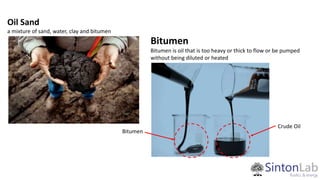

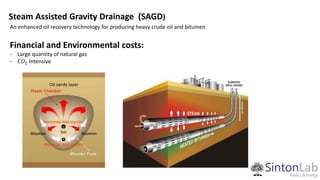

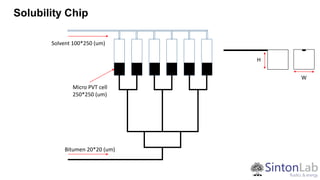

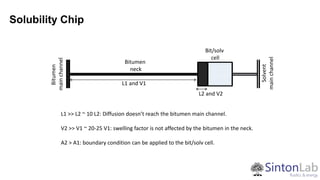

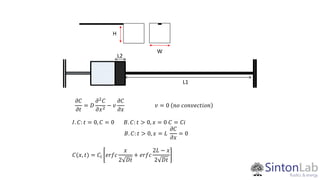

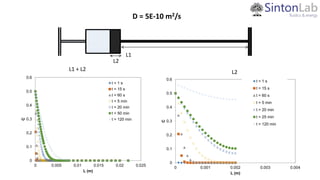

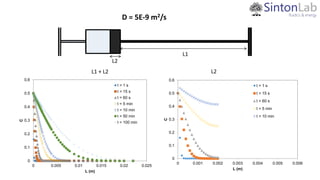

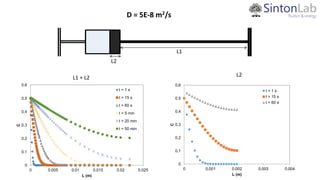

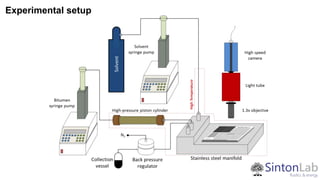

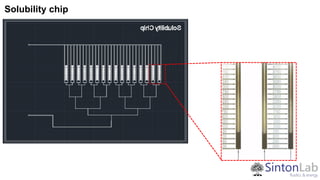

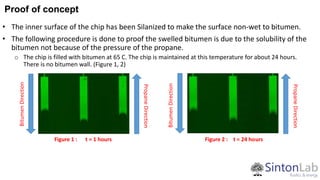

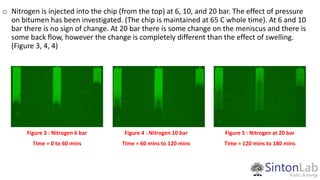

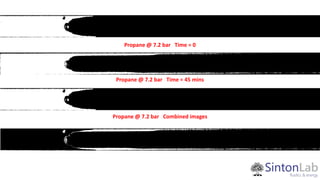

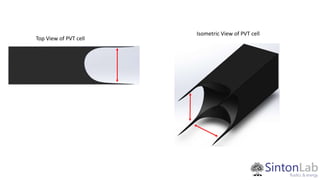

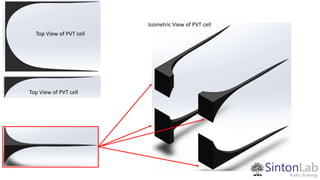

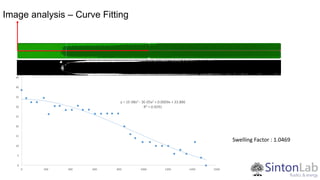

This document summarizes Soheil Talebi's master's thesis project on measuring fluid properties of Canadian oil reservoirs using microfluidic methods. The project aims to 1) measure bitumen solubility and viscosity through microfluidic chips to inform reservoir models, 2) enhance oil recovery from reservoirs through improved solvent-based extraction methods like SAGD that reduce emissions. Key aspects include designing microfluidic chips to measure solubility over a range of pressures and temperatures, and analyzing image data of bitumen swelling to calculate solubility. Preliminary results show the chip design works and surface treatment allows reusability. Overall the microfluidic approach enables high accuracy solubility measurements of reservoir fluids under reservoir conditions to optimize solvent selection and