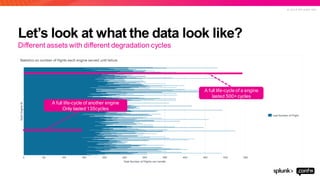

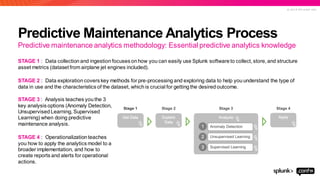

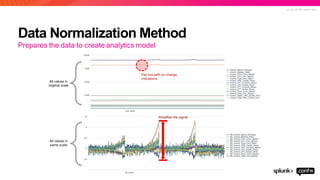

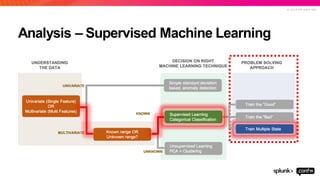

The document provides a comprehensive overview of implementing predictive maintenance within organizations, emphasizing its importance and cost-effectiveness. It outlines the predictive maintenance process, which includes data collection, analysis, and operationalization, while also addressing the various benefits and challenges associated with it. The content aims to equip practitioners with the foundational knowledge and analytics skills necessary to effectively utilize predictive maintenance strategies.