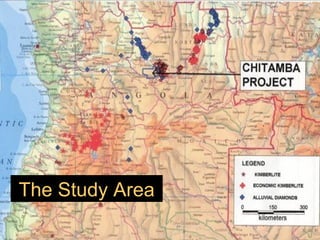

The document summarizes alluvial diamond mining in Angola. It discusses sampling methods used to evaluate placer deposits for diamonds, including grab samples, excavations, and drilling. Key challenges with placer sampling involve large rocks obscuring finer materials and ensuring samples are not unintentionally enriched. Accurate record keeping of sample data is also essential for reserve estimation. The document then outlines various methods used to estimate reserves and value placer diamond deposits. Careful consideration of geological conditions is important when selecting appropriate sampling and evaluation techniques.