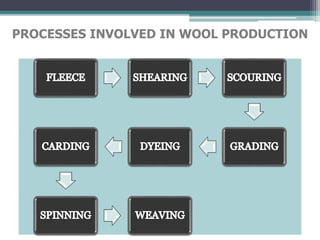

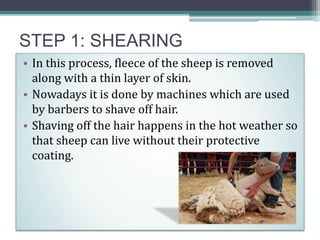

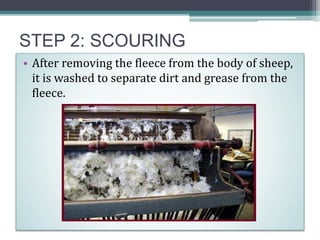

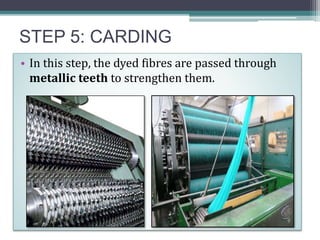

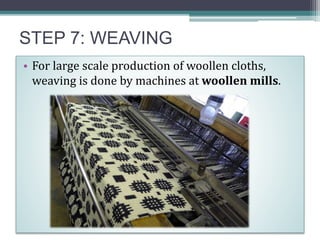

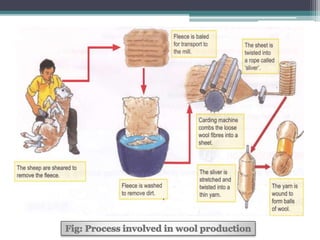

Wool is a natural fiber obtained from sheep fleece. The document outlines the 7 key steps to process wool from raw fleece to woven textiles: 1) shearing removes fleece from sheep, 2) scouring washes dirt and grease, 3) grading sorts by texture, 4) dyeing colors fibers, 5) carding strengthens fibers, 6) spinning rolls fibers into yarns, 7) weaving produces wool cloth using machines.