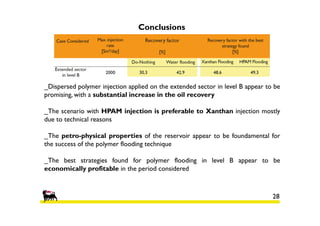

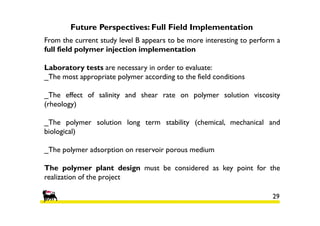

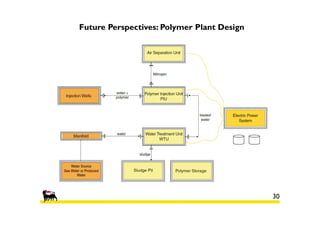

This document provides information about an oil reservoir in West Africa and enhanced oil recovery techniques being considered to increase production. It summarizes:

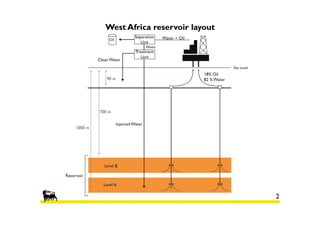

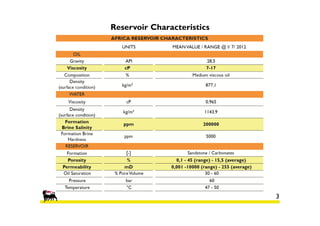

1) The reservoir began production in 1977 with 6 platforms and 49 wells currently. Polymer flooding is being evaluated as an enhanced oil recovery method.

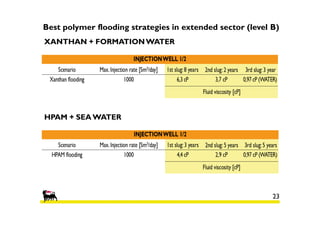

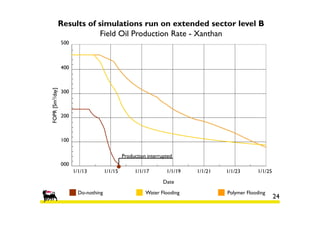

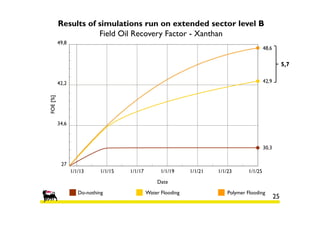

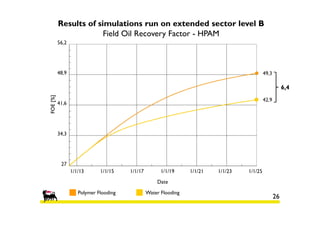

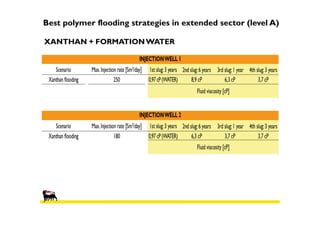

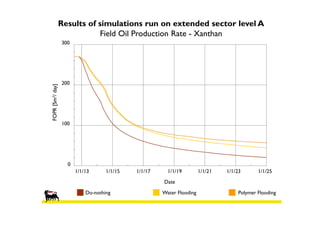

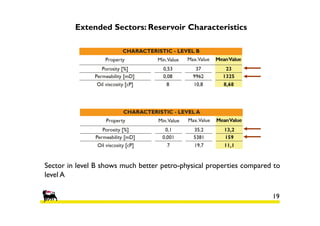

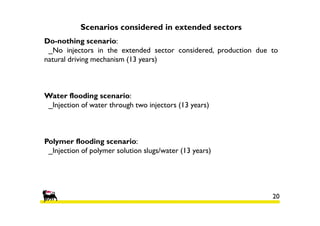

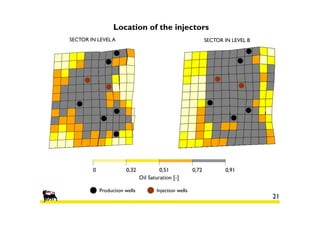

2) Simulations of polymer flooding were run on two extended sectors, with better results in Sector B. The best strategies were HPAM injection and xanthan polymer injection.

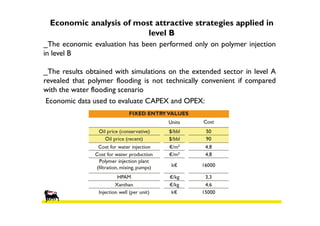

3) An economic analysis found polymer flooding in Sector B could be profitable over the evaluation period, while polymer flooding was not advantageous compared to water flooding in Sector A. Future work may include laboratory tests and full field implementation in Sector B

![Properties of polymer mixtures

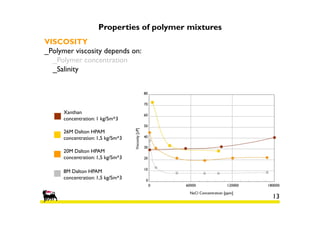

VISCOSITY

_Polymer viscosity depends on:

_Polymer concentration

ܭൌ

ܸ݅݊݅ݐݑ݈ݏ ݎ݁݉ݕ݈ ݂ ݕݐ݅ݏܿݏ

ܸ݅ݎ݁ݐܽݓ ݂ ݕݐ݅ݏܿݏ

Viscosity coefficient (K)

40

35

30

K [-]

25

20

15

10

5

0

0

1

2

3

4

Polymer concentration [kg/Sm^3]

5

12](https://image.slidesharecdn.com/polymerinjectioneor-140201054339-phpapp01/85/Polymer-injection-eor-13-320.jpg)

![Properties of polymer mixtures

VISCOSITY

_Polymer viscosity depends on:

_Polymer concentration

_Salinity

_Shear rate

Shear rate ≈ Velocity of propagation of the mixture

HPAM

concentration 1 kg/Sm^3

HPAM

concentration 1,5 kg/Sm^3

HPAM

concentration 2 kg/Sm^3

Polymer solution viscosity [cP]

HPAM solution Viscosity vs.Velocity

7

6

5

4

3

2

1

0

0

0,2

0,4

0,6

0,8

Velocity of propagation of the mixture

[m/day]

1

14](https://image.slidesharecdn.com/polymerinjectioneor-140201054339-phpapp01/85/Polymer-injection-eor-15-320.jpg)

![Properties of polymer mixtures

ADSORPTION

_Adsorption refers to the interaction, through physical adsorption, Van

Der Waals forces and hydrogen bonding, between polymer molecules and

porous media surfaces

_Adsorption causes a reduction in rock permeability

Polymer adsorption [g/grock]

HPAM adsorption curve

0,00003

0,000025

0,00002

0,000015

0,00001

0,000005

0

0

1

2

3

4

Polymer concentration [kg/Sm^3]

5

15](https://image.slidesharecdn.com/polymerinjectioneor-140201054339-phpapp01/85/Polymer-injection-eor-16-320.jpg)

![Results of simulations run on extended sector level A

1/1/2025

FOE = RECOVERY FACTOR

0,4

Do-nothing

Water Flooding

Polymer Flooding

0

0,08

0,16

0,24

0,32

0,4

Polymer Concentration

[kg/Sm^3]

22](https://image.slidesharecdn.com/polymerinjectioneor-140201054339-phpapp01/85/Polymer-injection-eor-23-320.jpg)