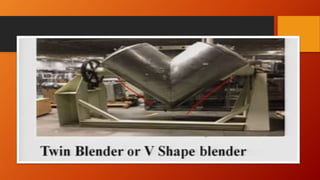

The document discusses considerations for scaling up a pilot plant for solid dosage forms production. Key features for the pilot plant include facilities for material handling, chemical weighing, dry blending, granulation, drying, particle size reduction, and compression. Material handling systems should accurately deliver materials to prevent cross-contamination. Chemical weighing is often centralized for efficiency. Dry blending must be thorough to ensure uniform drug distribution. The pilot plant equipment and processes should mimic production to effectively test scale-up.