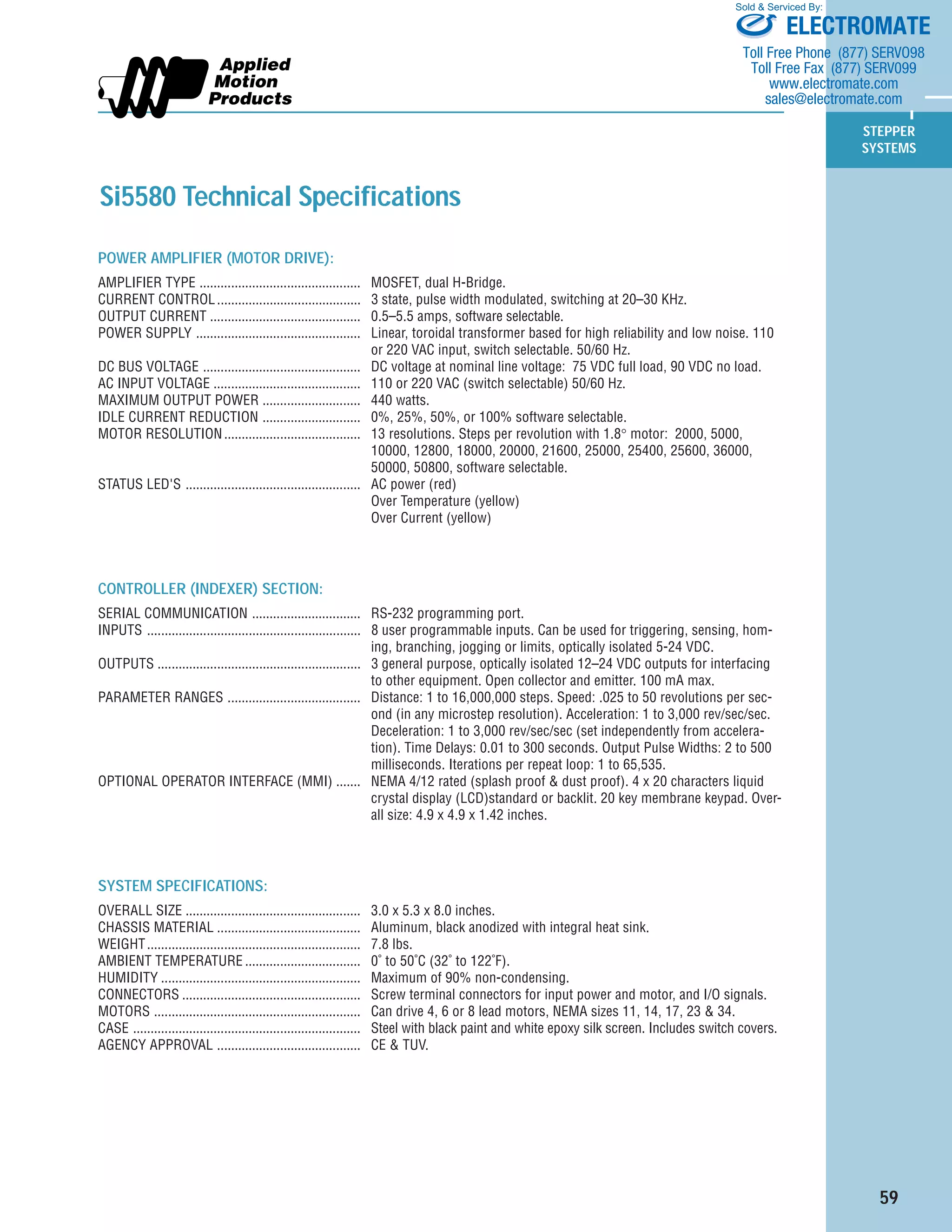

This document provides information on the Si5580 Programmable Step Motor Drive from Applied Motion Products, including its features, specifications, and recommended NEMA 23 and 34 stepper motors to use with the drive. The Si5580 allows software control of motor current, resolution, idle current reduction, and has 8 programmable inputs and 3 outputs. It can drive 4, 6, or 8 lead stepper motors and includes programming software.