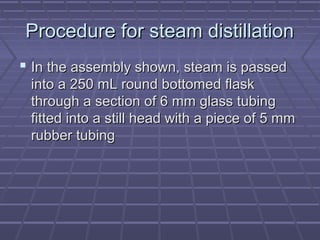

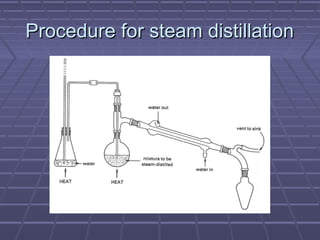

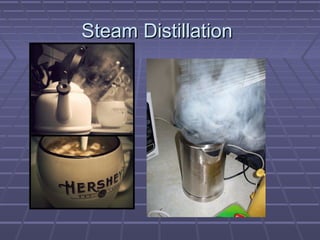

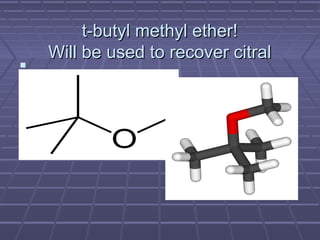

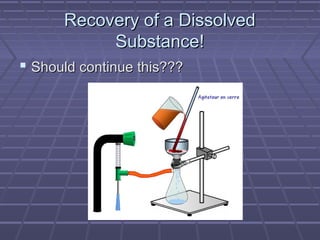

This document provides a procedure for steam distillation. Steam is passed through a round-bottomed flask containing a sample mixture to be separated. A trap allows control of the steam flow and removal of water from the steam line. Condensate containing separated compounds collects in a receiver flask. Once complete, the distillate is extracted with t-butyl methyl ether in a separatory funnel. The ether layer is dried, filtered, and evaporated to obtain the purified compounds, which are weighed and stored. The procedure is described to recover citral from lemongrass oil through steam distillation and extraction.