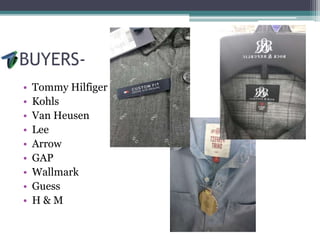

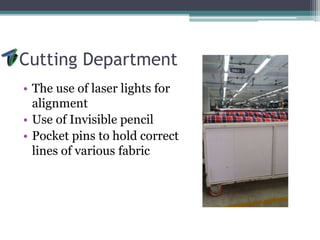

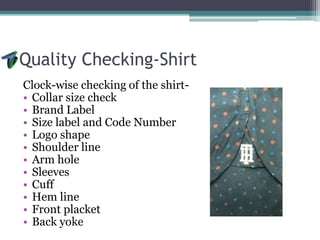

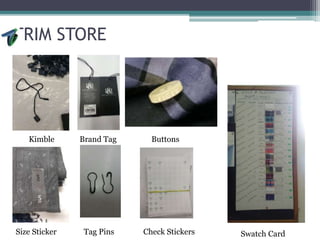

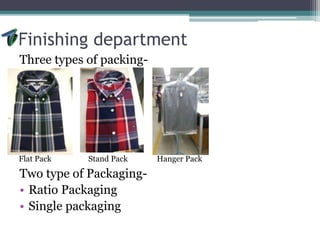

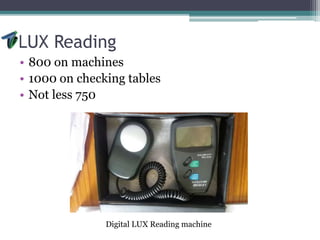

Texport Industries is a textile manufacturer located in India with 19 facilities. It produces 1.4 million garments per month and generates annual revenue of $80 million. The company focuses on shirts, blouses, polos and cargo shirts for major brands in the US and Europe. It has strict quality control processes and adheres to international labor laws. The factory is divided into specialized departments for cutting, sewing, finishing, and more. The manufacturing process involves fabric testing, pattern layout, cutting, sewing, finishing, washing, ironing and packaging. The company provides training to its 1,300 employees and aims to develop their skills.