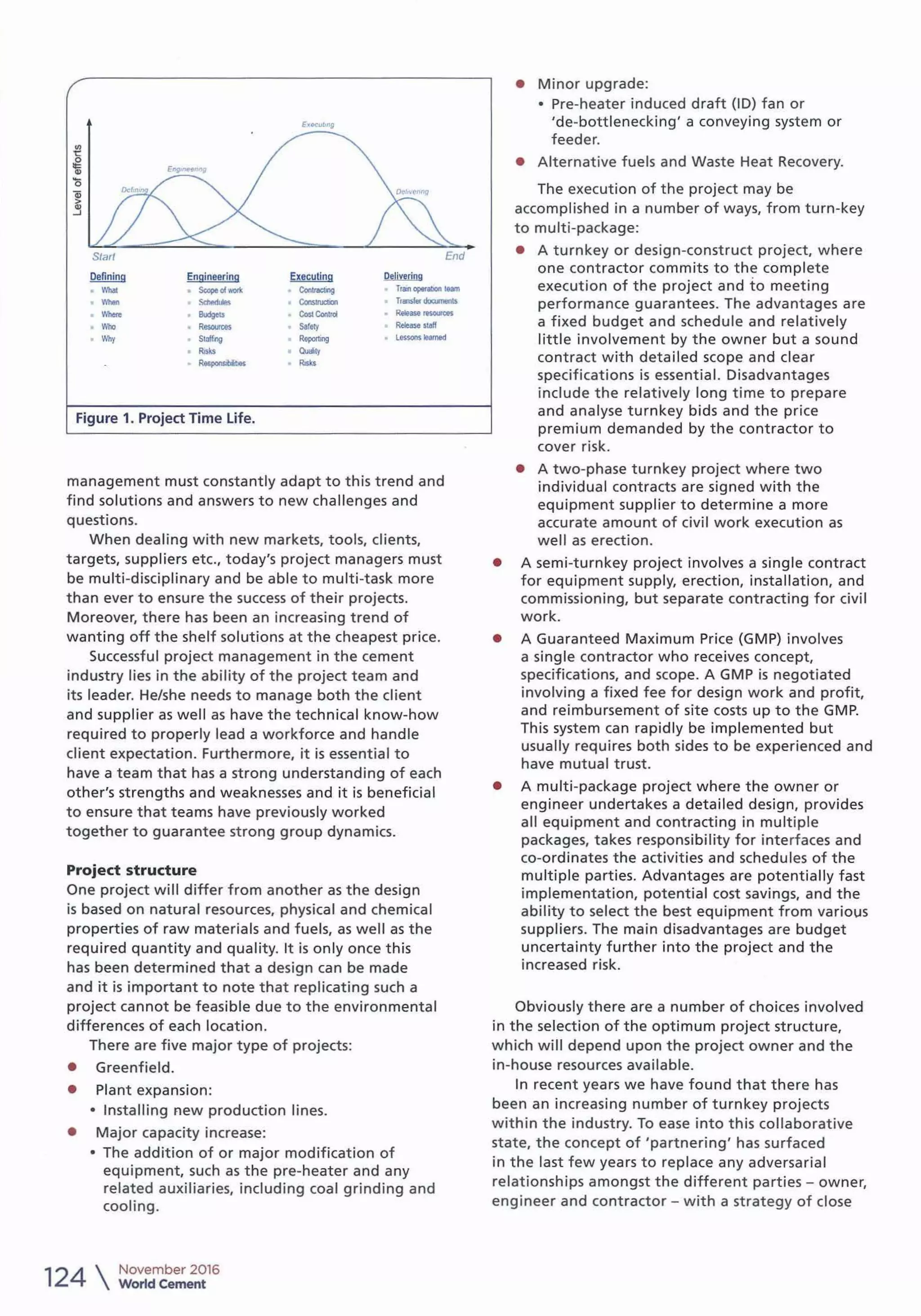

The document discusses the complexities of project management in the cement industry, emphasizing the need for multi-disciplinary project managers and effective team dynamics to ensure project success. It outlines various types of projects, execution methods, and the importance of clear communication and collaboration among stakeholders. Additionally, it highlights common pitfalls that can lead to project overruns and stresses the significance of proper planning and resource allocation.