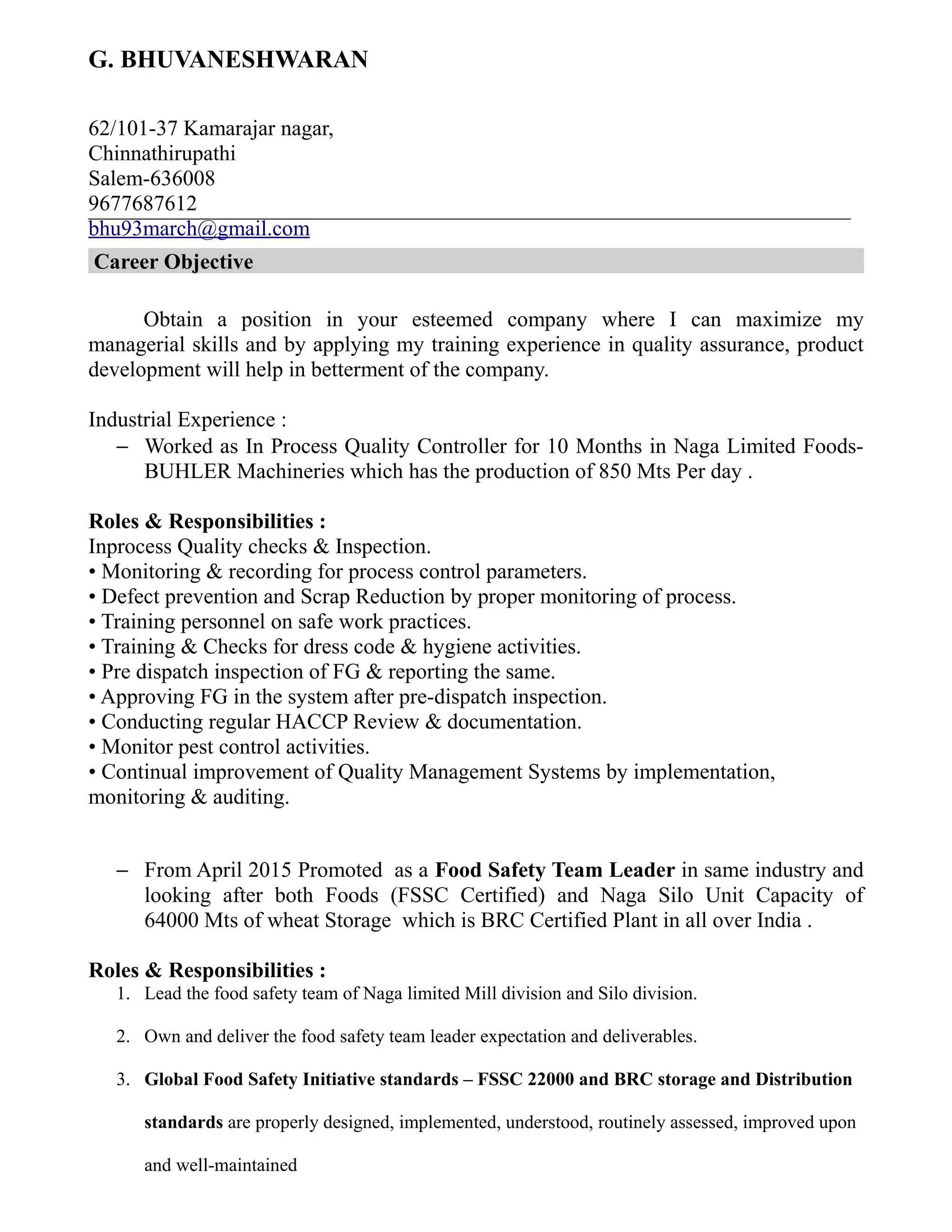

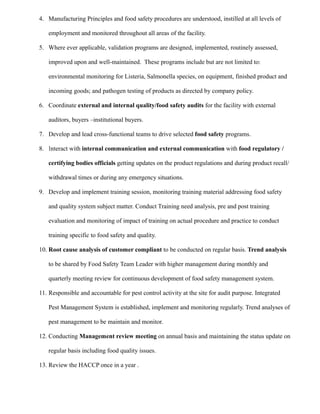

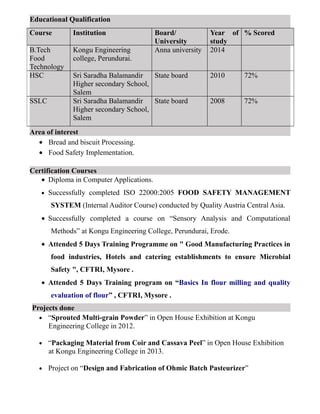

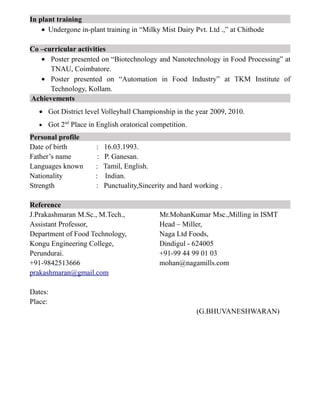

The candidate is seeking a position applying managerial and quality assurance skills. He has 10 months experience as an In Process Quality Controller and was promoted to Food Safety Team Leader responsible for a 64,000 MT wheat storage plant. He holds a B.Tech in Food Technology and certifications in food safety management and sensory analysis.