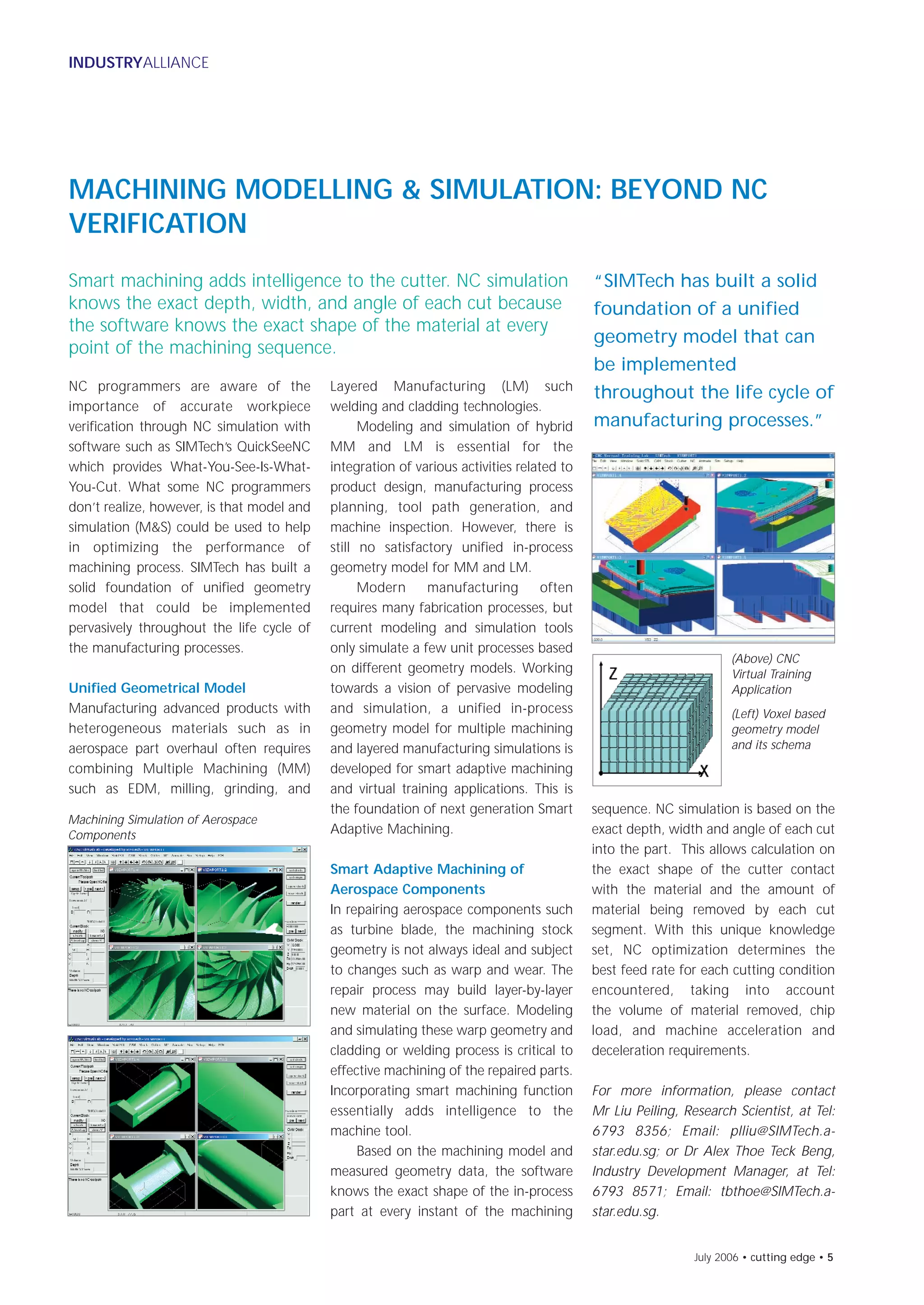

The document discusses advancements in machining modeling and simulation, highlighting the need for a unified in-process geometry model for both machining and layered manufacturing to enhance product design and manufacturing efficiency. It emphasizes the importance of smart adaptive machining, particularly in aerospace applications where repair processes involve complex geometries. Simtech has developed a robust unified geometry model to optimize machining performance through accurate simulations of cutting conditions and material interactions.