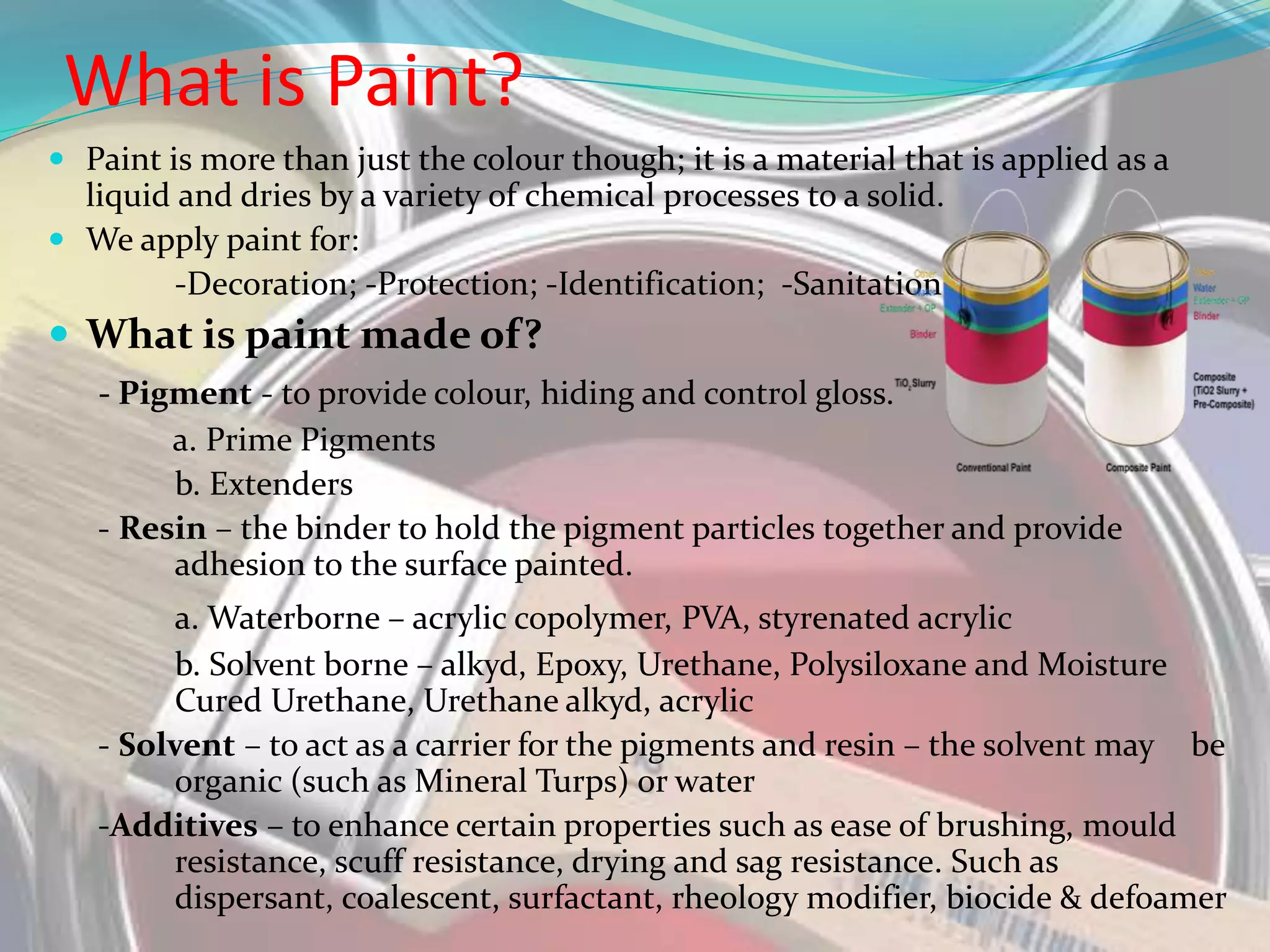

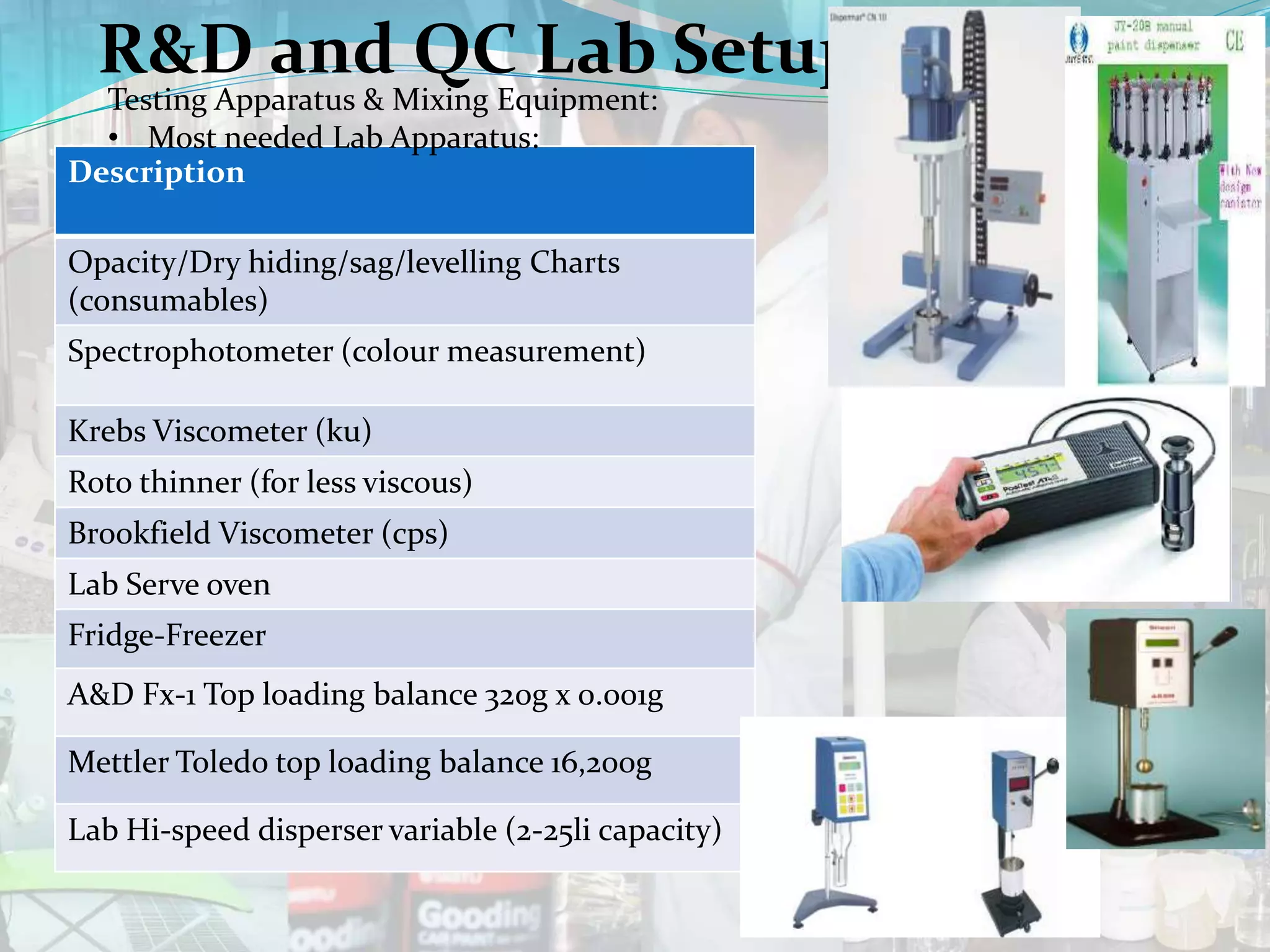

The document provides background on the presenter's qualifications and experience in paint and coating product development. It then discusses the key components of paint, including pigments, resins, solvents, and additives. The document outlines the equipment, materials, staffing, and testing needed for a paint research and development laboratory and production facility. It also discusses common process challenges in paint manufacturing and lists example standard paint products.