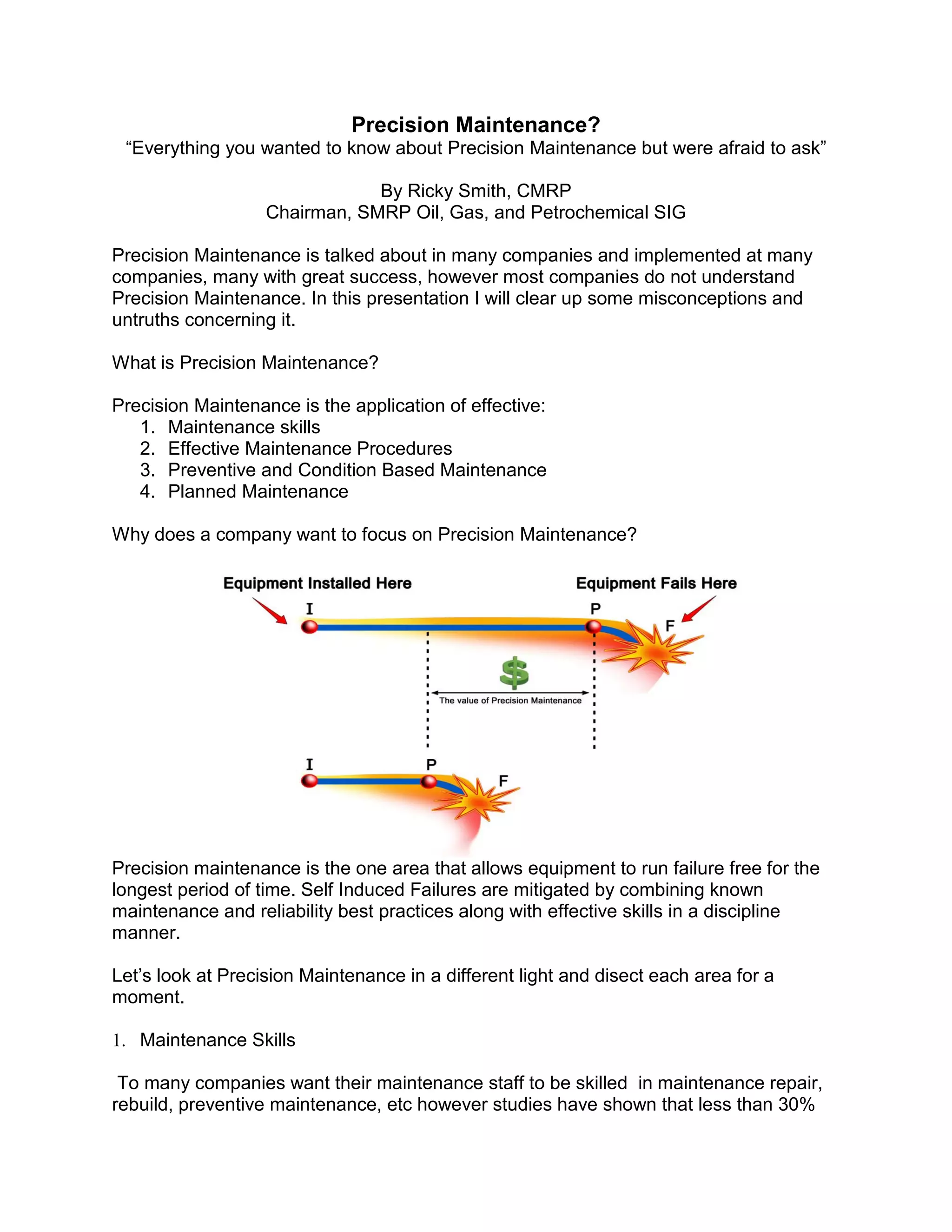

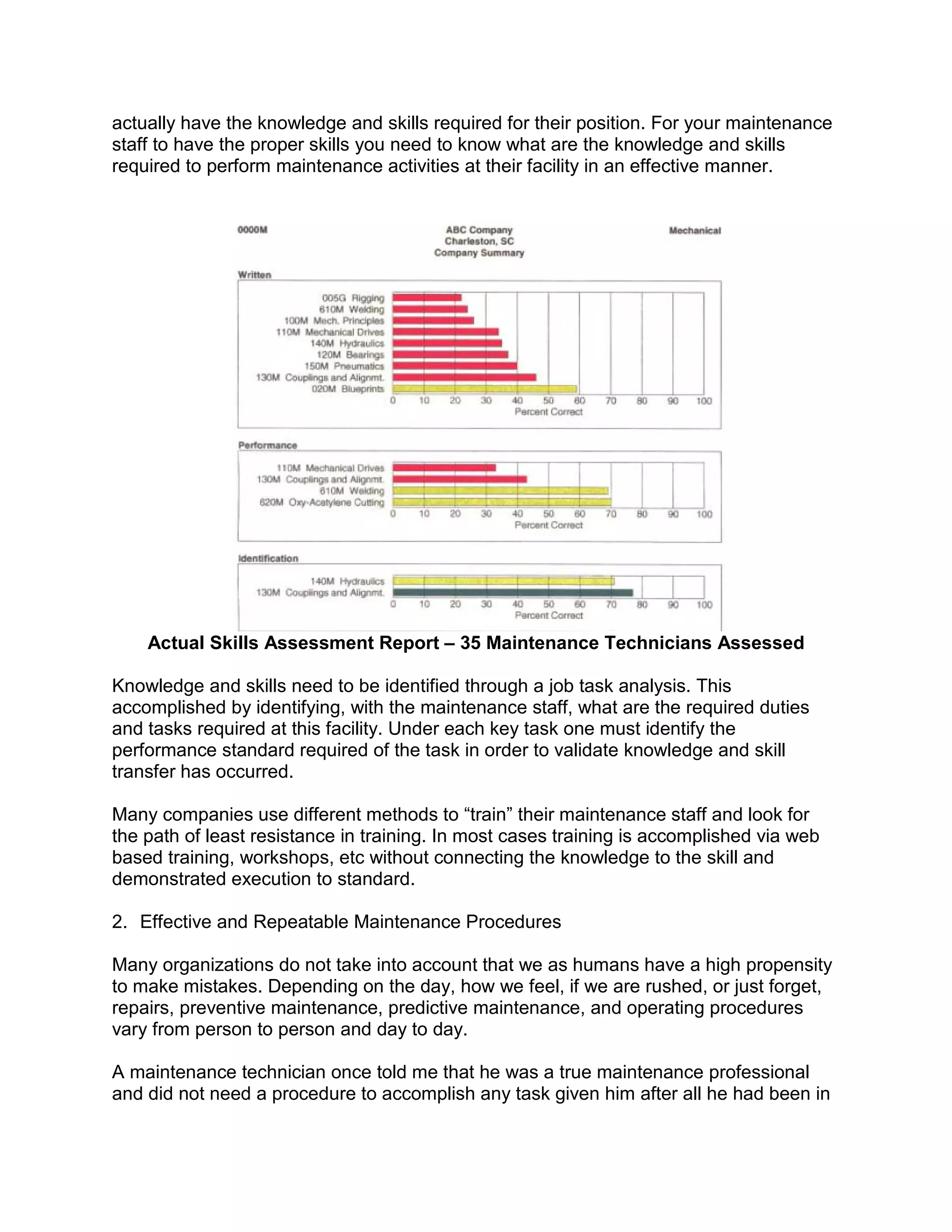

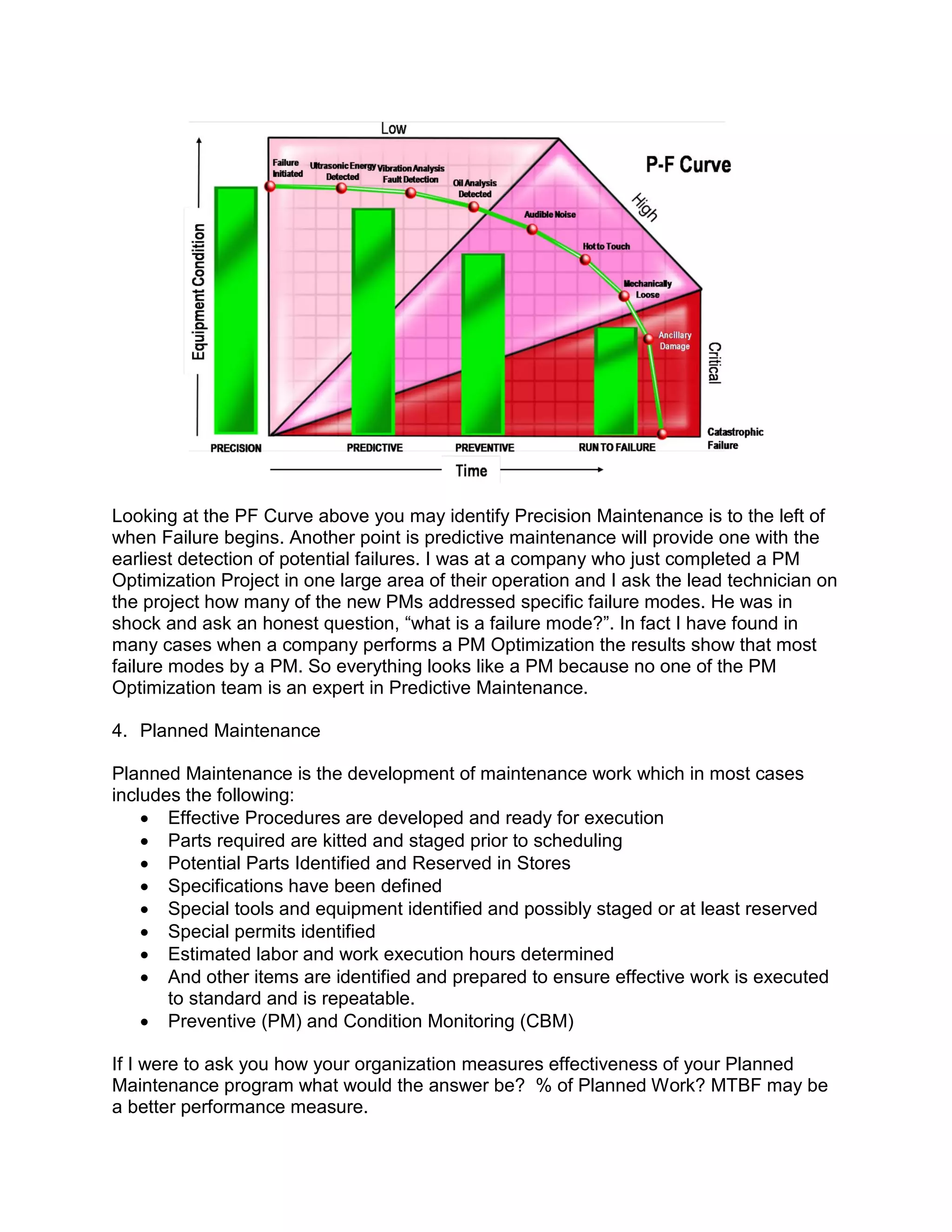

The document discusses precision maintenance and its importance in minimizing equipment failures through effective maintenance skills, procedures, preventive and condition-based maintenance, and planning. It emphasizes that many companies misunderstand precision maintenance, with a significant portion of maintenance staff lacking the necessary skills. The presentation aims to clarify misconceptions and highlight the need for repeatable procedures and performance measures to enhance maintenance effectiveness.