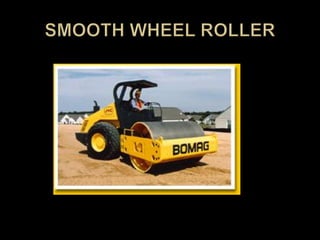

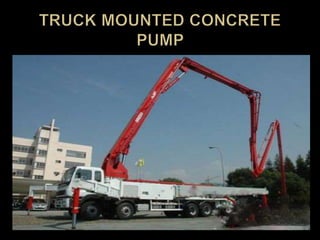

This document discusses the selection and analysis of various types of construction equipment. It covers factors to consider in equipment selection such as cost, suitability for the job, availability and maintenance. It then provides details on common equipment used in earthwork, excavation, hauling, compaction and finishing. This includes scrapers, dozers, loaders, dump trucks, rollers, graders and conveyors. The key factors in selecting the appropriate equipment for a construction job are analyzed.