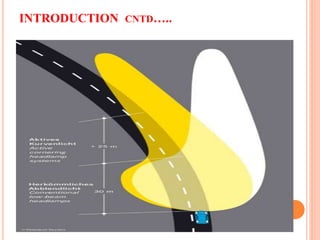

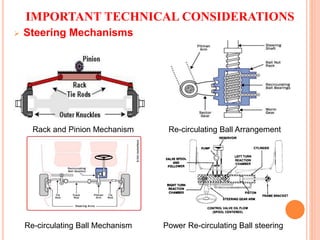

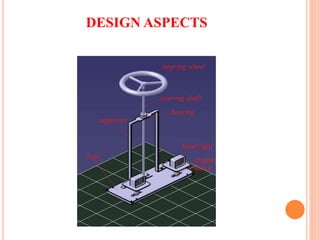

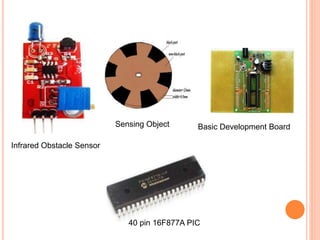

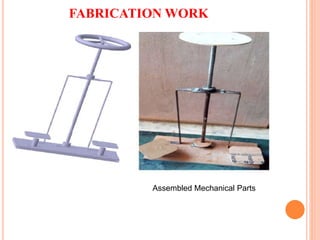

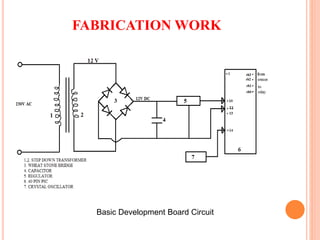

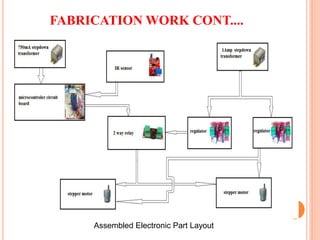

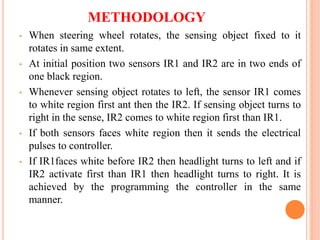

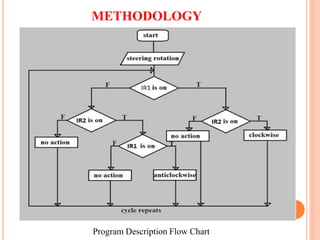

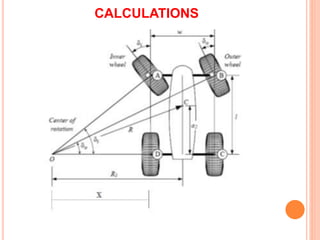

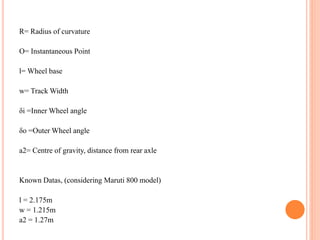

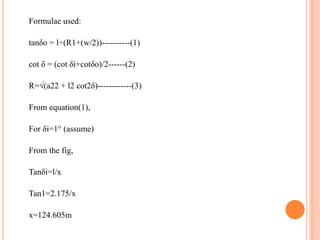

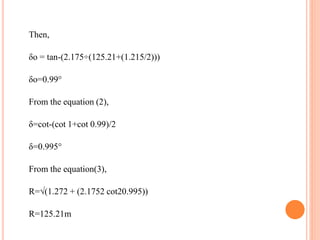

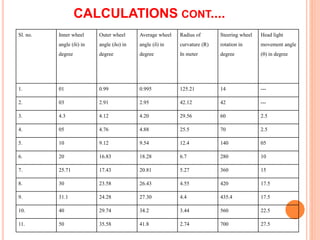

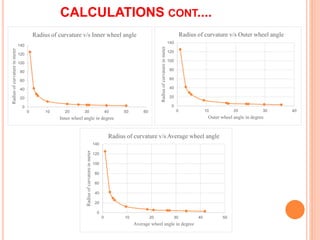

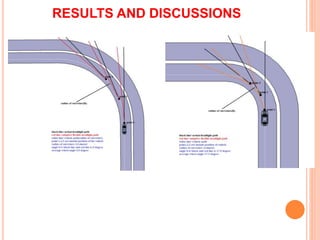

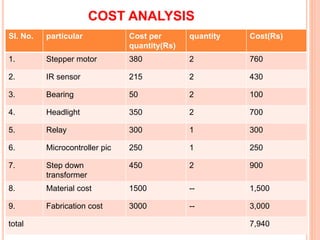

This document describes a student project to develop an adaptive flexible headlights system for four-wheel vehicles. The system uses sensors to detect steering wheel position and adjust the headlights accordingly for improved visibility around turns. Key components include stepper motors, infrared sensors, a microcontroller, and LED matrix headlights. The students designed the mechanical and electrical systems, conducted calculations to determine appropriate headlight angles based on steering inputs, and fabricated a prototype. Testing showed the adaptive headlights improved nighttime visibility and safety during turns. Future work could refine the design for different vehicle speeds and dimming functions.