The document summarizes the speaker's 30 years of experience in CAX (computer-aided design/engineering/manufacturing) developments. It discusses the speaker's contributions to unified modeling, simulation, verification and optimization. It provides an overview of technologies developed over the years including finite element analysis, computer-aided manufacturing, numerical control verification, and mold design. Examples of software developed are also mentioned.

![23/05/2016

9

Confidential © 2016 All rights reserved

Singapore Institute of Manufacturing Technology Slide 49

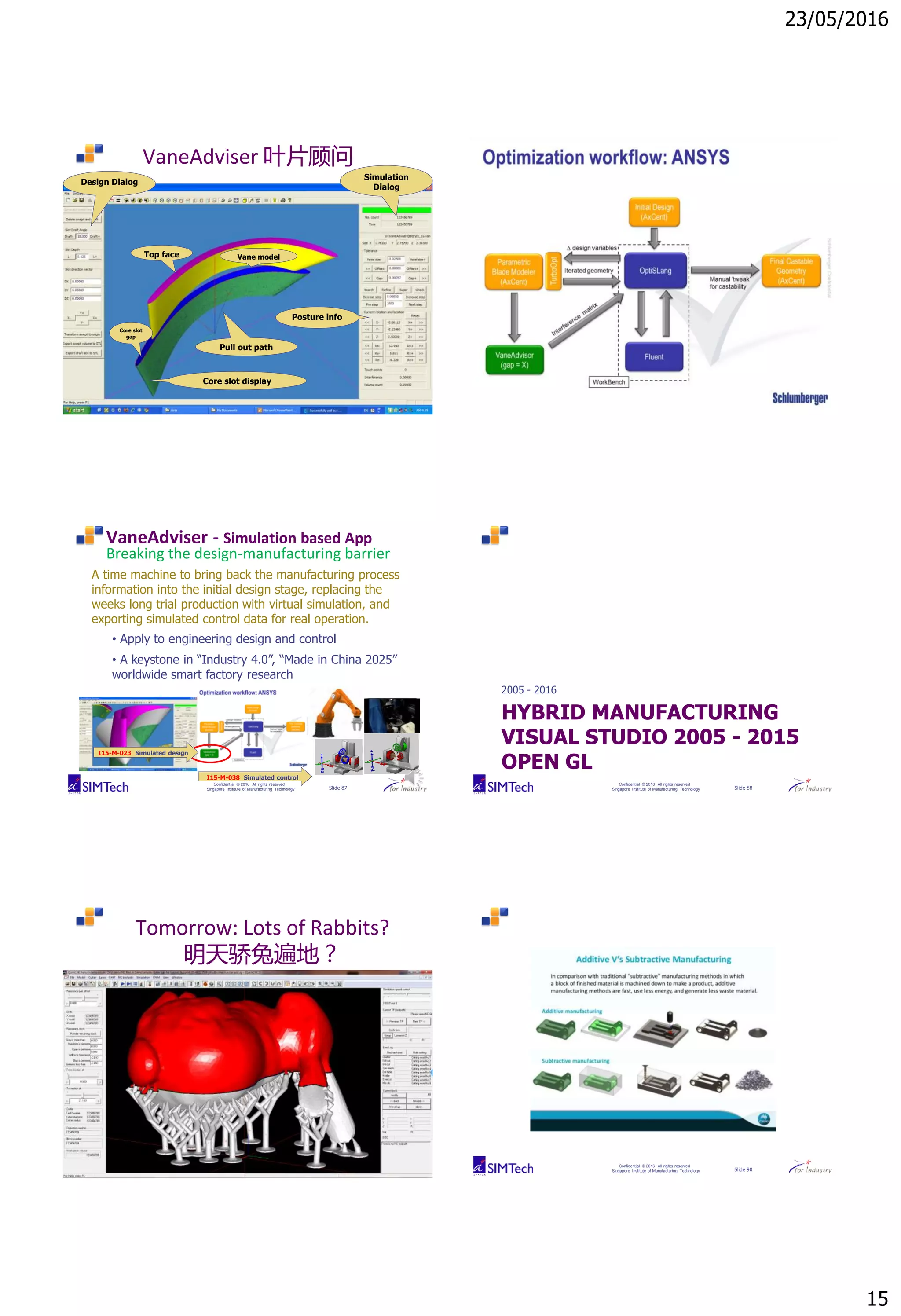

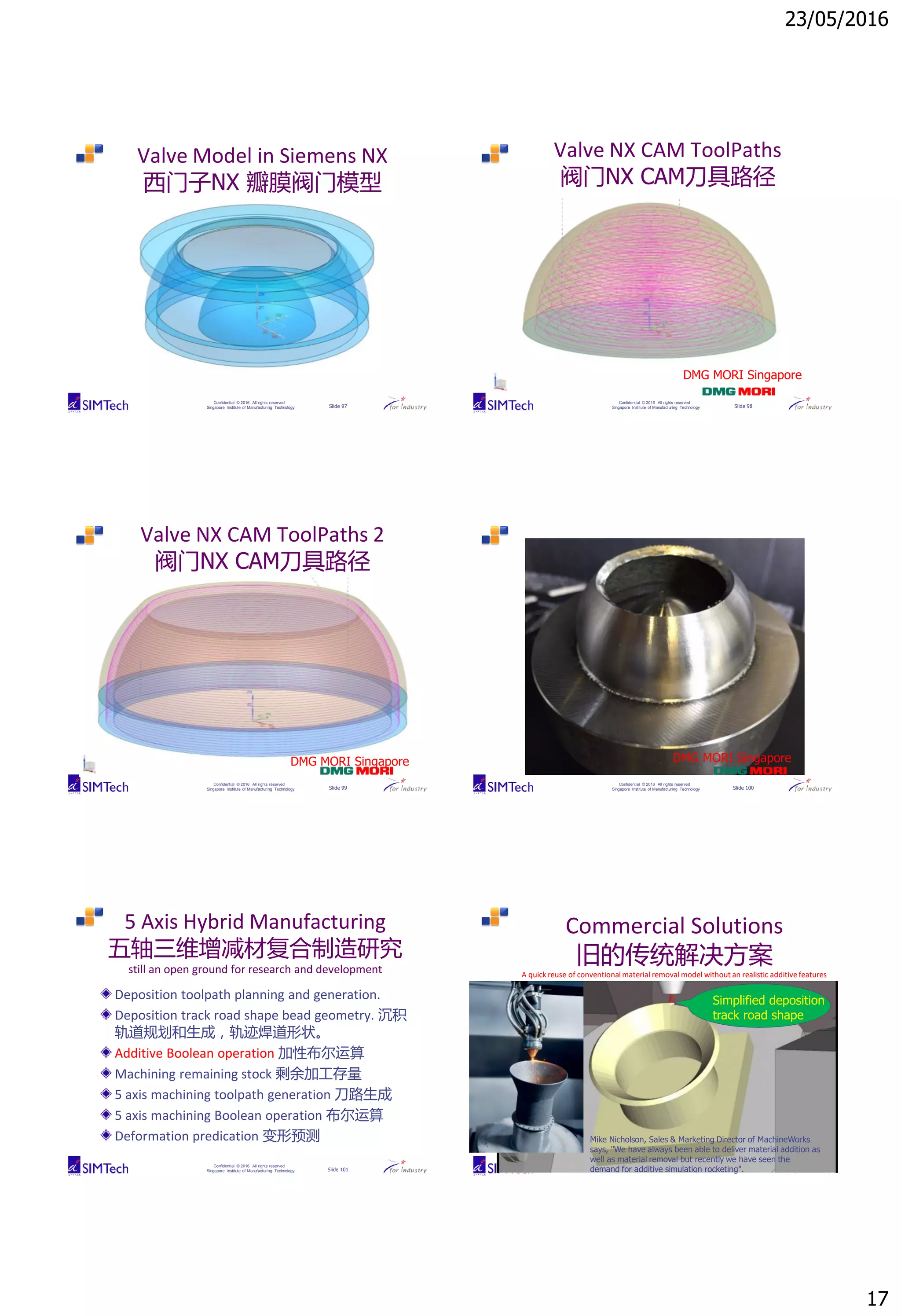

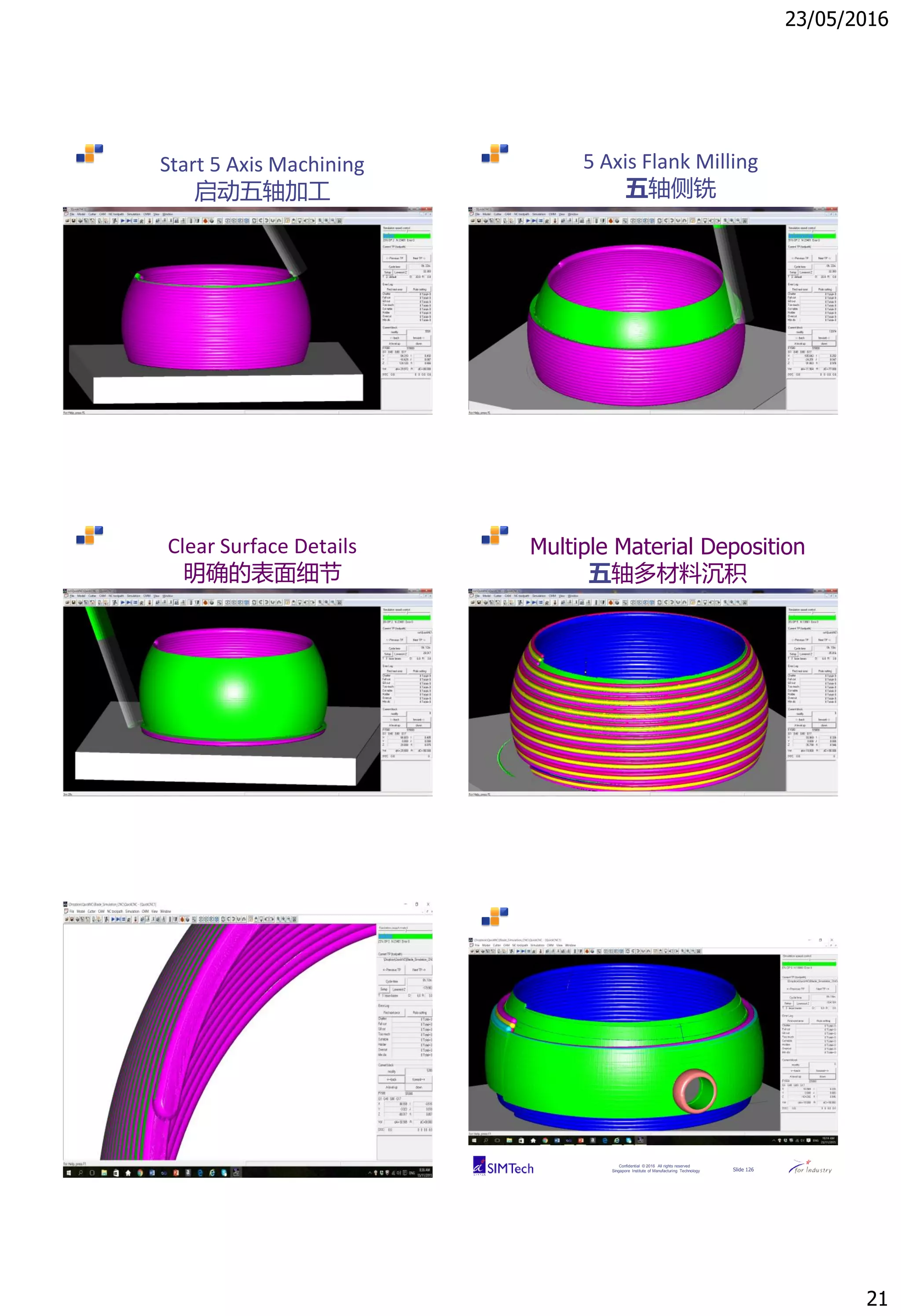

Create raw material from STL file of casting-forging part

Confidential © 2016 All rights reserved

Singapore Institute of Manufacturing Technology Slide 50

Automatic generate raw material around reference model

Confidential © 2016 All rights reserved

Singapore Institute of Manufacturing Technology Slide 51

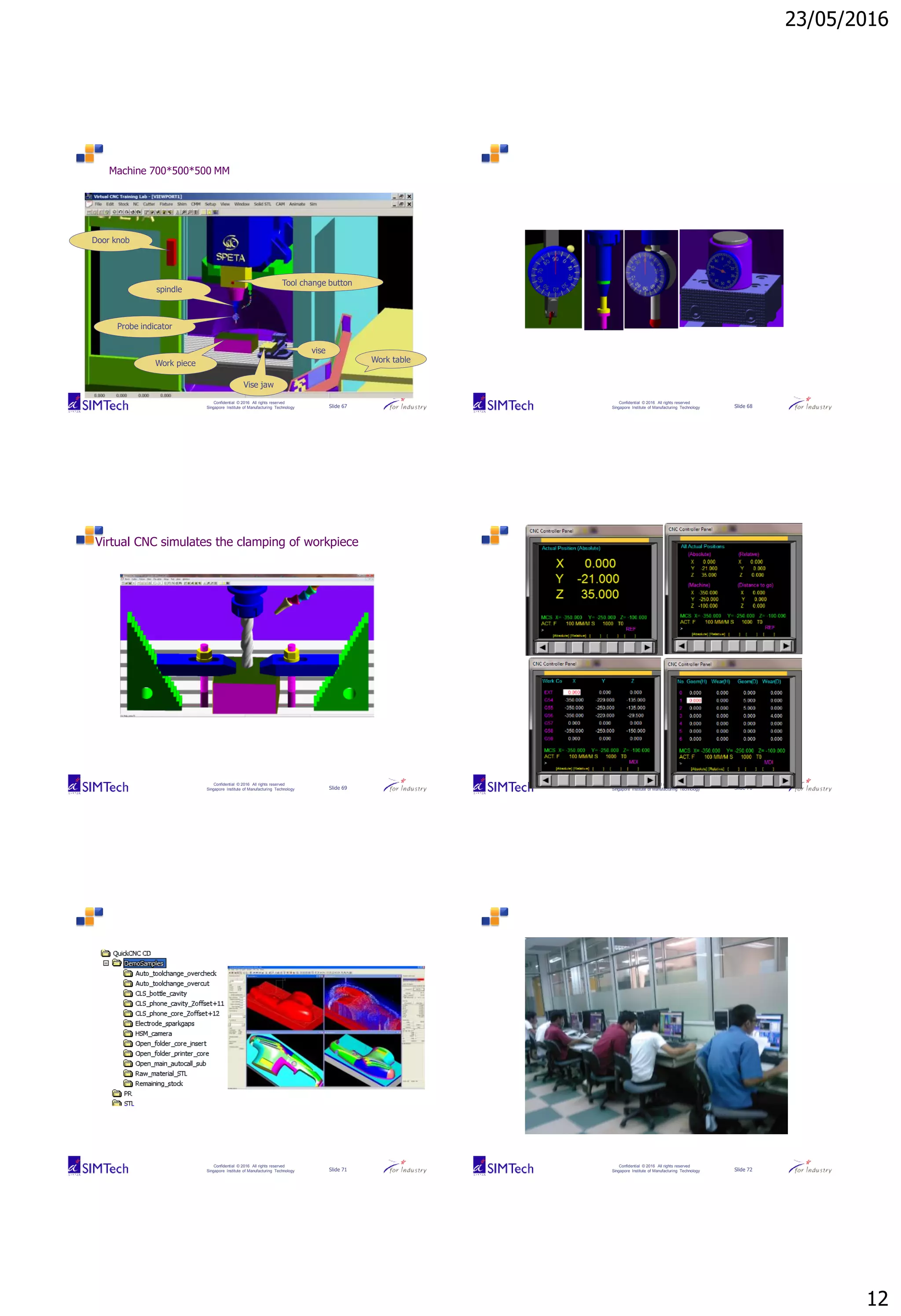

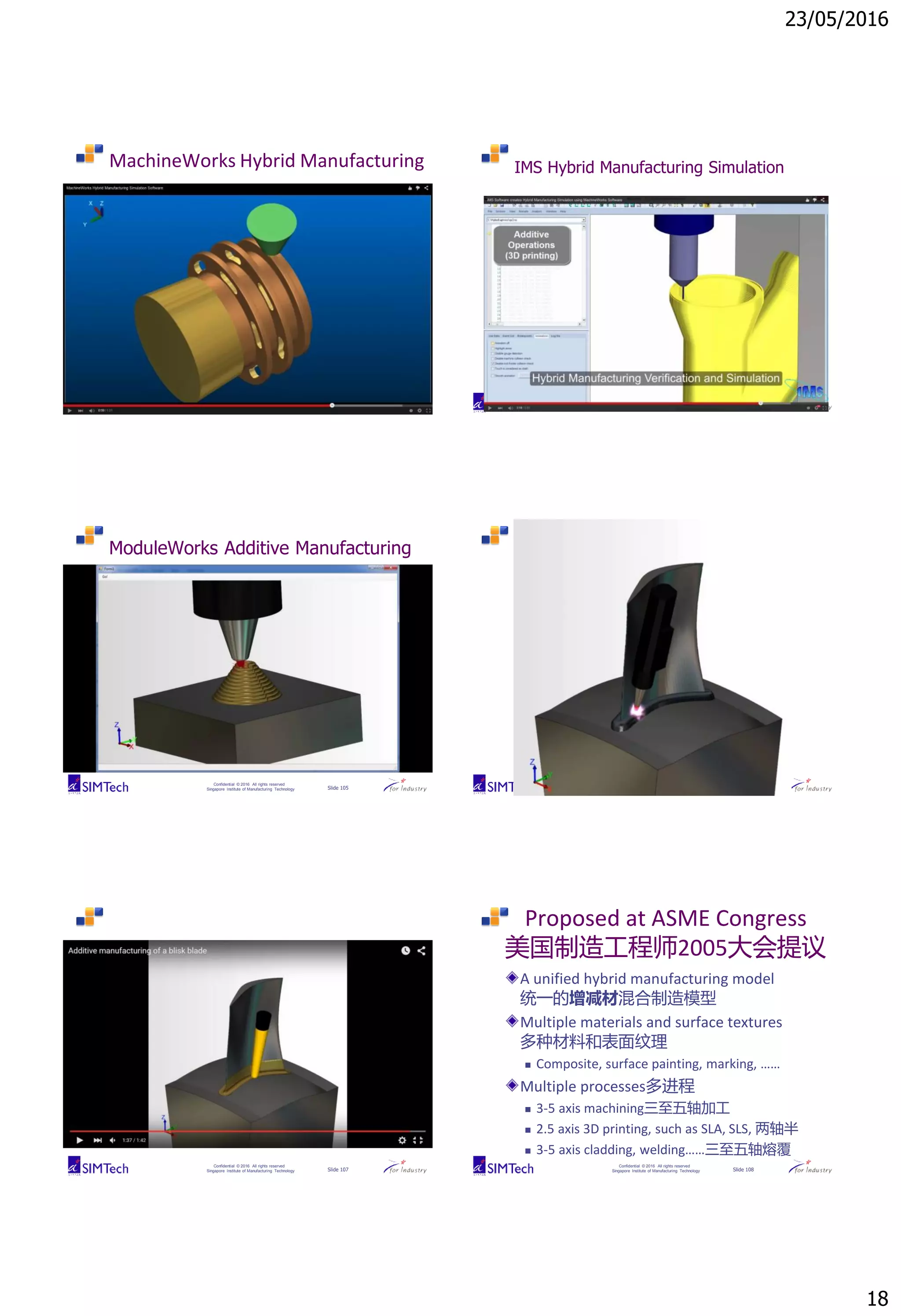

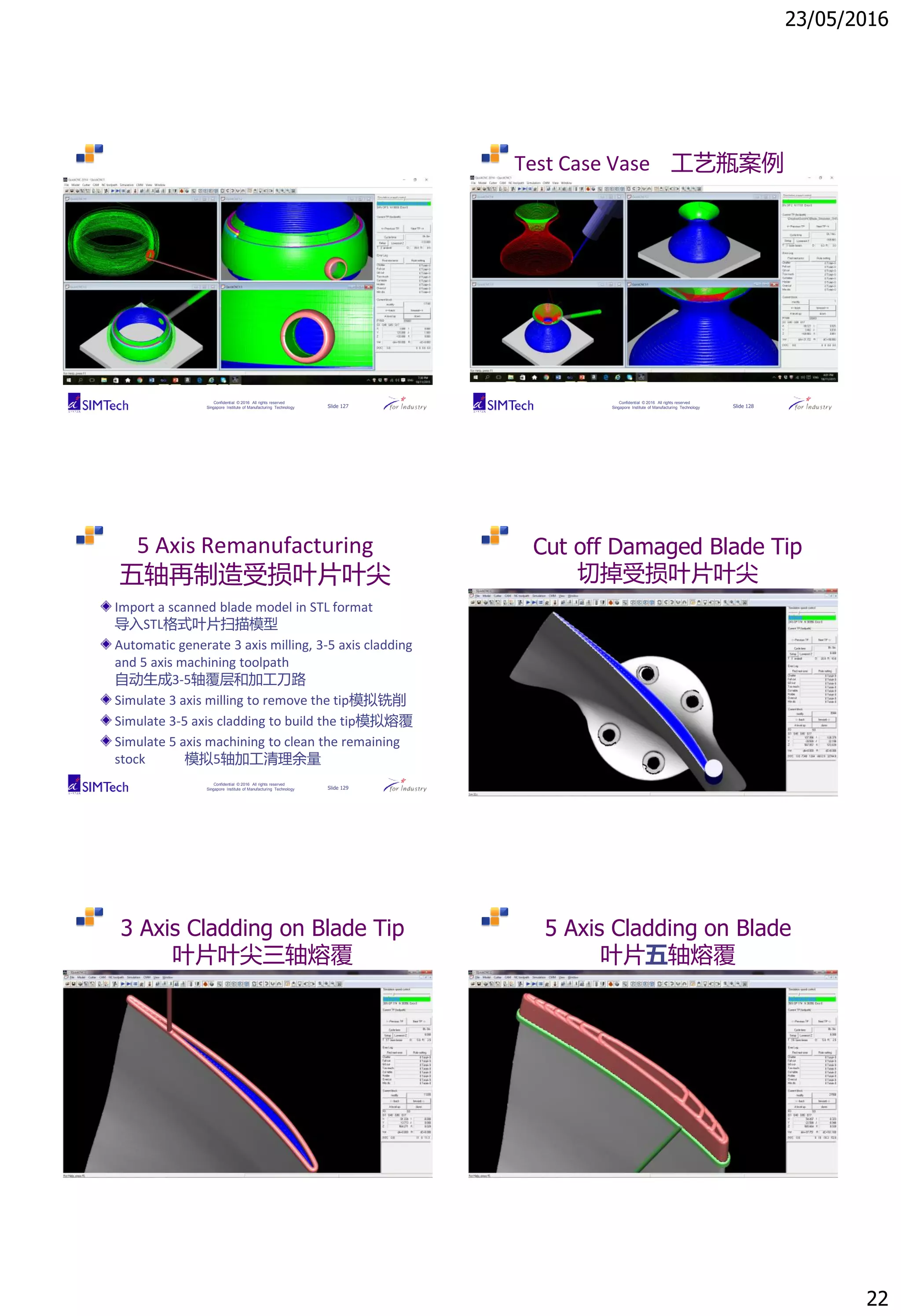

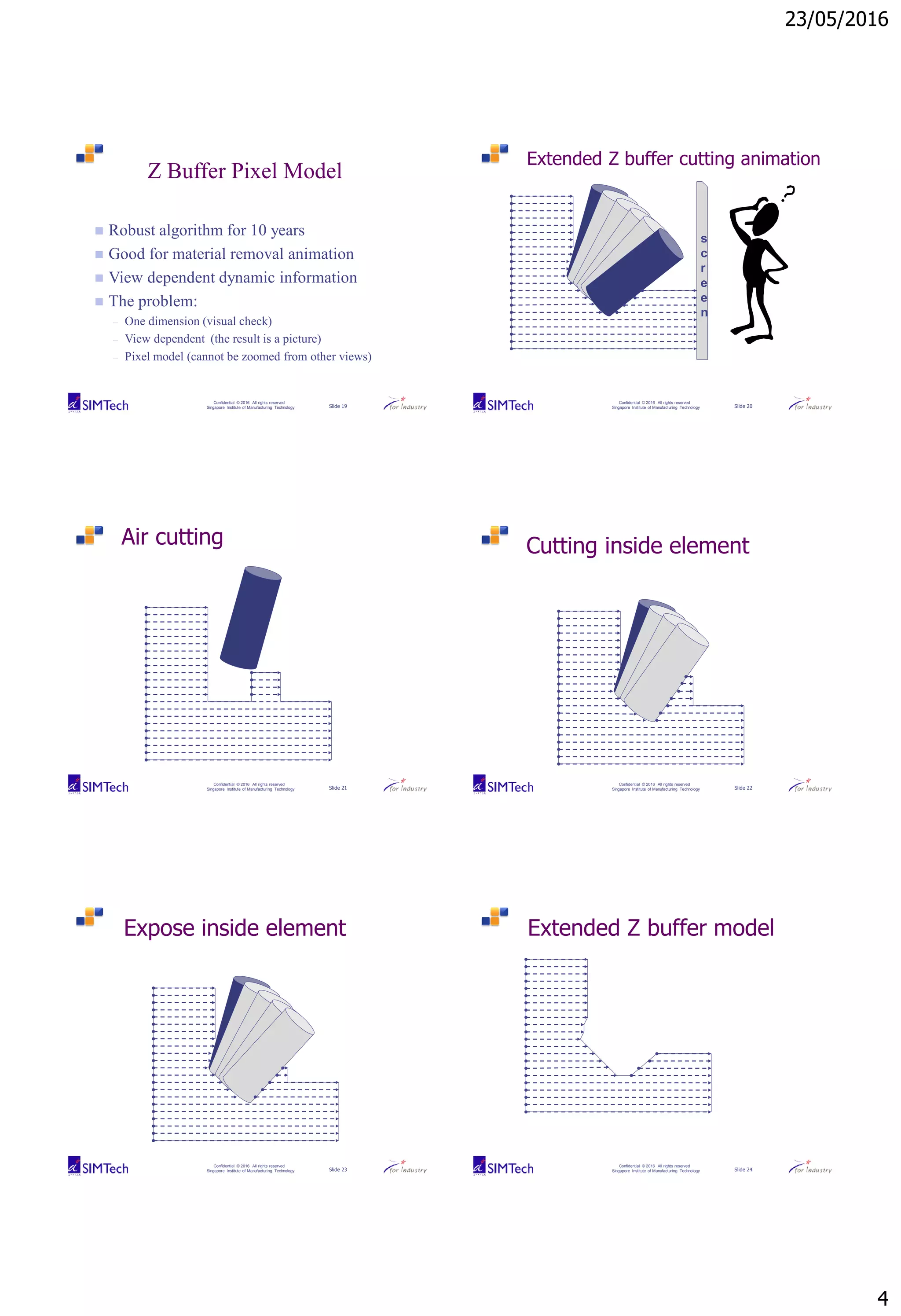

flute

Non cutting

FL

HD1 holder1

HL2

Angle > 0

CL

HD2 holder2

Angle < 0

HL

1

Confidential © 2016 All rights reserved

Singapore Institute of Manufacturing Technology Slide 52

Confidential © 2016 All rights reserved

Singapore Institute of Manufacturing Technology Slide 53

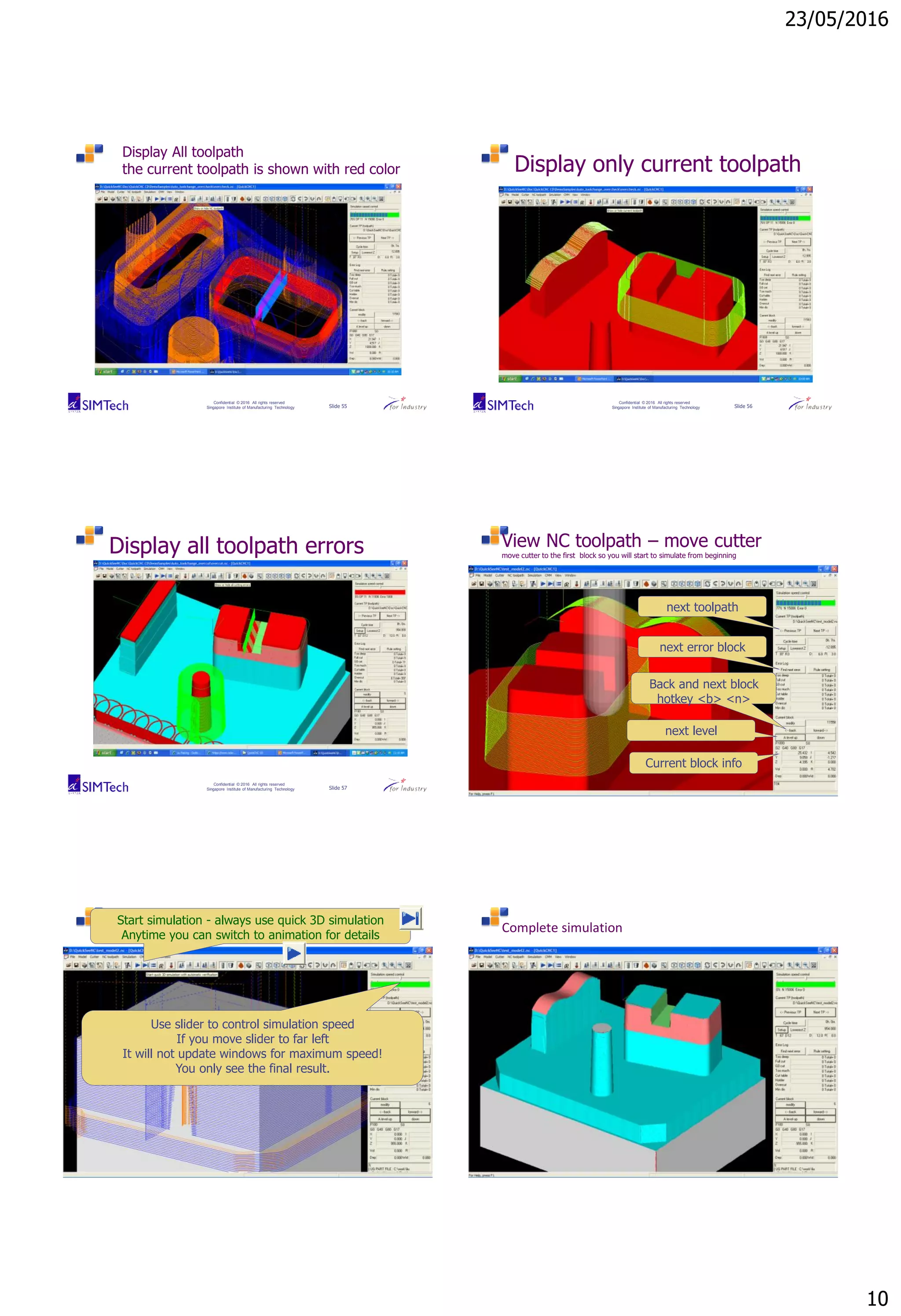

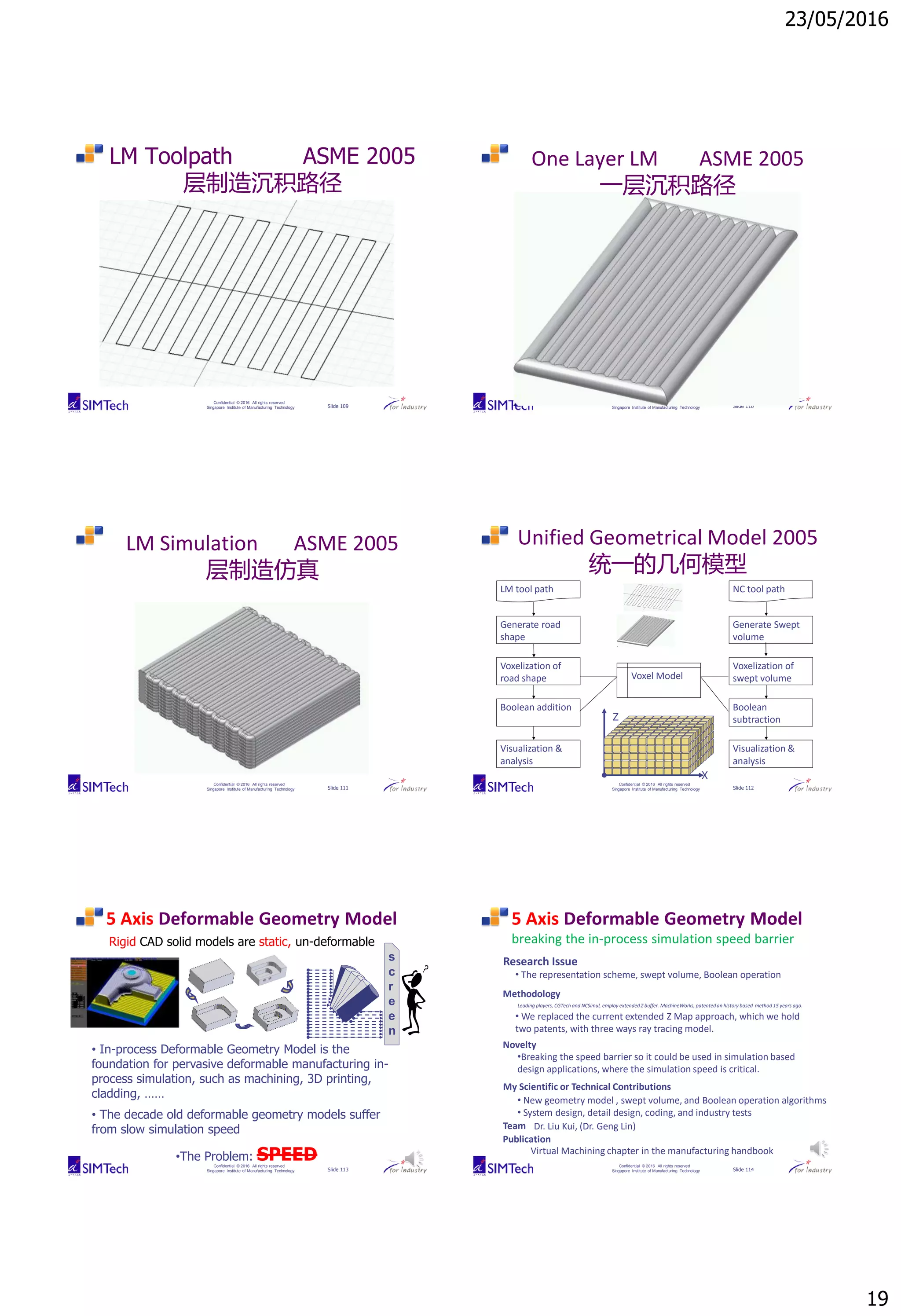

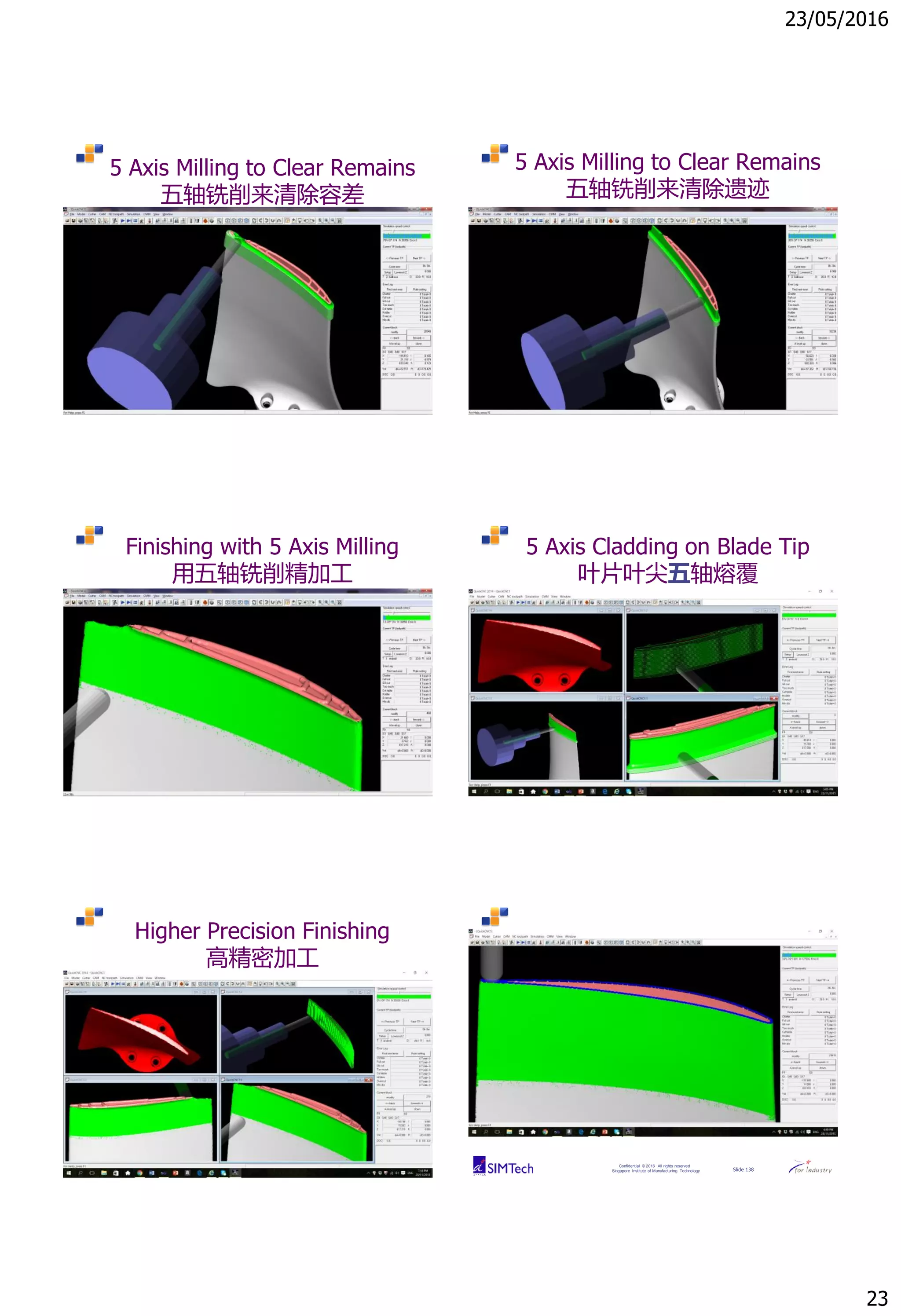

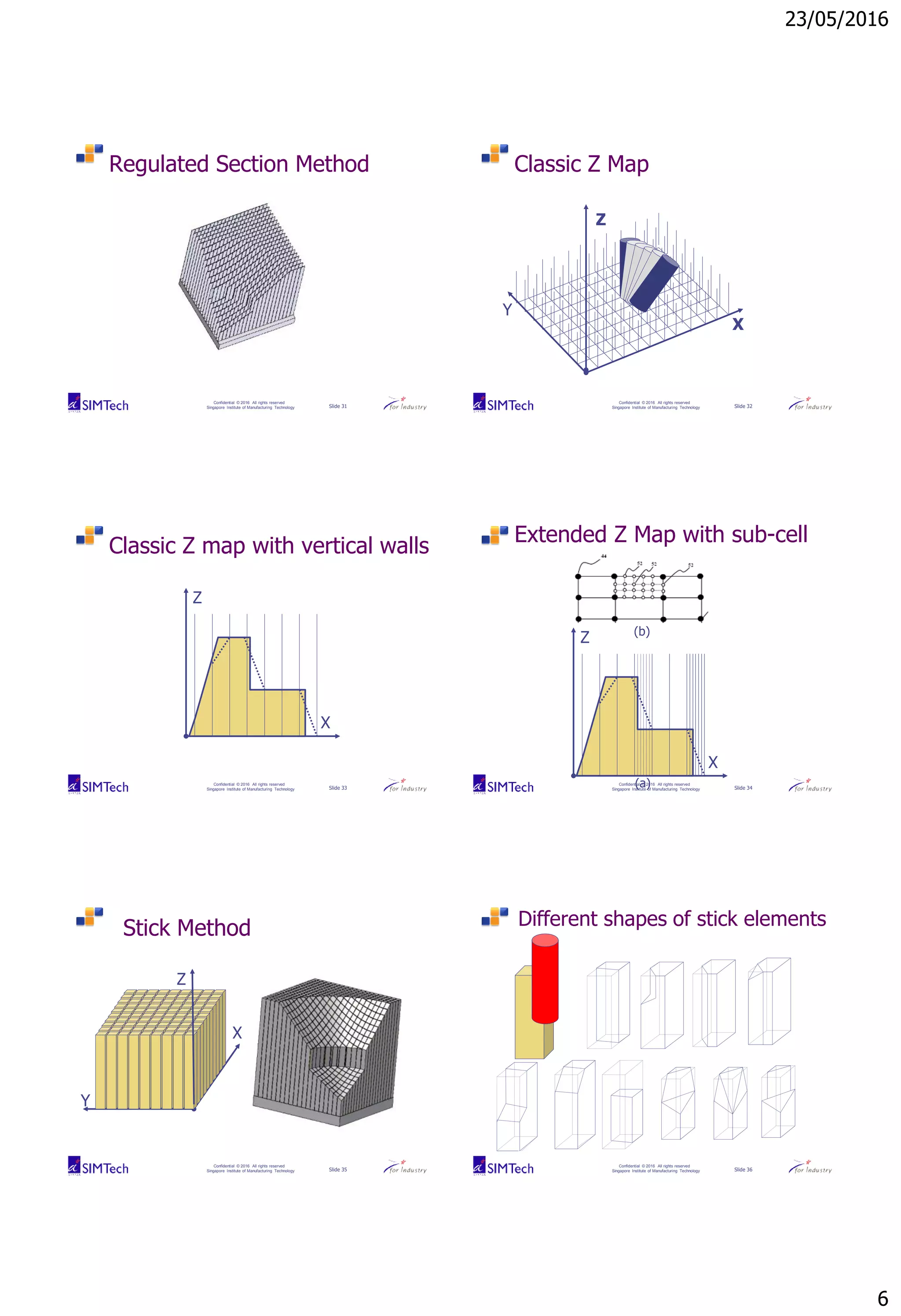

Open all NC files in the same folder

automatic search for cutter names: ( HTC50R4.5 )

%

O2001

(959CAIR01.nc)

(HTC50R4.5 process R)

G90 G0 G49 G40 G17 G80

G91 G28 Z0.0

G90 G54

G43 Z290. H#4120

M168

M00

Confidential © 2016 All rights reserved

Singapore Institute of Manufacturing Technology Slide 54

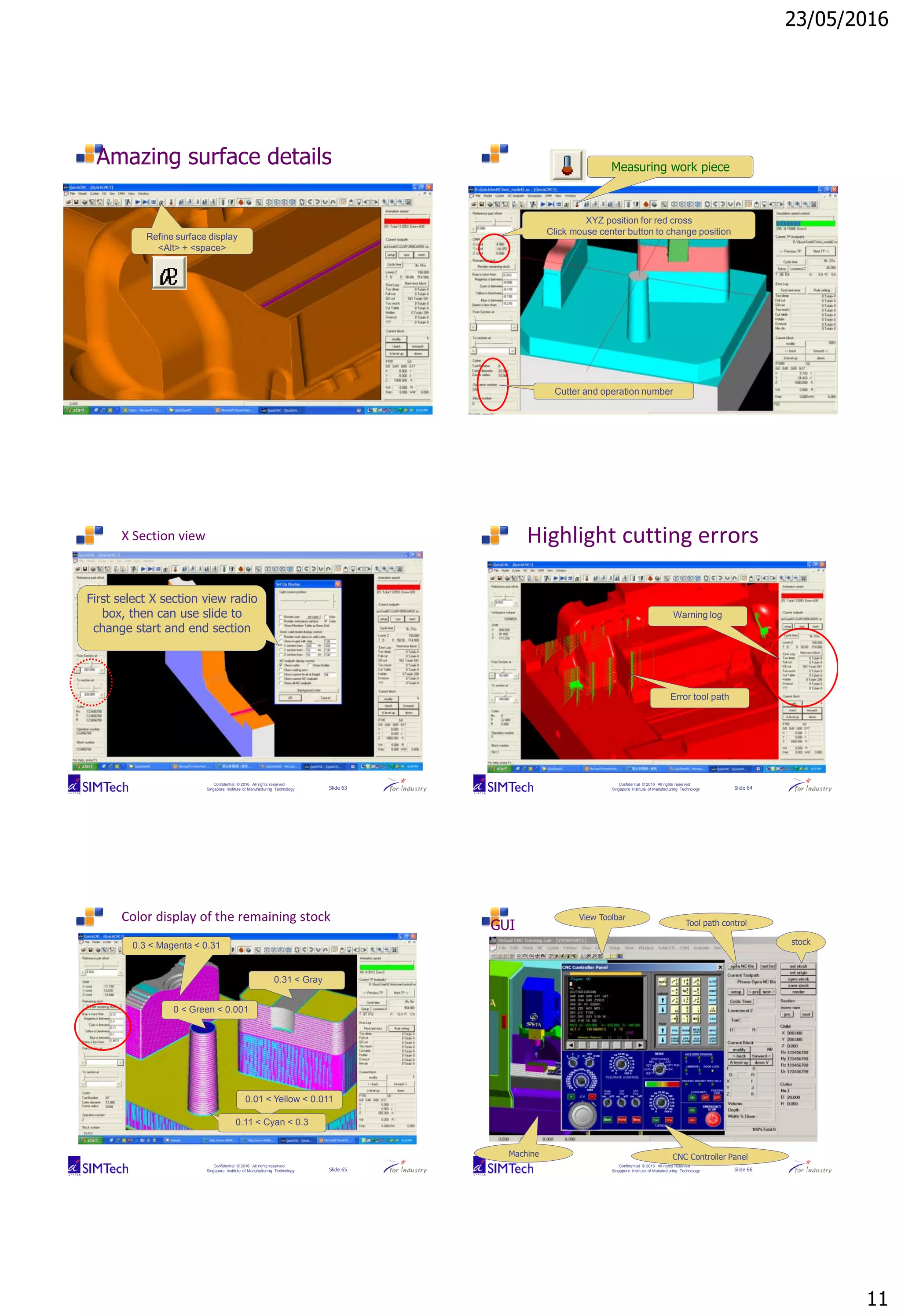

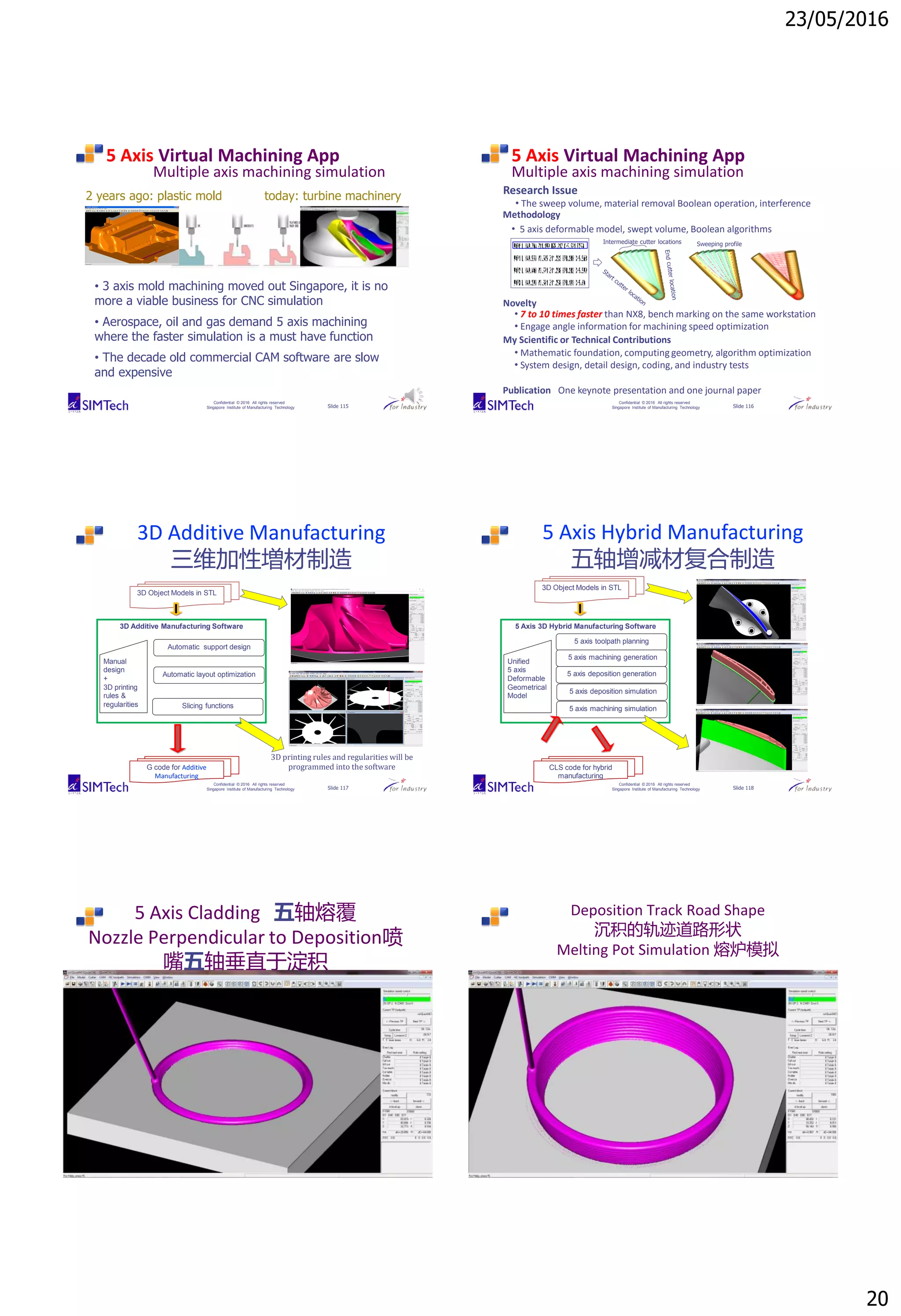

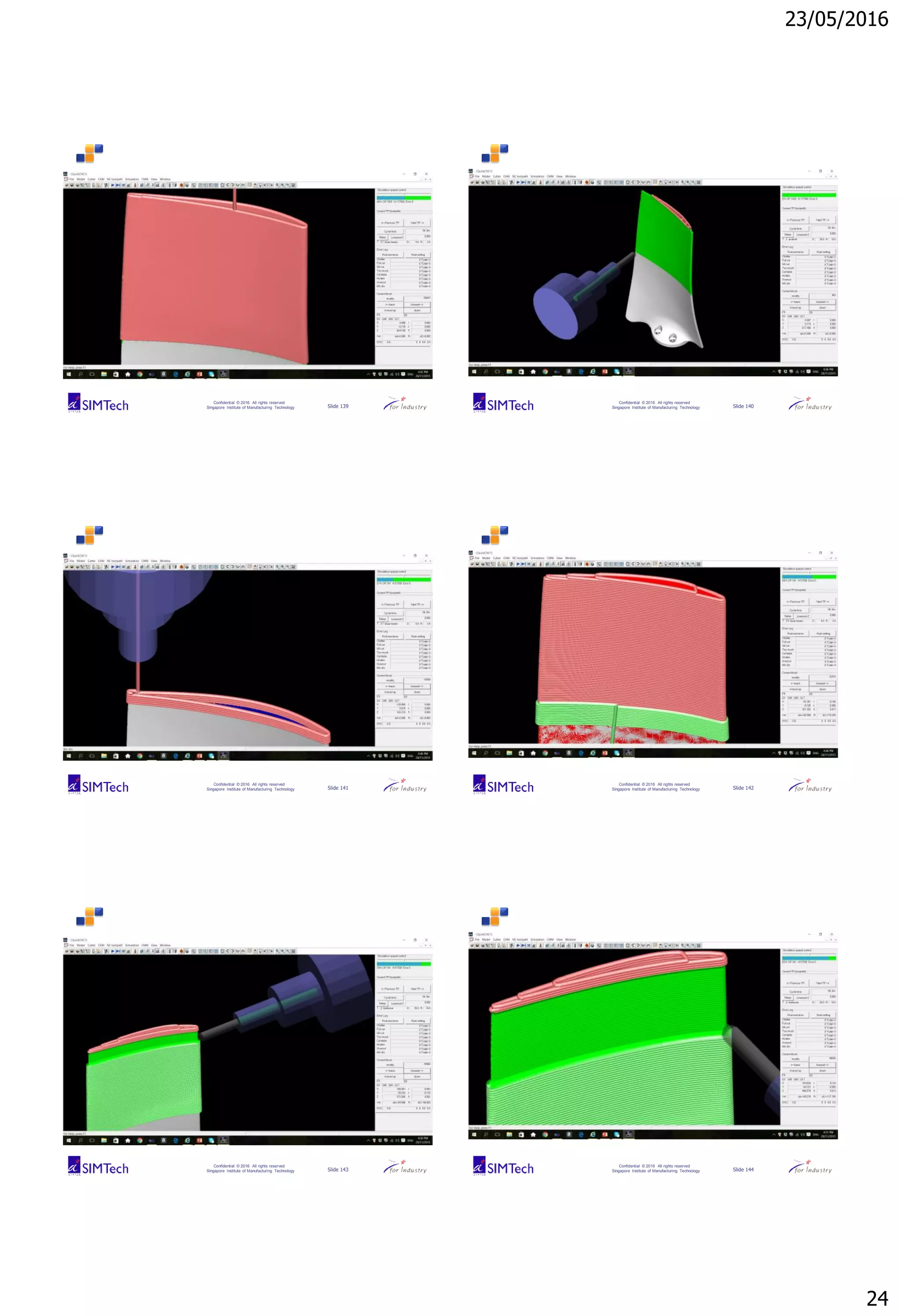

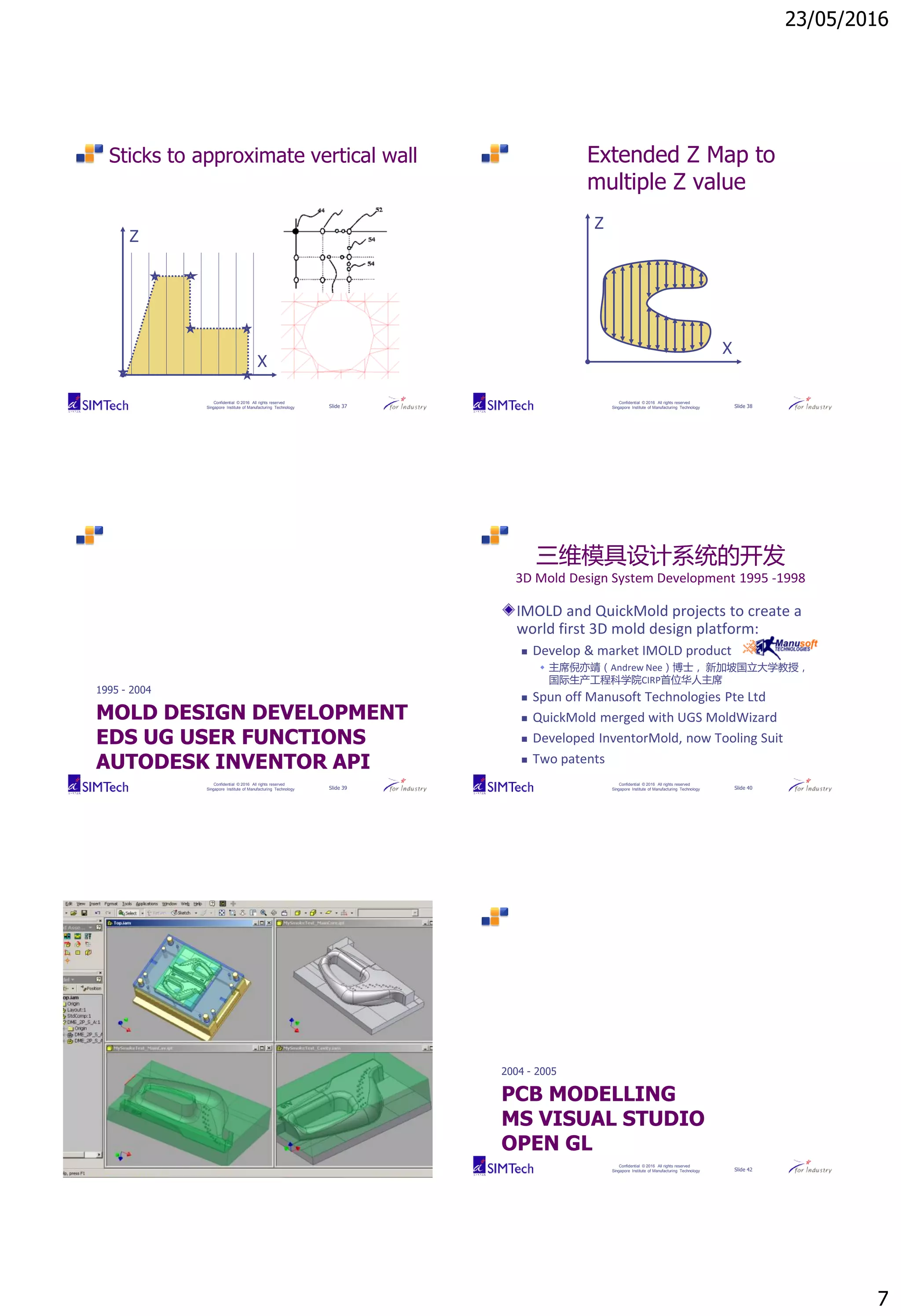

Open a main NC file and automatic search for

sub-programs in the same folder

%

O2590 (001CA-M1A)

G80G40G49G17G21G00

G91G28Z0

G28X0Y0

M168

G90G54X0Y0

N1 (SPOT10 process CD)

T1M6

G90G00G54

G43H#4120Z100.

#[13000+#4120]=5.000

S1500 M03

M128

G98 G81 Z-2. R2. F150. K0

G65P2501

……

%

O2501

(001CAF01.nc)

X-22.5 Y-160.5

X22.5 Y-160.5

X210.5 Y-22.5

X210.5 Y22.5

X22.5 Y160.5

X-22.5 Y160.5

X-210.5 Y22.5

X-210.5 Y-22.5

M99

%](https://image.slidesharecdn.com/30yearsofcaxdevelopments-160523102912/75/30-years-of-cax-developments-9-2048.jpg)