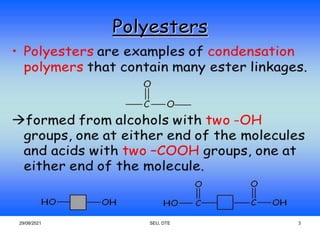

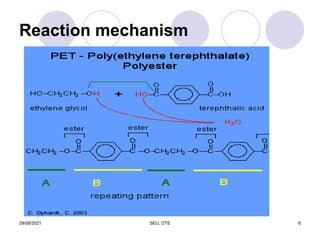

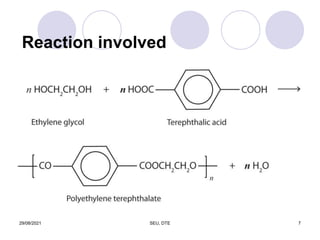

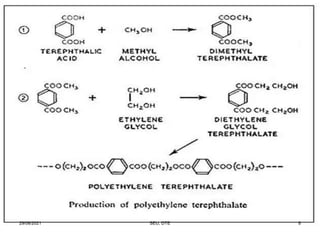

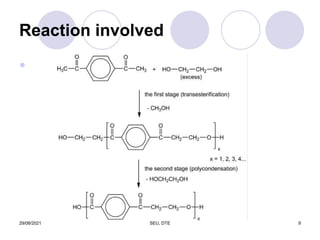

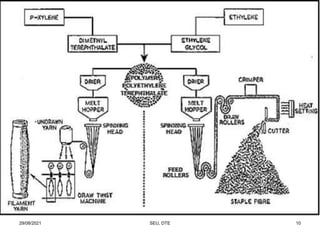

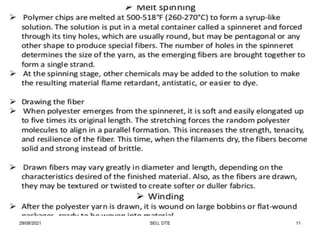

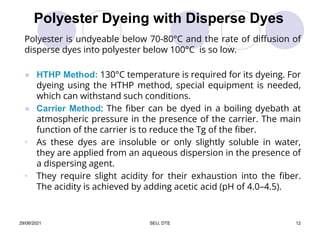

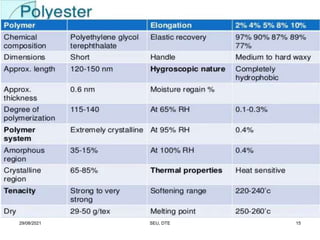

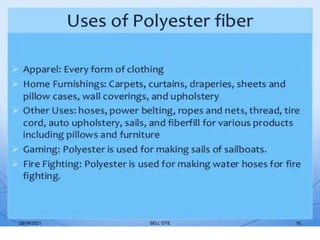

Polyester is the most commonly used synthetic fiber. It is manufactured through a condensation reaction between an organic alcohol and a carboxylic acid, forming an ester linkage. Polyester fibers have properties like resilience, wrinkle resistance, shape retention, durability and washability. However, they also have disadvantages like poor moisture absorption and generating static electricity. Polyester is dyed using disperse dyes at high temperatures via HTHP or carrier methods. It has many uses including in clothing fabrics due to its desirable qualities.

![Introduction

● Polyester is the most used synthetic fiber.

● can be manufactured in different shapes and sizes

for specific purposes.

● most commonly are prepared from a condensation

reaction

● between an organic alcohol (containing hydroxyl

[OH] groups) and a carboxylic acid (containing

carboxyl [COOH] groups).

● These two functional groups react to form the

characteristic ester linkage, a chemical group with

the structure.

29/08/2021 SEU, DTE 2](https://image.slidesharecdn.com/polyesterfiber-240404011644-3883593a/85/Polyester-Fiber-its-all-about-information-pptx-2-320.jpg)