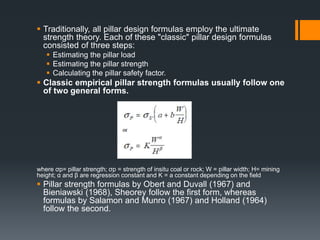

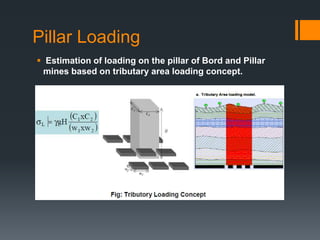

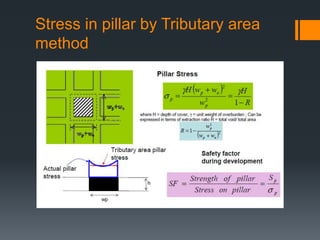

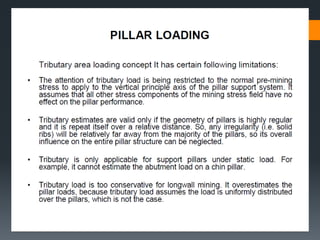

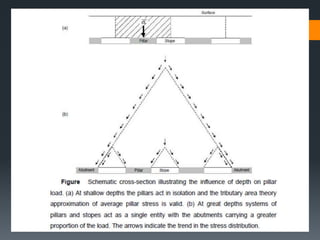

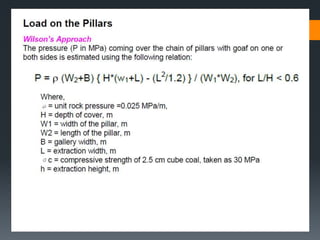

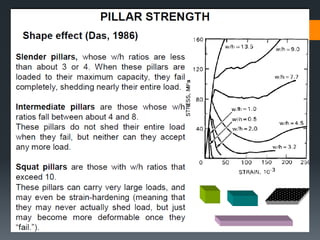

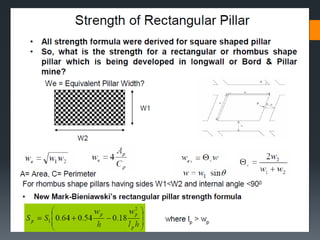

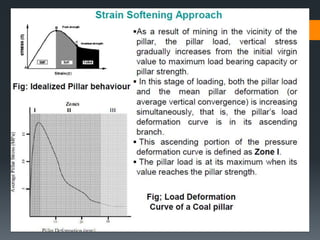

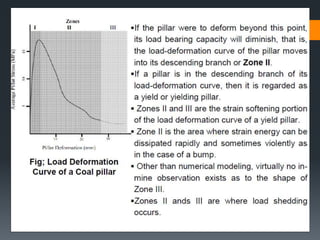

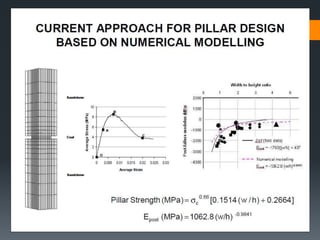

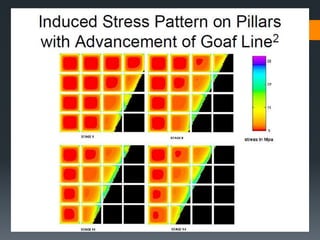

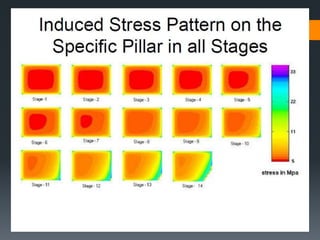

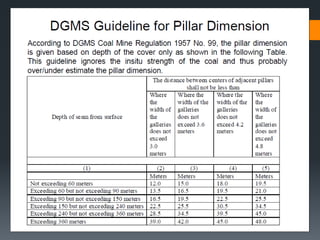

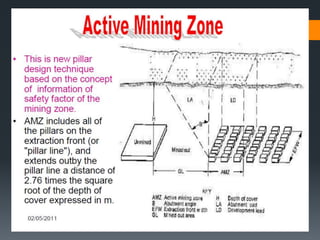

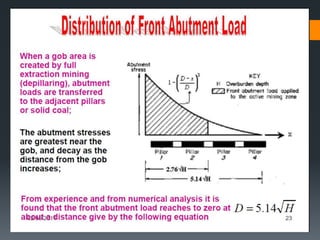

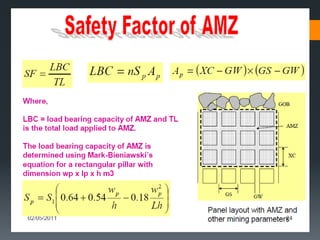

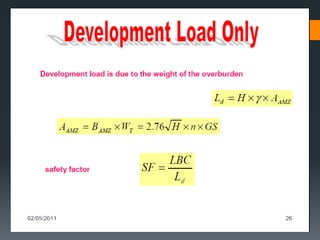

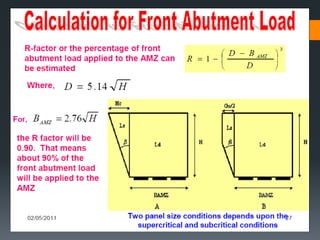

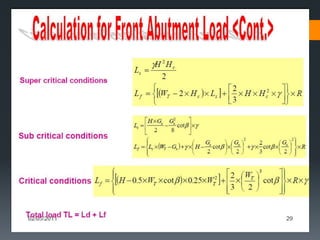

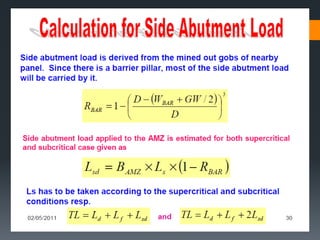

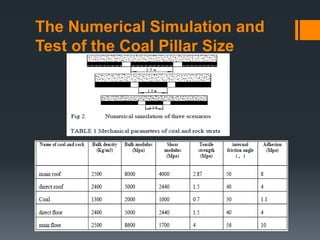

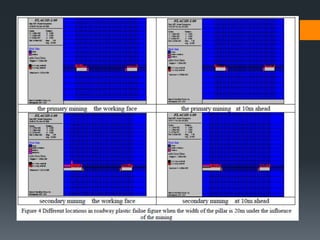

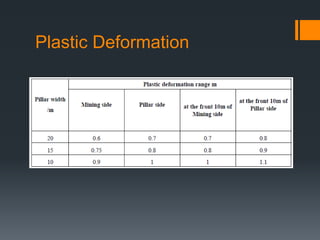

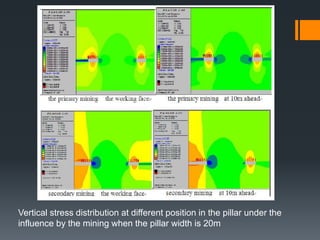

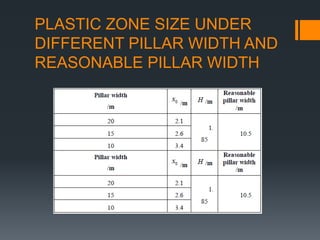

This document discusses various approaches to coal pillar design, including ultimate strength, progressive failure, and numerical modeling. It describes traditional empirical pillar strength formulas that estimate pillar load and strength to calculate a safety factor. These formulas generally relate pillar strength to properties like width, height, and material strength. The document also discusses pillar loading estimation using tributary area concepts and numerical simulation and testing of pillar size and plastic deformation zones under different widths.