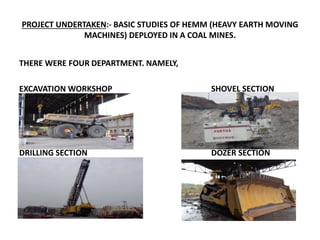

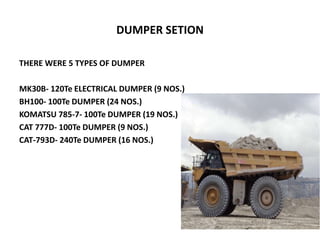

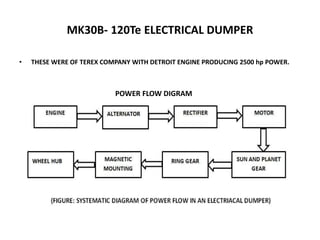

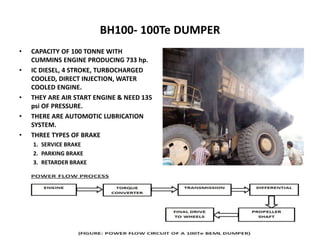

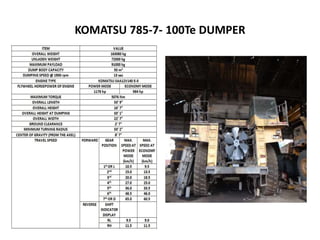

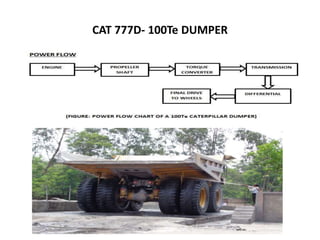

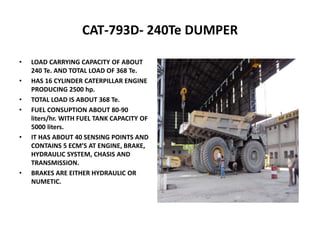

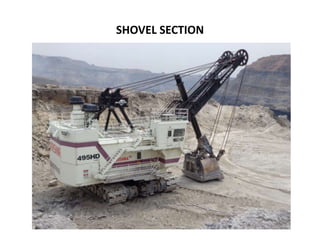

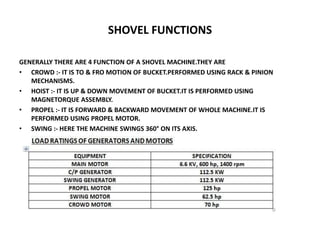

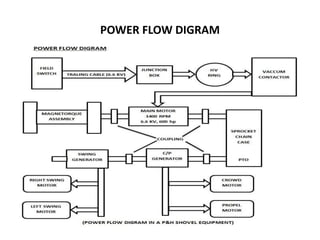

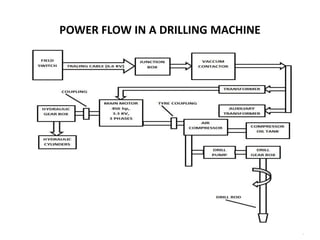

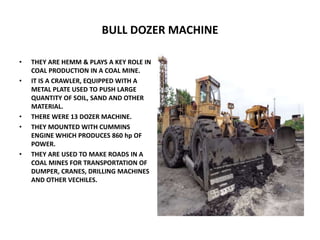

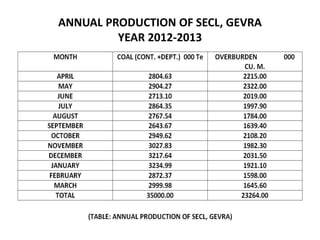

The document provides information about Akhilesh Kumar's summer training project at South Eastern Coal Field Limited's Gevra project in Chhattisgarh, India. It discusses Coal India Limited, the largest coal producer in India. It then describes the Gevra project, the largest open cast mine in Asia. The project involved studying heavy earth moving machines like dumpers, shovels, drills, and dozers used at the mine. Information about various machines, their specifications and functions is presented. The annual coal production for 2012-2013 is reported and plans to increase production capacity for 2013-2014 through larger machines are mentioned.