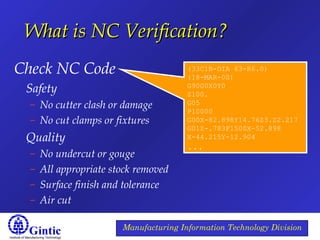

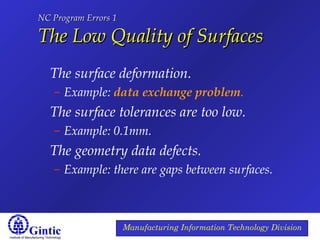

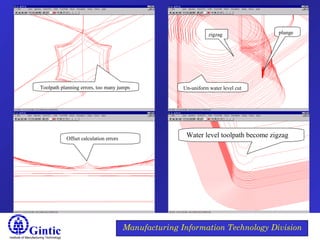

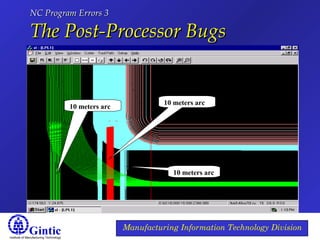

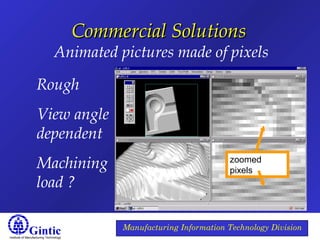

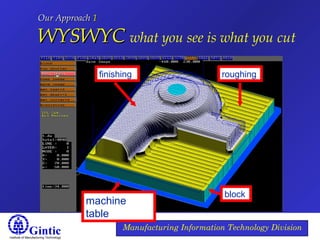

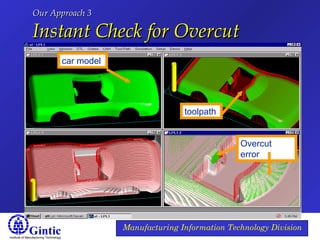

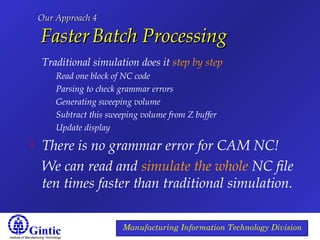

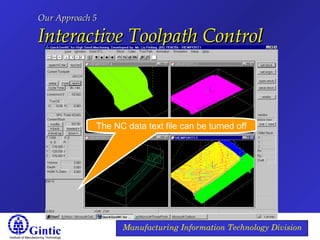

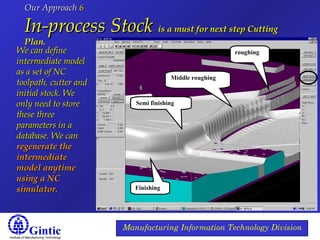

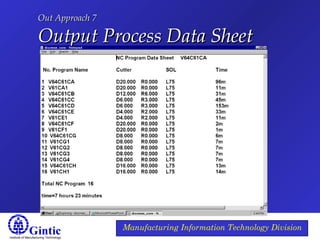

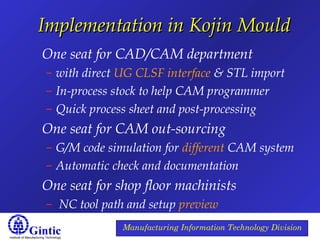

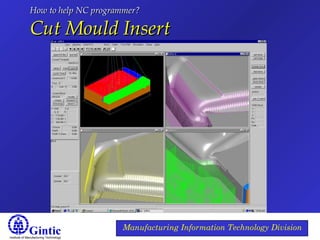

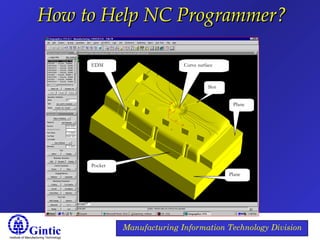

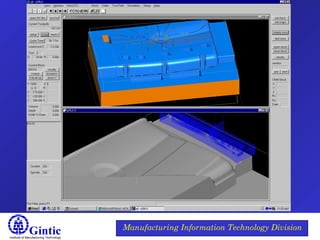

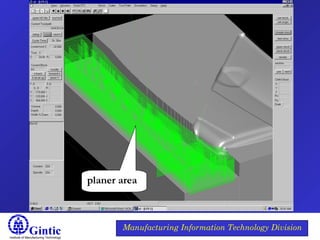

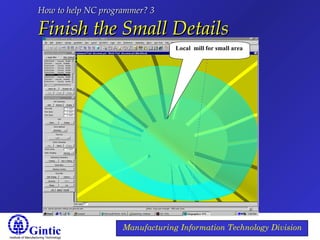

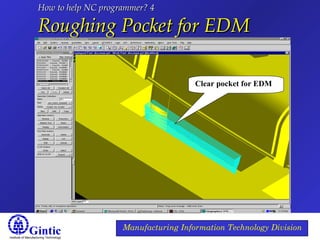

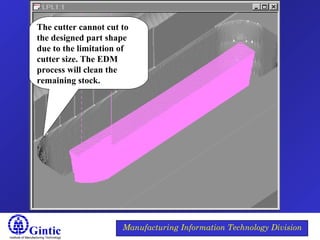

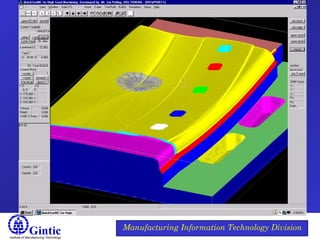

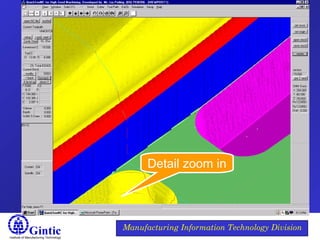

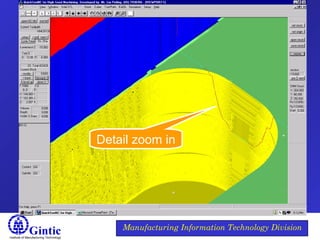

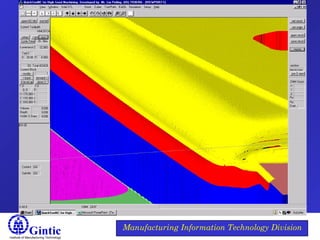

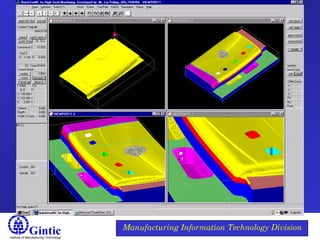

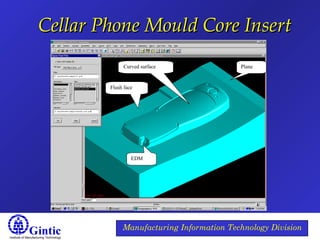

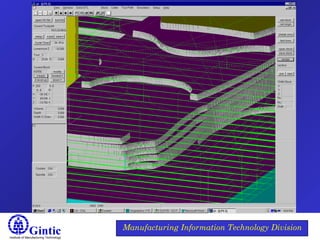

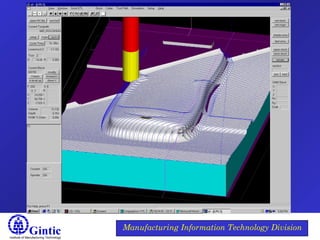

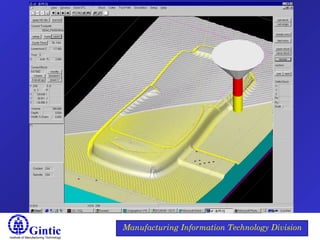

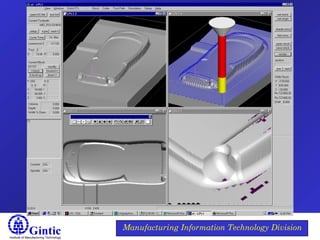

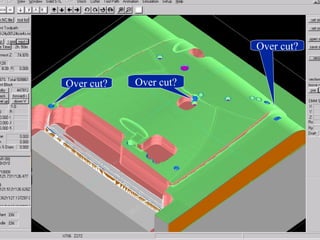

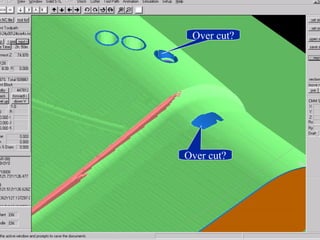

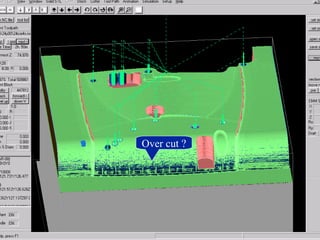

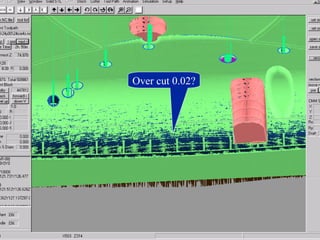

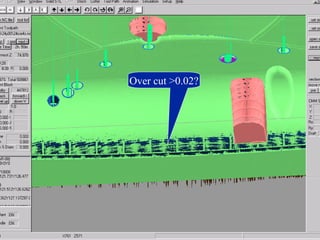

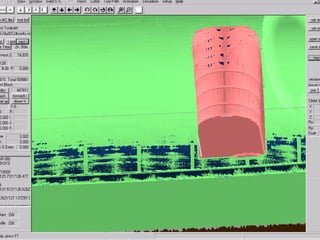

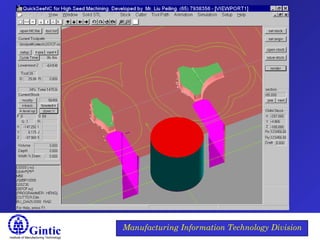

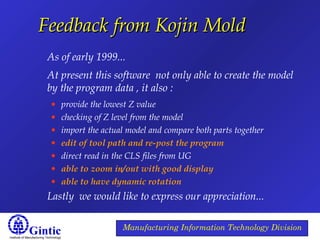

The document discusses a case study on Kojin Mould, a manufacturer of plastic molds, highlighting the importance of NC (Numerical Control) verification in their processes. It identifies various NC program errors, the need for faster verification due to high-speed machining, and the requirements for their NC programs. The proposed solutions include innovative approaches for instant checks and efficient toolpath control to ensure quality and safety in their manufacturing operations.