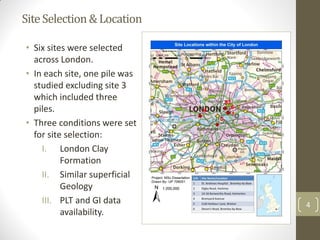

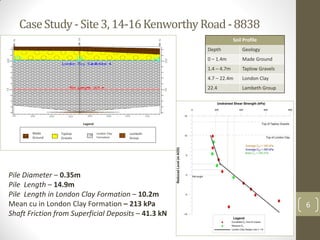

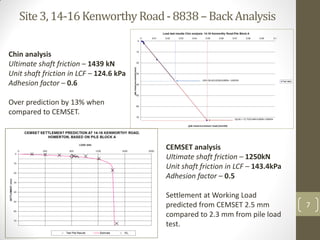

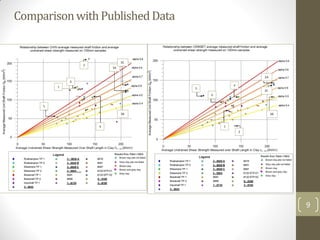

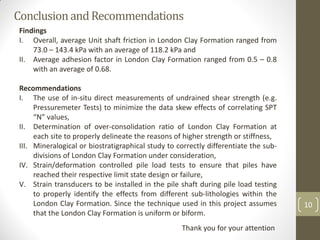

This document analyzes the unit shaft friction and adhesion factor (α) for piles constructed using the Continuous Flight Auger (CFA) technique in the London Clay Formation. Six sites were selected where CFA piles were constructed in similar geological conditions and where pile load test and ground investigation data was available. At one site with three piles, back analysis using the Chin and CEMSET methods obtained a unit shaft friction in the London Clay Formation ranging from 124.6 to 143.4 kPa and adhesion factors ranging from 0.5 to 0.7. Overall, average unit shaft friction across all sites ranged from 73.0 to 143.4 kPa with an average of 118.2 kPa, and average adhesion factors ranged