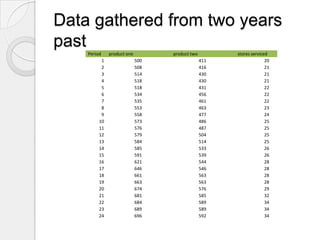

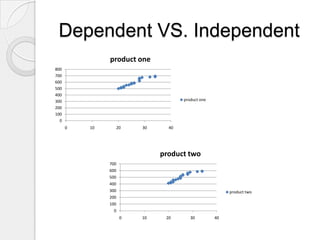

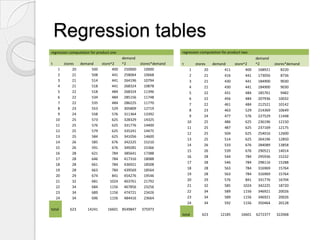

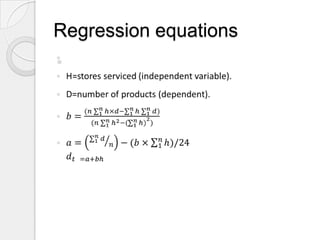

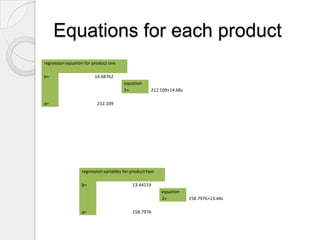

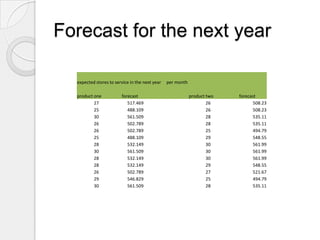

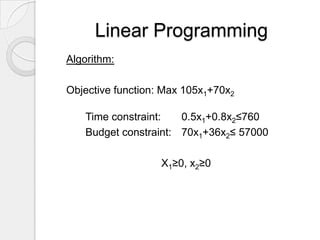

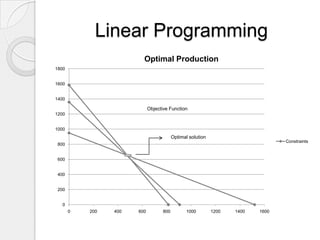

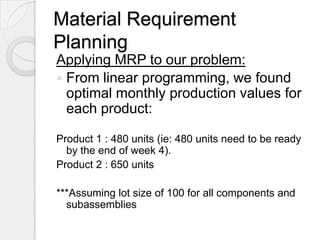

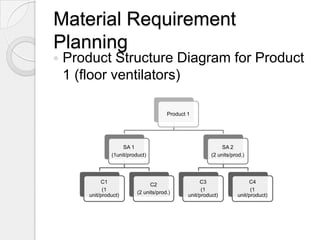

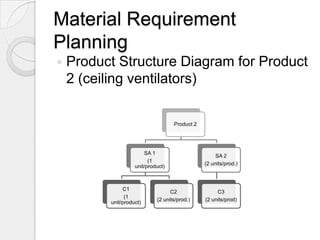

This document provides a summary of a company's production planning processes. It discusses that the company manufactures two types of ventilators and saw increased demand last year. To improve efficiency, it implemented forecasting, linear programming, and material requirements planning (MRP). Forecasting used linear regression on historical sales and store data to predict next year's monthly demand. Linear programming was used to determine the optimal production mix to maximize profits given time and budget constraints. MRP was applied to schedule ordering of components to ensure sufficient materials and avoid excess inventory or missing parts based on the production plans.