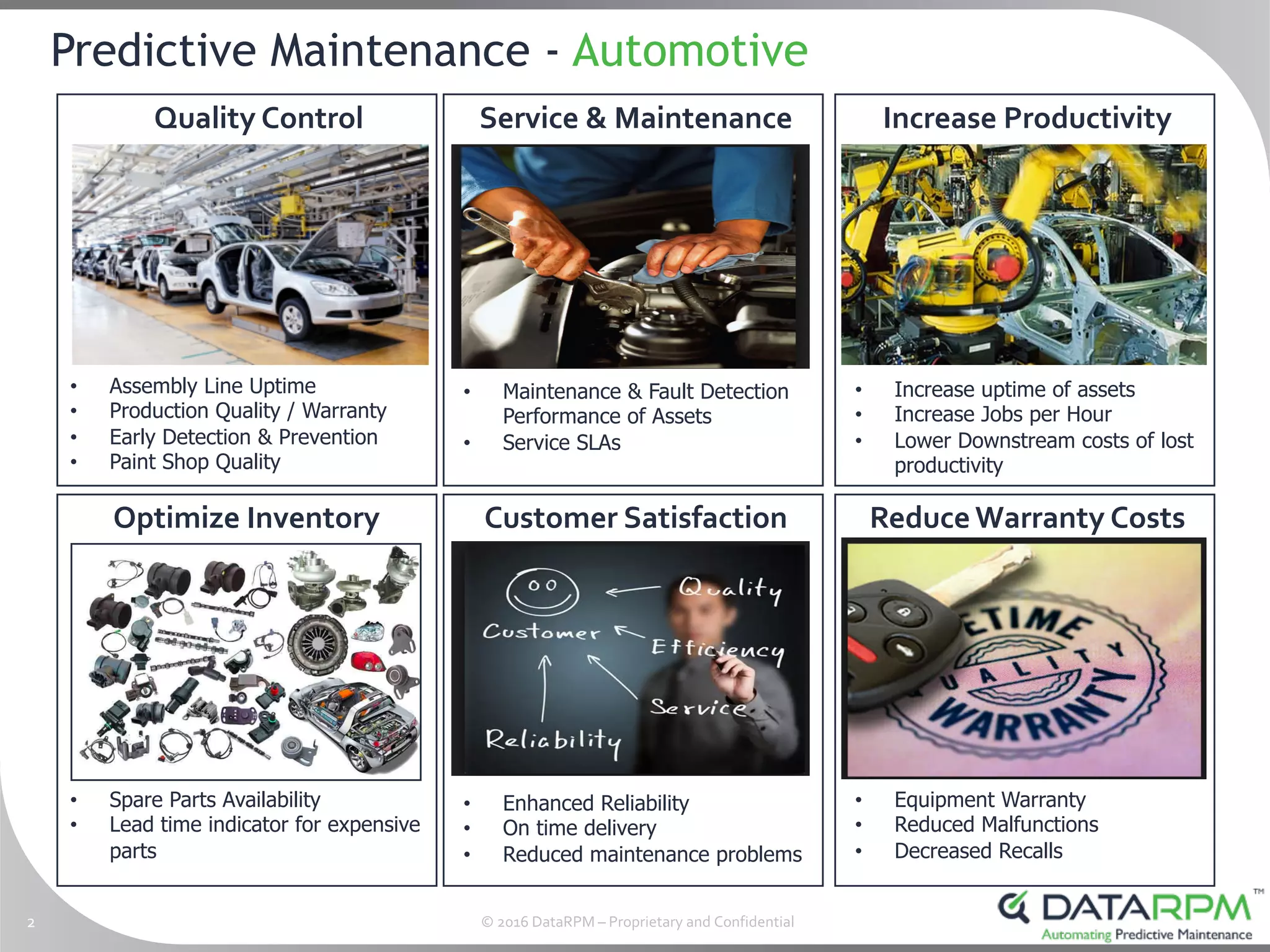

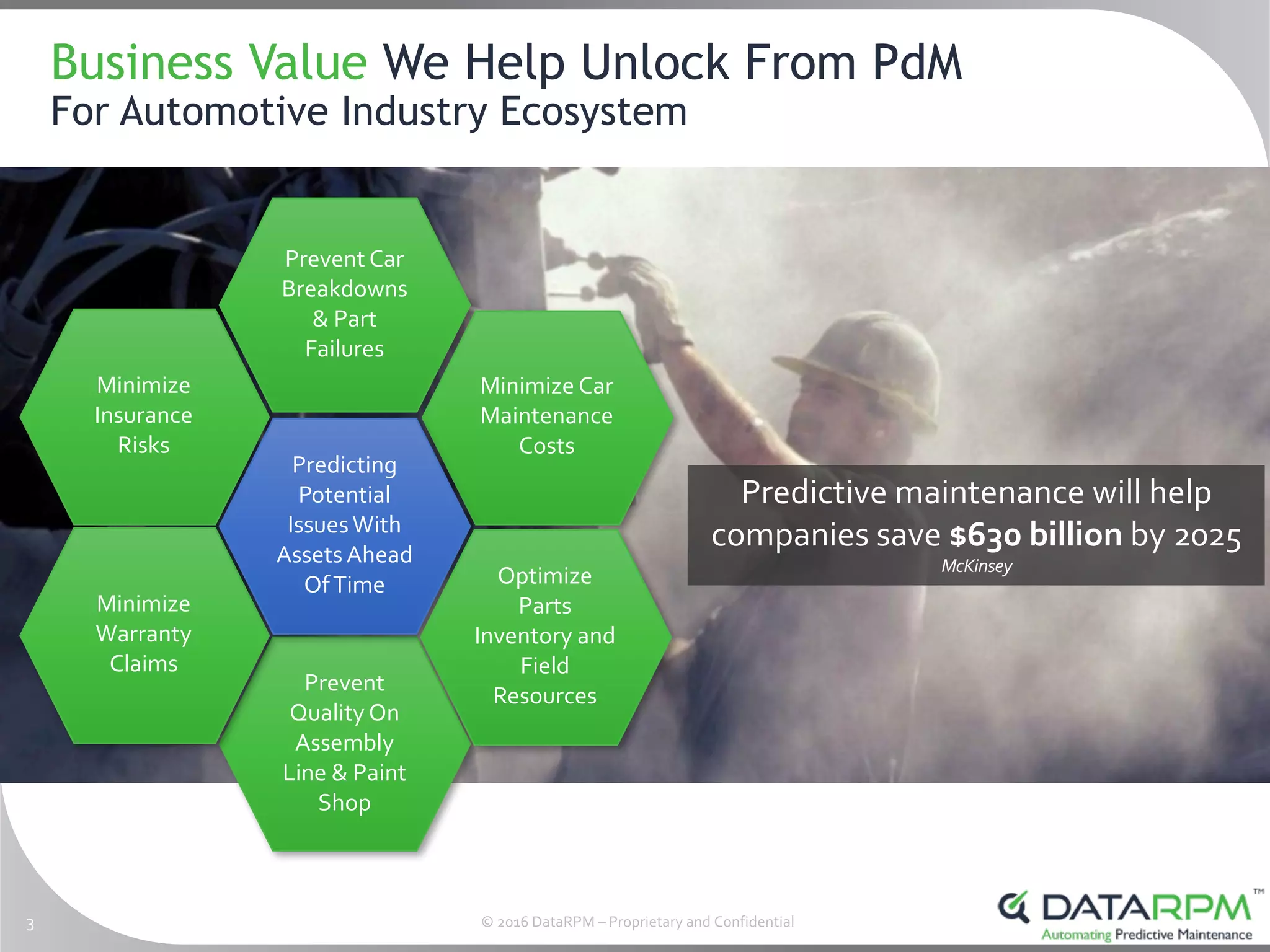

The document discusses a cognitive predictive maintenance (CPDM) platform designed for the automotive industry, leveraging meta-learning and machine learning to improve predictive capabilities for connected cars and assembly lines. By automating data science processes, it enhances prediction accuracy while minimizing costs and downtime, ultimately driving significant savings for companies. The platform addresses challenges in traditional maintenance approaches by continuously analyzing data from numerous sensors to deliver timely insights and recommendations.

![© 2016 DataRPM – Proprietary and Confidential88

We deliver a Cognitive Predictive Maintenance [CPdM]

software platform for the Industrial IoT [IIoT] that automates

Data Science with Meta-Learning on Machine Learning [MLML]

to solve large-scale problems

Automotive

Power | Energy | Utilities

Manufacturing

Healthcare

Oil | Gas

Transportation | Travel

SectorsResults

Results In

as quickly as

1/30th

the Time

with up to

30%

in Cost

Savings

at least a

300 %

increase in

Prediction

Power](https://image.slidesharecdn.com/cognitivepredictivemaintenanceforautomotive-160922100913/75/Cognitive-Predictive-Maintenance-for-Automotive-8-2048.jpg)

![© 2016 DataRPM – Proprietary and Confidential99

What Makes Us Different From Other PdM Solutions?

9

§ We are designed specifically to handle the challenges of doing PdM for IIoT

§ We cognitively automate the Data Science process at mass-scale

§ We utilize Meta-Machine-Learning [MLML] to teach machines to teach themselves

§ We Operationalize the best Ensembles & continually modify in-line & real-time

§ We partner with our customers to solve real problems and deliver ROI quickly](https://image.slidesharecdn.com/cognitivepredictivemaintenanceforautomotive-160922100913/75/Cognitive-Predictive-Maintenance-for-Automotive-9-2048.jpg)