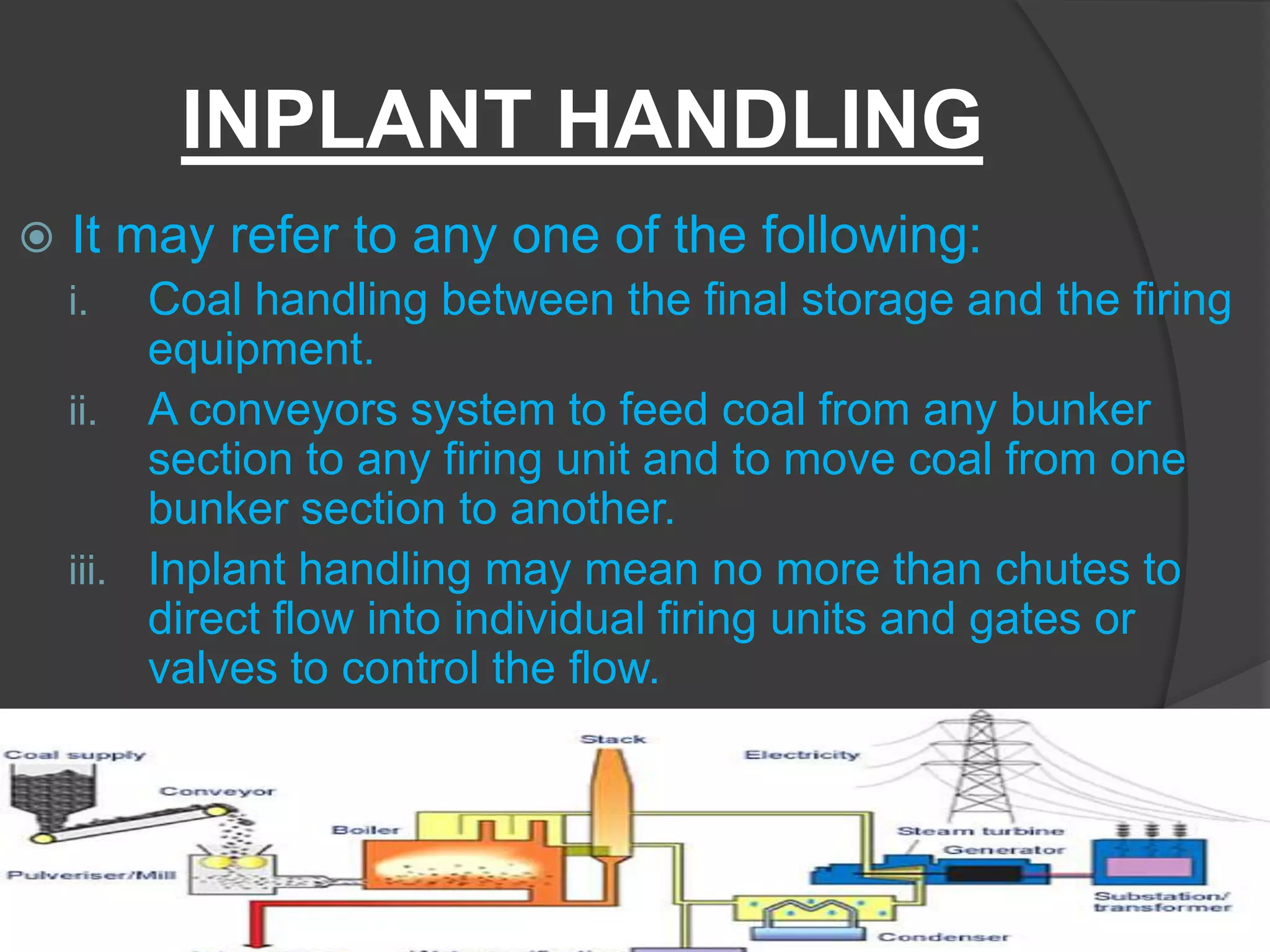

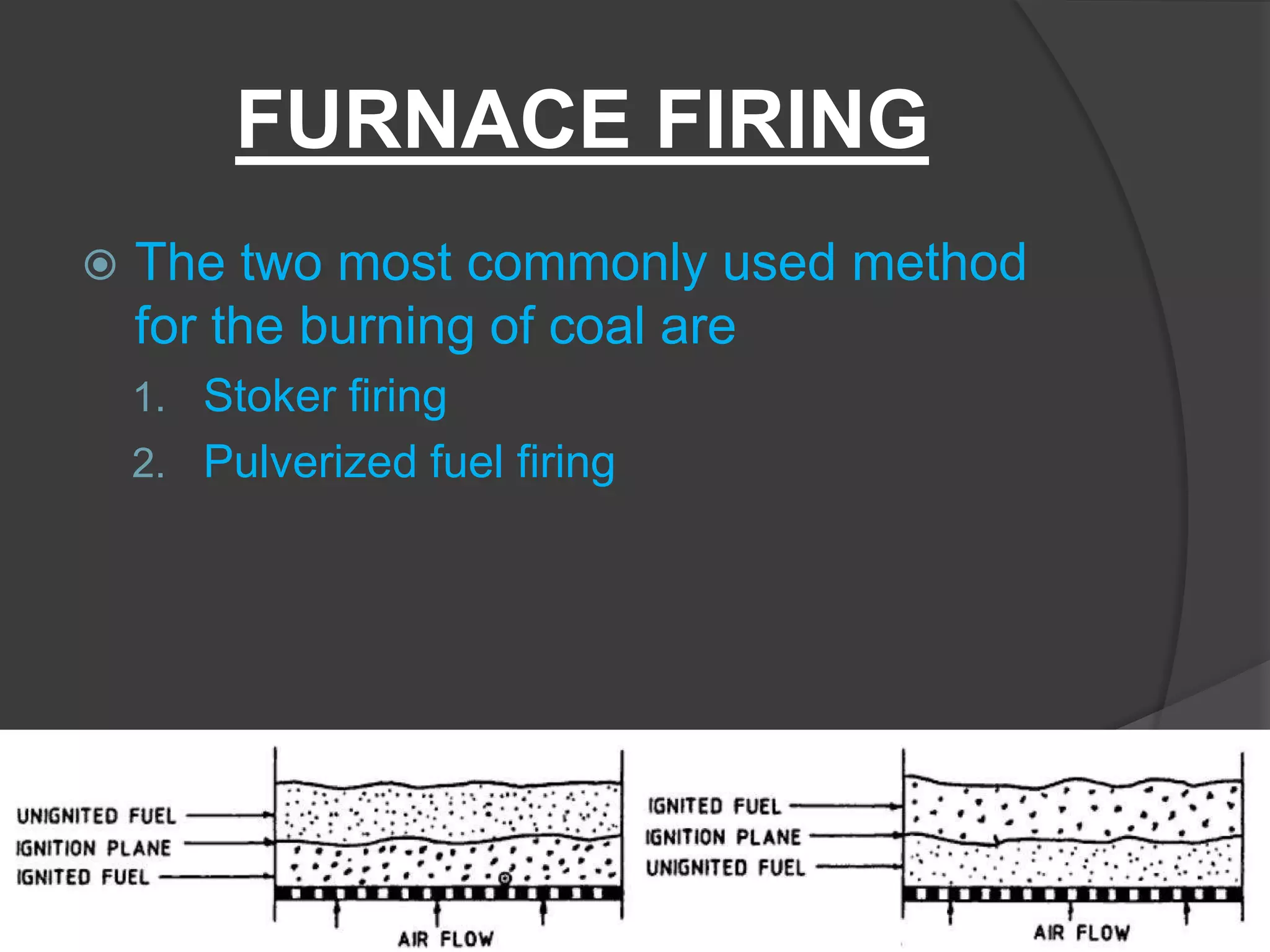

There are several stages in the coal handling process at a power plant: 1) Coal is delivered by rail, road, or ship and unloaded. 2) The coal may then be prepared through processes like crushing or grinding. 3) The coal is transferred to storage areas using conveyor belts or other equipment. 4) Coal is stored in piles or bunkers until needed. 5) In-plant equipment then moves the coal to furnaces where 6) weighing and measuring ensures the proper amount is fed to boilers for 7) furnace firing to generate power.