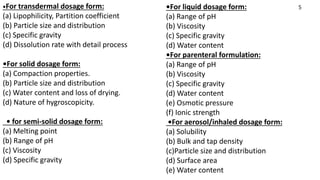

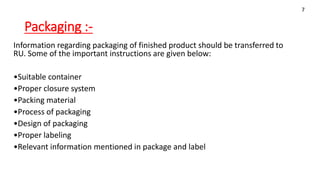

The document discusses the level of detail that should be provided about active pharmaceutical ingredients (APIs), excipients, finished products, and packaging materials when transferring technology from a source unit (SU) to a recipient unit (RU). For APIs, the SU should provide information such as the manufacturer, synthesis process, impurities, and stability studies. For excipients, the SU should detail the manufacturer, category, properties like solubility, and specifications for different dosage forms. The finished product specifications, storage conditions, and analytical test procedures should also be transferred. Finally, the SU should inform the RU about the suitable packaging, labeling, and ensure the packaging will not degrade the product.