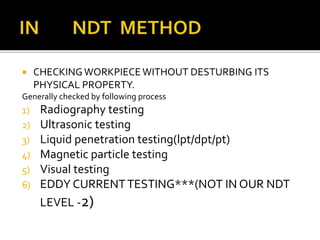

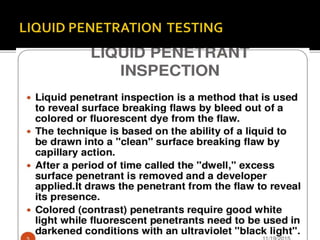

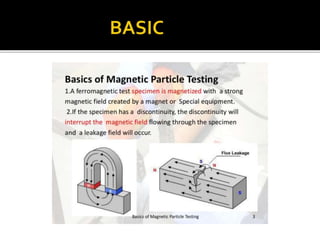

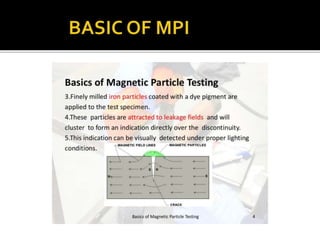

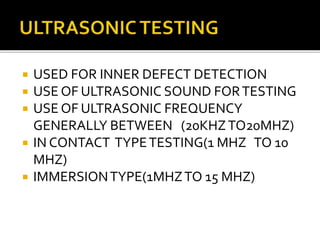

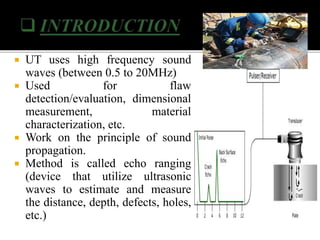

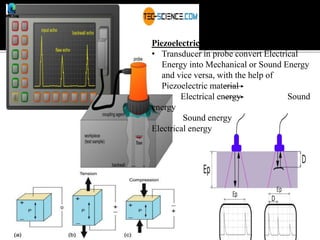

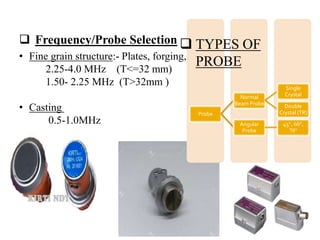

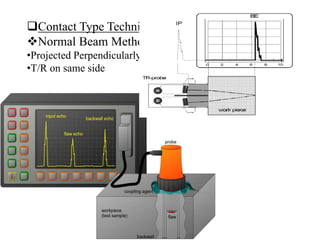

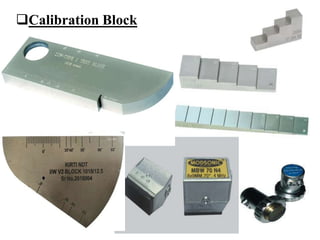

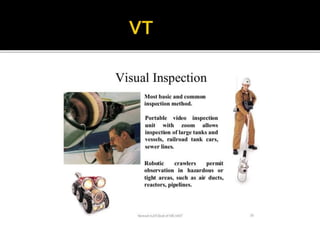

This document provides an introduction to non-destructive testing (NDT) methods. It discusses different NDT techniques including radiography, ultrasonic testing, liquid penetration testing, magnetic particle testing, and eddy current testing. For ultrasonic testing specifically, it describes how ultrasonic waves are used to detect inner defects by the echo ranging principle. It provides details on ultrasonic testing equipment, including pulsers/receivers, transducers, and displays. It also discusses factors like frequency selection, probe types, and the contact testing method using normal beam probes. In summary, the document introduces various NDT methods and focuses on describing how ultrasonic testing works and the associated testing equipment.