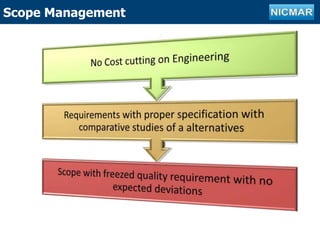

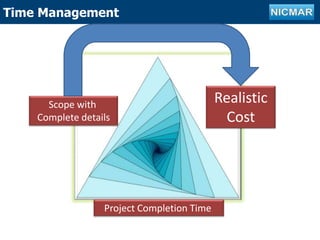

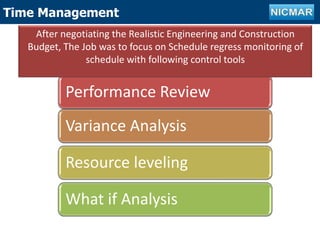

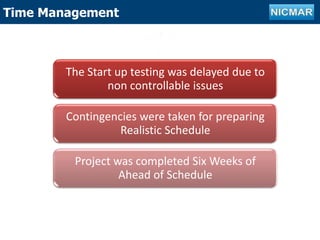

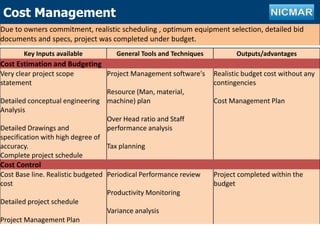

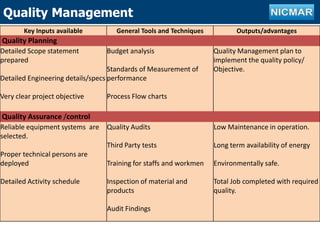

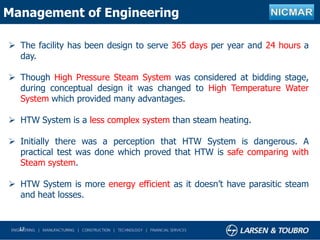

The Midfield Terminal Energy Facility project at the Pittsburgh International Airport was completed 6 weeks ahead of schedule and within budget. Key factors for the project's success included establishing a realistic budget based on comprehensive engineering studies, which allowed the project to be completed with high quality while controlling costs and schedule. Switching from a high pressure steam to a high temperature water system provided benefits like lower operation and maintenance costs and improved energy efficiency. Strategic project management and a focus on quality ensured strong integration and successful delivery of the project.