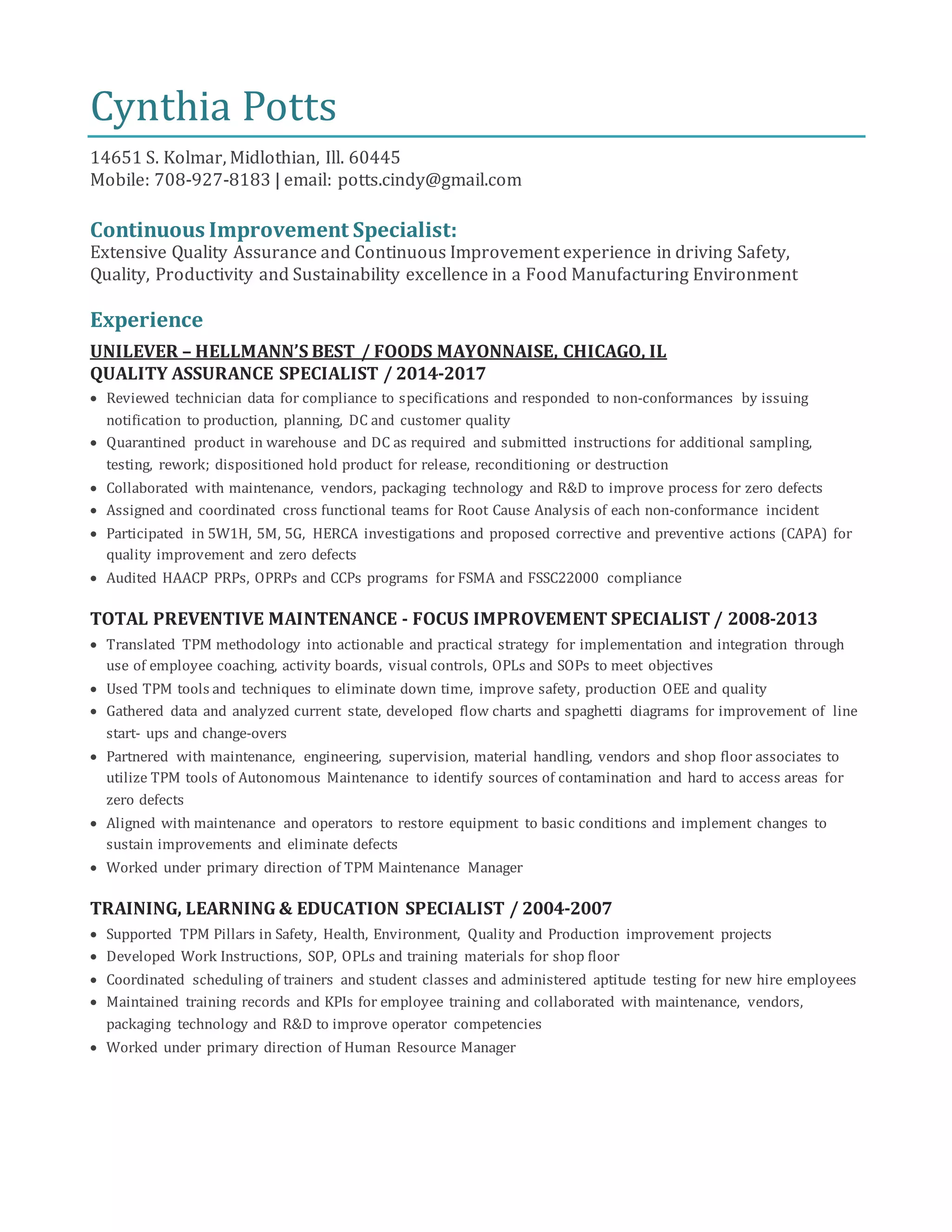

Cynthia Potts has over 15 years of experience in quality assurance and continuous improvement roles in the food manufacturing industry. She has held roles such as Quality Assurance Specialist, Total Preventive Maintenance Specialist, and Quality Control Supervisor. Her experience includes implementing quality programs, conducting audits, root cause analysis, and training. She has a bachelor's degree in biology and certifications in supply chain management, total productive maintenance, performance-based training, and food safety auditing.