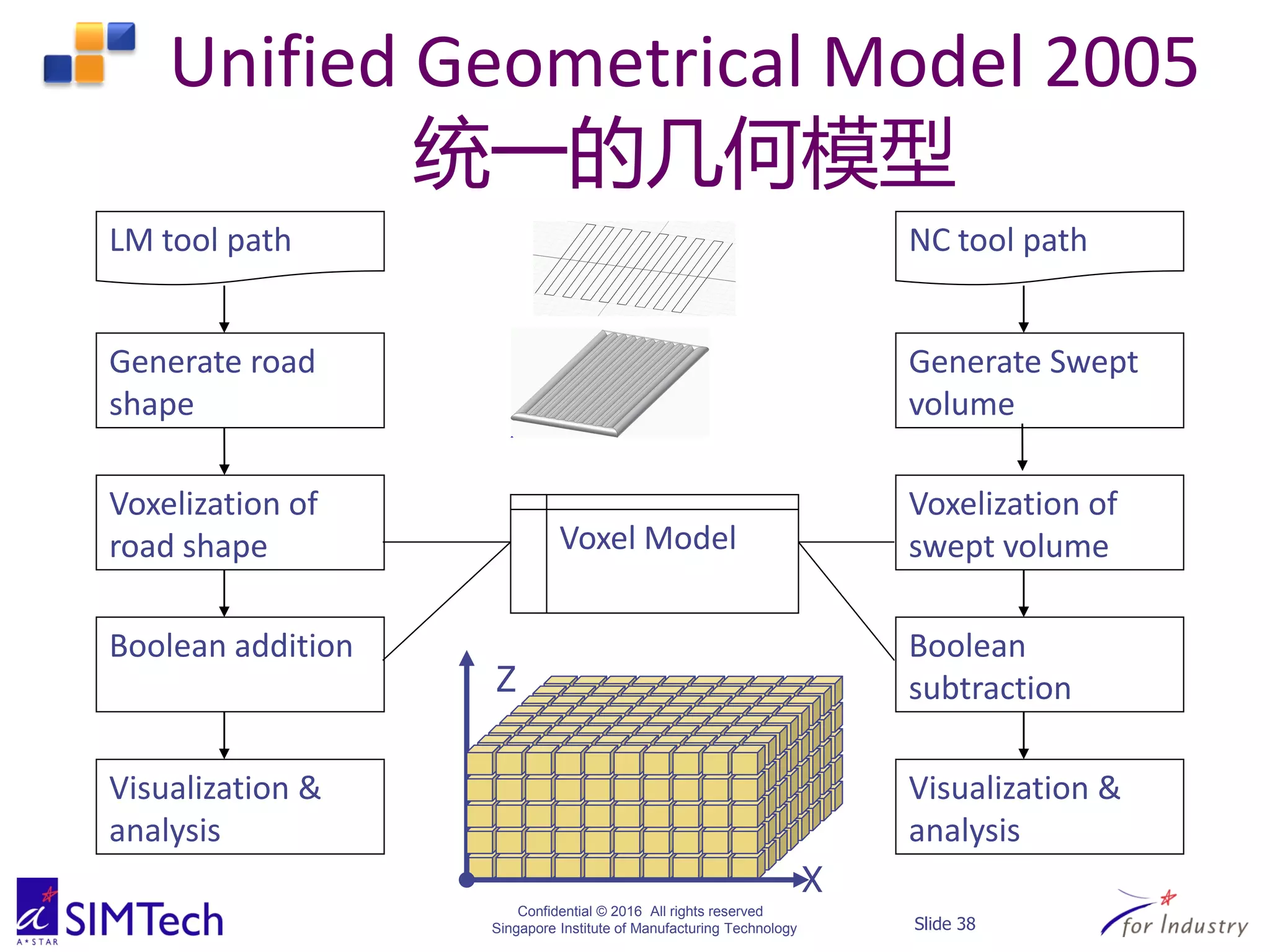

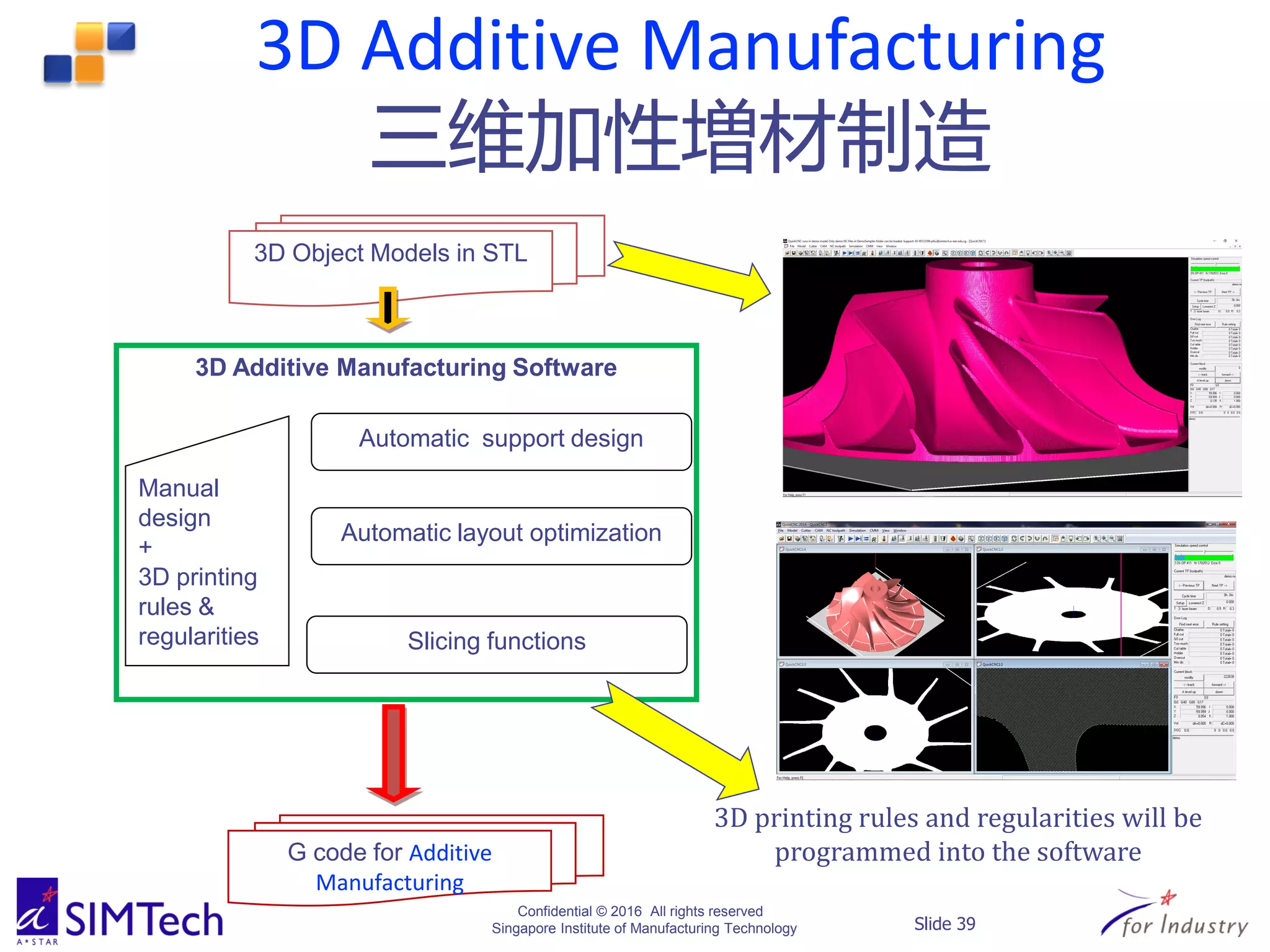

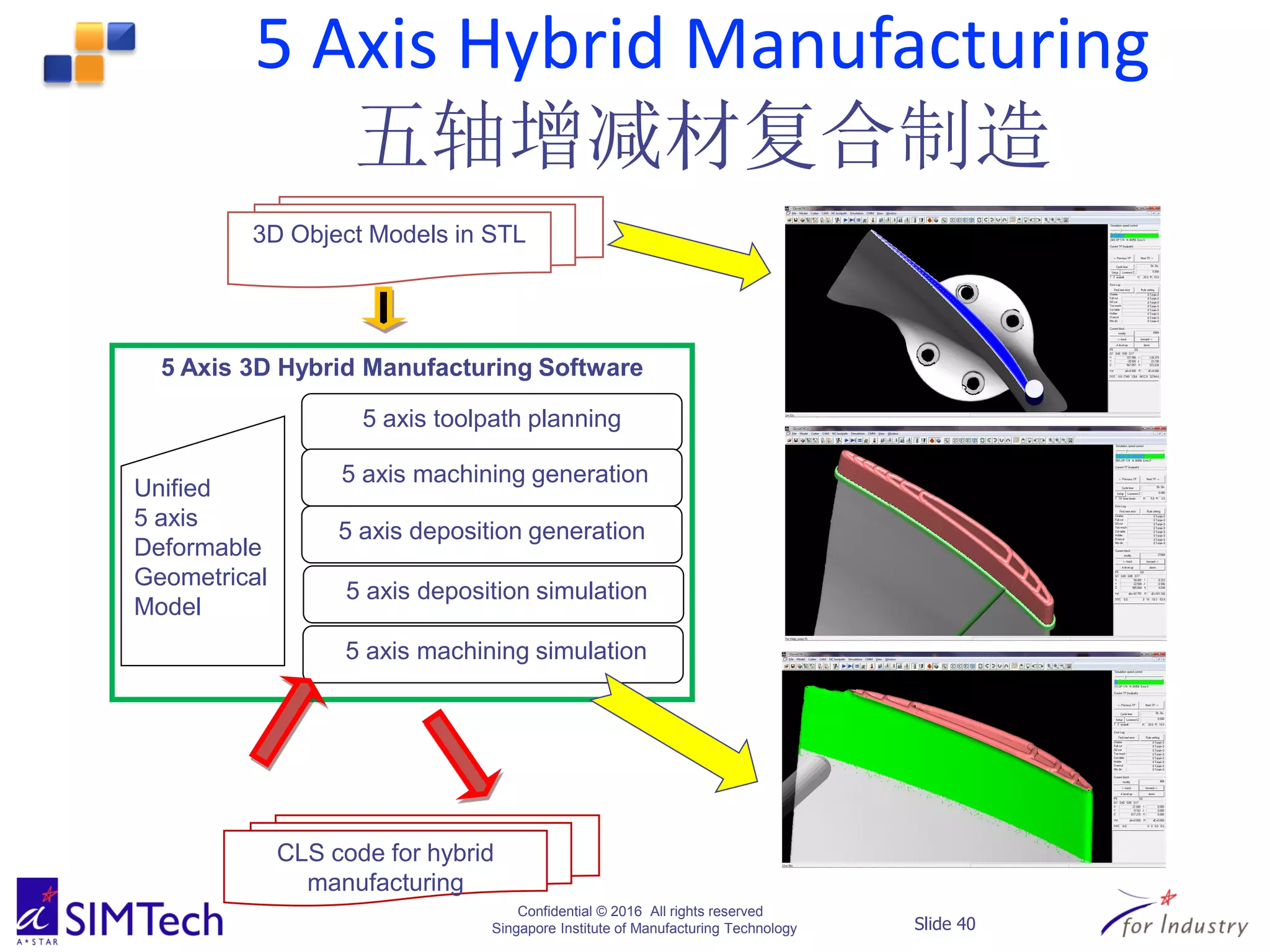

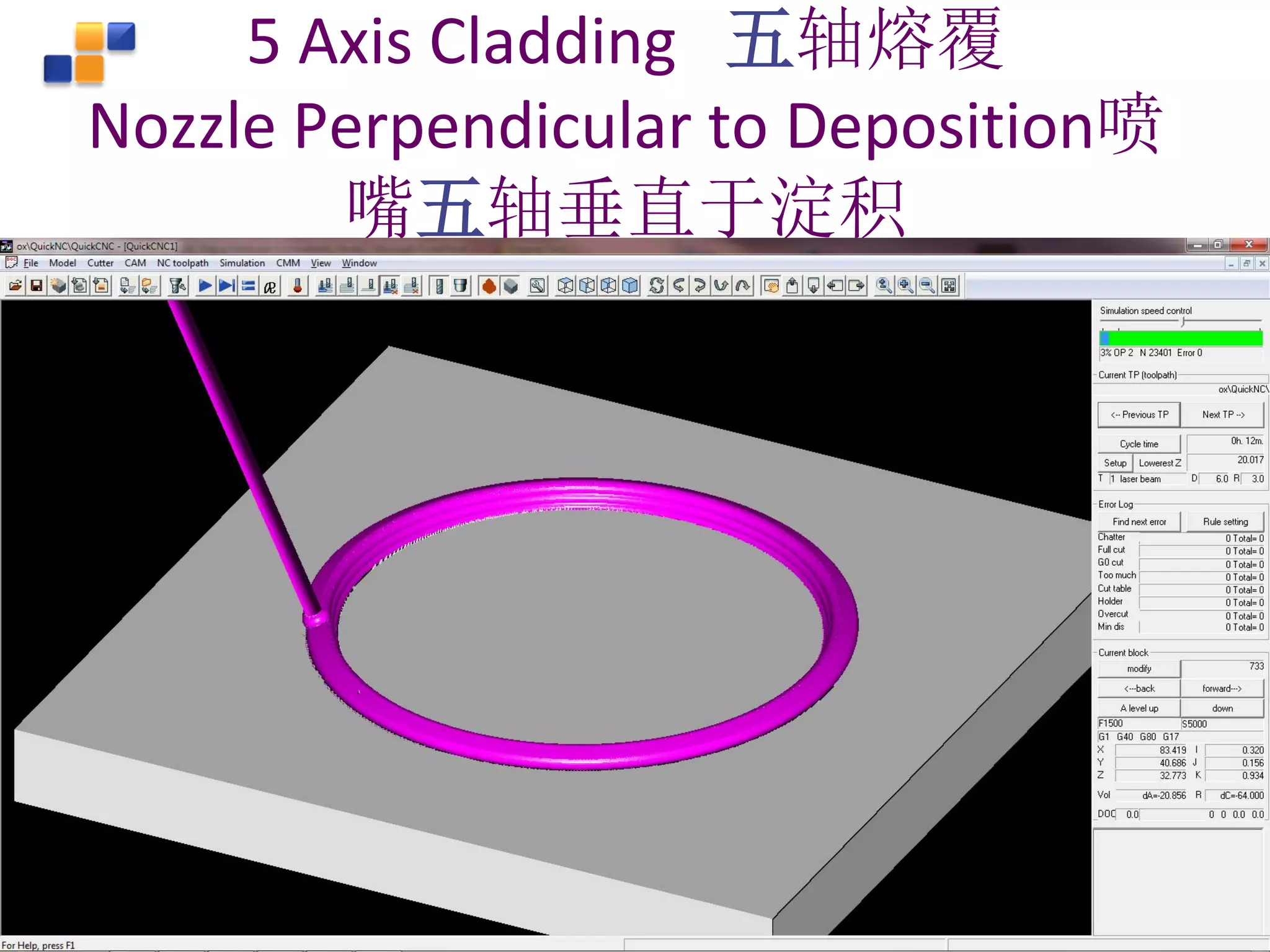

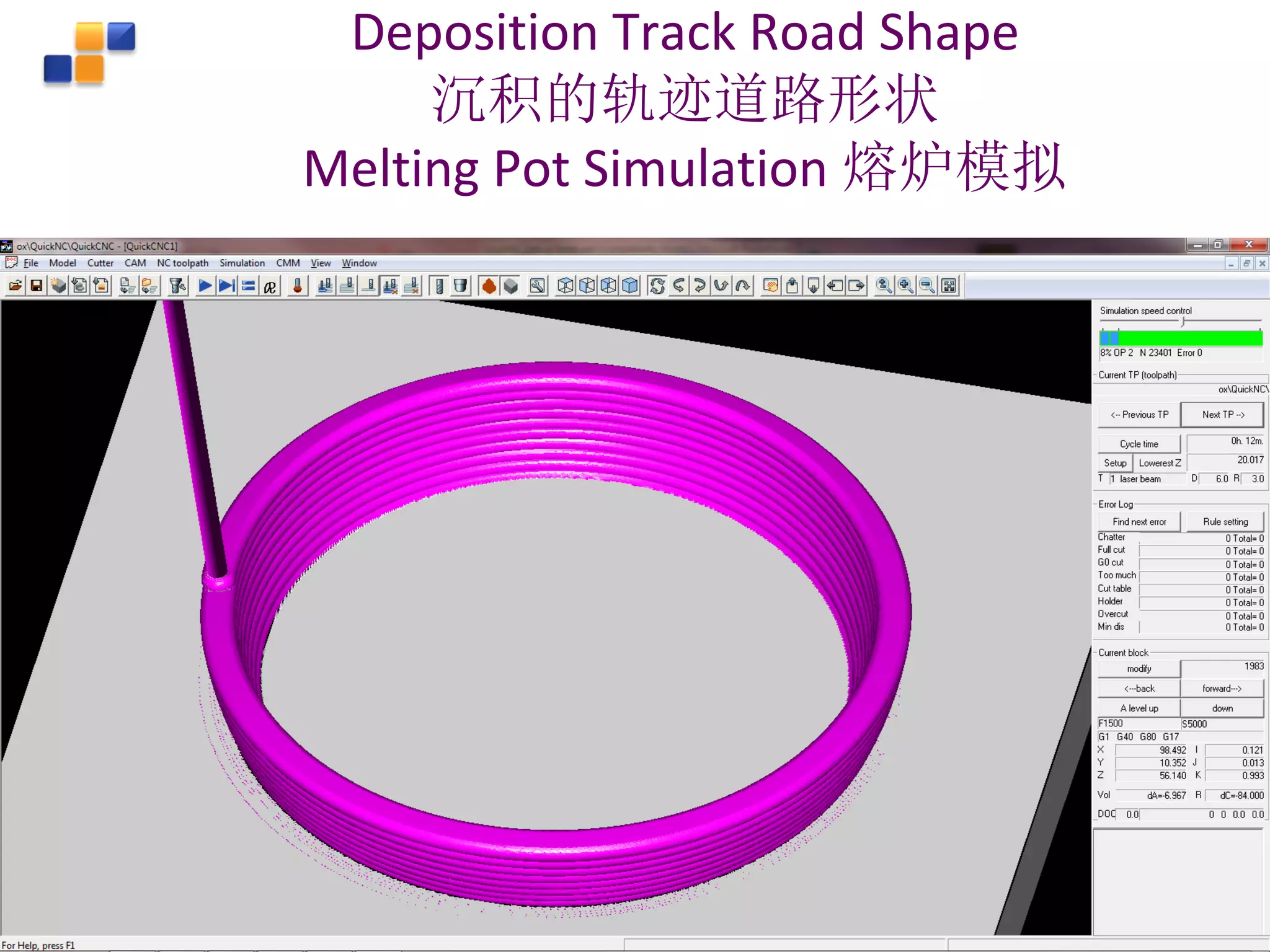

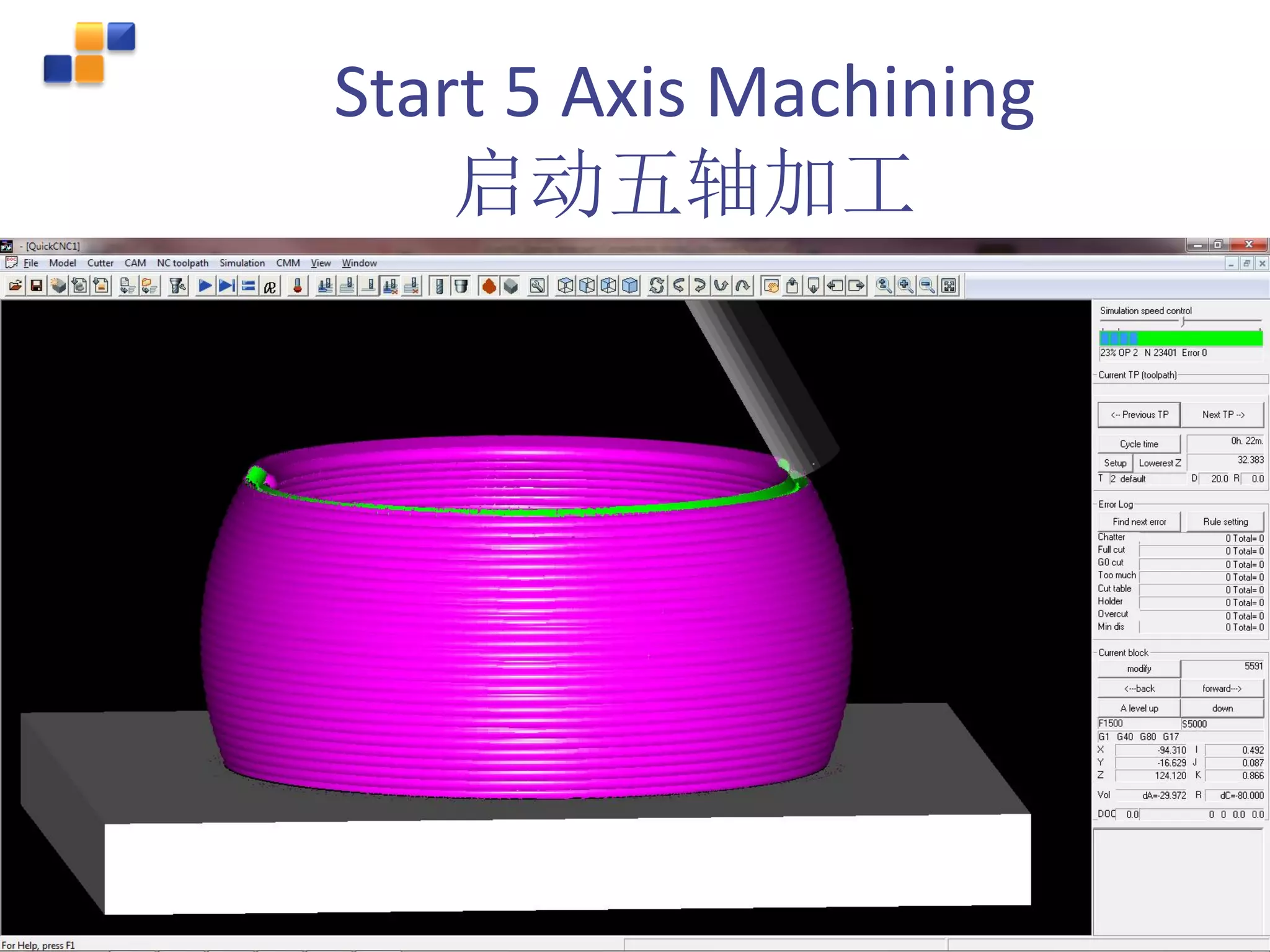

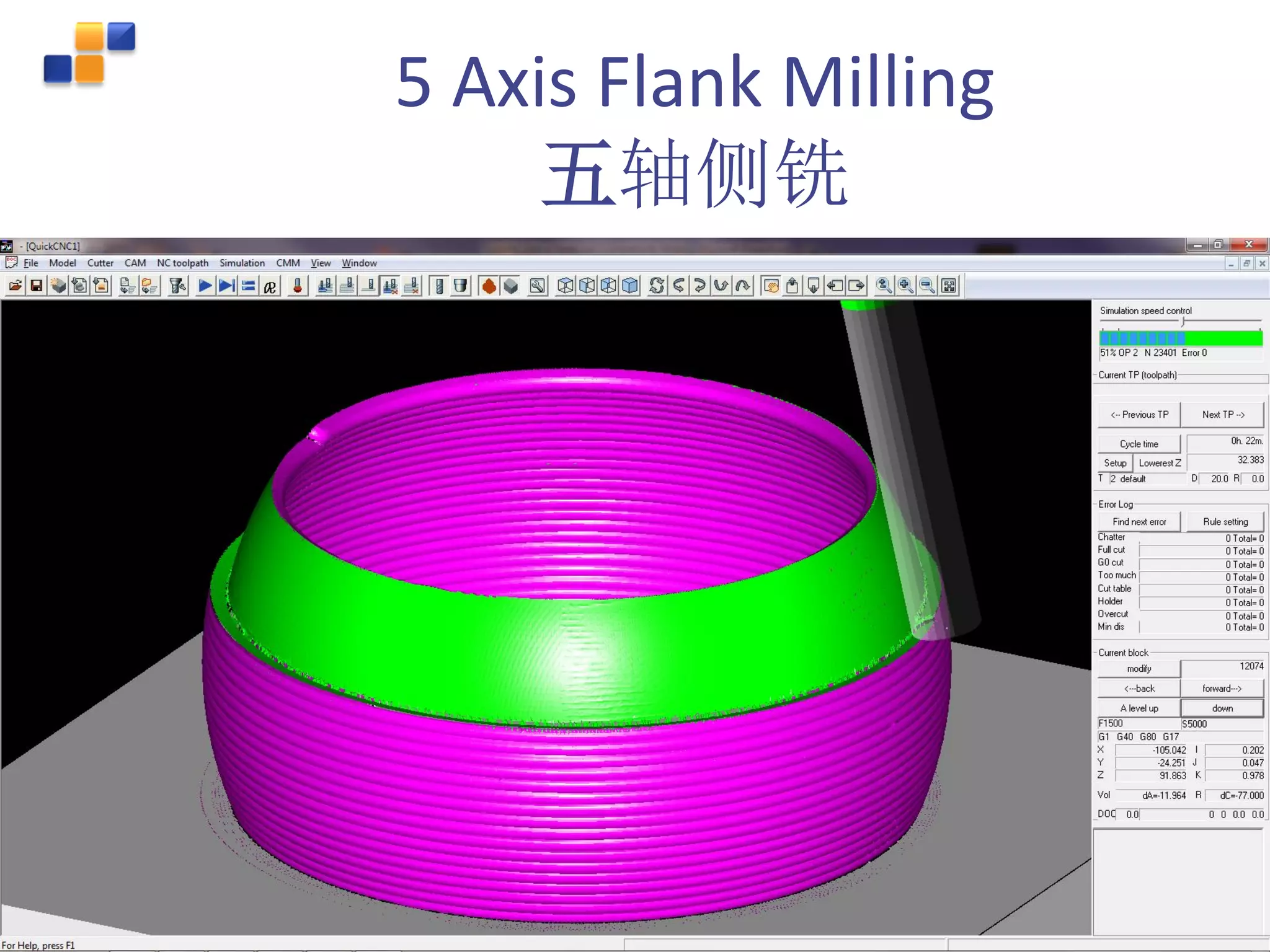

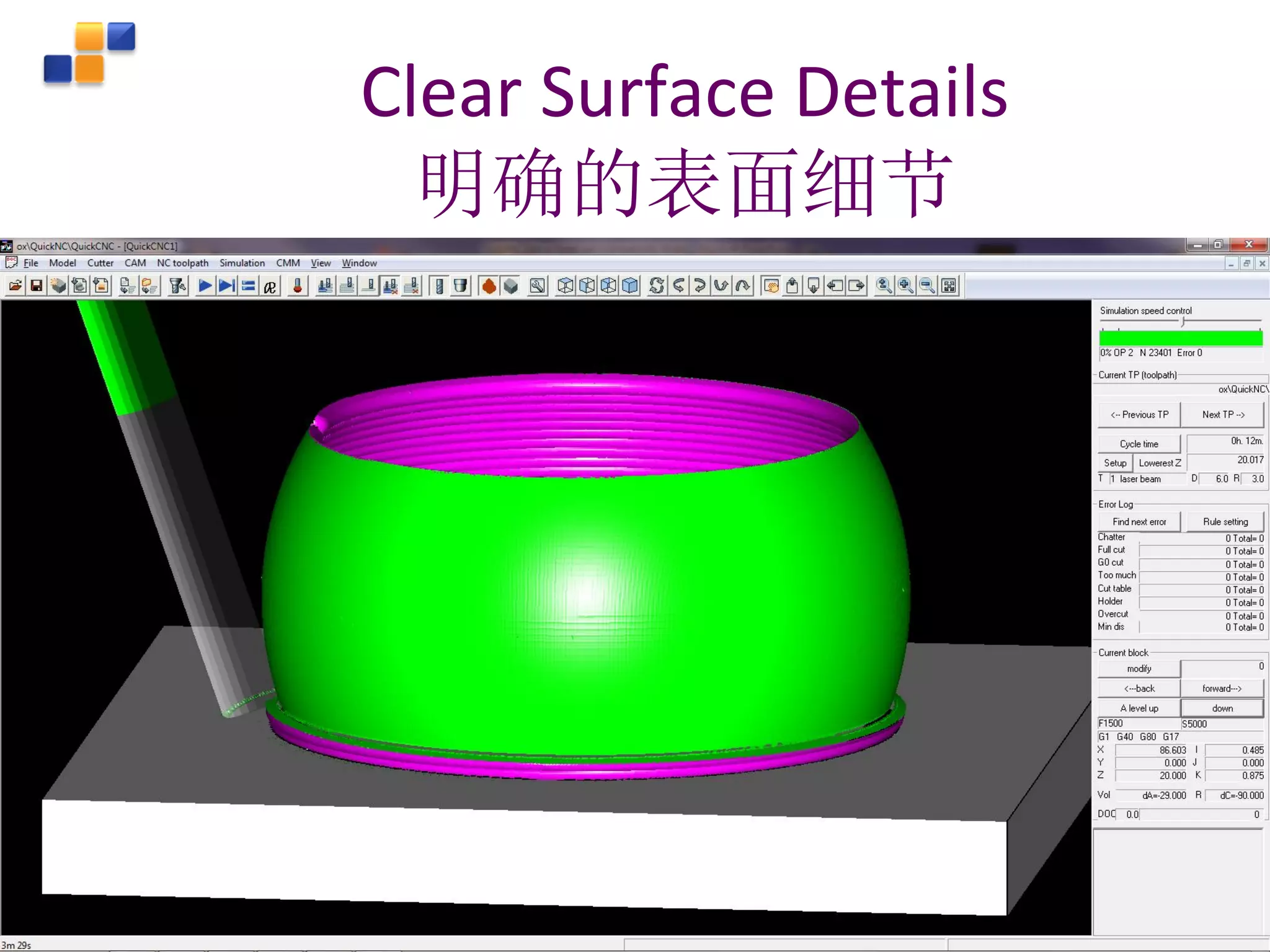

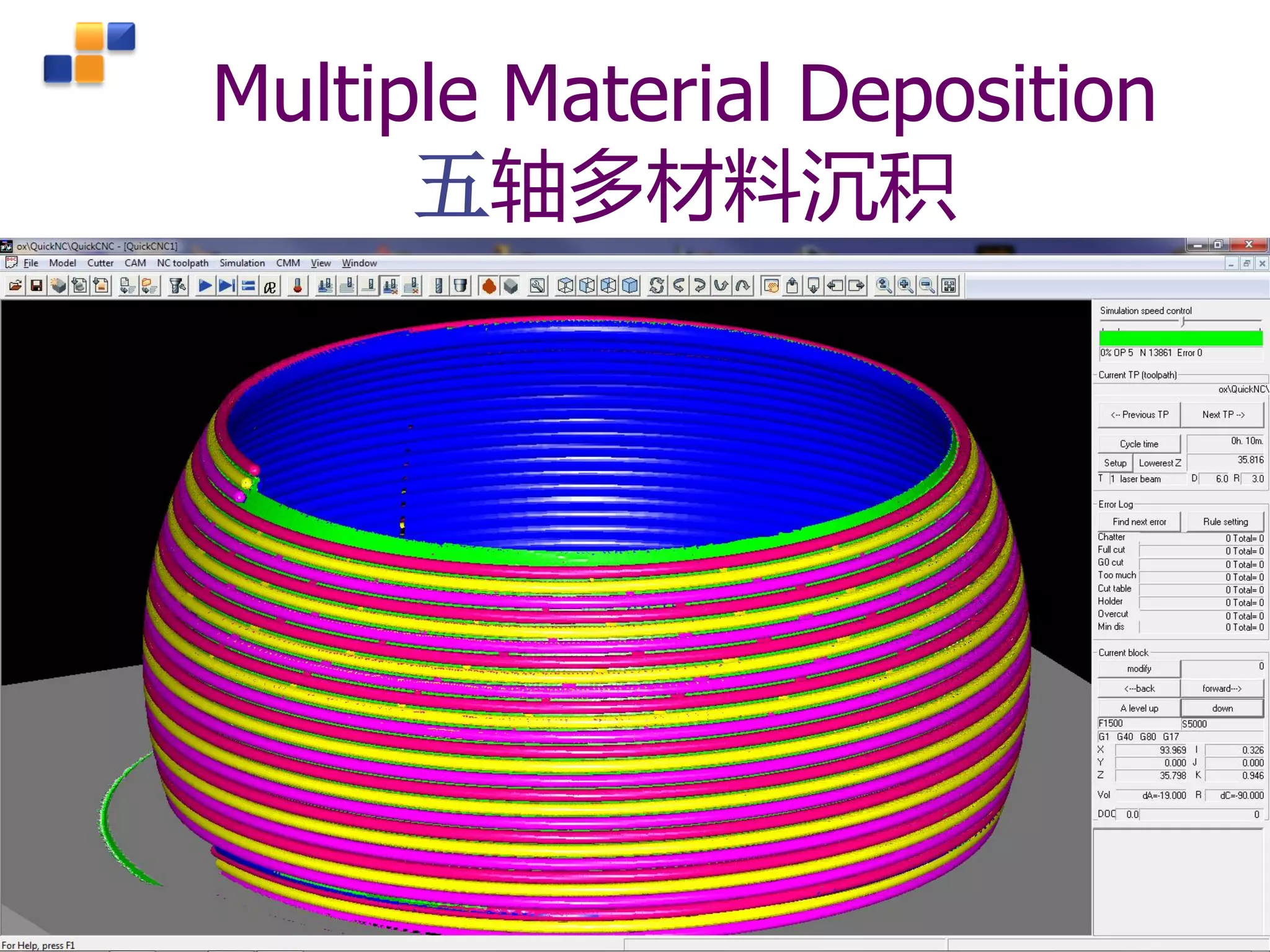

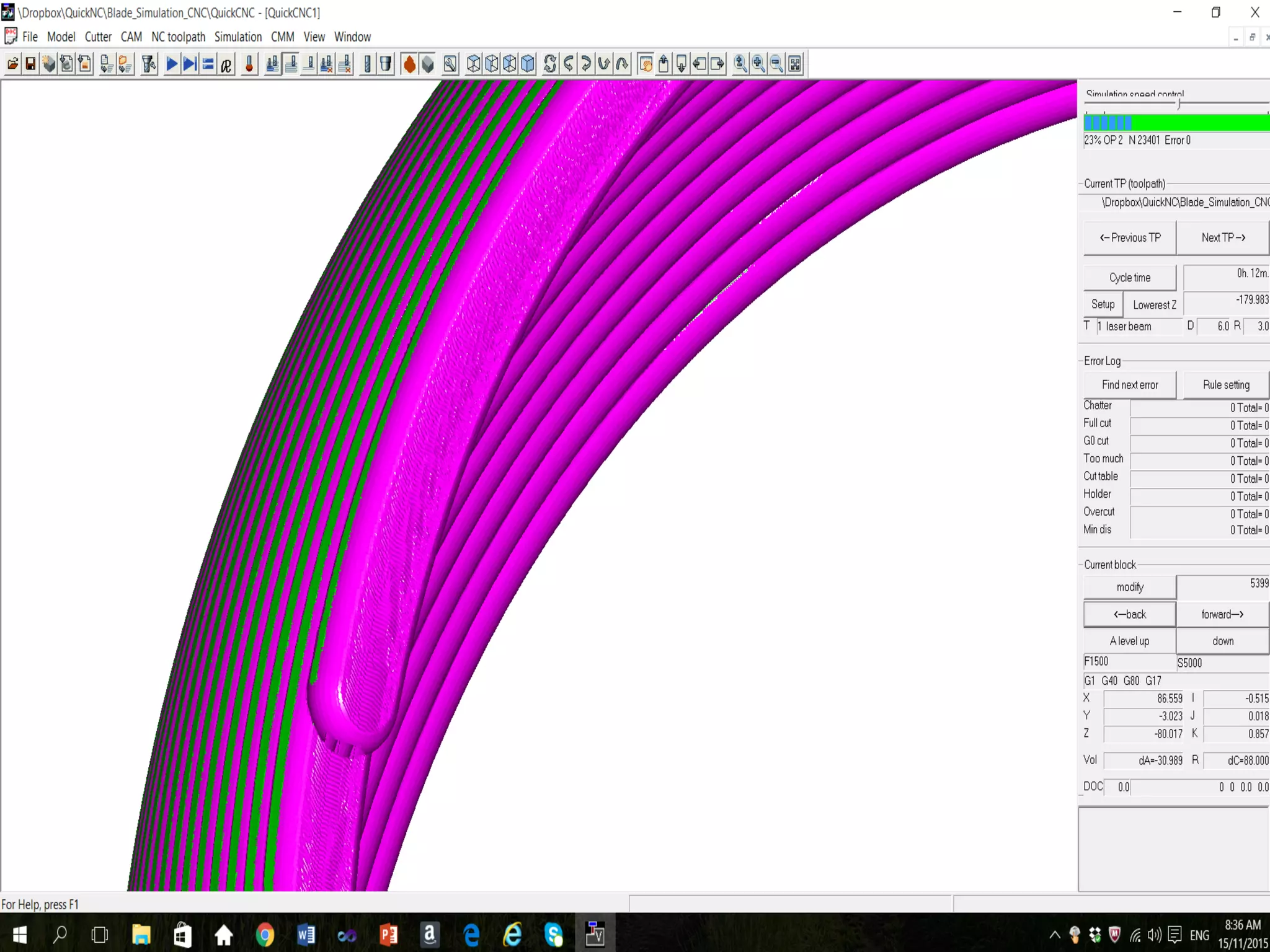

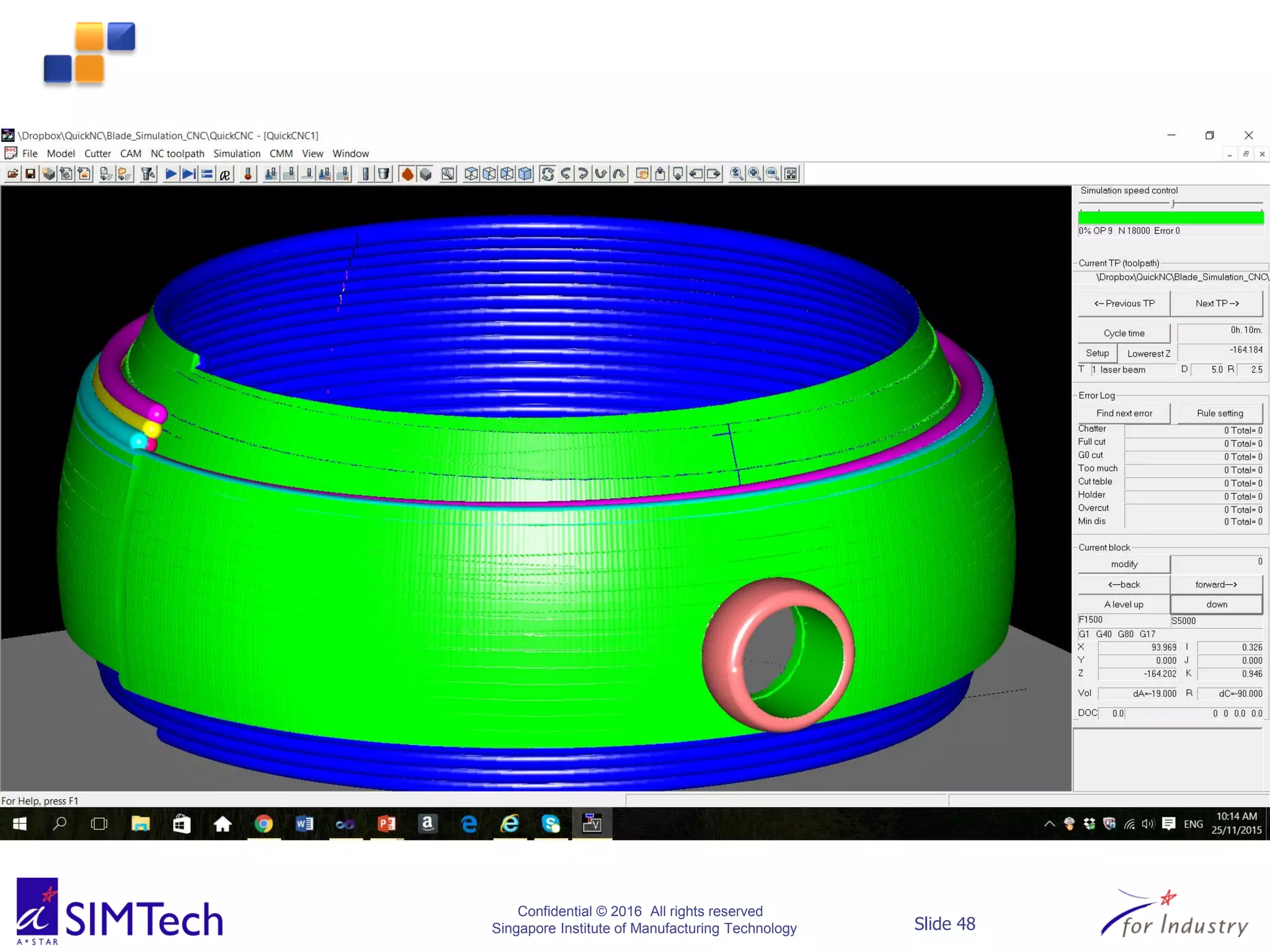

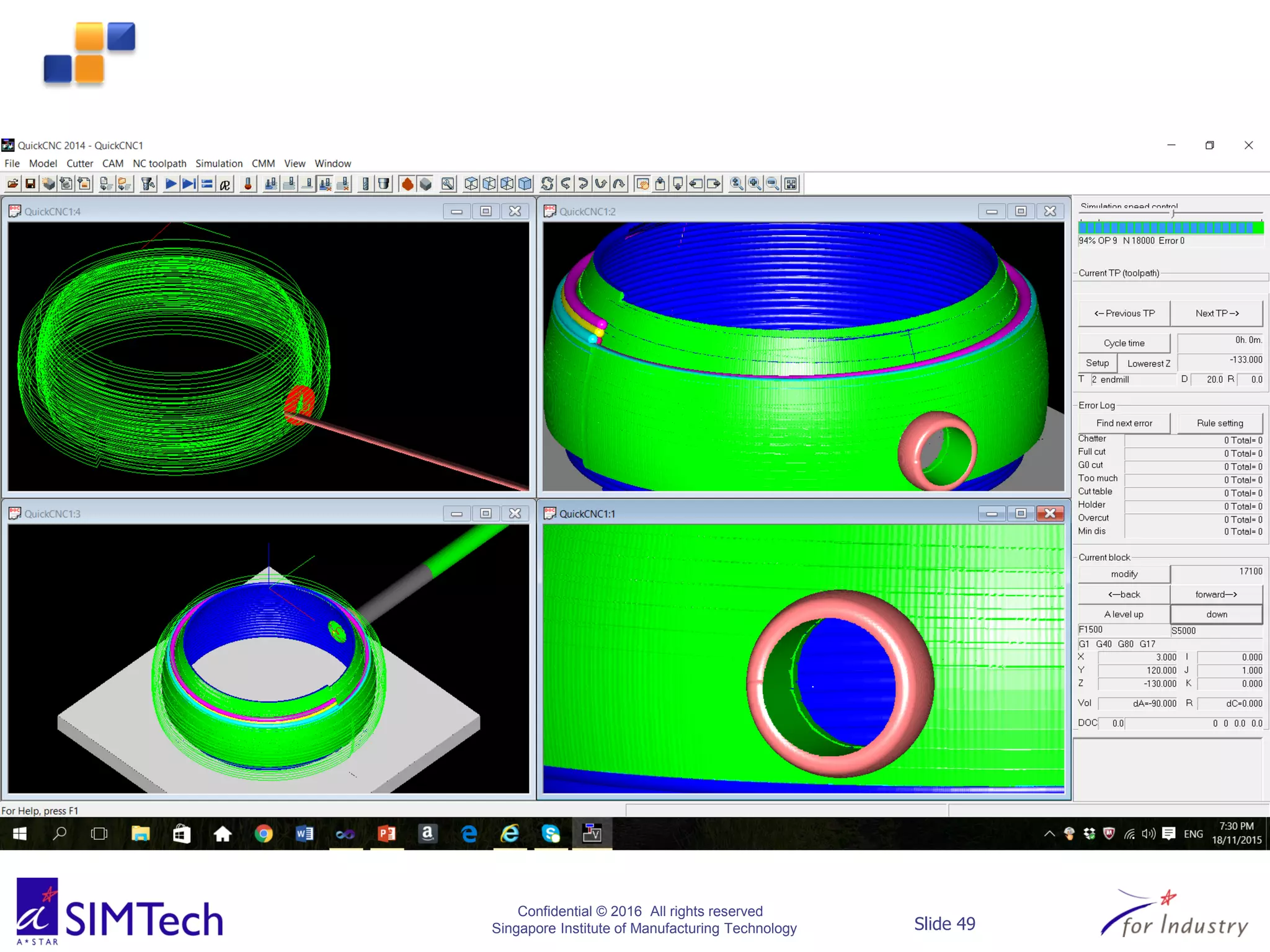

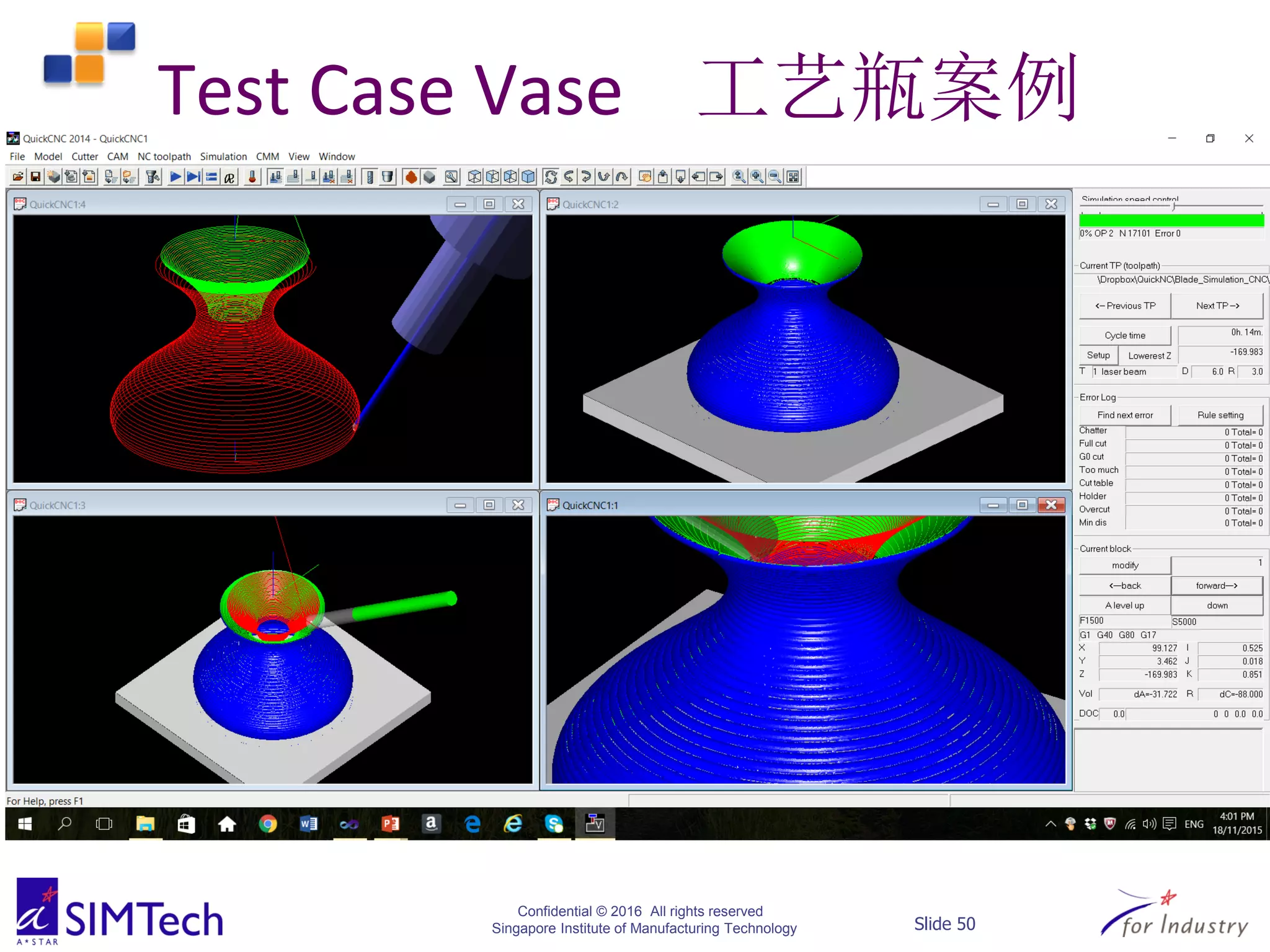

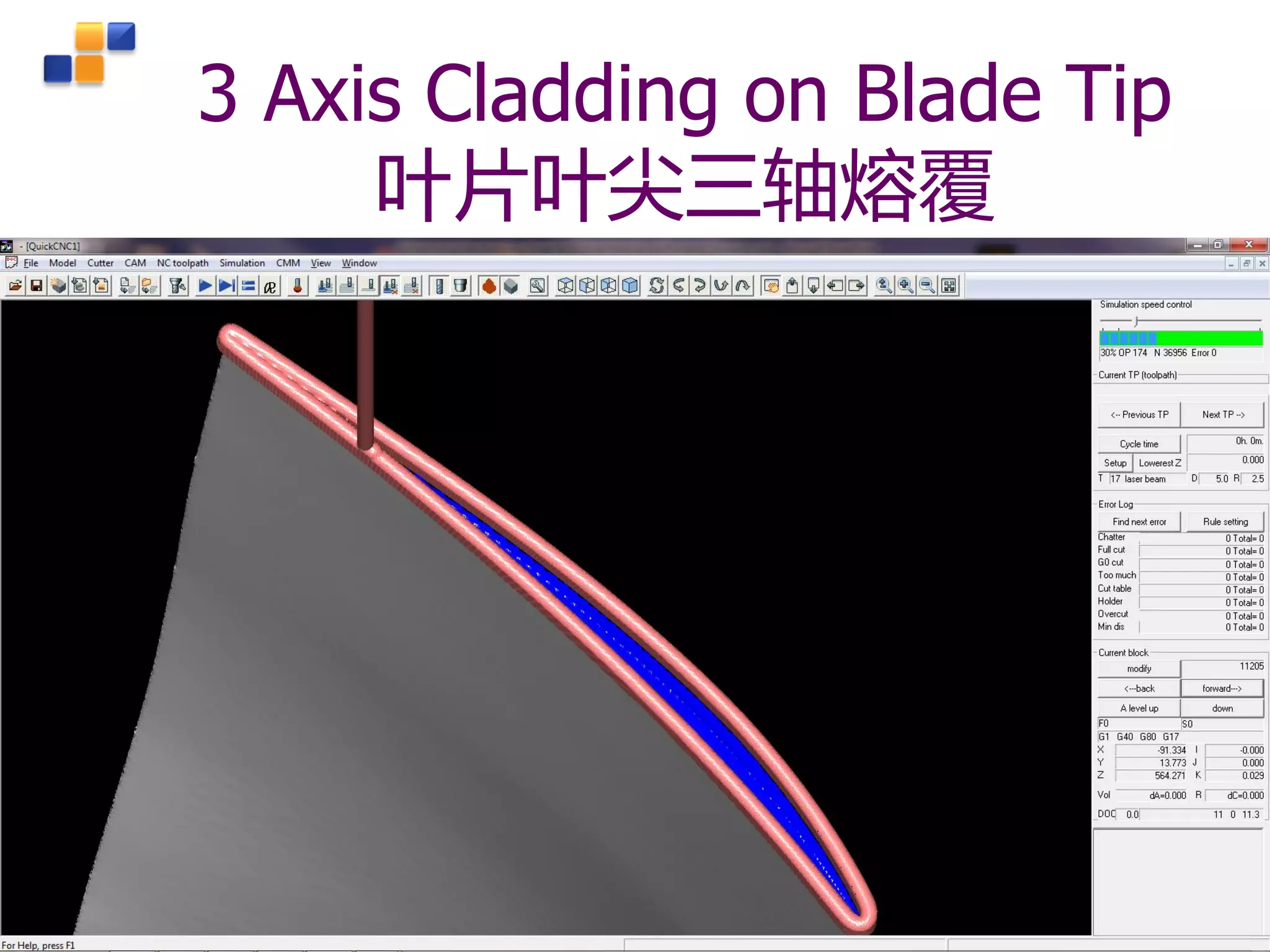

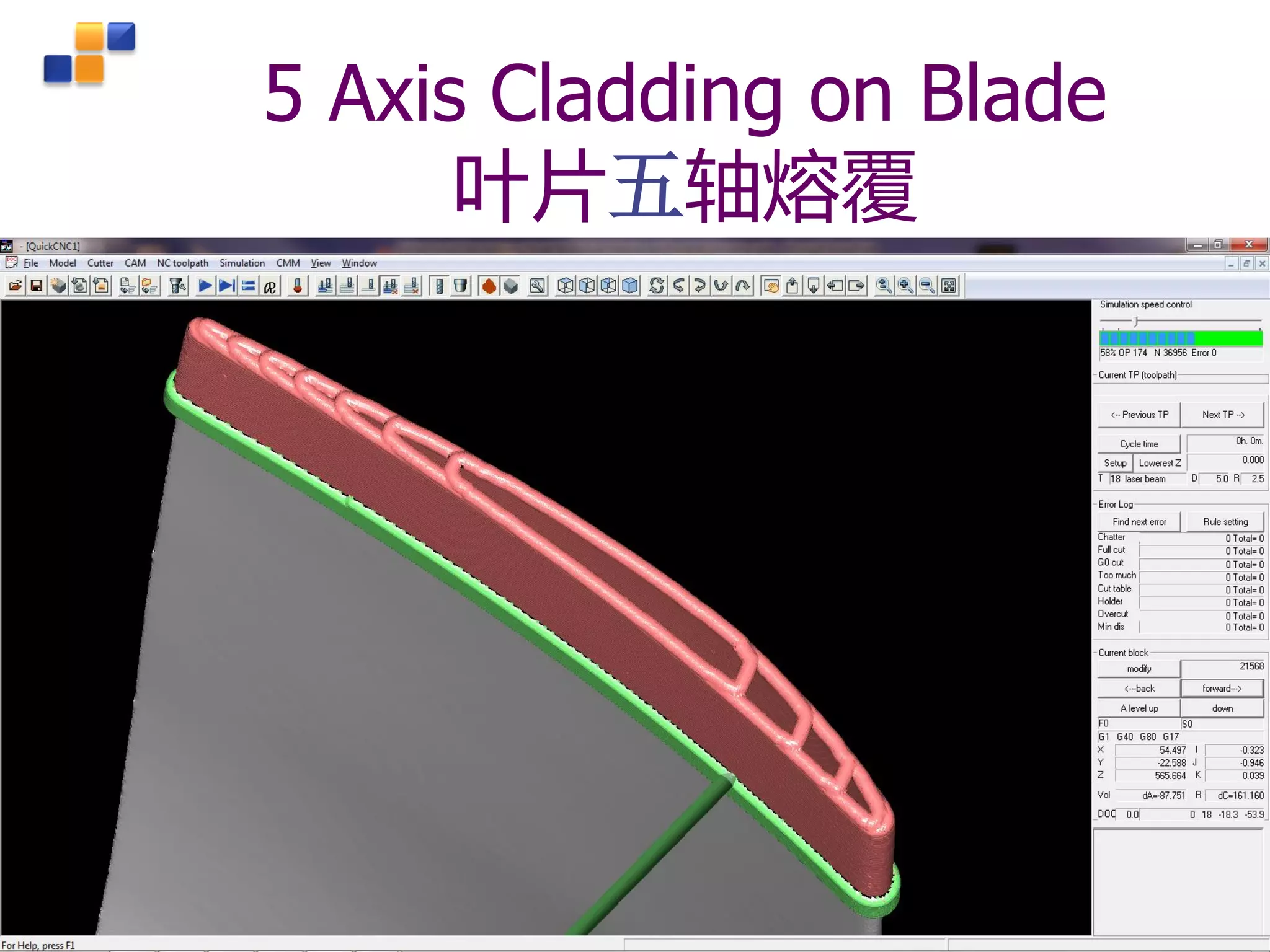

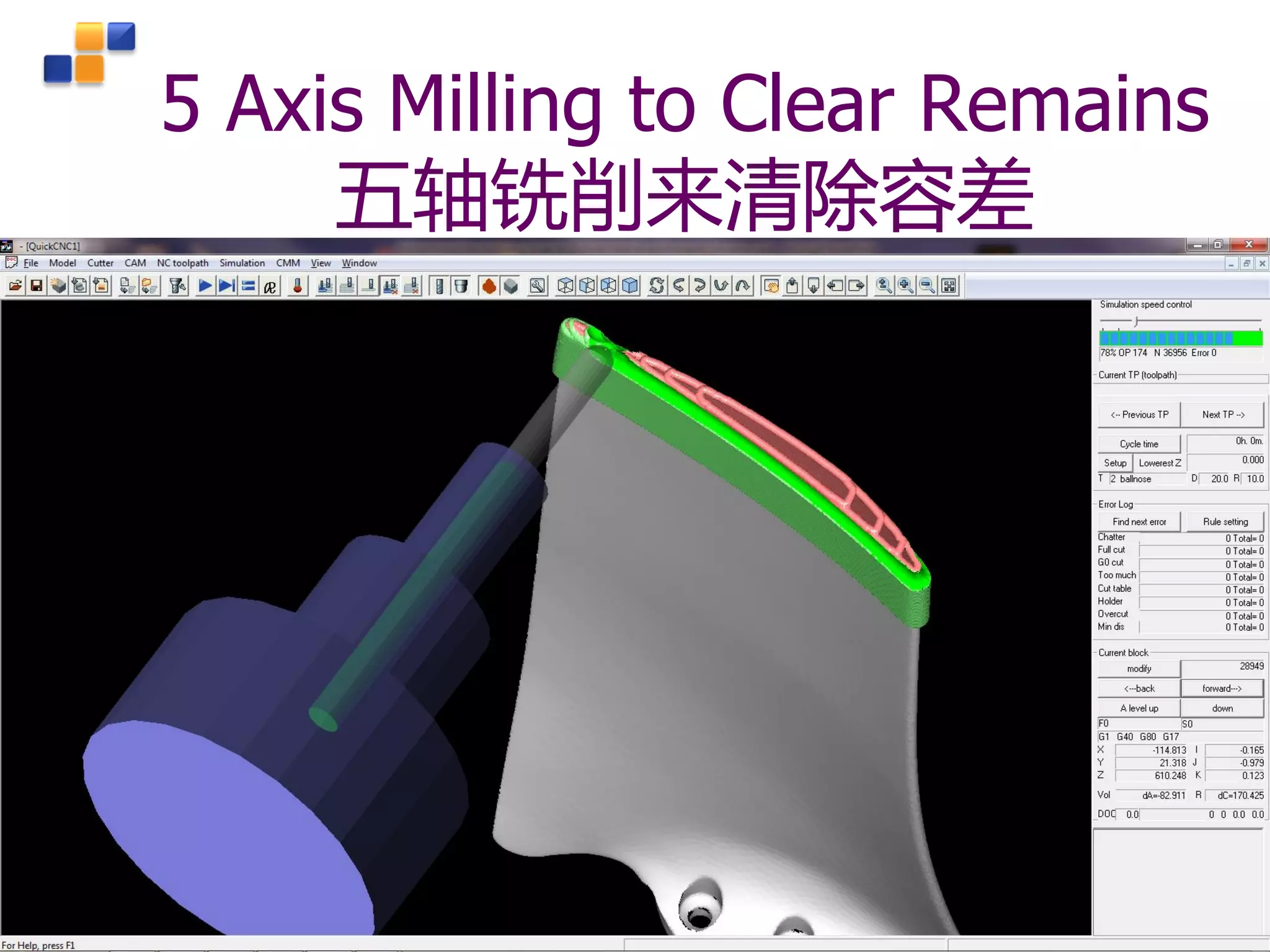

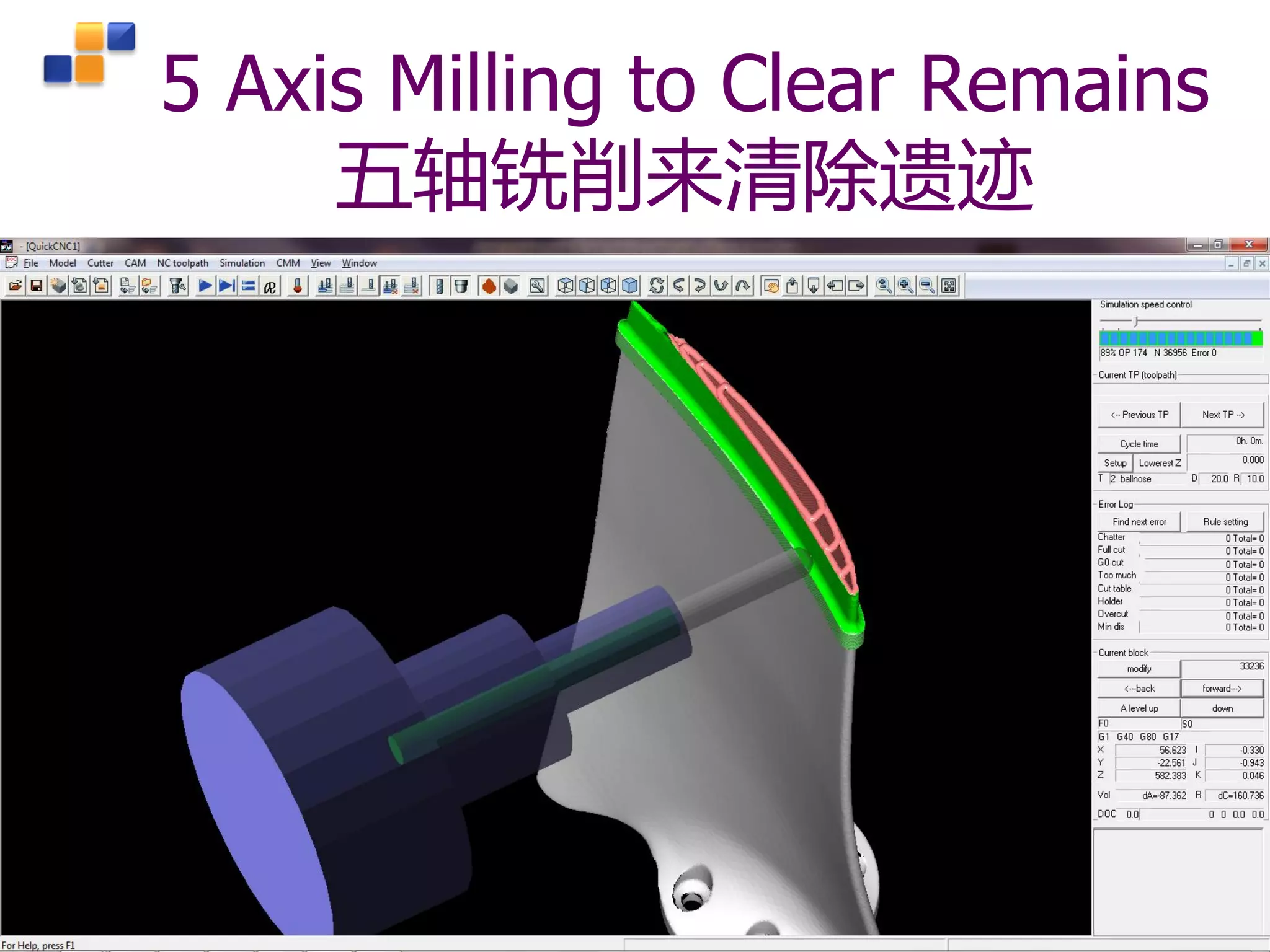

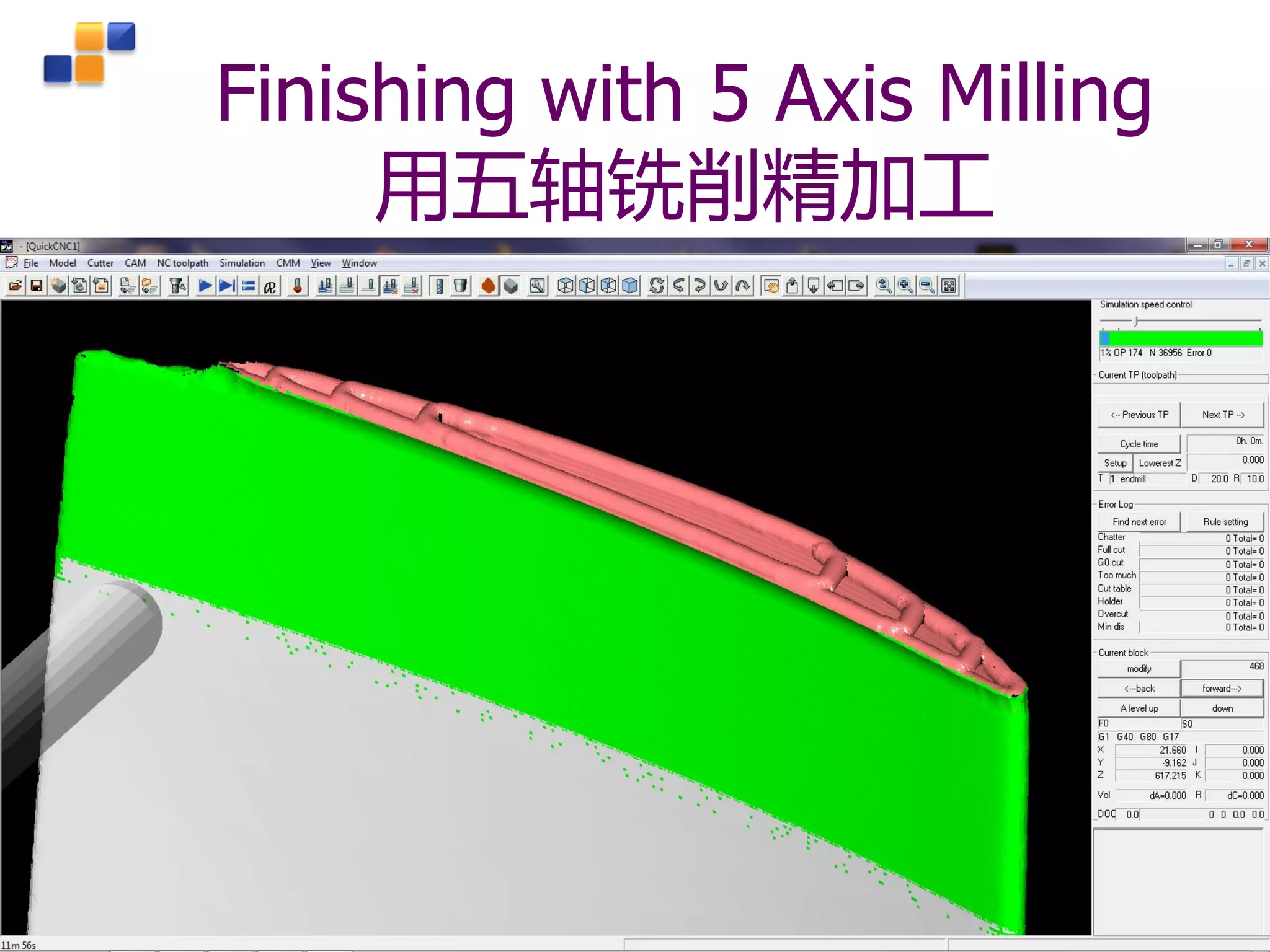

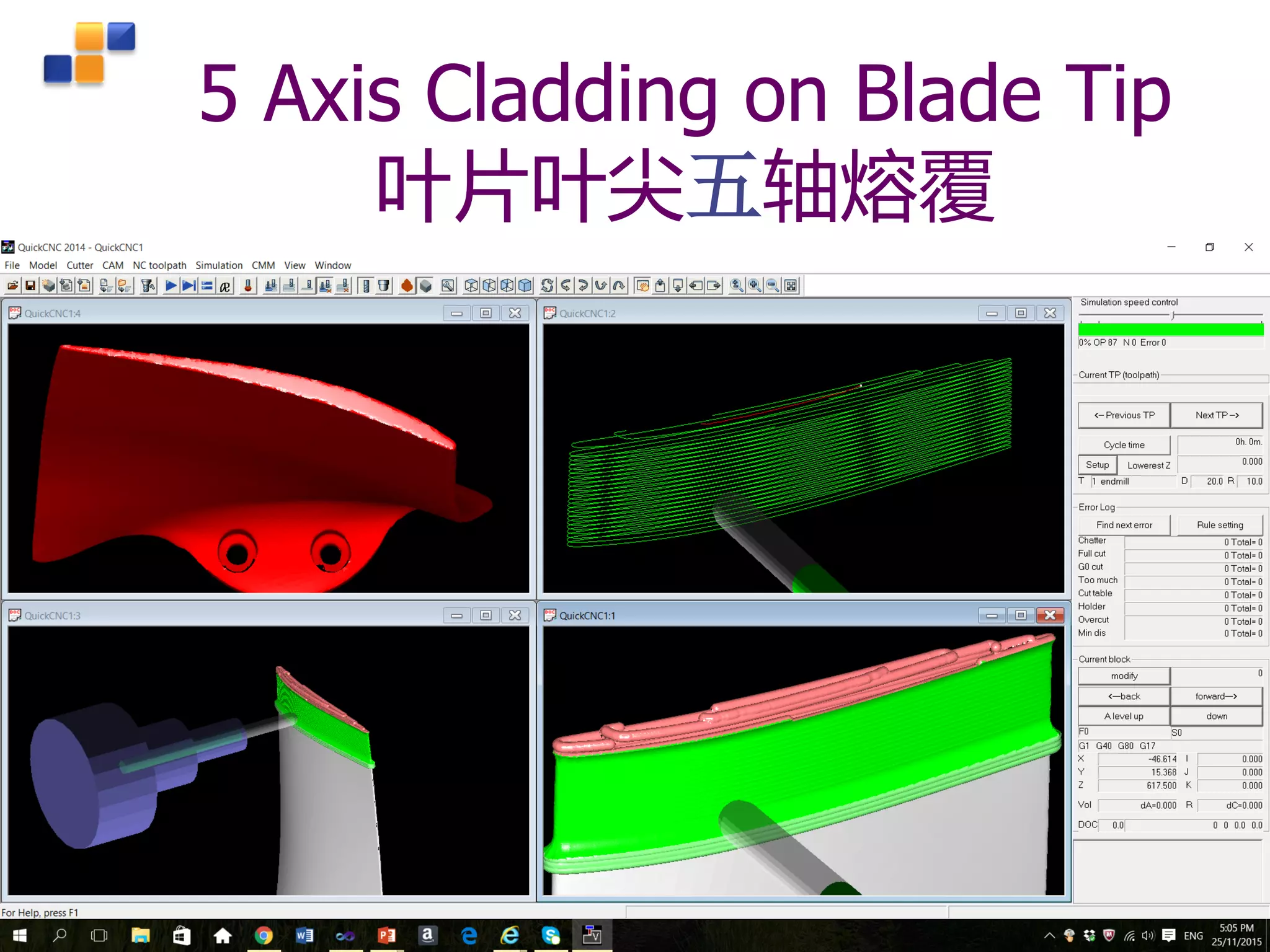

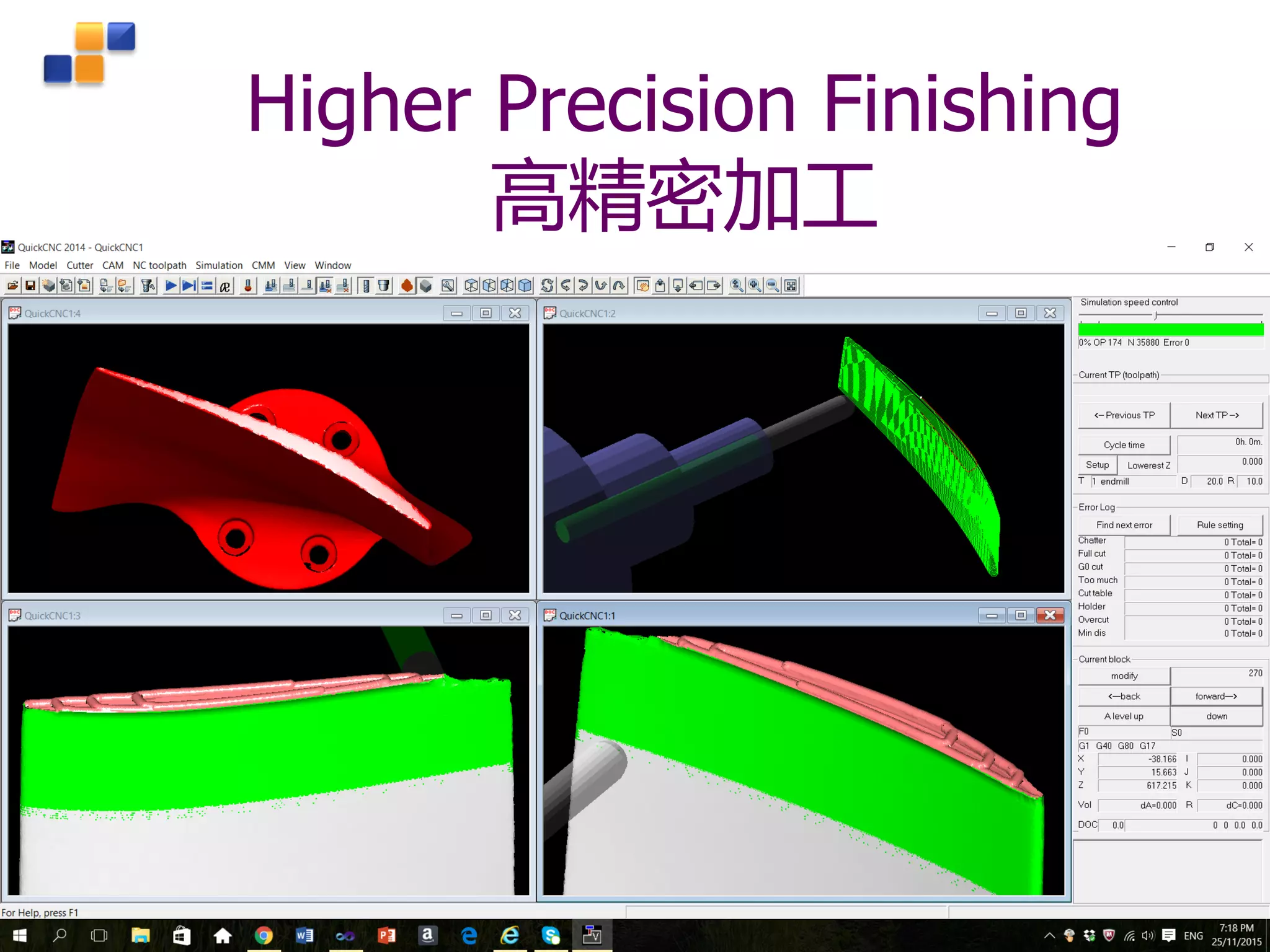

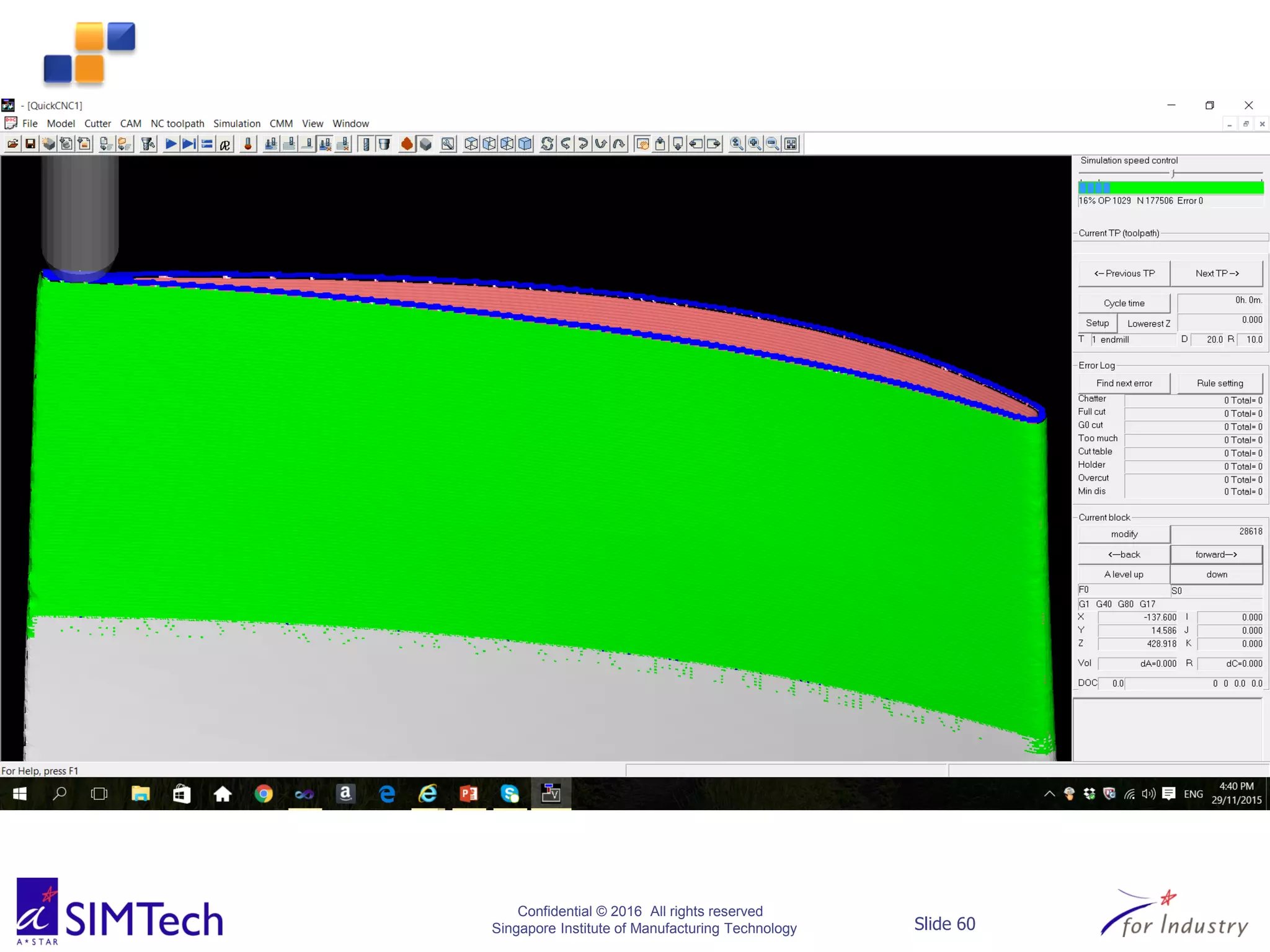

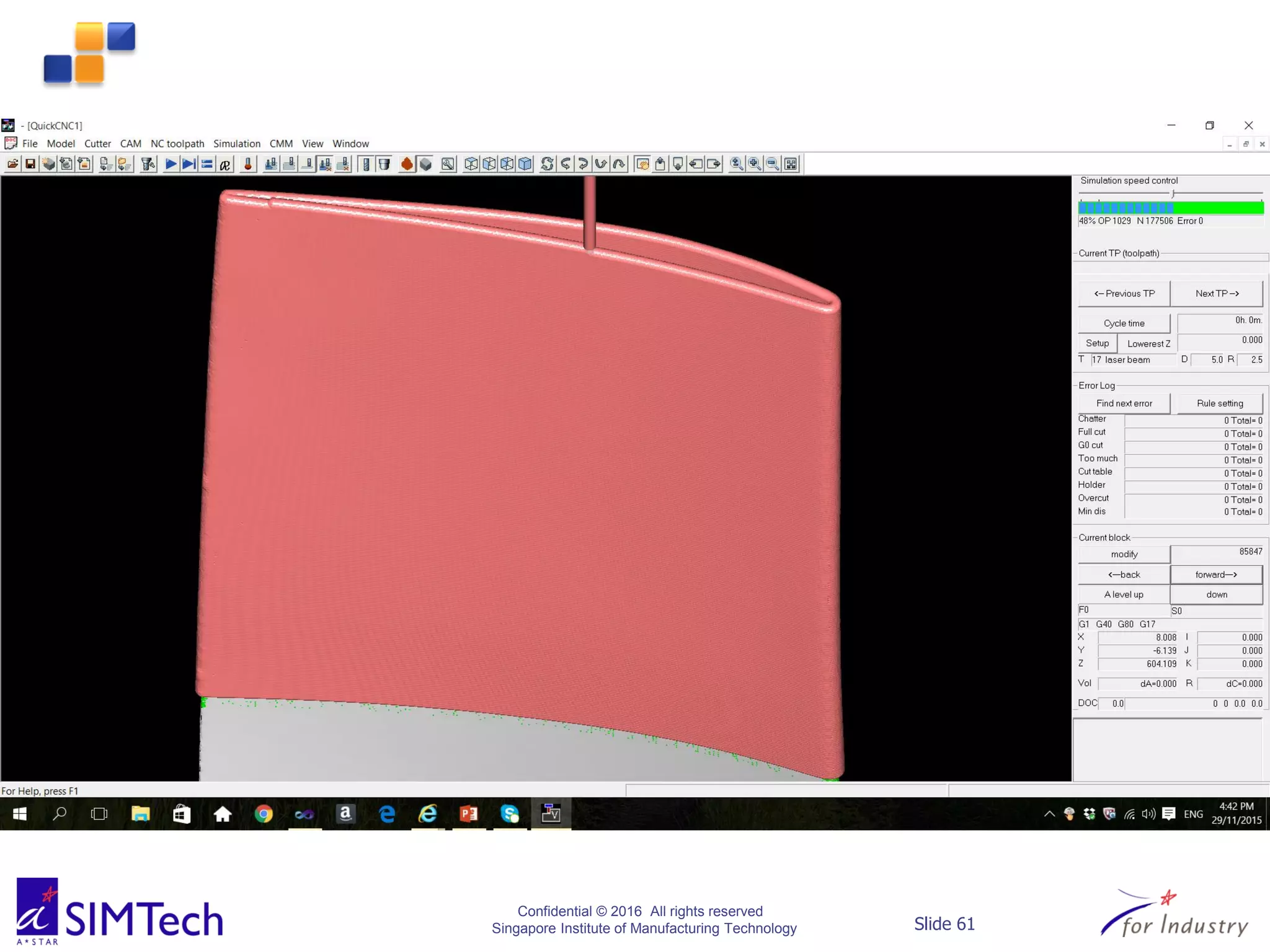

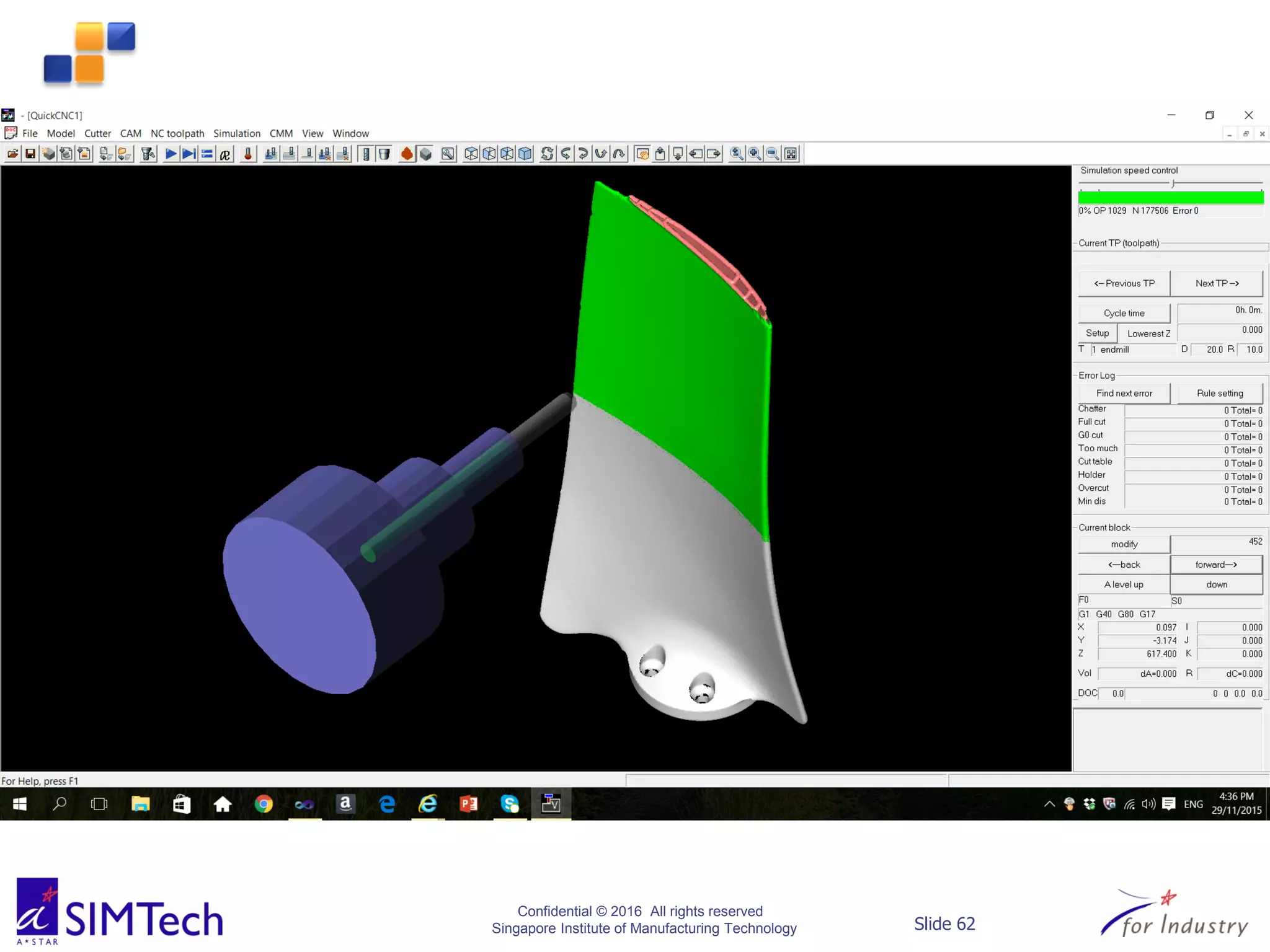

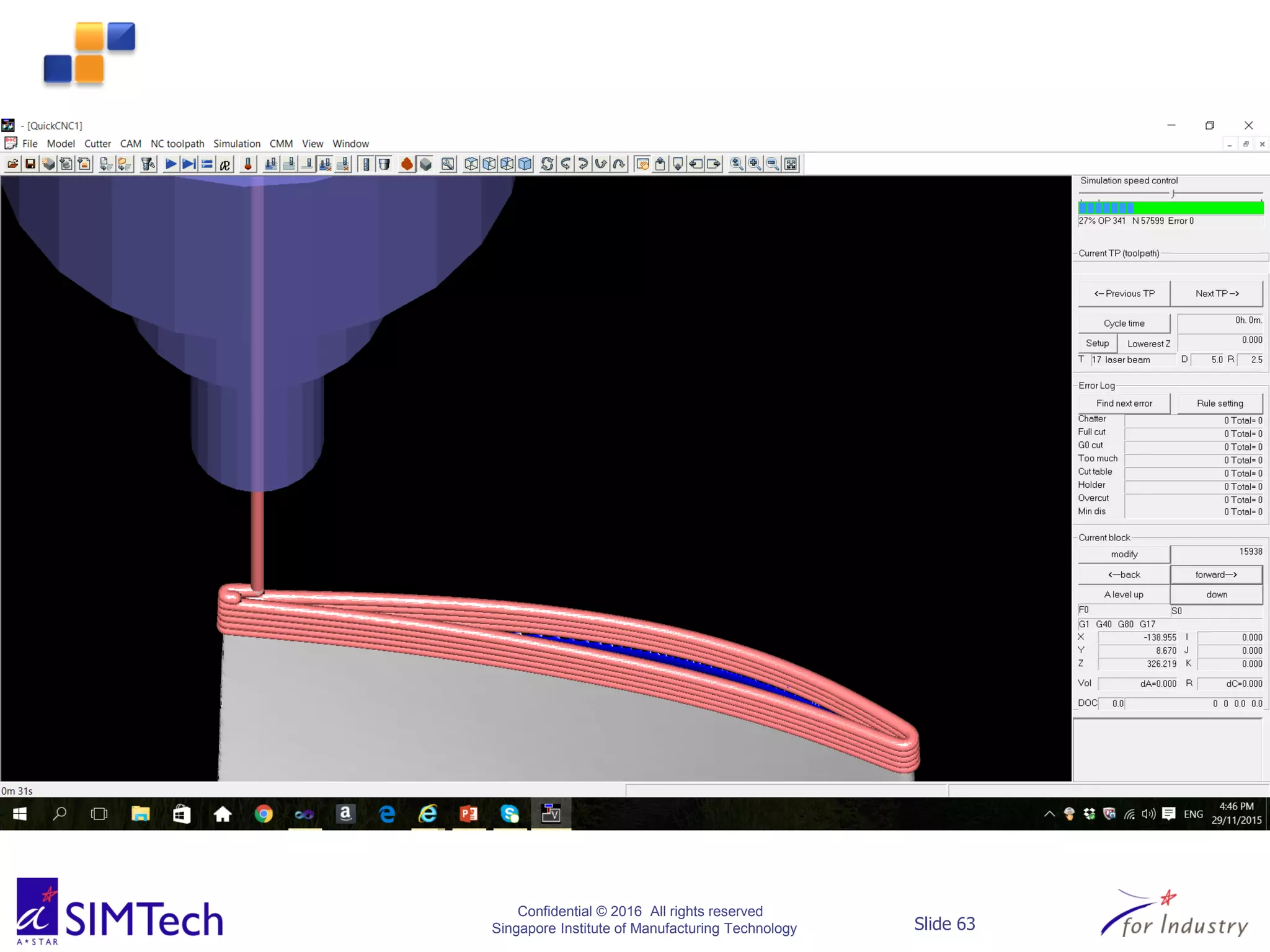

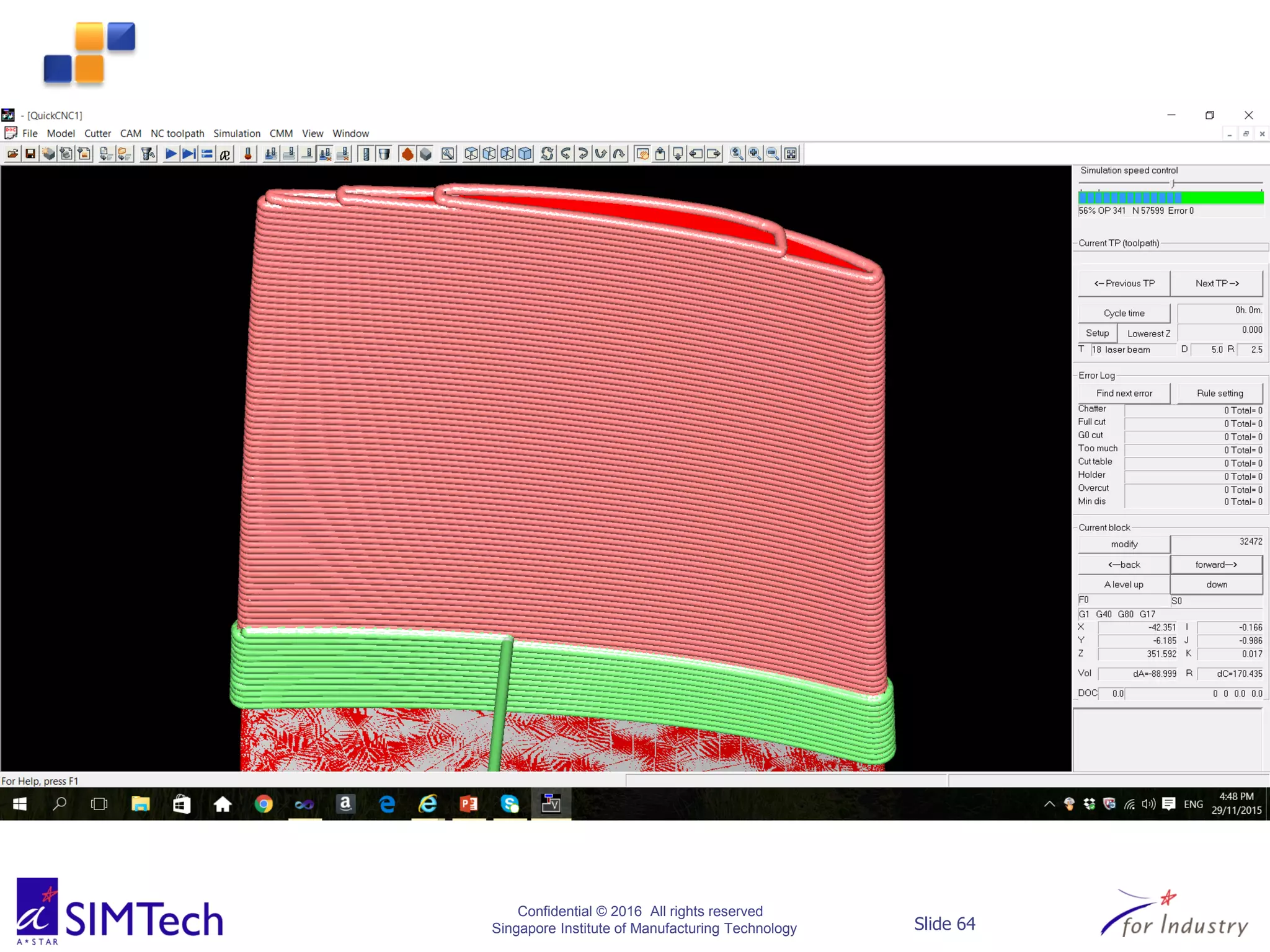

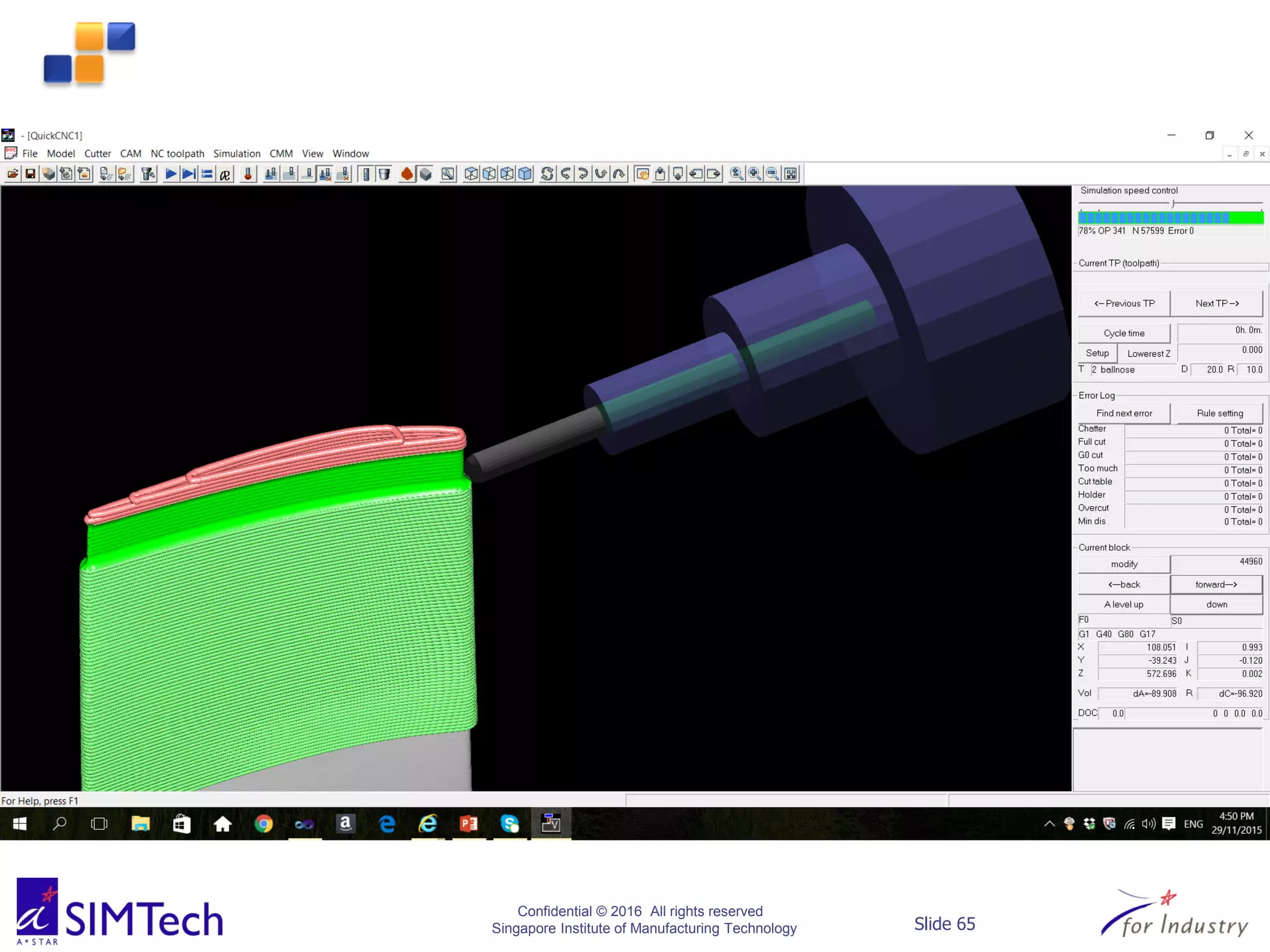

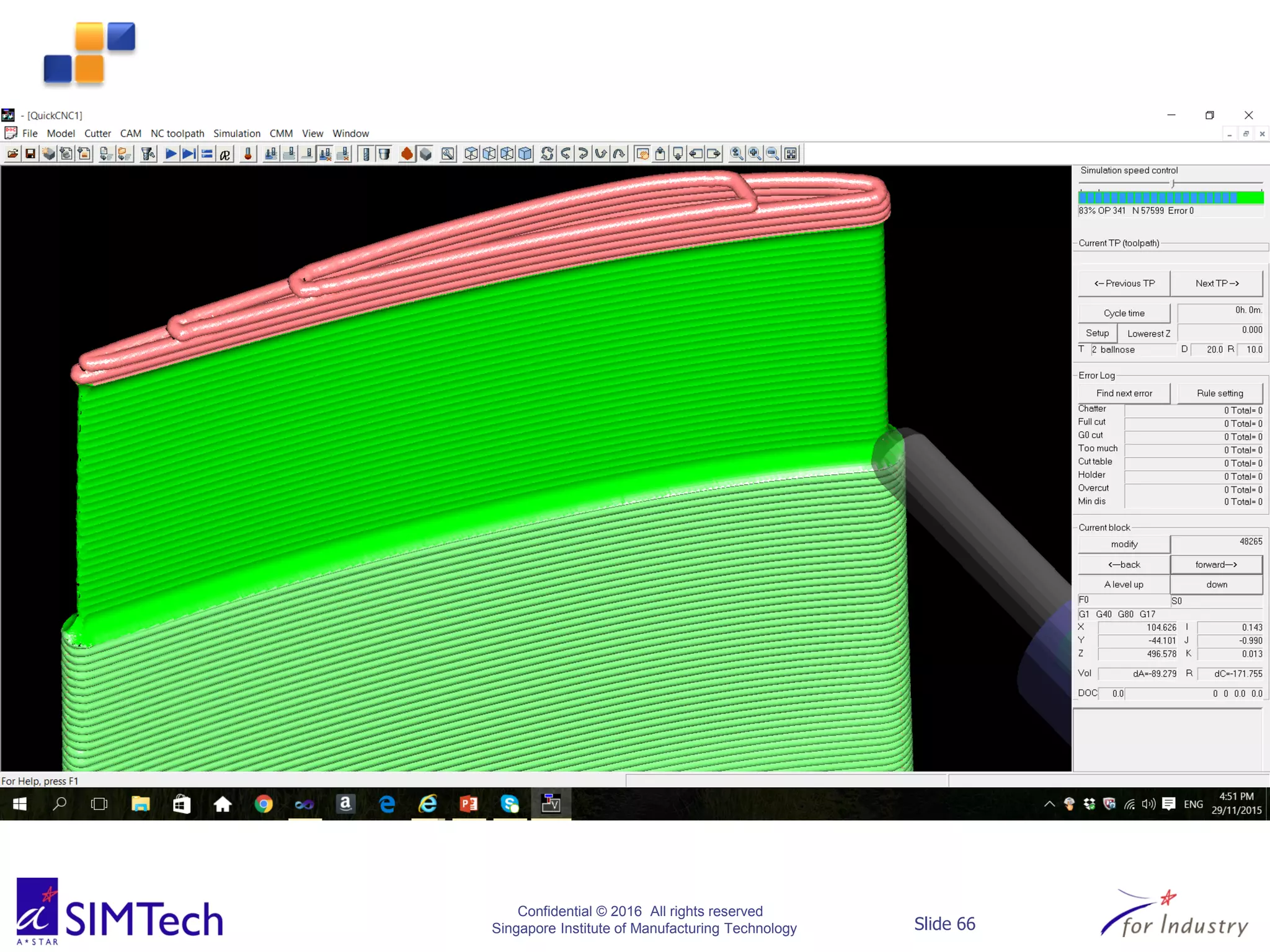

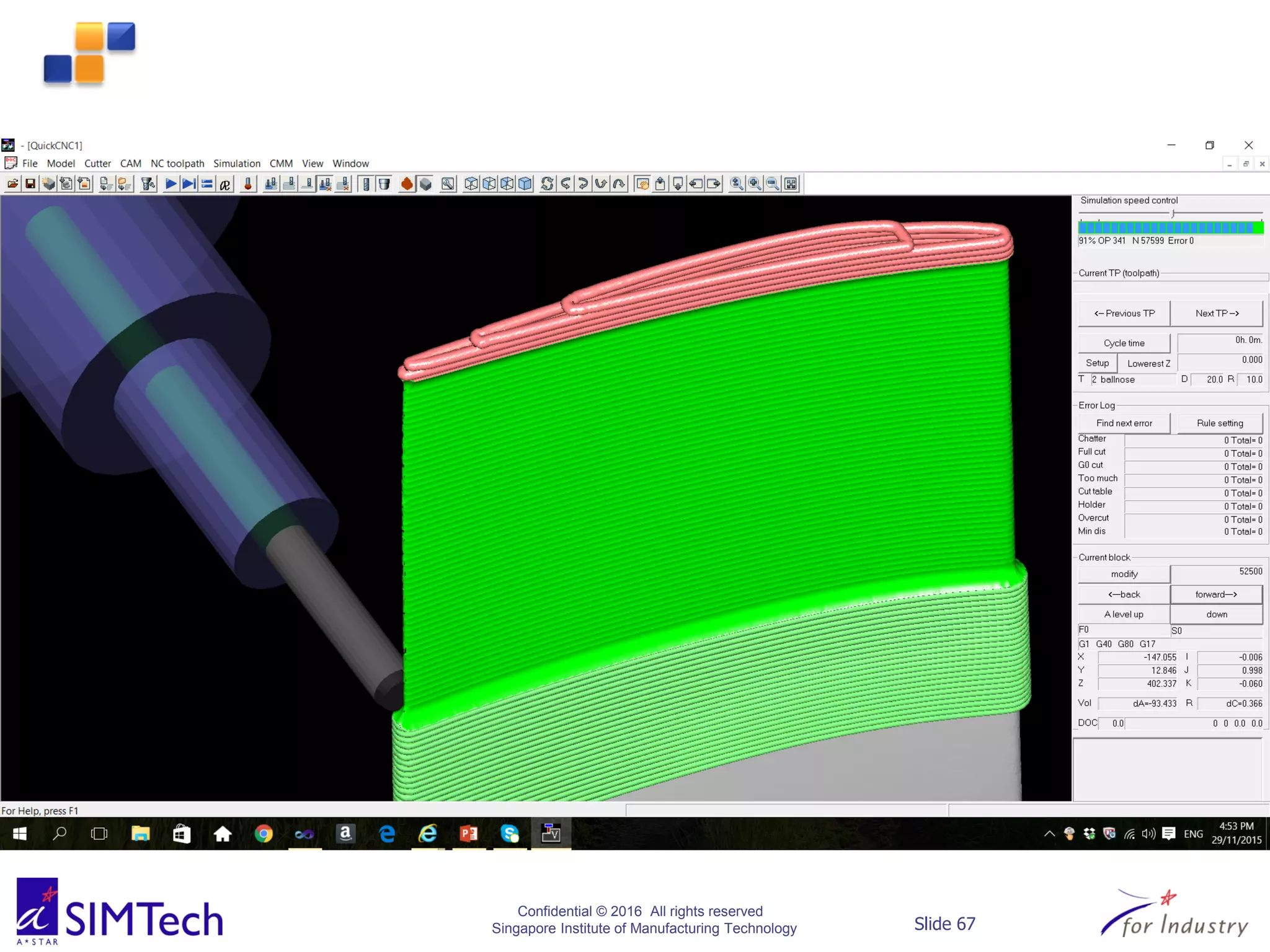

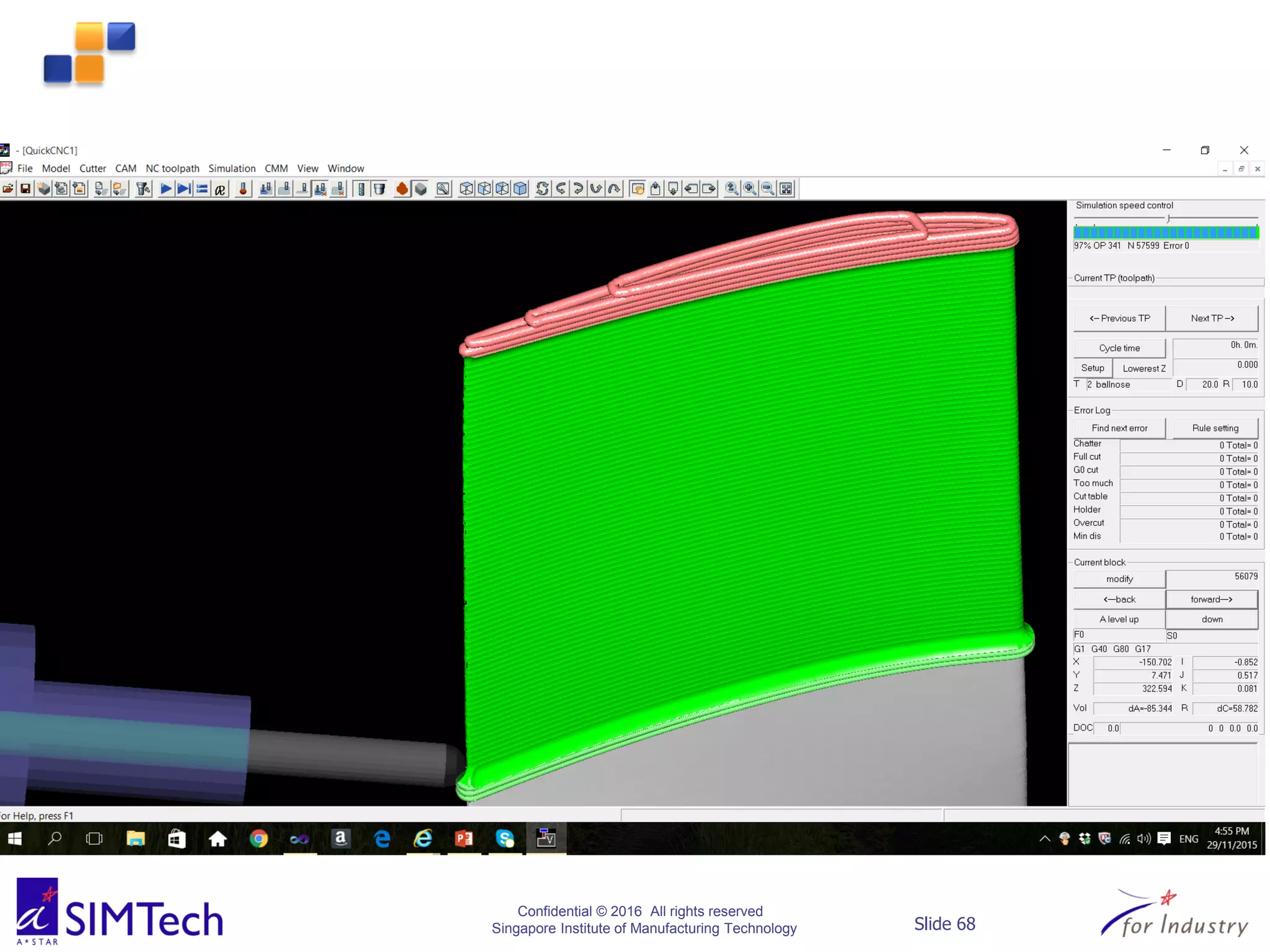

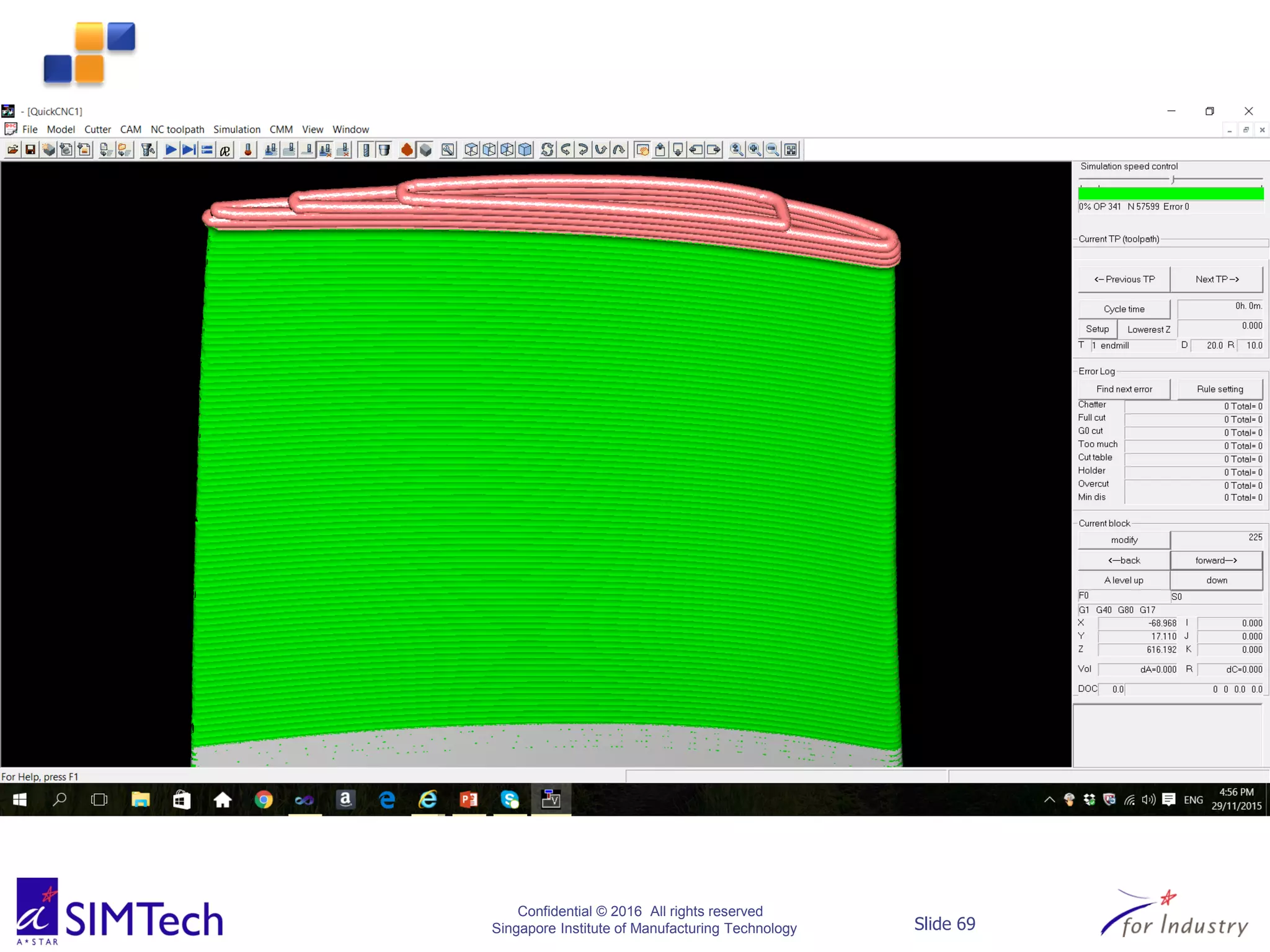

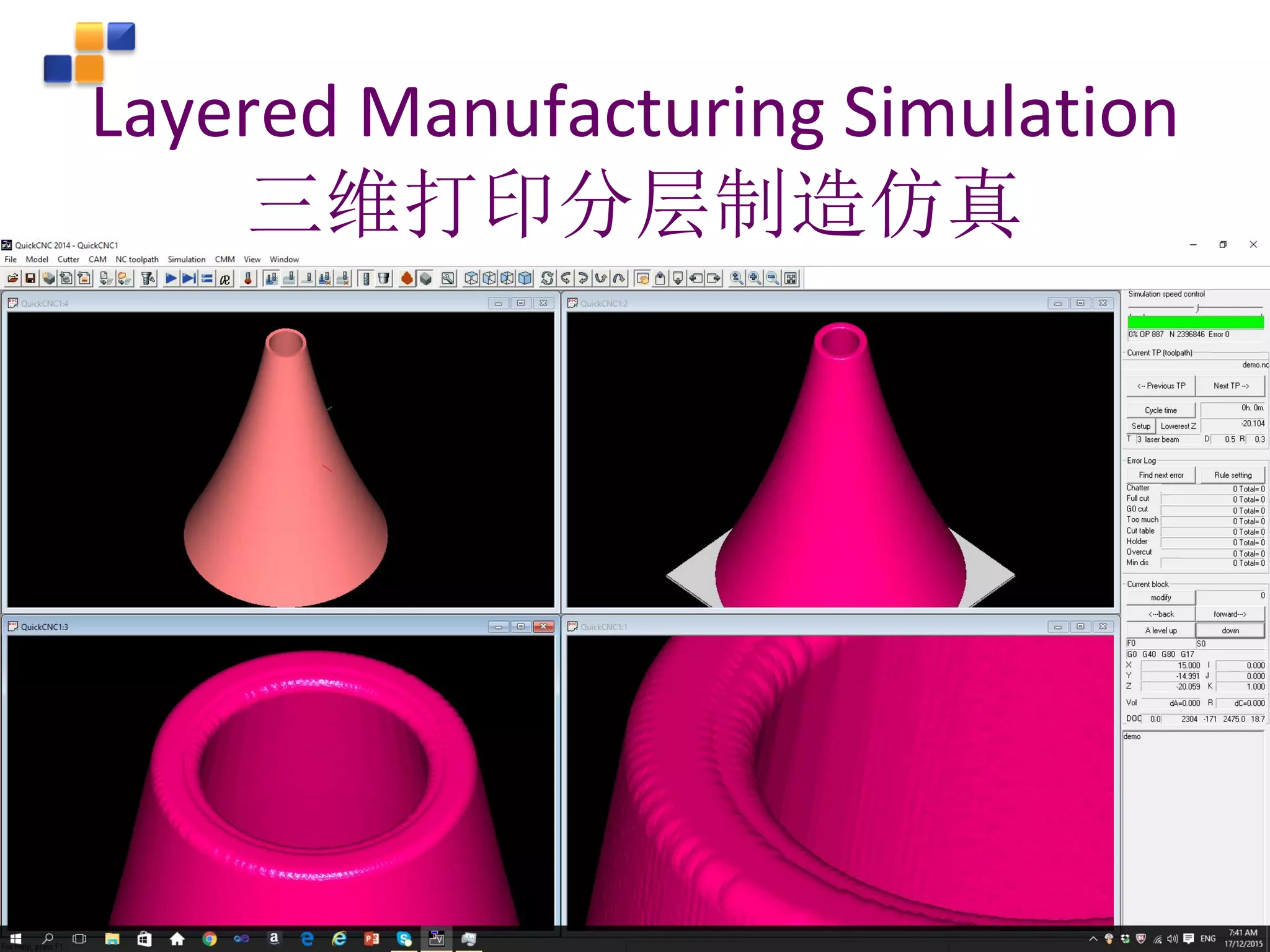

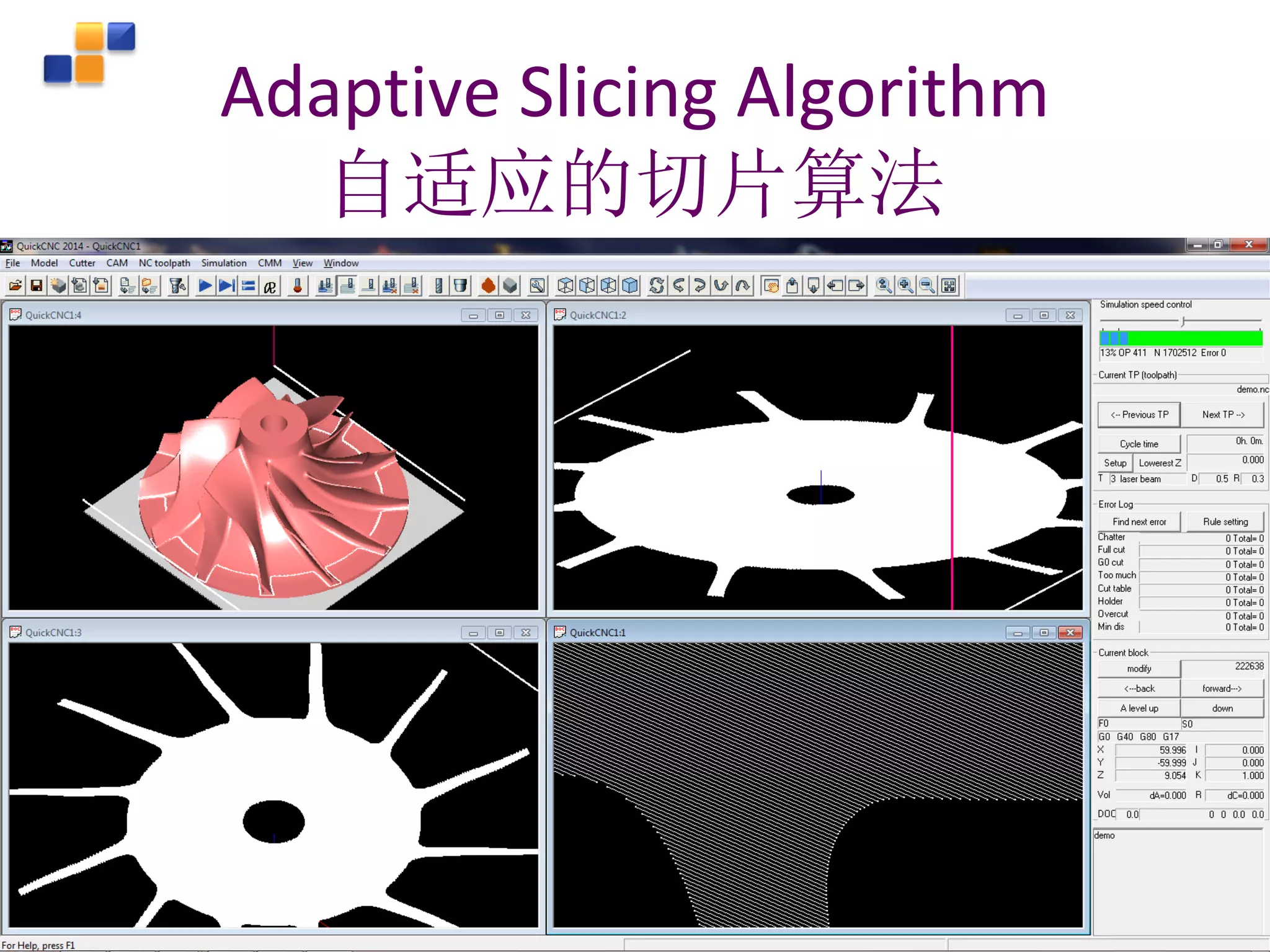

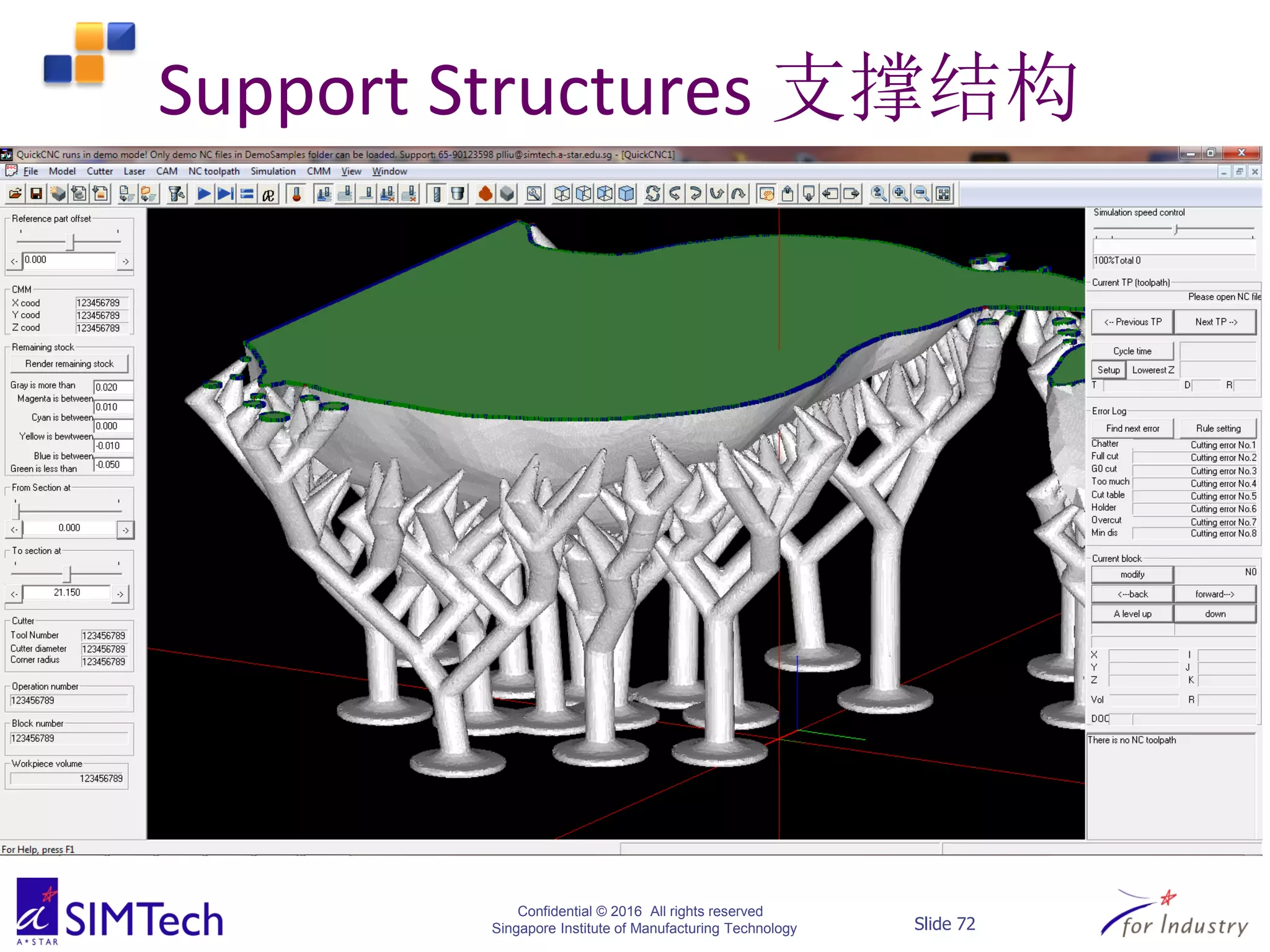

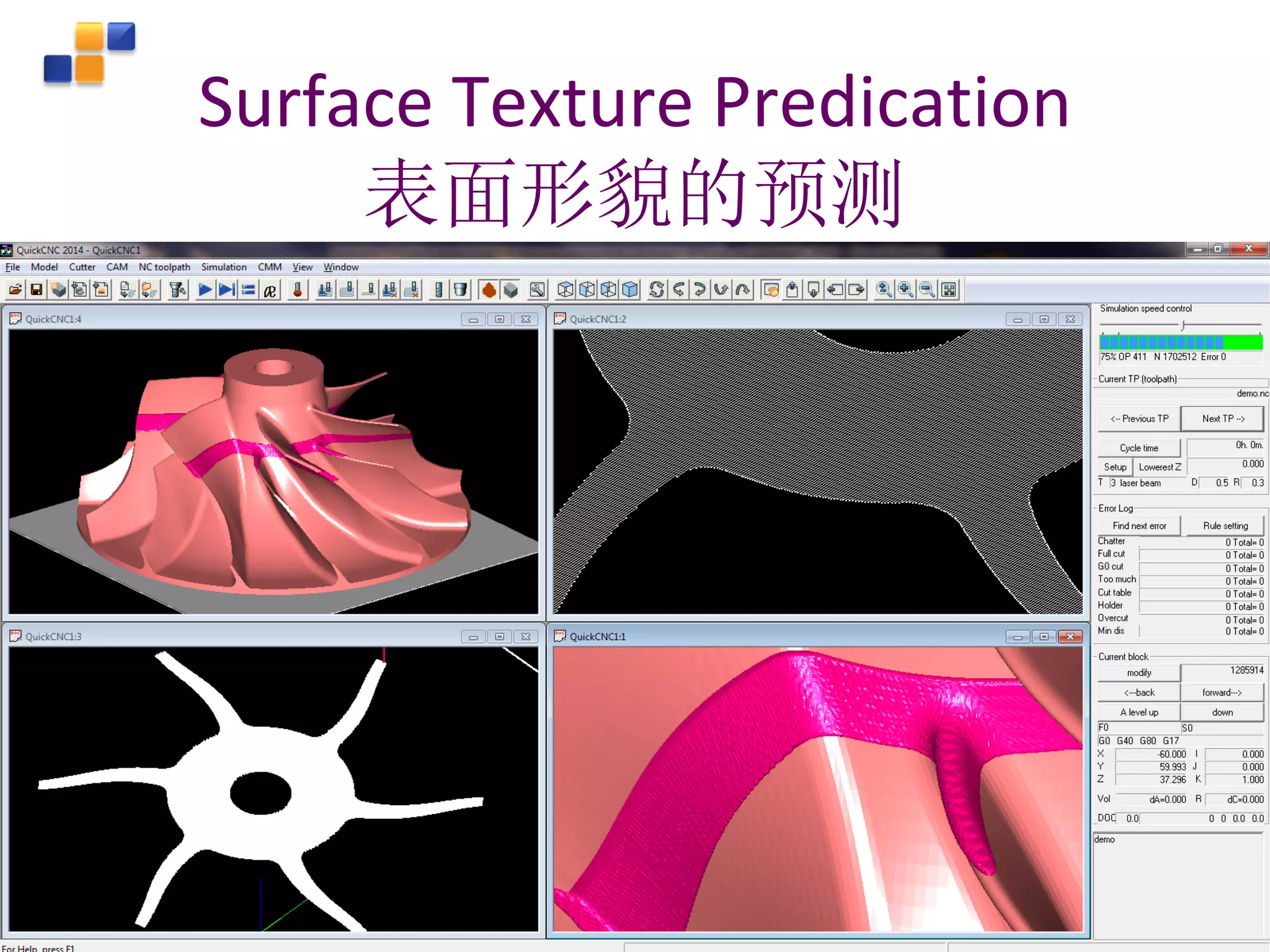

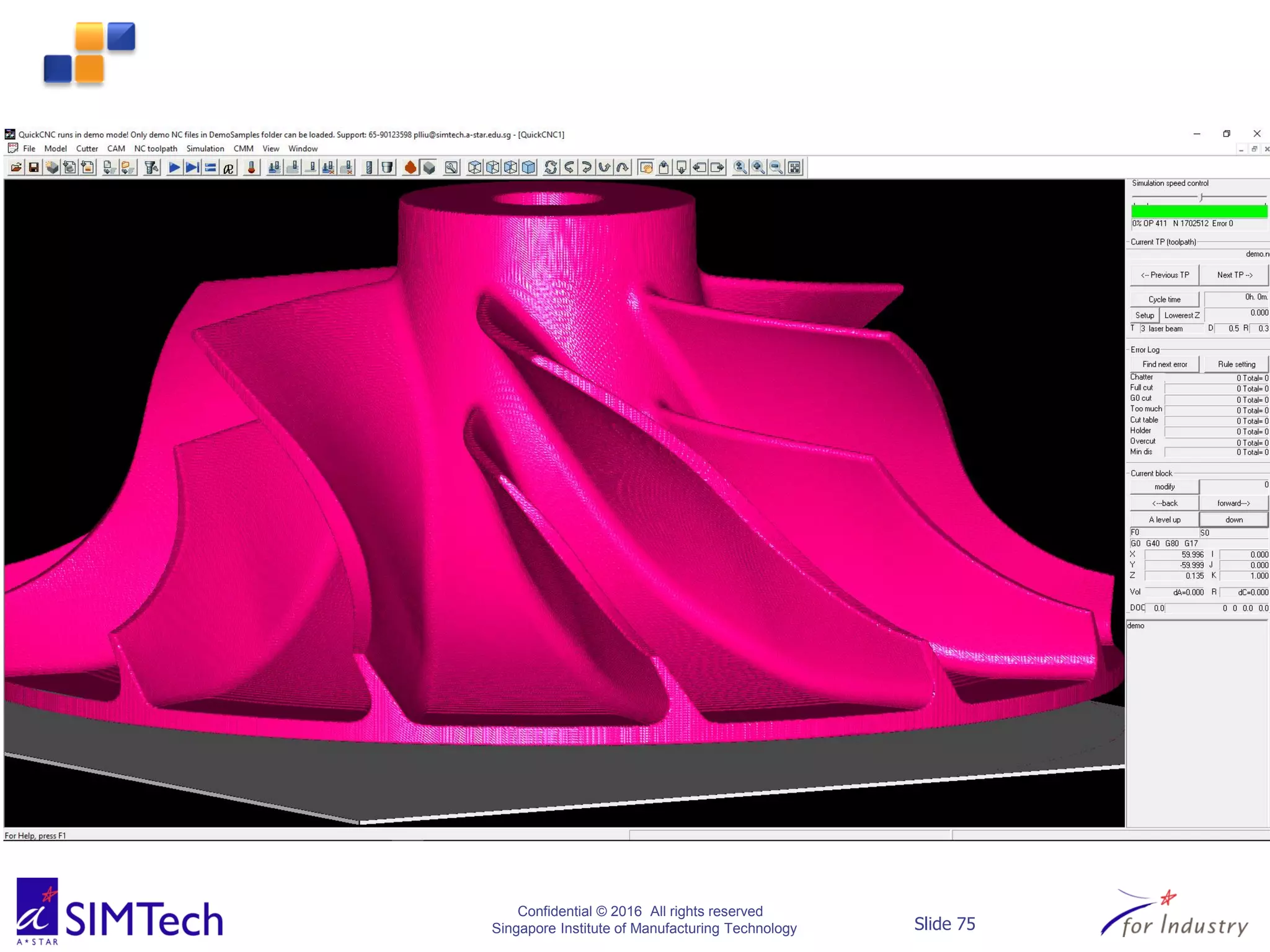

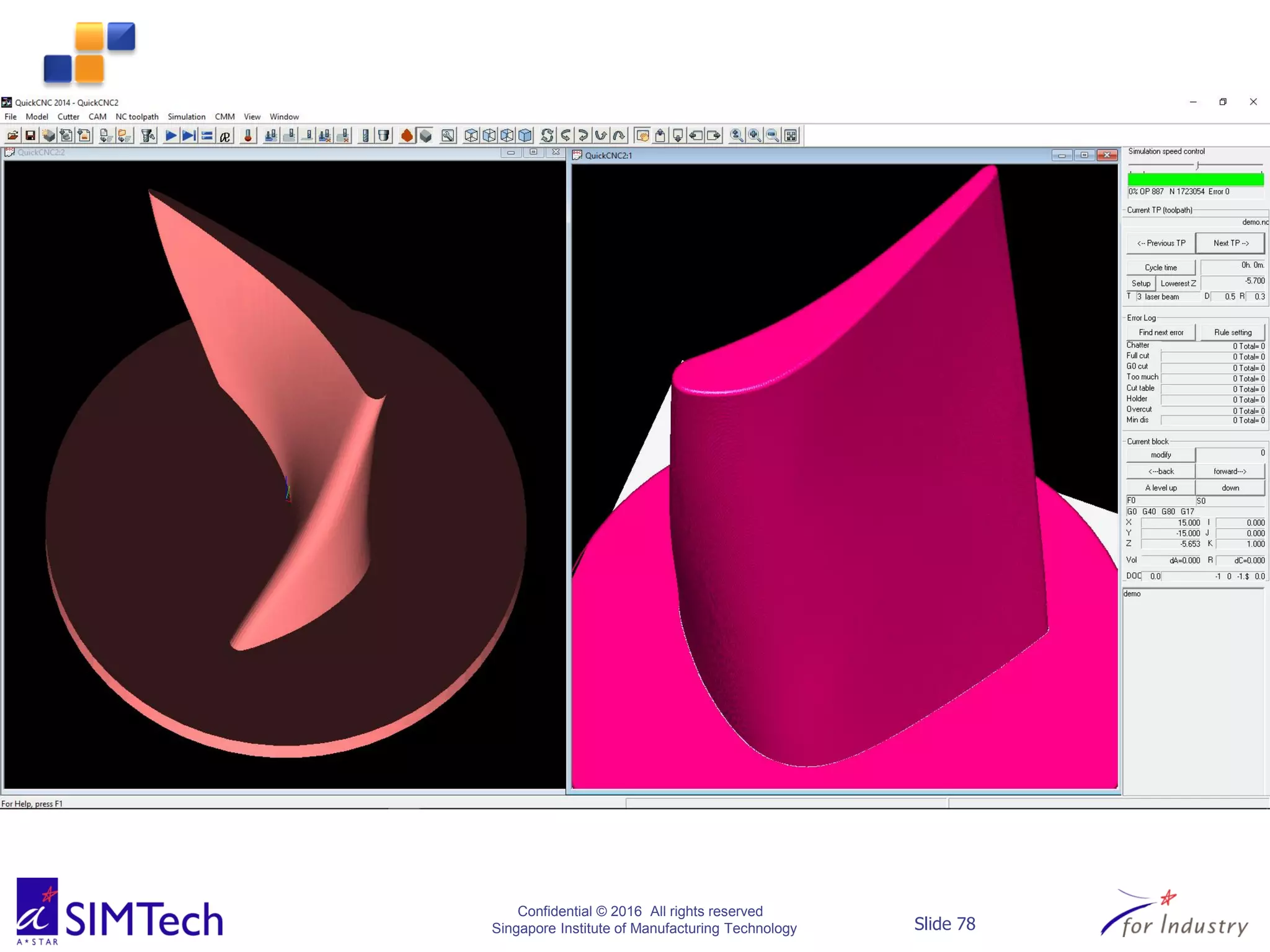

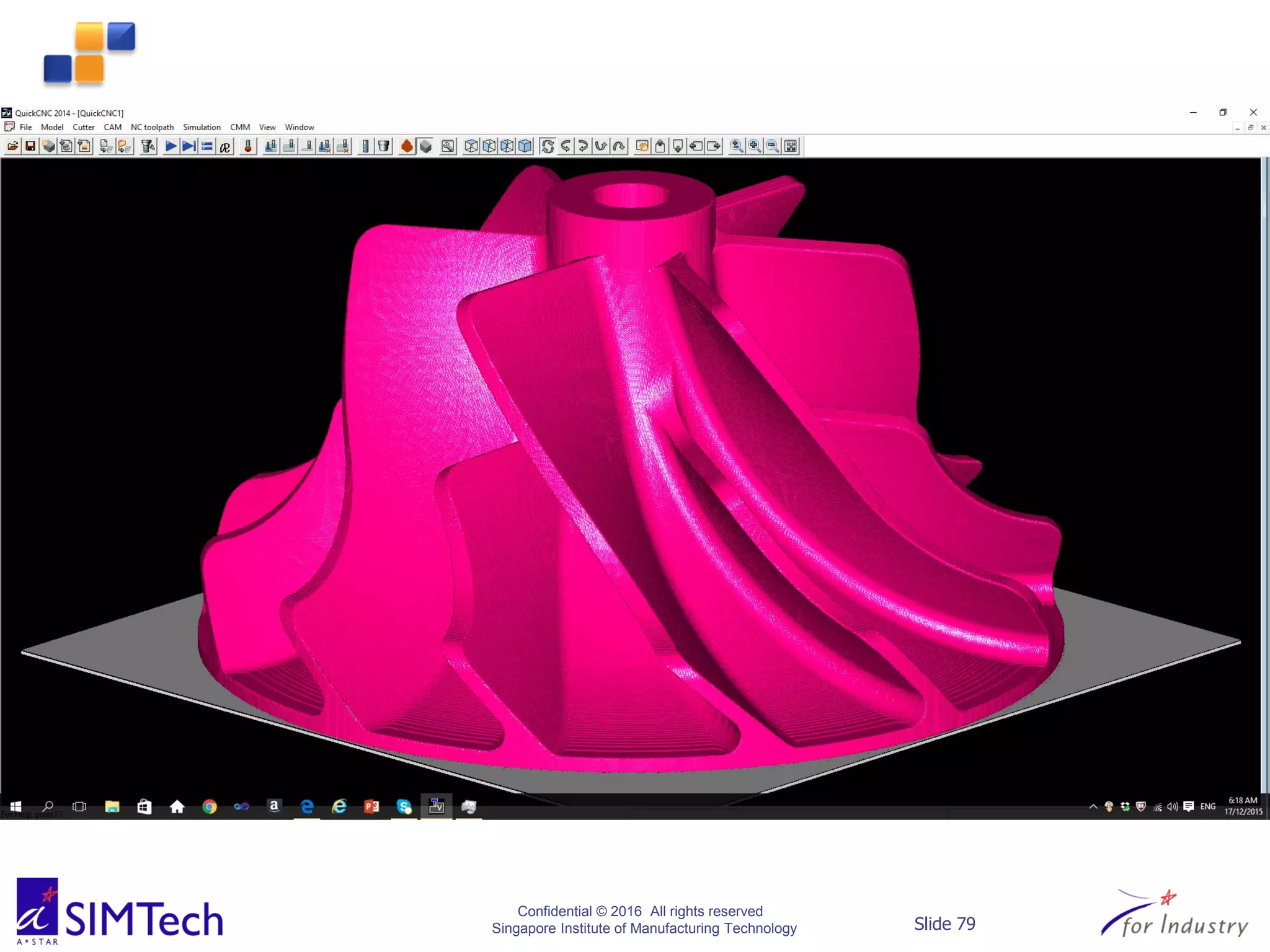

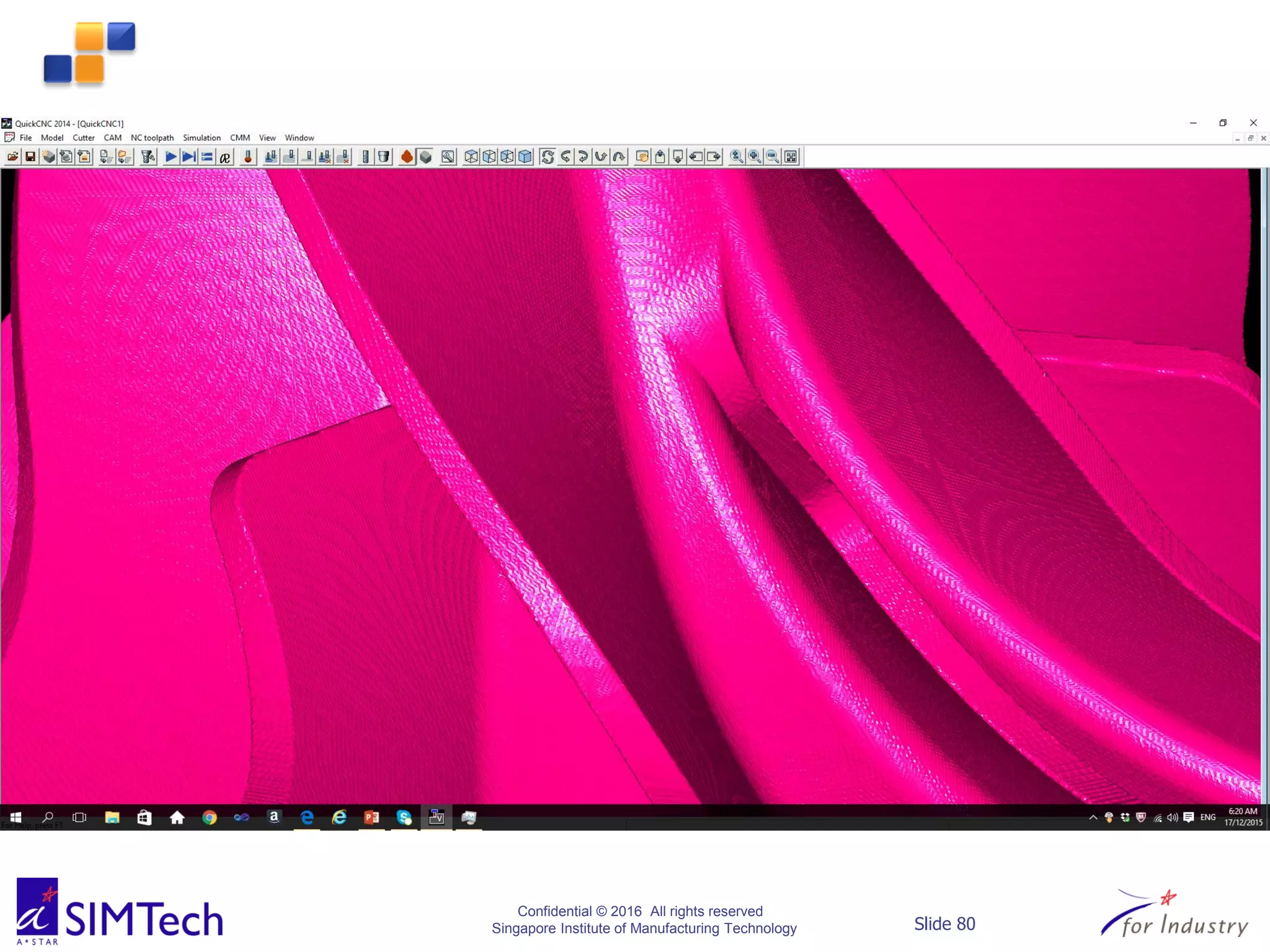

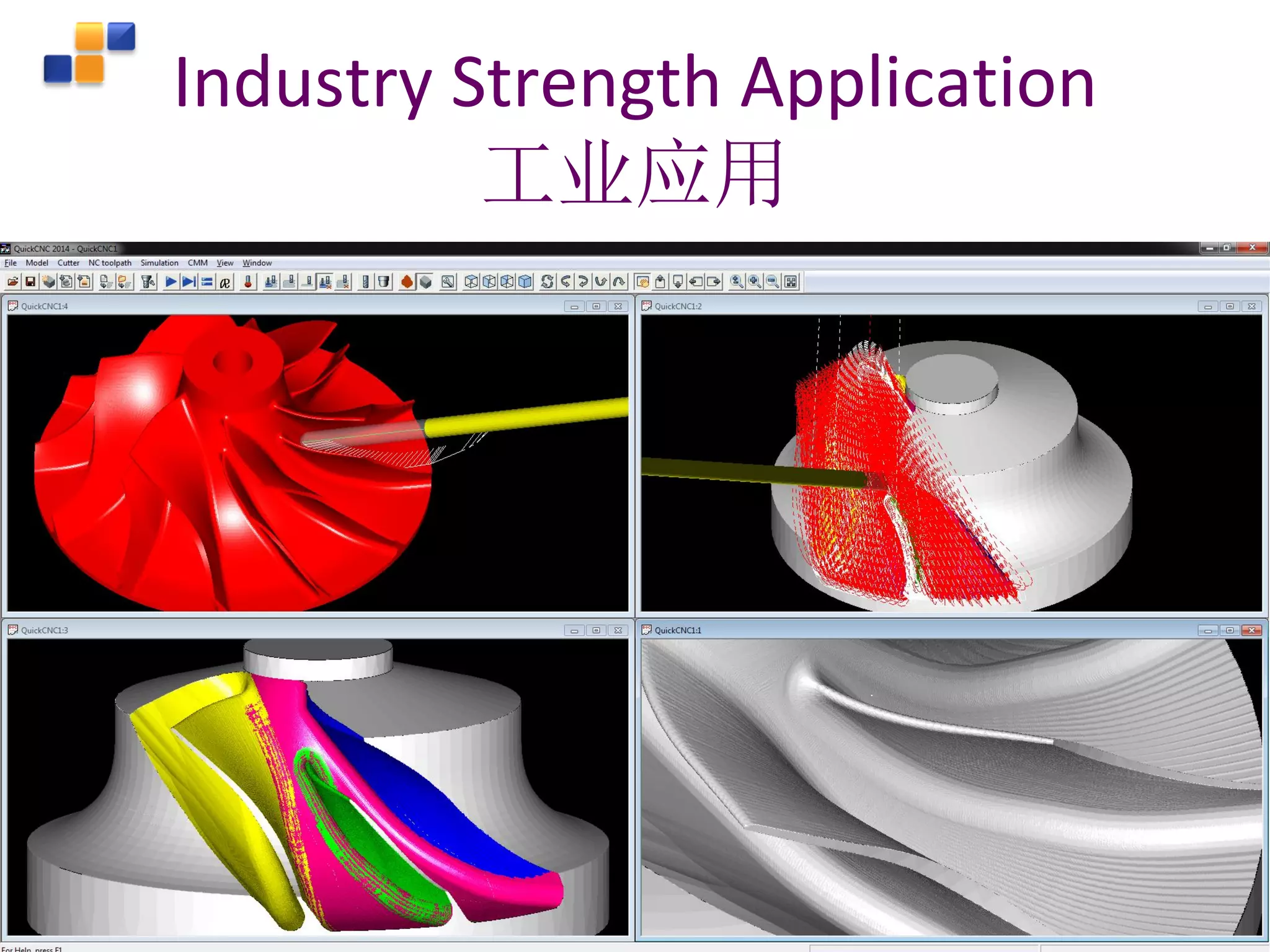

The document discusses advancements in 5-axis 3D hybrid manufacturing automation, focusing on the integration of additive and subtractive processes to improve efficiency and precision in manufacturing complex parts. It highlights the need for simulation-based design and optimization to address challenges like quality and dimensional accuracy in additive manufacturing. The presentation outlines various technologies and methodologies developed at the Singapore Institute of Manufacturing Technology to enhance manufacturing capabilities.