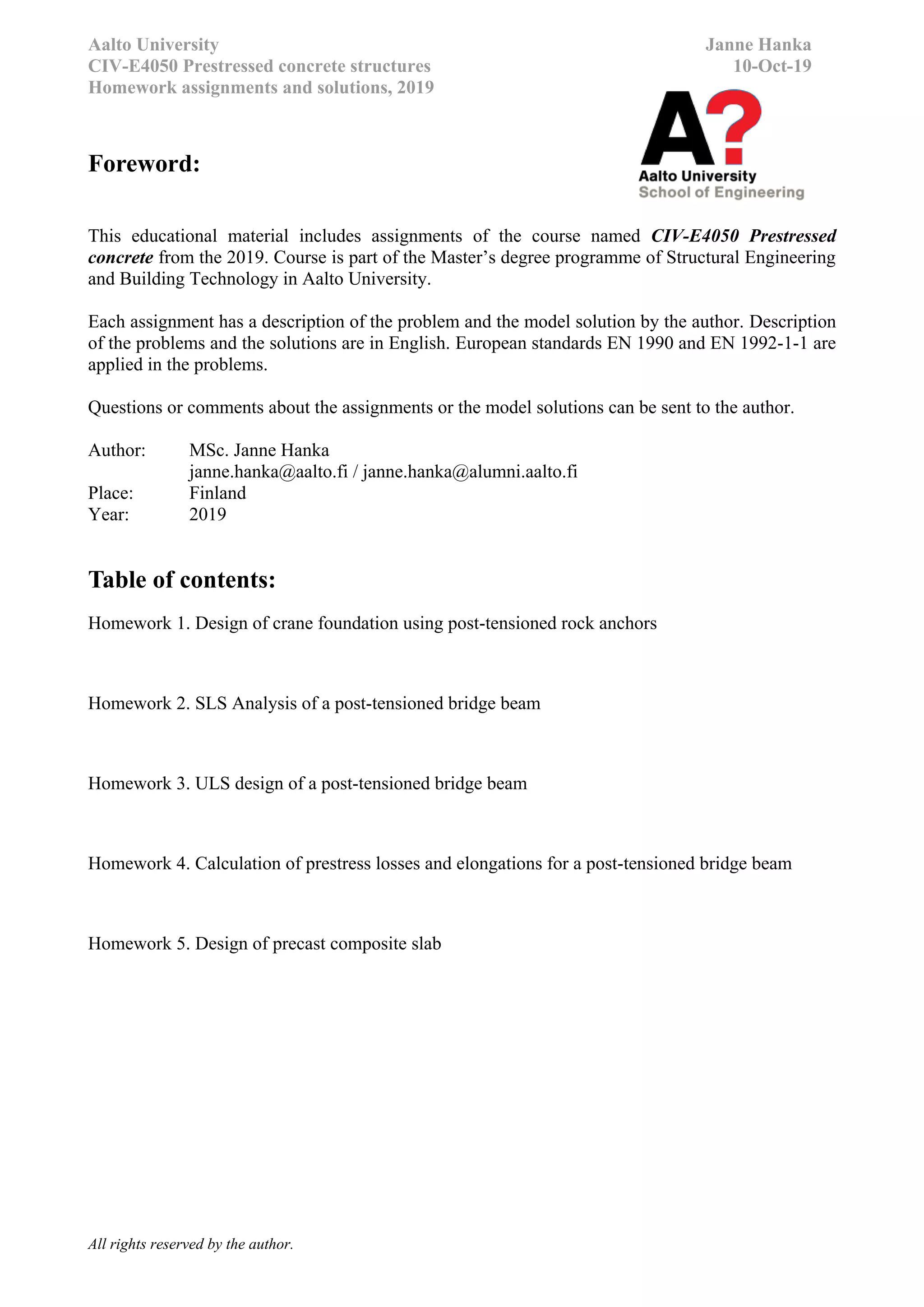

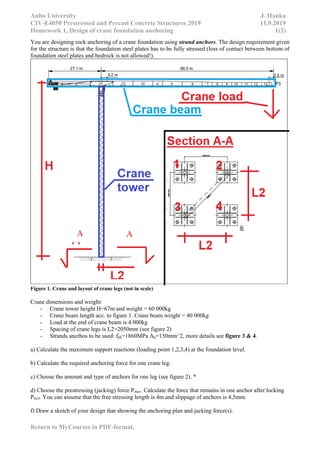

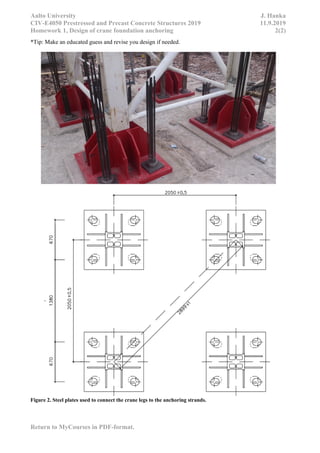

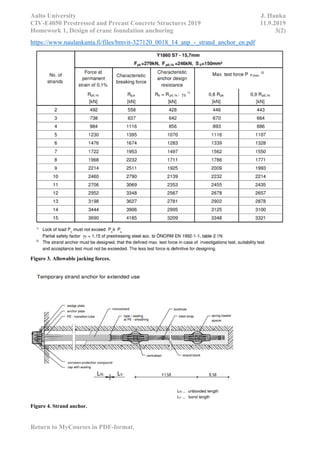

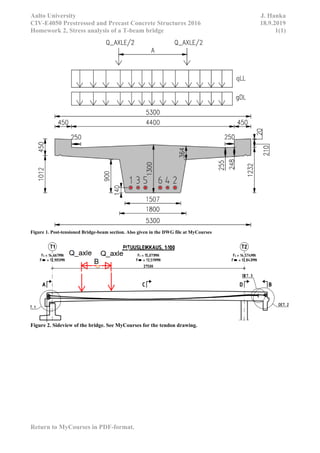

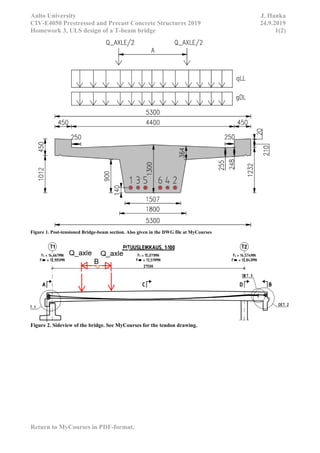

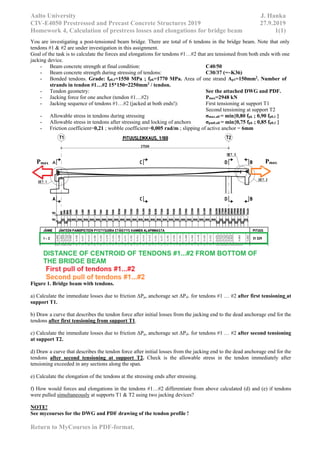

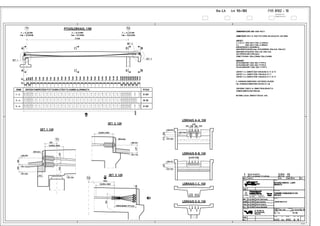

This document contains homework assignments for a course on prestressed concrete structures. It includes 5 assignments related to designing prestressed concrete elements like bridge beams, slabs, and foundations. The assignments provide structural details, material properties, and loading information and ask students to perform stress analyses, design reinforcement, check code requirements, and more. A student completing the assignments would gain experience in prestressed concrete design and applying Eurocodes.