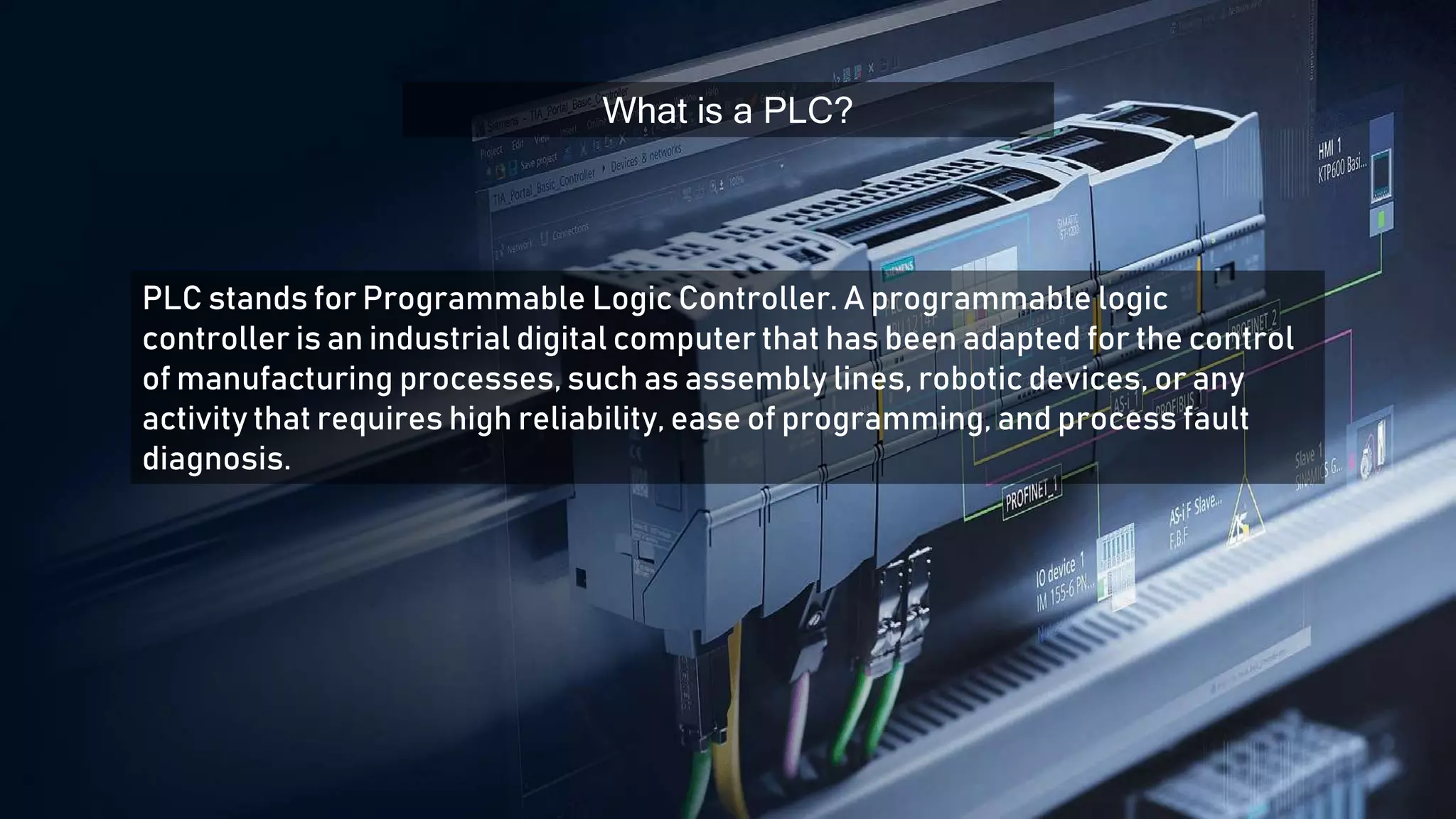

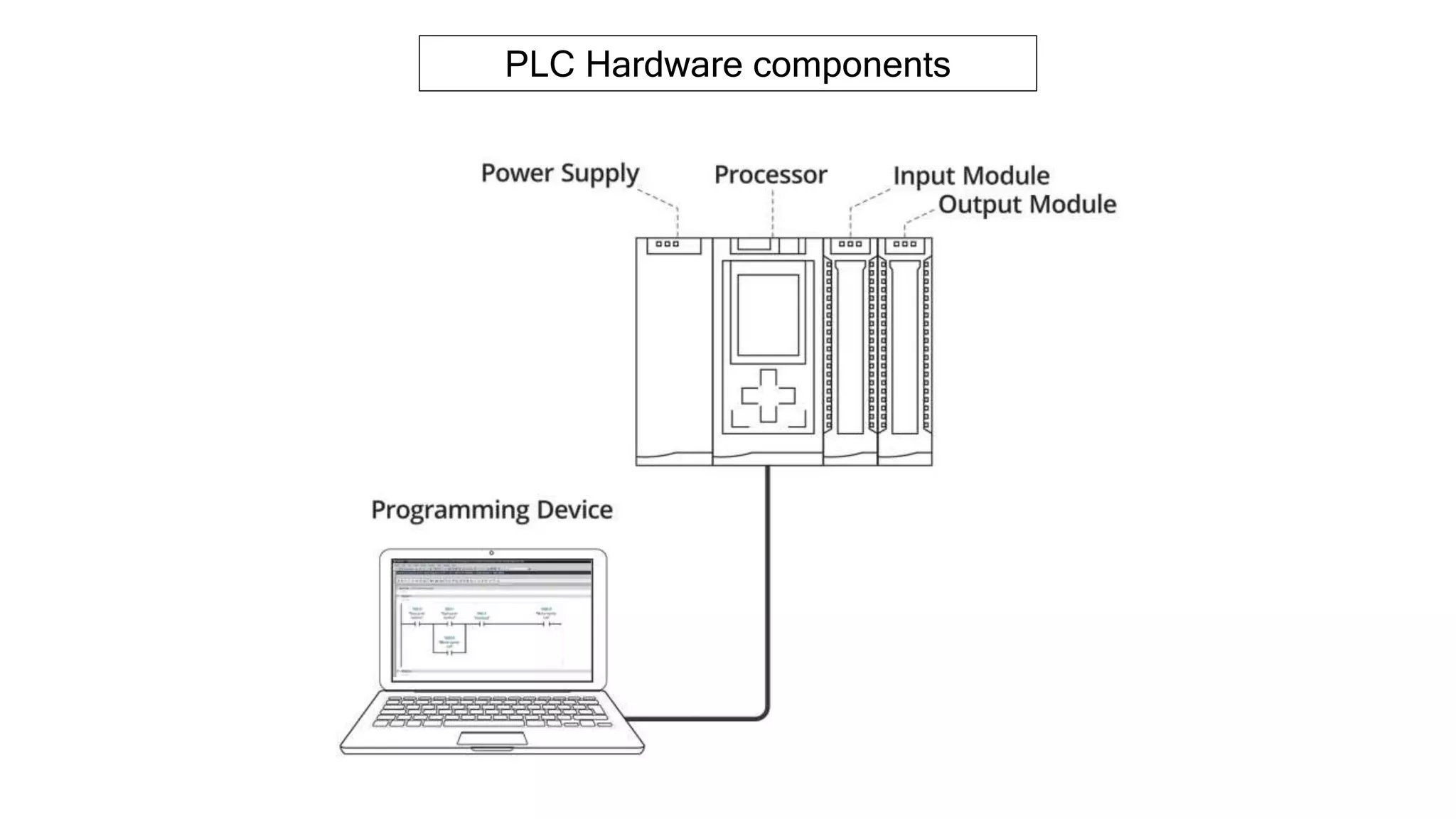

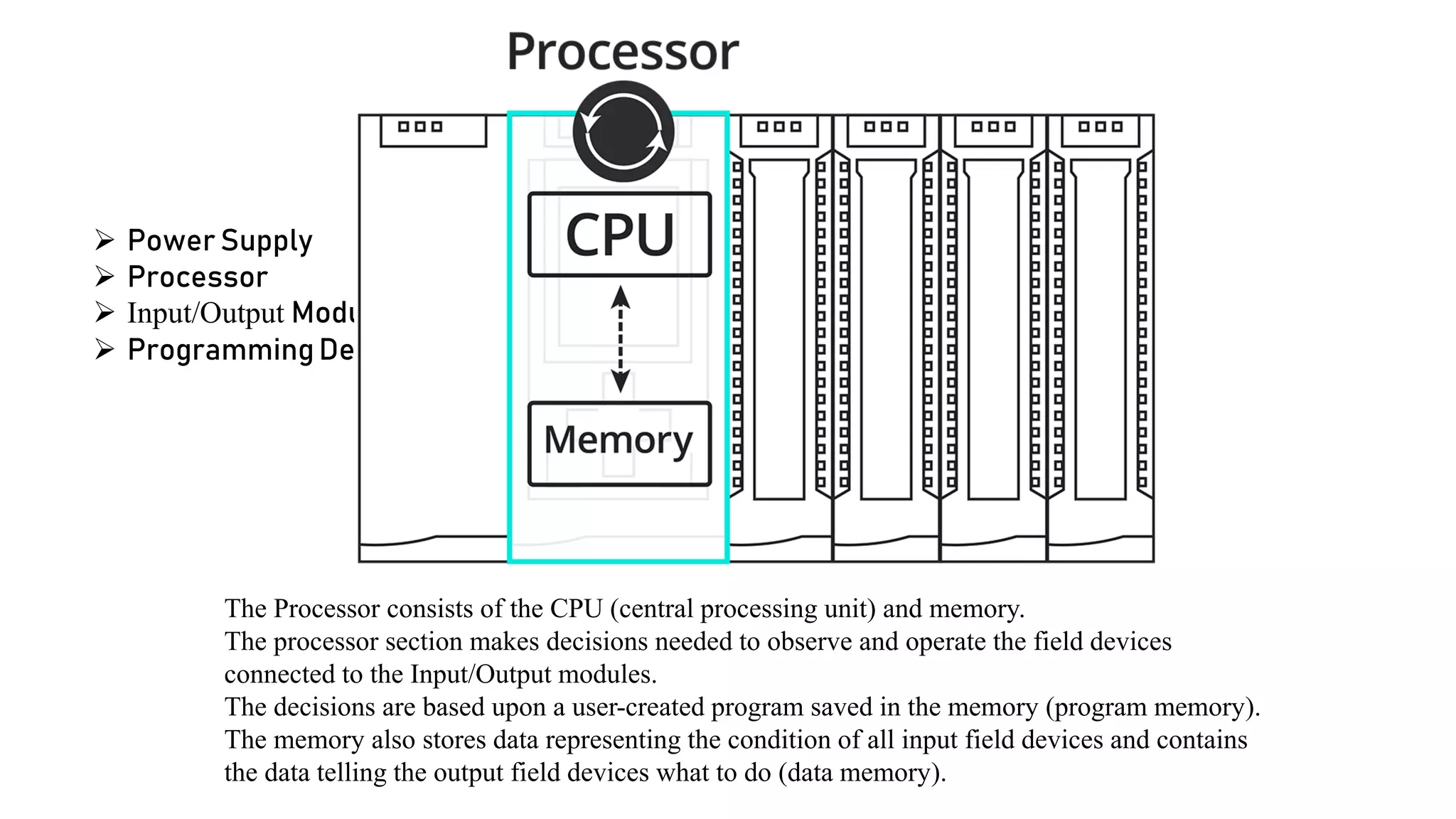

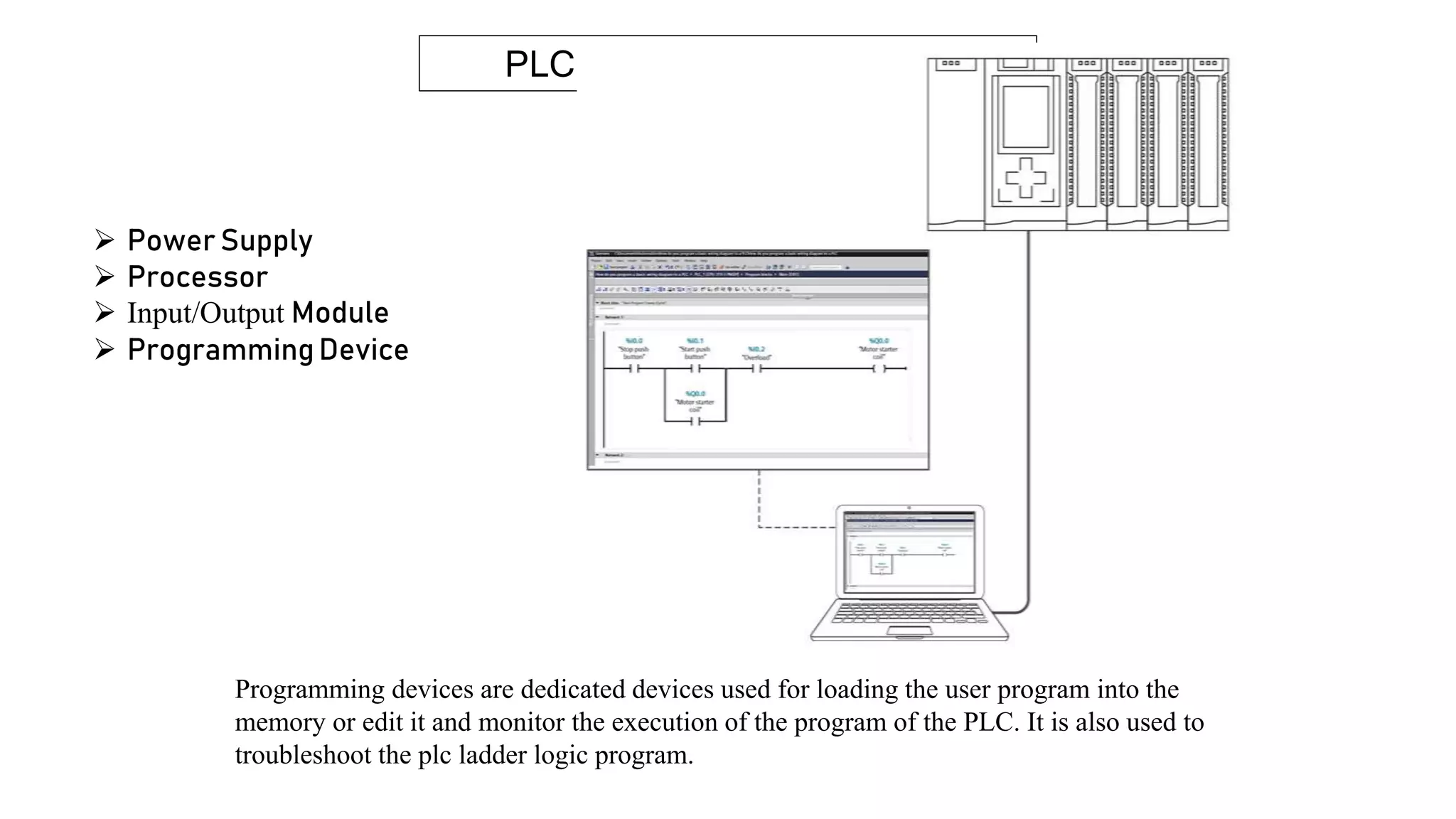

A programmable logic controller (PLC) is an industrial digital computer used for controlling manufacturing processes with high reliability. Key hardware components of a PLC include the power supply, processor, input/output modules, and programming device, which facilitate connections to field devices and execute user-created programs. Communication modules enable data transfer between PLCs and other devices, supporting modern industrial applications like the Industrial Internet of Things (IIoT).